Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

? Are you weighing whether the 14AK MIG Welding Torch, 14AK MB14 CO2 Gas Protective Welding Gun Assembly 0.81.2mm 160200A MIG Welder Torch 2 Meters for MIG130 is the right upgrade or replacement for your MIG setup?

Product snapshot and immediate impressions

You’ll get a practical replacement torch that’s presented as compatible with MIG130 setups and designed for protective gas welding. From the moment you look at the specification list, the torch positions itself as a straightforward, no-frills MB14 / 14AK style gun aimed at manual MIG work on metal.

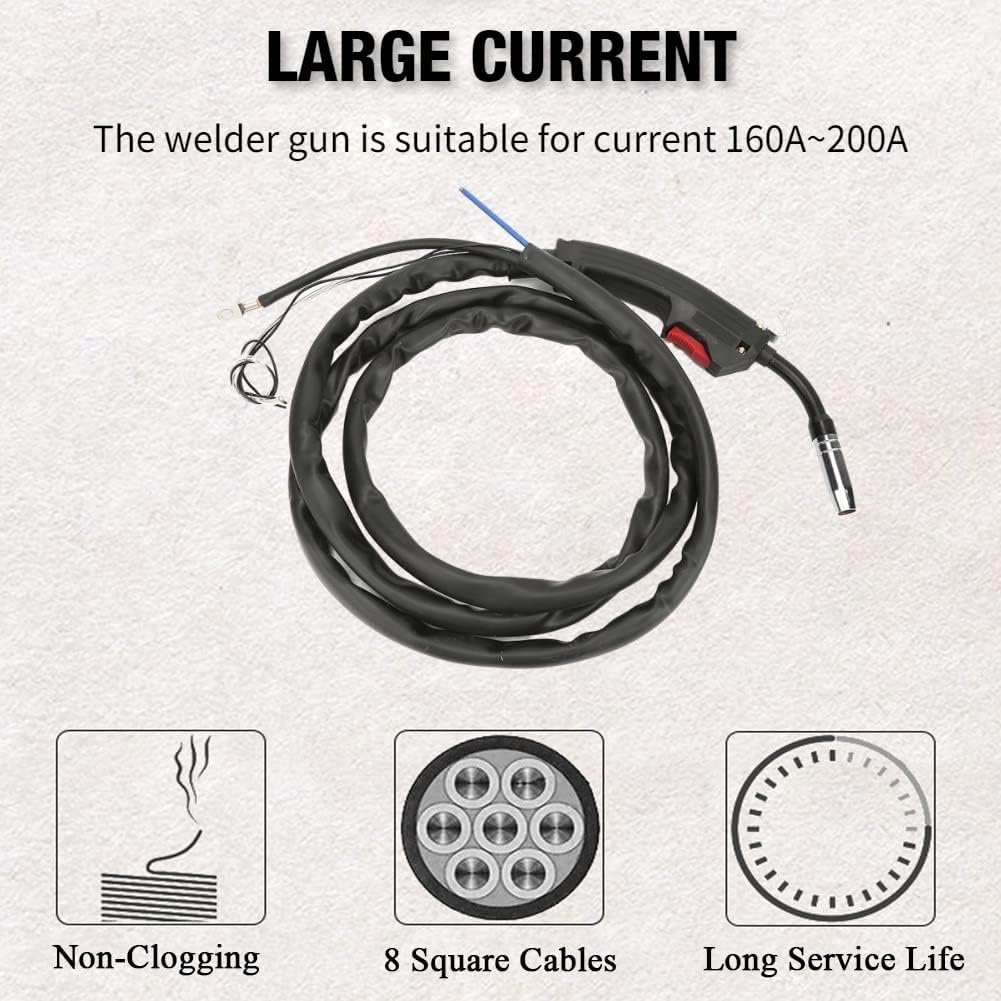

You’ll notice it’s marketed for a working current range of 160–200A and for wire diameters of 0.8–1.2 mm, which tells you the torch targets medium-duty MIG welding tasks. The 2-meter cable length and basic construction suggest a focus on cost-effective durability rather than premium ergonomics.

What the product name communicates

The full product name is long and descriptive, and it gives you most of the key facts up front: model (14AK MB14), gas protection type (CO2), wire diameter range (0.8–1.2 mm), current range (160–200A), length (2 meters), and intended fit (MIG130). That’s useful because you can quickly check compatibility with your machine and expected work.

You’ll find that the naming convention follows established MIG torch designations, so if you’ve used MB14/14AK guns before you’ll have a good idea what to expect physically and functionally.

Key specifications at a glance

You’ll want a quick reference table so you can match the torch to your machine and the welding tasks you commonly do. The table below summarizes the core details and helps you compare at a glance.

| Feature | Specification |

|---|---|

| Product name | 14AK MIG Welding Torch, 14AK MB14 CO2 Gas Protective Welding Gun Assembly 0.8 |

| Type / Model | 14AK / MB14 |

| Fit for | MIG130 |

| Working pattern | Protective gas welding (MIG) |

| Diver mode | Manual (trigger switch) |

| Action target | Metal |

| Rated current | 160–200 A |

| Wire diameter | 0.8–1.2 mm |

| Cable length | 2 meters |

| Gas type | CO2 (or CO2/Ar mixes depending on workpiece) |

| Materials | Premium material (manufacturer claim) |

| Intended use | Medium-duty MIG welding, repair work, light fabrication |

| After-sales | Seller offers quality after-sales service if unsatisfied |

You’ll find this table handy when comparing torches or verifying whether the gun suits the wire size and amperage you use most often.

Compatibility and fit (MIG130 and beyond)

You’ll want to be certain the torch physically fits and functions with your MIG machine. This torch is specifically listed as fit for MIG130, so it’s intended to be a direct match for that torch connection style.

You should double-check the connector type and the drive gun assembly on your machine to ensure plug-and-play compatibility. If your machine uses a different connector or has a different gas fitting, you may need an adapter or to swap consumables to get a perfect fit.

Machine output vs. torch rating

The documented current range of 160–200 A is important to note because you’ll need a machine capable of that output if you plan to push the torch near its upper limit. If your MIG130 machine delivers less amperage, the torch will still work at lower settings as long as the wire diameter and feed rates are compatible.

If you try to run the torch above your machine’s rating, you risk inconsistent arc performance and potential overheating. Always match torch capability to machine output for best results and safety.

Current capacity and performance expectations

You’ll see the torch marketed for 160–200 A. That means it’s meant for medium-duty welds where you’re joining thicker sheet, light structural elements, or doing routine workshop repairs.

You can expect stable performance within that range if your machine and consumables (wire, nozzle, contact tip) are sized appropriately. Running persistent high current on any torch will increase wear on contact tips and nozzles, so plan to keep spare consumables on hand.

How current affects welding behavior

Higher current means more penetration and faster travel speeds, which is great for thicker materials. You’ll notice more spatter with CO2 shielding at higher amperages than you would with argon-rich mixes, and that’s normal; proper technique and tuning mitigate it.

If you’re welding thinner materials, lower the amperage and use smaller wire diameters (0.8 mm) to reduce heat input and avoid burn-through. You’ll find the torch capable of handling both ends of the specified wire range, but technique matters.

Wire compatibility and consumable sizing

You’ll use filler wires between 0.8 mm and 1.2 mm with this torch, according to the specs. That covers the most common DIY and light-fabrication wire sizes and gives you flexibility across sheet metal, light structural, and automotive work.

Selecting the correct contact tip size for the wire diameter is key. If you use 0.8 mm wire, install a tip sized for 0.8 mm; for 1.0 mm or 1.2 mm wire, match the tip accordingly. A mismatched tip will cause feeding issues, spatter, and poor arc stability.

Consumables you’ll want on hand

You’ll want multiple contact tips (for 0.8, 1.0, and 1.2 mm), at least one spare gas nozzle, and a spare drive roll or liner if your feed system is compatible. These items wear with use, and having replacements reduces downtime.

If the torch uses a standard MB14-style configuration, many aftermarket consumables will fit, making replacements convenient and often inexpensive.

Build quality, materials, and durability

The product description claims “premium material” and “long service life,” and you should expect a solid, utilitarian build typical of MB14/14AK torches. The exterior usually includes heat-resistant plastics around the handle and a robust insulated cable.

You’ll likely get a torch that stands up to workshop use if you avoid abusive conditions like dropping it on abrasive surfaces or exposing connectors to excessive moisture. If you weld regularly at the higher end of the current range, you’ll accelerate wear on contact tips and cables.

What “sturdy and durable” means in practice

Sturdy in this price class often means a reinforced cable jacket, tight-fitting connectors, and a nozzle that resists deformation under normal use. Durability still depends on maintenance — keeping the nozzle clean and the liner free of spatter improves longevity significantly.

If you’re doing heavy production work, you may eventually want a heavy-duty industrial torch with a thicker cable and longer service intervals, but for many hobbyists and light professionals, this torch provides good value.

Cable length and handling (2 meters)

You’ll get a 2-meter cable, which is convenient for bench work and short-range welding. It keeps the torch light and manageable while giving you some reach without dragging a long cable.

If you need to weld across larger assemblies or in cramped positions, you might prefer a longer cable or an extension, but that comes with trade-offs in added weight and potential feed friction. The 2-meter option is a balance between control and reach.

Managing cable ergonomics

You’ll want to route the cable to avoid tight bends and to keep it from being pinched or dragged on sharp edges. Regularly inspect the cable for cracks or exposed inner conductors to prevent safety hazards.

Using cable ties or an overhead support can help reduce strain on the torch and make prolonged welding sessions less tiring for your arm.

Gas shielding and weld quality (CO2 focus)

You’ll be using CO2 as the protective gas according to the product name; CO2 is an economical choice and gives strong penetration with mild steel, though it tends to produce more spatter than argon-CO2 mixes. CO2 is easy to source and common in basic MIG setups.

If you care about bead appearance or want less spatter, consider an argon/CO2 blend (commonly 75/25 or 80/20) if your process and materials allow it. CO2 is fine and effective for many structural and repair welds, but the gas choice affects bead profile and cleaning time.

Typical weld results you should expect

You’ll see good fusion and penetration on mild steel within the torch’s rated amperage range, especially when you tune wire feed speed and voltage to match the wire diameter. With CO2 alone you’ll work a bit more on spatter cleanup, but weld strength will be solid when parameters are set correctly.

For thin metals, practice with lower heat and smaller wire to reduce burn-through and achieve a cleaner bead.

Trigger action and user control (manual)

This torch uses a manual trigger (diver mode: manual), which means you control the welding arc start/stop directly with the gun. That offers you full, tactile control and is standard for most MIG torches.

You’ll want to practice starting and stopping smoothly to avoid crater issues or wire burnback in the nozzle. If you’re used to robotic or automatic feeding setups, a manual trigger gives you more control but also requires steady hand technique.

Trigger feel and responsiveness

A responsive trigger contributes to better bead starts and less burnback. If the trigger feels sticky or inconsistent, check the wiring and trigger switch connections. Replacing a worn trigger switch is typically inexpensive compared to replacing the entire torch.

Ergonomics and user comfort

You’ll appreciate a lightweight, balanced torch when welding for extended periods because it reduces fatigue and helps maintain consistent travel speed. This torch is built with practicality in mind, which often means a comfortable grip and moderate weight.

If you anticipate long, continuous welds, evaluate how the weight distributes between the gun and cable. Lightweight gun and flexible cable make awkward positions and vertical welds easier to manage.

Grip and control tips

You’ll get better results when you maintain a stable wrist and hold the torch so the nozzle points in the travel direction at a slight angle. Use a steady travel speed and consistent distance from tip to workpiece to keep bead appearance uniform.

Avoid gripping too tightly; a relaxed hand reduces shake and allows finer adjustments to arc length.

Installation and setup guidance

You’ll install the torch by matching the connectors to your MIG130 or compatible machine, securing gas lines and the wire feed connection, and then selecting the correct consumables for your wire size. Make sure electrical and gas connections are tightened and leak-free.

Run a short test weld on scrap material to tune wire feed speed and voltage before tackling your project. That initial setup run helps you confirm feed consistency, arc stability, and correct shielding gas flow.

Step-by-step quick setup checklist

You’ll find the following checklist helpful: confirm connector compatibility, install the correct contact tip, attach the nozzle, check gas hose and flow, thread wire carefully through liner and tip, set wire feed speed and voltage low to start, and perform a test bead on scrap. Following these steps reduces troubleshooting time and gets you welding sooner.

Maintenance, cleaning, and spare parts

You’ll maintain the torch by cleaning spatter from the nozzle, replacing worn contact tips, and inspecting the liner for debris or flattening. Regular cleaning extends consumable life and improves wire feeding reliability.

Keep a small kit of contact tips, extra nozzles, and a replacement liner if your machine supports it. Cleaning the nozzle with a wire brush and using anti-spatter spray (sparingly) help reduce buildup and make tip replacement easier.

Troubleshooting common issues

If you see irregular arc or birdnesting (wire tangles), check the liner and drive roll alignment first. Poor wire feed often comes from a damaged liner, incorrect drive roll pressure, or a worn tip causing friction.

If you get excessive spatter, verify gas flow and consider switching to a blend or adjusting parameters. If triggering is intermittent, look at the trigger switch wiring and connector contacts for dirt or corrosion.

Safety recommendations

You’ll always follow welding safety basics: wear an appropriate welding helmet with the correct shade, gloves, flame-resistant clothing, and ensure ventilation to avoid fume buildup. CO2 and CO2/argon mixes are generally safe with ventilation, but welding fumes still require attention.

Inspect the torch and cable for insulation damage before use, and never weld in damp conditions or with compromised electrical insulation. Proper PPE and workspace preparation prevent most common welding hazards.

Safe handling of consumables and parts

You’ll handle hot nozzles and tips with pliers or gloves to avoid burns, and let used consumables cool before storage. Keep spare consumables in a clean, dry place to avoid contamination and corrosion.

If gas leaks occur, turn off regulators and fittings immediately and check for loose connections or damaged hoses. Gas safety is critical to avoid fire risks and maintain weld quality.

Pros and cons — practical takeaways

You’ll appreciate this torch for its clear compatibility with MIG130, suitable wire range for many tasks, and claimed durable construction. It’s a budget-friendly, practical option for hobbyists, small shops, and repair work.

On the downside, the 2-meter length may limit reach for some projects, and the 160–200 A rating might not match smaller MIG machines if you’re using the torch at higher settings. You should also plan for consumable replacement over time, as with any MIG torch.

Summary pros

You’ll benefit from: clear fit for MIG130 machines, support for common wire diameters, solid medium-duty current rating, and a design based on widely used MB14/14AK parts that makes consumable sourcing easier.

Summary cons

You’ll want to be aware of: a moderately short cable for larger work areas, potential mismatch with lower-output machines if you expect to use the high end of the current range, and the need to manage CO2 spatter if appearance matters.

Value for money and target users

You’ll find this torch offers good value if you need a reliable replacement or an entry-level upgrade that won’t break the bank. It’s especially attractive if you already own a MIG130 or a compatible machine and want a matching gun without high cost.

If you’re a production welder who relies on continuous heavy-duty operation, you might want to evaluate higher-end torches designed specifically for sustained industrial use. For general workshop and light professional work, this torch represents solid value.

Who should buy it

You’ll appreciate this torch if you’re a DIYer, hobbyist, small-fabrication shop, or automotive enthusiast needing a practical MIG gun. It’s also suitable if you want a spare or backup torch that aligns with common MB14 configurations.

Practical welding tips and parameter suggestions

You’ll get the best results when you set wire feed and voltage according to wire diameter and material thickness. As a basic guideline, start with recommended settings from your welding machine and adjust feed speed until the arc sounds steady and the bead profile looks even.

For 0.8 mm wire on thinner materials, use lower voltage and slower feed speeds; for 1.2 mm on heavier plate, increase both voltage and feed. With CO2 shielding, expect more penetration; you may need to slow travel speed slightly to avoid excessive reinforcement.

Example parameter starting points (general)

You’ll use these rough starting points as a baseline, then fine-tune:

- 0.8 mm wire on 1–2 mm steel: voltage low, wire feed around 5–8 m/min (machine-specific).

- 1.0 mm wire on 2–3 mm steel: medium voltage, wire feed medium.

- 1.2 mm wire on 3–6 mm steel: higher voltage, faster feed rates toward the torch’s upper range.

Always make a test bead on scrap before welding the final workpiece to dial in the right settings.

Buying considerations and questions to ask the seller

You’ll want to verify connector type and ensure it matches your machine. Ask the seller whether the package includes contact tips and nozzle or if those are sold separately, and confirm the exact connector pin configuration if connectors aren’t standardized in your region.

Also ask about warranty or return terms, and be ready to request after-sales support if parts are missing or the fit isn’t perfect. The product listing states the seller will provide quality after-sales service if you’re unsatisfied, so document any issues promptly.

What to check on delivery

You’ll inspect the torch for physical damage, verify the cable length and connector details, and make sure any included consumables match listed sizes. If something’s off, contact the seller immediately and use your purchase record to expedite resolution.

Comparisons with common alternatives

You’ll find other MB14-style torches and branded alternatives in the market that vary in cable length, current rating, and ergonomic design. Branded torches from premium manufacturers often offer longer warranties, better heat tolerance, and optional longer cable lengths, but they’re pricier.

If you want a low-cost replacement that closely matches MIG130 dimensions and parts, this torch is a convenient choice. If you want extended reach or heavy-duty continuous use, compare models with longer cables and industrial-grade components.

When to opt for a premium torch instead

You’ll consider a premium torch if you weld long hours every day, need extended cable lengths without adding resistance, or require a torch designed for high-impact or harsh industrial environments. Premium models often include improved liners, thicker cable insulation, and better trigger ergonomics.

Final verdict and purchasing decision guidance

You’ll find the 14AK MIG Welding Torch, 14AK MB14 CO2 Gas Protective Welding Gun Assembly 0.81.2mm 160200A 2 Meters for MIG130 to be a sensible, practical option if you want a compatible, medium-duty manual MIG torch. It suits many hobby, automotive, and light-fabrication needs and gives you flexibility with common wire diameters.

If your projects fall into those categories and your machine supports the current range, this torch should meet your expectations for cost, durability, and ease of use. Make sure to confirm connector compatibility and keep spare consumables on hand to stay productive.

After-sales and support reminder

You’ll note the seller offers after-sales service if you aren’t satisfied. If anything arrives defective, contact the seller with order details and photos so they can assist quickly and get you back to welding.

Useful accessories and spare parts to buy with the torch

You’ll reduce downtime by ordering contact tips in 0.8 mm, 1.0 mm, and 1.2 mm sizes, an extra gas nozzle, and a liner or drive-roll spare if compatible. Also consider a set of nozzle pliers, anti-spatter gel, and a small parts organizer so you can swap consumables easily.

Buying a basic consumable kit with the torch is a low-cost way to keep working while you learn the best tuning for your setup.

Consumable care tips

You’ll clean the nozzle after each session, store tips clean and dry, and avoid letting wire sit exposed where rust can form. Replacing consumables before they fail helps maintain weld quality and prevents frustrating machine downtime.

Troubleshooting quick guide

You’ll check the following if you have issues: wire feeding erratically (liner or drive roll), excessive spatter (gas flow or parameter tuning), intermittent trigger (wiring/connector), and poor arc stability (wrong tip size or incorrect polarity). Address the simplest fixes first, and enlist the seller if hardware defects appear.

You’ll find many common problems are solved by cleaning, replacing worn tips, and taking a moment to adjust feed tension.

When to reach out for help

You’ll contact the seller or a qualified technician if the torch overheats quickly, connectors are damaged, or the trigger is dead despite good connections. For persistent performance problems despite correct setup, professional diagnosis can save time.

Closing note on practical use

You’ll get a work-ready MIG gun that covers the typical needs of many welders, from repair jobs to light fabrication. With correct matching to your machine, proper consumables, and routine maintenance, the torch should serve you well for a variety of metalworking tasks.

You’ll be set to start welding as soon as you confirm compatibility, install the correct consumables, and tune your machine on scrap. If you run into questions during setup, reach out to the seller for support and consider stocking spare parts for steady workflow.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.