Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you looking for a reliable welding wire that handles mild steel well and works with both Argon and CO2 shielding gases?

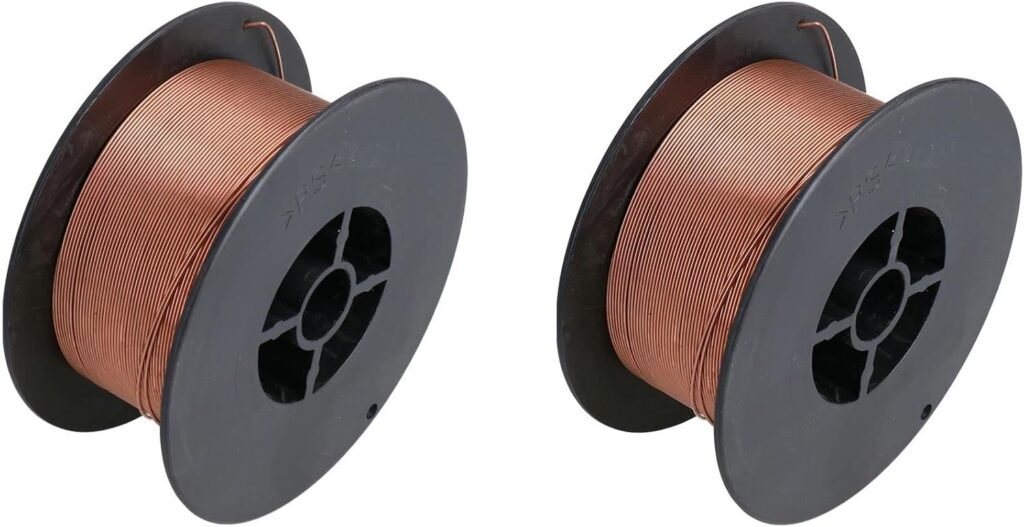

Product Overview: 0.6mm Mild Steel Mig Welder Welding Wire Spool Gas Argon CO2 1.0kg Reel 2pk

You’ll find this product name describes exactly what you get: two 1.0kg spools of 0.6mm mild steel MIG welding wire designed for gas-shielded MIG welding. The wire is suitable for general mild steel work and is intended for use in MIG welders using Argon, CO2, or mixed shielding gases.

You’ll appreciate that the offering comes as a 2-pack, which reduces how often you need to reorder and gives you a backup spool for continuous projects. The wire size is on the finer side, making it suitable for thinner materials and more controlled welds.

What the Product Is Best For

This wire is aimed at hobbyists, small shop fabricators, and maintenance work where mild steel is the primary material. You’ll find it useful for automotive sheet metal repairs, light structural work, metal art, and small fabrication tasks.

You should expect good feedability in most consumer and prosumer MIG welders, and the 0.6mm diameter gives you a finer arc and better control on thinner sections than thicker wires.

What’s Included in the Package

You’ll receive two spools, each containing 1.0kg of 0.6mm mild steel MIG welding wire. That means a total of 2.0kg of consumable wire right out of the package.

You won’t normally get special accessories like liners, contact tips, or spool adapters unless the seller specifically bundles them, so plan to check whether your welder needs a specific spool adapter or a feed hub.

Packaging and Initial Condition

The spools generally arrive sealed to minimize rust and contamination; you’ll want to inspect them for any surface oxidation or handling damage upon arrival. If you see rust, dirt, or kinks in the wire, address it before using the spool to avoid feeding problems and weld defects.

Most sellers will package the spools in a plastic bag or shrink wrap, but if you’re buying a bulk amount for an important project, consider storing unopened spools in a dry, climate-controlled area.

Specifications and Key Details

This section lays out the essential specs so you can compare quickly. Below is a clear table to break down the main specs for easy reference.

| Specification | Details |

|---|---|

| Product Name | 0.6mm Mild Steel Mig Welder Welding Wire Spool Gas Argon CO2 1.0kg Reel 2pk |

| Wire Diameter | 0.6 mm |

| Material | Mild steel |

| Spool Weight | 1.0 kg per spool |

| Pack Size | 2 spools (2.0 kg total) |

| Gas Compatibility | Argon, CO2, and mixed gases suitable for gas-shielded MIG |

| Intended Use | Mild steel welding, general fabrication, repair |

| Welder Compatibility | All gas MIG welders (check drive roll and tip compatibility) |

| Typical Applications | Automotive bodywork, thin sheet welding, light fabrication |

You’ll find the table useful when matching the wire to your machine and job requirements. Use it to ensure your welder’s drive roll, contact tip or nozzle can handle 0.6mm wire without extra setup.

Important Notes on Compatibility

You’ll want to double-check your welder’s spool hub and drive system. Some MIG welders require a specific spool mount or liner length to feed smaller diameter wires reliably.

Also confirm that your contact tip fits 0.6mm wire. If your machine usually runs heavier wire diameters, you may need to swap to a smaller tip and possibly a softer drive roll to prevent bird-nesting and feeding issues.

Performance and Welding Quality

When you use this 0.6mm mild steel MIG wire, you’ll notice a relatively stable arc suitable for thin-to-medium mild steel. The finer diameter helps produce less heat input than thicker wires, which reduces burn-through on thin sheets.

The deposited weld bead from this wire typically flows well with an even ripple when you match the correct voltage and travel speed. With a balanced setup, you’ll get good fusion and acceptable penetration for most light fabrication tasks.

Weld Appearance and Cleanliness

You’ll usually get a clean-looking bead when welding with Argon or Argon-CO2 mixes, with reduced spatter compared to pure CO2. The surface finish is generally smooth enough for light grinding and finishing.

Keep in mind that wire cleanliness and storage affect weld appearance. Contaminated or rusted wire will create extra spatter, porosity, and inconsistent bead formation. Always keep spools dry and free from oil or grease.

Gas Options: Argon vs CO2 and Mixed Gases

You can use Argon, CO2, or a mixture (commonly 75% Argon/25% CO2 or other ratios) with this wire, but each gas choice changes arc characteristics and penetration. You’ll get less spatter and a softer arc with higher Argon content and deeper penetration with more CO2.

If you’re welding thin sheet metal, leaning towards Argon or low-CO2 mixtures helps reduce burn-through and keeps the bead tidy. If you need deeper penetration for thicker pieces, increasing CO2 content will give you the penetration boost but expect more spatter.

Recommended Flow Rates

You’ll want to set your gas flow typically between 10–20 liters per minute (L/min) depending on nozzle size and welding position. Lower flow risks porosity; higher flow can waste gas and create turbulence that draws in air. Check your welder’s manual and test small sections to find the sweet spot.

Setup and Machine Settings

You’ll need to adjust your MIG welder settings to match the 0.6mm wire. Typical voltage and wire speed ranges depend on the material thickness, shielding gas, and welding position. It’s best to start with manufacturer or chart recommendations and fine-tune on scrap pieces.

Make sure your welding machine is set for a fine wire feed: adjust the drive roll pressure to prevent crushing the smaller wire, and choose a contact tip sized for 0.6mm to avoid bird-nesting or erratic arc behavior.

Typical Settings Guide (Starting Point)

Below is a guideline table to help you start, but remember to test and adjust for your exact machine and material.

| Material Thickness | Shielding Gas | Voltage (approx.) | Wire Speed (approx.) | Travel Speed |

|---|---|---|---|---|

| 0.5–1.0 mm | Argon-rich (75/25 Ar/CO2) | 12–14 V | 4–6 m/min | Fast, steady |

| 1.0–2.0 mm | Argon/CO2 mix | 14–16 V | 6–8 m/min | Moderate |

| 2.0–3.0 mm | CO2 or 75/25 mix | 16–18 V | 8–10 m/min | Slower for penetration |

You’ll need to refine voltage, wire feed, and travel speed while watching bead profile and penetration. Keep records of settings that work well on your specific machine and material thickness for future reference.

Feeding and Spool Handling

Because the wire diameter is 0.6mm, you’ll want a soft or U-groove drive roll that prevents slippage without crushing the wire. You’ll also find that shorter liner lengths and smoother feed paths help maintain consistent feeding.

When mounting the spool, ensure it spins freely and is properly seated on the spool hub. Any friction or improper orientation can cause feed issues, leading to start-stop feeding and inconsistent welds.

Troubleshooting Feeding Problems

If you experience bird-nesting or feed jams, check the liner for contamination or damage, verify the drive roll pressure, and examine the contact tip for clogs. If the spool was kinked during handling, unwind a small amount and straighten the wire before threading.

You should also make sure the spool orientation matches your machine’s feed direction. Wires wound in the wrong direction can put stress on the feed path and cause entanglement.

Practical Applications and Use Cases

You’ll find this wire ideal for tasks that require control on thinner mild steel materials. Common use cases include automotive body repairs, patch welding, light structural repairs, metal artwork, and small appliance repairs.

Because it’s a gas-shielded wire, you will get better weld quality and less cleaning than with flux-core wire in many thin-material applications, assuming you can use an appropriate shielding gas.

Projects Where This Wire Shines

You’ll benefit from this wire on projects like brake line brackets, fender repairs, exhaust hangers, and fabrication of delicate brackets. The smaller diameter minimizes heat distortion and makes it easier to achieve tack welds and fine passes.

For larger structural components or heavily rusted/thick stock, you might prefer a heavier wire or flux-core options that are intended for out-of-position or thicker welds.

Pros and Cons

Here’s a clear breakdown so you can make an informed decision. Consider both the strengths and the limitations when thinking about what tasks you’ll use the wire for.

Pros:

- You’ll get good control and lower heat input on thinner materials thanks to the 0.6mm diameter.

- Pack of two 1.0kg spools gives you redundancy and value.

- Compatible with Argon, CO2, and mixed gases, offering flexibility.

- Suitable for a wide range of mild steel fabrication and repair tasks.

Cons:

- You’ll need appropriate machine setup (tips, liners, drive rolls) for consistent feeding.

- Not ideal for heavy structural welding or very dirty/rusty metal without preparation.

- Spools are relatively small, so frequent changes on larger jobs may be needed.

Why Choose This Wire

You’ll likely pick this wire if you prioritize finesse, thinner material work, and cleaner welds when using gas-shielded MIG setups. It’s a solid match for hobbyists and small shops that do a lot of light fabrication.

If you often work with thicker materials, heavy rust, or need out-of-position welding, consider looking at thicker wire diameters or flux-core options for better deposition rates and forgiveness.

Comparison with Alternative Wire Options

When comparing similar products, you’ll typically weigh diameter, material compatibility, spool weight, gas requirements, and overall cost. Here’s a snapshot comparison versus common alternatives.

- 0.8mm mild steel wire: You’ll get higher deposition and deeper penetration but less control on thin sheet and more heat input.

- Flux-core wire (e.g., 0.9mm): You’ll gain the ability to weld without gas and better performance on dirty metal, but you’ll have more slag and cleanup.

- Stainless or brazing wires: Those are for different materials and processes; you’ll use mild steel wire only on common steels.

When to Switch to Alternatives

You’ll switch to thicker wire when welding heavier sections or when you need faster fill rates. Choose flux-core if you’re outdoors and can’t control shielding gas or if the surfaces are not well cleaned.

If you need corrosion-resistant joints for stainless steel, pick a stainless filler rather than mild steel wire.

Cost, Availability, and Value

You’ll find that a 2-pack of 1.0kg spools is usually priced competitively for hobby and light shop use. The per-kilogram cost is often lower than individual small spools, making the 2-pack a practical buy if you do routine small jobs.

Availability can vary by retailer, but this wire is generally common and stocked by welding suppliers and online marketplaces. If you plan to keep a steady supply on hand, buying multiple packs when on sale can save money.

Calculating Consumable Cost per Project

You’ll estimate consumption by measuring weld length and bead size. For many thin-sheet jobs, 2.0kg total can go a long way, but for continuous welding or structural projects, plan on higher usage. Track your consumption across a few projects to better predict reorder times.

Storage and Shelf Life

You’ll need to store mild steel wire in a dry, low-humidity environment to prevent rust. Keep spools in their original packaging or sealed plastic bags with desiccant, and store them off concrete floors to avoid moisture pickup.

If you’ll store wire long-term, use sealed containers and perhaps a dehumidifier in your storage area. Rusted wire is harder to weld and increases the risk of weld defects like porosity and inclusions.

How to Tell If Wire Has Gone Bad

You’ll know the wire has degraded if you see visible rust, a sticky surface, or if it feeds poorly even after cleaning. When in doubt, test-weld a sample; increased spatter, porosity, and poor arc stability indicate contamination or degradation.

Maintenance and Care of Consumables

Keep the contact tip clean and replace it when it becomes oversized or clogged. You’ll also want to inspect the liner periodically and replace it if you notice feed resistance or irregular feeding.

Wipe off any oil, grease, or contaminants from the wire before loading it. Clean your spools and station to reduce dust and metal particulate that can compromise weld quality.

Routine Checks Before Welding

You’ll check spool rotation, liner condition, drive roll wear, and contact tip condition before starting a job. Also verify shielding gas flow and connections; leaks or improper flow will cause porosity and weak welds.

A brief test weld on scrap stock will show whether your setup is dialed in and whether the wire is in good condition.

Common Troubleshooting and Fixes

If you experience porosity, check gas flow and seals first, then examine the wire for rust or contamination. If the arc is erratic, inspect the contact tip and liner for clogs or worn areas.

For feed issues, verify the drive roll type and pressure, confirm spool orientation, and examine the spool for kinks. If spatter is excessive, adjust your voltage and wire speed; more CO2 often increases spatter but can improve penetration.

Quick Fix Checklist

You’ll follow these steps when encountering problems:

- Confirm gas is on and flowing at the right rate.

- Swap to a clean contact tip and inspect the liner.

- Reduce drive roll pressure if wire is flattened or increase if slipping.

- Test on scrap and adjust voltage/wire speed in small increments.

- Replace the spool if the wire is visibly corroded or kinked.

Safety Considerations

You’ll use standard welding personal protective equipment: helmet with the correct shade, gloves, long sleeves, and welding apron if needed. Ensure proper ventilation when welding with CO2 or mixes to reduce weld fumes exposure.

Keep fire safety in mind: remove flammable materials from the welding area and have a fire extinguisher accessible. Shielding gas containers should be secured and checked for leaks as part of your safety routine.

Fume and Ventilation Tips

You’ll reduce fume exposure by working in well-ventilated areas and using local exhaust ventilation or fume extraction when possible. Thinner materials and higher CO2 content can increase fume generation, so monitor your workspace accordingly.

Best Practices and Welding Tips

You’ll get the best results by cleaning the base metal thoroughly, tacking parts to prevent distortion, and using small increments when adjusting settings for a fine wire. Keep your travel angle and speed steady to maintain consistent bead appearance.

If you weld thin sheet, use intermittent welds and stitch patterns to reduce heat build-up and distortion. Let parts cool between passes if necessary rather than trying to run heavy welds in a single pass.

Tip: Tack and Measure Before Welding

You’ll find that tacking pieces in multiple spots and measuring alignment before final welding saves time on rework. Tack welds should be short and strong enough to hold alignment but small enough to remove or blend into final welds easily.

Who Should Buy This Product

If you’re a hobbyist, auto-restorer, metal artist, or run a small fabrication shop working primarily with mild steel and thin materials, this wire is a logical choice. You’ll enjoy the finer control and cleaner finish when welding with gas-shielded setups.

If you do heavy industrial welding, outdoor welding in windy conditions, or need greater deposition rates, consider larger-diameter wires or flux-core alternatives that are more suited to those environments.

Ideal User Profile

You’re an ideal buyer if you:

- Work with mild steel primarily.

- Use gas-shielded MIG welding equipment.

- Prefer finer control on thin sheet and small parts.

- Want a cost-effective 2-pack for regular small projects.

Final Verdict

You’ll find the 0.6mm Mild Steel Mig Welder Welding Wire Spool Gas Argon CO2 1.0kg Reel 2pk a practical, value-oriented choice for light fabrication and thin sheet mild steel welding. Its fine diameter is forgiving on thinner stock and provides a more controlled arc compared to heavier wires.

With proper storage, machine setup, and tips for feeding, this wire will serve well for automotive repair, hobby projects, and small shop tasks. If your projects require higher deposition rates or outdoor, dirty-work capability, complement this wire with other filler options suitable for those conditions.

Frequently Asked Questions

You’ll often ask a few consistent questions before buying and using this wire. Below are answers that should help clear up common concerns.

Q: Will this wire work in my MIG welder? A: As long as your welder supports gas-shielded MIG wires and you can fit a 0.6mm contact tip and appropriate drive roll, it will work. Check spool fit and liner length also.

Q: Can I use it without gas? A: No. This specific wire is intended for gas-shielded MIG welding. For gasless welding, use a flux-core wire designed for that purpose.

Q: Is it suitable for stainless steel? A: No. This wire is mild steel and should only be used on mild/low-carbon steels. Use dedicated stainless filler for stainless steel base metals.

Q: How should I store the spools? A: Keep them in a dry environment, ideally sealed in plastic or a container with desiccant. Avoid damp or unheated garages that can promote rust.

Q: What contact tip size should I use? A: Use a contact tip sized for 0.6mm wire. Consult your welder and tip manufacturer for best fit specifications.

Q: How do I reduce spatter when using CO2? A: Lowering voltage slightly, adjusting wire speed, and using Argon-rich mixes reduce spatter. Also keep the wire clean and tip in good condition.

You’ll be ready to use these tips and guidelines to get the most out of your 0.6mm Mild Steel Mig Welder Welding Wire Spool Gas Argon CO2 1.0kg Reel 2pk.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.