Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you trying to find a compact, multi-process welder that can handle garage repairs, hobby projects, and light professional tasks without needing a separate gas supply?

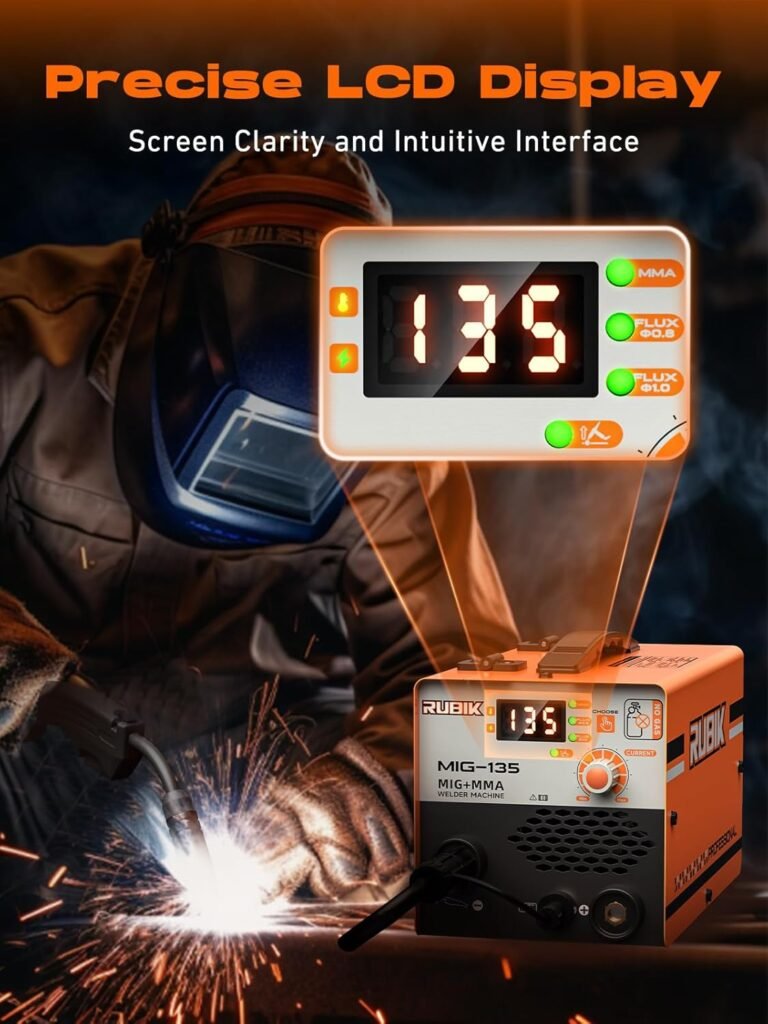

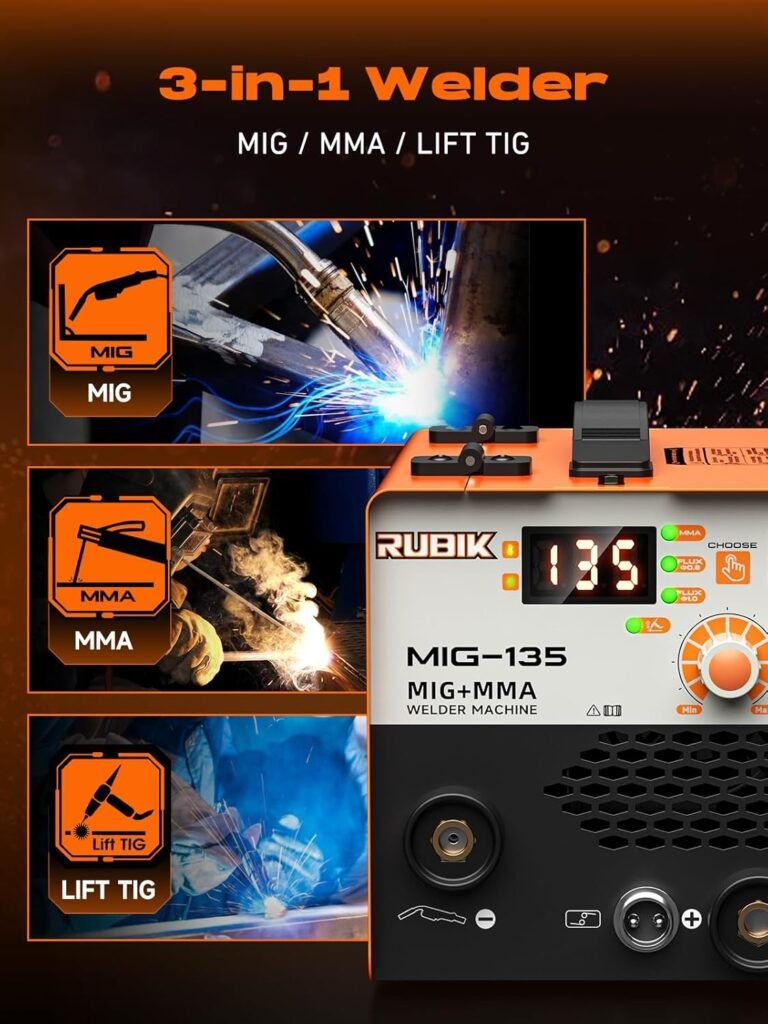

Product overview — 135A MIG Welder, 3 in 1 Gasless Welder Flux MIG/Lift TIG/Stick MultiProcess Mig Welder, 110V Welding Machine, Flux Core Welder with IGBT Inverter Synergic Control and LCD Display

This unit gives you three processes in one compact package: gasless flux-cored MIG, Lift TIG (torch sold separately), and stick welding. You get a 110V input machine that’s designed to be easy to use while still offering enough power for many common welding jobs.

You’ll appreciate that it supports multiple wire sizes and electrodes, and that it’s built with modern inverter tech (IGBT) and synergic control to simplify setup. The LCD display and automatic voltage matching make it straightforward to dial in good results quickly.

What you get in the box

You receive the MIG-135 welder unit itself plus the most common accessories you’ll need to get started. The basic kit is aimed at convenience so you can start welding right away on flux-cored projects.

You’ll find a MIG welding torch, a ground clamp, an electrode holder for stick welding, a steel brush, a spool of welding wire, and a user manual included. If you want Lift TIG welding you’ll need to buy a TIG lift torch separately.

Quick specifications

Below is a clear breakdown to help you understand the key specs at a glance. This table makes it easy to see what the machine can and cannot do before you commit to a purchase.

| Specification | Detail |

|---|---|

| Model Name | 135A MIG Welder, 3 in 1 Gasless Welder Flux MIG/Lift TIG/Stick MultiProcess Mig Welder, 110V Welding Machine, Flux Core Welder with IGBT Inverter Synergic Control and LCD Display |

| Input Voltage | 110V (single-phase) |

| Output Current | Up to 135 A |

| Welding Modes | Flux-cored MIG (gasless), Lift TIG (torch not included), Stick (E6013, etc.) |

| Wire Compatibility | 0.030″, 0.035″, 0.040″ flux-cored wire |

| Electrode Compatibility | E6013 (and similar) |

| Max Plate Thickness | Up to ~2/5″ (about 5–6 mm) depending on technique |

| Control Type | Synergic control with LCD display |

| Protections | Overheat, overcurrent, overvoltage, overload |

| Weight | Approximately 7 lbs |

| Package Includes | MIG-135 unit, MIG torch, ground clamp, electrode holder, steel brush, welding wire, user manual |

| Technology | IGBT inverter |

| Portability | Compact and lightweight for outdoor and elevated work |

This table summarizes the essentials so you can quickly compare this machine with others or check if it meets your project requirements. The synergic control and LCD help you match voltage to wire feed speed without guesswork.

Performance and welding quality

The machine delivers up to 135 amps, which gives you enough heat for light steel fabrication and common repair tasks. You’ll be able to weld thin sheet metal up to light plate, and you can tackle medium-thickness jobs with the right technique.

Synergic control helps maintain consistent arc characteristics as you adjust wire feed speed. That means fewer burn-through incidents and a smoother ramp to productive welds, especially useful if you’re newer to welding.

Flux-cored MIG mode performance

In gasless flux-cored mode the welder lets you work outdoors and in breezy conditions without worrying about shielding gas. You’ll find it much easier to move between job sites since you don’t have to carry a gas cylinder.

You can expect good penetration and decent bead appearance on mild steel when you match the correct wire size and wire feed speed. For the best results, use clean material and the recommended wire sizes (0.030″–0.040″).

Lift TIG mode performance

Lift TIG is a low-cost way to add TIG capability without a full TIG setup, but you’ll need to buy a TIG lift torch separately. You’ll initiate the arc by touching and lifting the tungsten (lift arc) rather than using high-frequency, so you’ll want to practice the technique to get smooth starts.

You can achieve cleaner, fine-control welds with the right filler rod and technique, but this machine’s TIG capability is best suited to thinner materials and touch-up work rather than high-end TIG projects.

Stick welding performance

Stick welding (SMAW) gives you flexibility in adverse conditions and on rusty or dirty metal. The included electrode holder supports common rods like E6013, and you’ll be able to perform simple repairs, farm work, and maintenance reliably.

You’ll find stick welding forgiving for vertical and overhead work, and it pairs well with the portability of this unit when you need to weld in remote locations.

Synergic control and LCD display

Synergic control automates voltage adjustment based on wire feed speed, making setup faster and reducing the trial-and-error phase. You won’t need to guess volts as you change wire diameter or travel speed.

The LCD display gives clear feedback so you know where settings are and can make consistent changes. This is particularly helpful when you’re switching tasks or lending tools to others who may not know your preferred settings.

How synergic control helps you

Synergic systems pair input variables to produce a ready-to-weld parameter set, which reduces decisions and setup time. If you’re newer to welding, this system helps you achieve better-looking beads sooner.

You’ll still have control over the feed rate and other variables, but the machine handles the tricky part of matching voltage to feed rate automatically. That means more time welding and less time setting up.

Using the LCD display

The LCD makes it easy for you to confirm wire feed speed and voltage settings at a glance. You’ll appreciate the clear digital readout if you switch between wire sizes or processes mid-job.

The display also helps you diagnose whether a setting change is actually being applied, which is useful for troubleshooting arc behavior or finishing quality.

Safety features and protections

This welder includes multiple safety protections—overheat, overcurrent, overvoltage, and overload—to protect both you and the machine. Those protections give you peace of mind during continuous or demanding work.

You should still follow standard welding safety practices, including proper PPE, ventilation, and safe handling of the torch and electrode. Protections reduce risk but do not replace safe welding habits.

Overheat protection

The machine will shut down or reduce output when internal temperatures rise above safe limits. You’ll see protection messages on the LCD if the system detects overheating, which helps prevent permanent damage.

Let the unit cool and follow the manufacturer’s recommended duty cycle to avoid repeated trips into overheat protection during long welds. This is especially important when welding near the machine’s maximum output.

Electrical protections

Overcurrent and overvoltage protections help prevent damage from power anomalies or short-circuits. You’ll be safeguarded if the supply fluctuates or if an internal fault occurs.

Still, you should use a properly rated extension cord if necessary and avoid long, undersized cords that might cause voltage drop. Maintaining stable input voltage improves performance and reduces the chance of protective trips.

Portability and build

At around 7 pounds this welder is very portable; you can easily carry it from the shop to a job site or up a ladder for overhead repairs. The compact design means you won’t need a truck to transport it, and it fits on a crowded workbench.

The enclosure and connectors are generally solid for light-duty environments, but you’ll want to avoid harsh exposure to water and prolonged rust-prone conditions. Treating it like a protected tool extends the life considerably.

Ideal use cases for portability

You’ll find this machine great for mobile repair tasks, small construction jobs, fence and trailer maintenance, and hobbyist projects. The gasless MIG capability particularly suits outdoor or windy conditions where gas shielding would be unreliable.

If you frequently weld heavy structural steel or require sustained high-amp TIG work, you’ll need a heavier-duty machine, but this model excels at light-to-medium duty portable tasks.

Durability notes

The build is appropriate for workshop use but doesn’t match rugged industrial welders designed for daily heavy production. You should keep it clean, avoid impact, and store it in a dry place.

Regularly inspect leads, torches, and connectors for wear. Replacing consumables and cordaged components before they fail helps keep performance reliable.

Wire, electrode, and material compatibility

You can use 0.030″, 0.035″, and 0.040″ flux-cored wire with this machine, which covers most common flux-cored welding needs. You’ll also use standard stick electrodes such as E6013 for SMAW tasks.

The machine is optimized for mild steel and typical workshop steels. You can weld thin sheet metal and plates up to about 2/5″ (approximately 5–6 mm) with proper technique and joint preparation.

Choosing the correct wire and electrode

Select wire diameter based on material thickness and your wire feed capability. Thinner materials often prefer 0.030″, while 0.035″–0.040″ suits heavier sheet and light plate.

For stick welding, E6013 is versatile for general-purpose welding, including vertical and overhead. If you need different characteristics (deeper penetration, different slag removal), consider other electrode types, but check compatibility with the machine’s amperage range.

Material preparation tips

Clean the metal where possible for better weld quality; remove heavy rust, scale, and paint near the weld area. You’ll get better arc stability, penetration, and bead appearance with cleaner base metal.

For flux-cored welding you get some tolerances for less-than-perfect surface conditions, but removing loose rust and heavy contaminants is still recommended.

Setup and first-time use

Setting up the machine is straightforward: mount the spool, thread the wire through the feed system, adjust wire feed speed, and set the synergic control parameters. You’ll need basic knowledge to route the wire correctly and secure connections.

Before you start welding, check grounding, confirm electrode polarity, and ensure the workpiece is secured. Run a few test beads on scrap metal to dial in the settings and establish a comfortable travel speed.

Basic step-by-step setup

- Mount the flux-cored wire spool and route the wire through the feed mechanism.

- Set the machine for gasless MIG mode and select the appropriate wire diameter on the control.

- Set a starting wire feed speed according to the chart or LCD guidance and allow the synergic control to set voltage.

- Do a few short beads on scrap to refine feed speed and travel speed until you get a smooth arc and desired bead profile.

You’ll get faster at setup with practice, and using scrap helps avoid ruining a workpiece while you tune settings.

Polarity and connections

Make sure you use the correct polarity for flux-cored wire (commonly DCEP for self-shielded wire, but check your wire manufacturer’s recommendation). The electrode holder and ground clamp should be securely attached.

Incorrect polarity will cause poor arc behavior and weak welds, so double-check connections before starting.

Practical tips for better welds

Practice good travel angle and speed: a slight push or drag technique works depending on the joint type and wire. You’ll also want to maintain a consistent stick-out (distance from nozzle to work) for stable arc conditions.

Use short, controlled runs on thin material to avoid burn-through, and build up multiple passes on thicker joints. Good bead appearance comes from consistent travel speed, arc length, and wire feed.

Recommended travel angles and technique

For fillet welds use a roughly 15–20° travel angle from vertical and maintain a steady speed. For butt joints, keep a slightly drag angle to encourage penetration into the root.

Adjust your technique when switching between flat and vertical positions. You’ll find adjustments in travel speed and weave help control penetration and bead shape.

Avoiding common mistakes

Avoid running the machine at too high a wire feed speed for thin material to prevent burn-through. Similarly, very low feed speeds result in weak, underfilled welds.

Make sure wire spool tension is reasonable; too tight causes feed problems and too loose allows birdnesting. Clean contact tips and replace worn consumables when arc performance degrades.

Maintenance and consumables

Keep contact tips, nozzles, and drive rollers clean and replace them when worn. You’ll get more consistent feeding and better arc performance when consumables are in good condition.

Check cables and connectors regularly for damage, and keep the machine’s vents clear to prevent overheating. A little preventive maintenance enhances reliability and prolongs service life.

Consumable change intervals

Inspect the contact tip for spatter buildup after each few hours of use and change when the bore is enlarged or fouled. Replace drive rollers if they show flat spots or excessive wear.

Keep spare contact tips, nozzles, and a fresh spool of wire on hand if you do many projects; downtime is minimized when you have spares ready.

Cleaning and storage

Wipe the exterior and vents periodically to remove dust and spatter. Store the unit in a dry location and avoid leaving it outside or exposed to the elements.

If you’ll be storing the unit for a long time, remove the wire spool and protect internal parts from corrosion by using desiccant in the case or storage area.

Troubleshooting common issues

If wire feeding is jerky, check the drive rollers, spool tension, and liner for obstruction. Most feed problems trace back to dirty or worn feed components.

If the arc is unstable, confirm polarity, verify the wire type and condition, and ensure proper contact tip size. Instability can also come from incorrect voltage or a worn or dirty ground clamp.

No arc or weak arc

Confirm power supply and fuse. Check connections at the torch, ground, and electrodes. A weak arc can result from too-long stick-out, low wire feed speed, incorrect polarity, or worn consumables.

Reset the machine and try again after checking all connections. If the unit shows a protection message on the LCD, follow the user manual guidance for clearing or correcting the fault.

Excessive spatter or poor bead shape

Reduce voltage/feed speed slightly and improve travel speed consistency. Spatter can increase with incorrect settings, dirty material, or low-quality wire.

A clean base metal and fresh wire also reduce spatter. If spatter accumulates in the nozzle, clean it often to maintain gasless arc stability.

Pros and cons

You’ll want to weigh the strengths and limitations of this machine before buying. It’s a strong contender for the right use cases but not a universal solution for heavy production welding.

This section lays out the practical advantages you’ll get and the trade-offs to expect in real-world use.

Pros

- Very portable at ~7 lbs, ideal for mobile work and DIY projects.

- 3-in-1 functionality (gasless MIG, Lift TIG, stick) gives you flexibility without buying multiple machines.

- Synergic control and LCD make setup simpler and reduce guesswork for beginners.

- Strong protections for safer operation under varying conditions.

- Good value for hobbyists, repair techs, and light-fabrication users.

You’ll likely find this machine delivers a strong balance of capability and convenience for non-industrial use.

Cons

- Lift TIG requires a separate torch, so it’s not a fully bundled TIG package.

- Max 135 A limits heavy structural welding and long TIG runs on thicker materials.

- Not designed for continuous heavy industrial use; duty cycle and cooling constraints matter.

- Gasless MIG is fantastic for outdoors but can be less clean than gas-shielded MIG for critical cosmetic work.

If your projects require sustained high-amp TIG or gas-shielded MIG for stainless or aluminum, you’ll need a different machine or additional accessories.

How it compares to competitors

Compared to single-process budget welders, you get more flexibility here with three processes and synergic control. You’ll often find similar-priced welders offer only one or two functions and fewer user-friendly controls.

Against higher-end inverter welders, this unit is lighter and more portable but lacks the robust duty cycles and higher amperage those machines provide. You’ll trade industrial endurance for convenience and price.

Value proposition

You get a lot of capability for the price if your primary tasks are light to medium-duty and you value portability. The synergic control and LCD add perceived and real value for users who want fewer setup headaches.

For professional shops doing high-volume production, this is more of a secondary or mobile solution than a primary production machine. For home users and mobile repair techs, it’s a highly practical choice.

Who should buy this welder

You should consider this machine if you’re a hobbyist, DIYer, small-farm owner, or mobile repair person. It’s ideal when you need portability, process flexibility, and an easy-to-use control system.

Avoid this model if you’re doing heavy structural welding daily, need high-duty-cycle TIG for thick materials, or require specialty gas-shielded MIG for aluminum or stainless with perfect cosmetic finishes.

Suitable projects

- Small trailer and fence repairs

- Automotive body patching and small fabrication

- Home and hobby workshop projects

- Farm and ranch gear maintenance

- On-site, outdoor repairs where carrying a gas cylinder is impractical

You’ll get the most value by using the welder on thin-to-moderate steel projects and in locations where portability matters.

Accessories and recommended add-ons

To maximize the machine’s usefulness, consider buying a TIG lift torch if you plan to do TIG welding, and keep spare contact tips, nozzles, and a fresh spool of wire handy. A welding cart, a better ground cable, and protective covers can improve convenience and safety.

If you’ll weld indoors often, consider a quality respirator and local ventilation. If you plan to weld aluminum or stainless, you’ll need a different process and possibly a spool gun or gas-shielded MIG setup.

Must-have extras

- TIG lift torch for Lift TIG capability (torch sold separately).

- Extra spools of flux-cored wire in appropriate diameters.

- Spare contact tips and nozzles for uninterrupted work.

- High-quality welding helmet, gloves, and protective clothing.

- Dedicated ground clamp and heavy-duty cables if you weld outdoors frequently.

These accessories reduce downtime and help you maintain consistent welding quality across multiple projects.

Frequently asked questions (FAQ)

You’ll likely have practical questions before buying; this FAQ addresses common concerns to help you decide.

Q: Can I weld aluminum with this welder?

A: Not effectively. Flux-cored gasless MIG is for mild steel. Welding aluminum typically requires a spool gun and gas-shielded MIG or AC TIG equipment.

Q: Does it come with a TIG torch?

A: No, Lift TIG requires a TIG lift torch which you must purchase separately. The machine supports the Lift TIG function but does not include the torch.

Q: What duty cycle can I expect?

A: Duty cycle varies by machine and ambient conditions. Expect a light-to-moderate duty cycle appropriate for hobby and repair tasks, not industrial continuous welding.

Q: Can you weld outside without gas?

A: Yes, gasless flux-cored MIG is specifically designed for outdoor welding and windy conditions where gas shielding would blow away.

Q: Is the synergic control automatic?

A: Synergic control automatically adjusts voltage to match the wire feed speed, simplifying arc setup. You still control wire feed speed and other parameters.

These answers help you match the machine capabilities to your needs and avoid surprises after purchase.

Final thoughts and recommendations

If you want a lightweight, flexible welding machine for general shop work, repairs, and mobile tasks, you’ll find a lot to like in the 135A MIG Welder, 3 in 1 Gasless Welder Flux MIG/Lift TIG/Stick MultiProcess Mig Welder, 110V Welding Machine, Flux Core Welder with IGBT Inverter Synergic Control and LCD Display. It’s an excellent entry-level and mid-level tool that balances convenience, functionality, and price.

You should buy it if you prioritize portability, need gasless MIG for outdoor work, or want a single machine to cover multiple light-to-medium welding processes. Expect to invest in a TIG lift torch if you plan to use the TIG capability, and keep spare consumables on hand.

Practical final tip

When you first get your unit, spend time running practice beads on scrap metal to get comfortable with synergic settings and wire feed speed. A little practice will significantly improve your weld quality and help you understand the limits of the machine for your projects.

You’ll be rewarded with a versatile, portable, and user-friendly tool that fits many welding tasks without the complexity and bulk of larger machines.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.