Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you tired of sending your woodworking band saw blades out for repair or throwing them away when a small break ruins the whole blade?

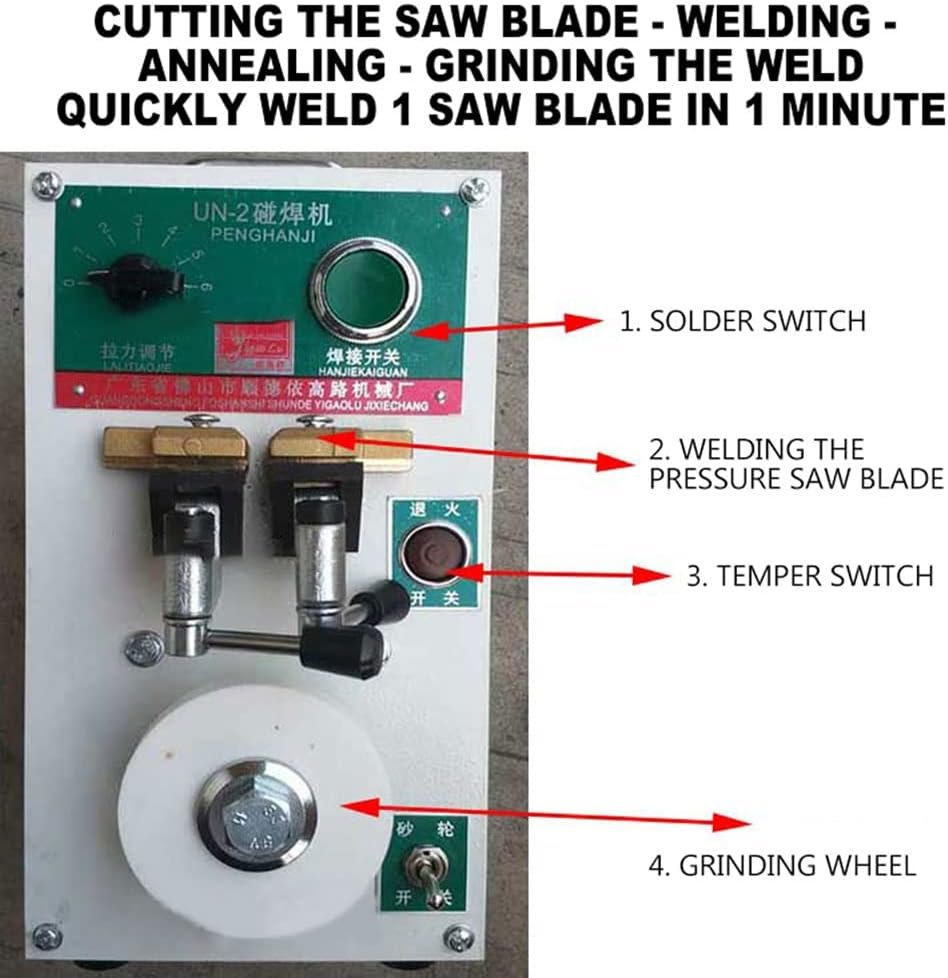

Product overview

You’ll find the “3 in 1 Portable Electric Welder Band Saw Blade Welding Machine Grinder Cutter 0.6-0.75mm Thickness BandSaw Blade Butt Welder Tempering, Wood Pruning Saw Reciprocating Saw Blade Welder only woodworking” is designed specifically to make small shops and hobbyists self-sufficient when it comes to band saw blade repairs. The unit combines a resistance butt welder with a small grinding wheel and cutter, so you can weld, temper, grind, and trim woodworking band saw blades without purchasing separate tools.

Key specifications

This section gives you the quick numbers you care about so you can immediately judge whether the machine fits your workshop needs. The specs below reflect the core capabilities and limits you should pay attention to.

| Feature | Specification |

|---|---|

| Welding method | Resistance butt welding (no filler or adhesives) |

| Welding time | Typically under 2 seconds for the butt weld |

| Weldable thickness | 0.6–0.75 mm (woodworking band saw blades only) |

| Maximum welding width | 20 mm (2 cm) |

| Voltage | 4.8 V (low-voltage design, low energy consumption) |

| Additional tools | Built-in saw blade grinder, built-in cutter |

| Tempering/annealing | Yes, annealing/tempering function included |

| Portability | Compact and lightweight, handheld-friendly |

| Material compatibility | Only woodworking saw blades; not suitable for metal blades |

| Length limit | Unlimited (you can weld blades to any length) |

What’s included in the package

You’ll get more than just a welder when you unpack this machine; the kit is arranged so you can complete a repair from start to finish. Expect the main welding head, an integrated grinder wheel, a cutter, a small white hacksaw-like blade accessory, and basic clamps and jigs designed for band saw blades.

First impressions and build quality

When you pick it up, you’ll notice how compact and lightweight it is, which makes it comfortable to carry around or store in a small shop. The construction is focused on portability and convenience rather than heavy industrial duty, so you get a well-thought-out design that suits woodworking tasks but not high-volume metalworking environments.

How the welder works

You’ll operate a resistance butt-welding process that brings the two blade ends together and passes a controlled current to heat and fuse them. The machine forms a butt weld quickly — often within two seconds — and then applies tempering/annealing to strengthen the joint and reduce brittleness.

Welding cycle explained

You’ll position the two blade ends into the clamps, ensure proper alignment, and activate the welding pulse; the machine does the rest in a short automatic sequence. After the initial weld, the annealing mode reduces stress in the joint so the weld resists cracking when the blade bends during use.

Why resistance butt welding makes sense here

You’ll appreciate that resistance welding avoids the need for fillers, brazing rods, or adhesives that can complicate repairs and add expense. The weld is a direct metal-to-metal fusion that, when performed correctly and tempered, returns a reliable connection suitable for most woodworking cutting cycles.

Welding performance and strength

You’ll notice the machine promises fast weld times and a firm joint after tempering, and in practical use you can achieve consistent results if you follow the alignment and surface prep guidance. The combination of quick heating and annealing helps the joint reach good tensile resistance for normal woodworking workloads.

Speed and cycle time

You’ll usually have a completed weld in under two seconds, though total cycle time including alignment, grinding, and tempering runs a little longer. This fast active welding stage saves you time compared to manual brazing or sending blades out for repair.

Tensile and fatigue resistance

You’ll want the joint to handle bending and cutting forces; after tempering the welded junction demonstrates strong tensile resistance for typical woodcutting tasks. Keep in mind that while suitable for woodworking blades, the joint won’t match the performance of factory continuous blades for heavy industrial cutting.

Grinder and cutter functions

You’ll find the built-in grinder and cutter are convenient, saving you the need to buy separate small grinders and cutting tools. They are sized and configured to handle blade preparation and final trimming so you can shape the joint and clean the weld for smooth operation.

Using the grinder

You’ll use the small grinding wheel to remove oxidized metal and burrs, and to shape the ends for a flush butt weld that aligns perfectly. The grinder is compact but effective for preparing 0.6–0.75 mm thick blades; it’s not designed for large-scale metal removal.

Using the cutter

You’ll trim excess material and shape the welded area with the included cutter so the blade tracks cleanly on your saw’s wheels. The cutter is optimized for woodworking band saw blades and works well with the integrated grinder to give a neat finished joint.

Compatibility and limitations

You’ll need to be aware of what this machine will and will not do so you don’t try to force a function outside its design. It is explicitly designed for woodworking band saw blades with thickness between 0.6 and 0.75 mm, and it cannot be used for metal cutting blades or higher thickness ranges.

Blade types and materials supported

You’ll use the machine for mainstay woodworking blades, pruning saw blades, and reciprocating saw blades intended for wood. If your blade is a bi-metal, carbide-tipped, or otherwise engineered for metal cutting, you should not use this unit on it.

Thickness and width constraints

You’ll be limited to blades within the 0.6–0.75 mm thickness range and up to 20 mm in width for reliable fusion. Trying to weld thicker or wider blades will likely give poor welds or overload the machine.

Usability and user interface

You’ll find the controls are straightforward: clamp the blade, align it, engage the welding trigger, and the machine runs its programmed cycle including annealing. The simplicity makes it approachable for a hobbyist or small shop operator, but you’ll still benefit from a bit of practice to get consistently neat joints.

Alignment and clamping tips

You’ll want to take your time ensuring the blade teeth and body line up precisely before welding, as a small misalignment can cause tracking problems on the saw. Use the provided clamps and check tooth spacing across the joint so the blade runs true after the weld.

Power and energy considerations

You’ll work with a low-voltage, low-energy design (4.8 V) that’s energy-efficient and safe for bench use, though you should still follow electrical safety practices. This low voltage helps portability and reduces power draw while still delivering the current needed for resistance welding.

Portability and workshop fit

You’ll appreciate the machine’s compact footprint and light weight if you move between job sites or have limited bench space. It fits well in small woodworking shops, portable setups, and for mobile arborists or landscapers who need to repair pruning saw blades on site.

Carrying and storage

You’ll be able to stow the unit in a toolbox or cabinet and carry it along to job sites without much effort. Its compact dimensions make it a practical accessory if you value low storage impact and quick accessibility.

Suitability for different shop sizes

You’ll find it perfect for hobby shops, small custom woodshops, farm or property maintenance, and arborist crews that need to repair blades on the go. It’s less suitable for heavy production shops that routinely weld thick or metal blades, where larger industrial welders are appropriate.

Safety considerations

You’ll need to follow basic safety protocols because the welder generates heat and electrical current and the grinder produces sparks and metal dust. Always use eye protection, gloves, and ensure you have proper ventilation and a secure working surface when grinding or welding.

Electrical and fire safety

You’ll observe that even low-voltage equipment can cause burns and sparks; keep flammable materials away from the working area and inspect cords and connectors before each use. A fire extinguisher nearby and a tidy workspace reduce risk significantly.

Personal protective equipment (PPE)

You’ll wear safety glasses, a face shield for grinding, hearing protection if your environment is noisy, and gloves to protect against hot metal and sharp blade edges. Proper PPE makes quick repairs much less risky and reduces the chance of accidental injury.

Maintenance and care

You’ll keep the machine functioning reliably by performing a few routine maintenance tasks such as checking connections, replacing the grinding wheel when worn, and keeping moving parts free of debris. A little maintenance extends the life of the machine and ensures consistent welding quality.

Cleaning and inspection

You’ll clean the jaw surfaces and grinding areas after each use to prevent metal buildup that could affect alignment. Periodically inspect the clamps and electrical contacts for wear or oxidation and clean them with appropriate contact cleaner.

Replacement parts and consumables

You’ll replace the small grinding wheel and any consumable blades as they wear; those parts are commonly available and inexpensive. Keeping a spare wheel and a few accessory blades on hand prevents downtime when you need to repair a blade quickly.

Step-by-step welding procedure

You’ll get the best results by following a clear, repeatable sequence that prepares the blade, performs the weld, tempers it, and finishes the joint. Below is a practical workflow you can adopt the first time you use the machine.

- Inspect the blade ends and cut away ragged edges so the ends mate cleanly.

- Use the grinder to remove oxidation and ensure a flat, clean surface where the metal will fuse.

- Align the two blade ends in the clamps, checking tooth spacing and body alignment carefully.

- Activate the welding cycle and allow the machine to perform the rapid resistance weld.

- Let the tempering/annealing program run to relieve stresses and strengthen the joint.

- Use the cutter and grinder to trim excess material and form a smooth profile that tracks properly.

- Inspect the weld visually and by flexing gently; if anything looks off, grind and redo the weld.

Tips for getting consistent, strong welds

You’ll improve outcomes by focusing on surface preparation, precise alignment, and allowing the annealing cycle to complete. Small improvements in these areas dramatically increase joint strength and reduce the chance of a blade failing prematurely.

Surface prep matters

You’ll make sure the ends are clean and free of rust or scale because contamination prevents a good fusion. Use the grinder to achieve a flat, clean interface—this is the single most important factor for a solid weld.

Alignment and tooth match

You’ll align teeth spacing across the joint so the blade tracks straight on the saw wheels; a mismatched tooth pattern will cause vibration and premature wear. Use a straight edge to check the faces before committing to the weld.

Troubleshooting common issues

You’ll run into a small number of recurring problems when you first start welding blades; the good news is most are fixable with minor adjustments. The most common issues stem from poor surface prep, misalignment, or worn consumables.

Welds that crack or break

You’ll suspect poor tempering, contamination, or incorrect blade thickness if a weld cracks under normal load. Address this by regrinding the ends, ensuring good contact, and letting the annealing cycle run fully; if the blade is outside the 0.6–0.75 mm range, the machine may not produce a durable weld.

Poor tracking after welding

You’ll usually see tracking problems when the blade ends aren’t aligned or the finished contour isn’t ground smoothly. Re-grind the joint so the body thickness and tooth spacing match, and make fine adjustments before next use.

Comparison to alternative repair methods

You’ll find different methods for repairing band saw blades ranging from bolt splices to brazing, but this 3-in-1 unit offers convenience and speed for woodworking blades. Compared to brazing or buying new blades, this welder is faster, cleaner, and cheaper for occasional repairs if you stay within its material and thickness range.

Benefits versus brazing and soldering

You’ll save time because the weld and anneal happen quickly and with no filler materials to handle or buy. Brazing can offer a different metallurgical result that may be stronger for some metals, but it requires more skill and removes the portability advantage.

Benefits versus bolt splices and clamps

You’ll prefer butt welding for a smooth continuous blade that runs in the track without an elevated splice bulge. Bolt splices are convenient but add extra bulk and can cause vibration and uneven cutting performance.

Who should consider buying this machine

You’ll be a good candidate if you own a small woodworking shop, maintain pruning saws and reciprocating saw blades, or frequently repair tractor or log-cutting blades used on wood. The machine particularly suits hobbyists and tradespeople who need portable, occasional repairs without investing in bigger equipment.

Not a fit for heavy industrial shops

You’ll avoid this machine if you weld metal-cutting blades regularly or need to process large volumes of blades daily, since it’s optimized for woodworking blade thickness and light-to-moderate duty cycles. High-volume shops will benefit more from dedicated industrial welders with greater capacity.

Real-world use cases

You’ll use this machine on-site for timber framing, estate maintenance, pruning and arborist work, hobbyist joinery, and small sawmill tasks. It’s also handy for custom blade length adjustments and emergency repairs where buying a new blade or sending it out would be impractical.

Mobile repair scenarios

You’ll carry it to a job site to repair a blade rather than interrupt work to fetch a replacement, which saves time and money. The lightweight design makes it easy to keep in a service van or toolbox.

Small shop convenience

You’ll keep production flowing in a small shop by repairing broken blades between jobs rather than ordering replacements and waiting. For occasional blade failures this machine is often the fastest and most pragmatic option.

Pros and cons

You’ll want a balanced view before purchasing, so here’s a concise summary to help your decision. The pros focus on convenience and portability, while the cons reflect limits on materials and industrial capacity.

Pros:

- You’ll get a fast weld cycle that allows quick repairs, often within two seconds.

- You’ll appreciate the integrated grinder and cutter, reducing the number of tools you need.

- You’ll benefit from annealing/tempering to increase joint strength.

- You’ll enjoy portability and low energy consumption, making it fit for mobile use.

- You’ll be able to weld blades to any length as needed.

Cons:

- You’ll be restricted to woodworking saw blades in the 0.6–0.75 mm thickness range.

- You’ll not be able to weld metal-cutting or thicker blades, limiting your workshop scope.

- You’ll need a bit of practice to consistently produce factory-like joints.

- You’ll rely on consumable parts like the grinding wheel that will require replacement over time.

Value for money

You’ll find this machine delivers high value if you repair blades regularly for woodworking tasks and value portability and speed. Because it removes the need to buy a separate grinder and cutter, you’ll often recoup the purchase price relatively quickly compared to repeated blade replacement costs.

Final thoughts and buying recommendation

You’ll find the “3 in 1 Portable Electric Welder Band Saw Blade Welding Machine Grinder Cutter 0.6-0.75mm Thickness BandSaw Blade Butt Welder Tempering, Wood Pruning Saw Reciprocating Saw Blade Welder only woodworking” is a well-rounded tool for anyone who needs to maintain woodworking blades on the go. If you predominantly work with blades within the supported thickness and material range and value fast, portable repairs, this machine is a practical and economical addition to your toolkit.

Frequently asked questions (FAQ)

You’ll get answers to the most common questions people ask before buying so you can make an informed decision quickly.

Q: Can you weld bi-metal or carbide-tipped blades?

A: No. You’ll only use this machine on woodworking band saw blades; carbide-tipped or bi-metal blades are not supported.

Q: How long does the weld last under normal conditions?

A: You’ll typically get a durable weld suitable for routine woodworking tasks, provided you prepare the ends correctly and let the tempering cycle complete. Lifespan depends on use pattern, blade tension, and cutting conditions.

Q: Is special training required to use the machine?

A: You’ll need only basic instruction and a little practice to get consistent welds; no formal certification is necessary. Following the steps for surface prep, alignment, and tempering will make the biggest difference.

Q: Are replacement parts easy to find?

A: You’ll replace the grinding wheel and consumable cutter blades periodically; these parts are commonly available online or through the seller. Keep spares on hand for uninterrupted repairs.

Q: Can you weld blades longer than factory lengths?

A: You’ll be able to join blades to any length since the machine doesn’t limit total blade length. Make sure the joined blade is well aligned and tensioned correctly in your saw.

Q: Does the machine require a specific power source?

A: You’ll use the unit as designed on its supplied low-voltage power system; check the product manual for exact connectors and adapter needs. Its low energy consumption makes it convenient for mobile and bench use.

Q: What safety gear should you use?

A: You’ll wear eye protection, gloves, and a face shield for grinding; ensure a clean work area and proper ventilation. Treat the unit with respect and follow standard safety practices for welding and grinding.

If you want, you can ask for a condensed buying checklist, a printable quick-start welding flow, or a comparison chart against two specific competing models you’re considering.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.