Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

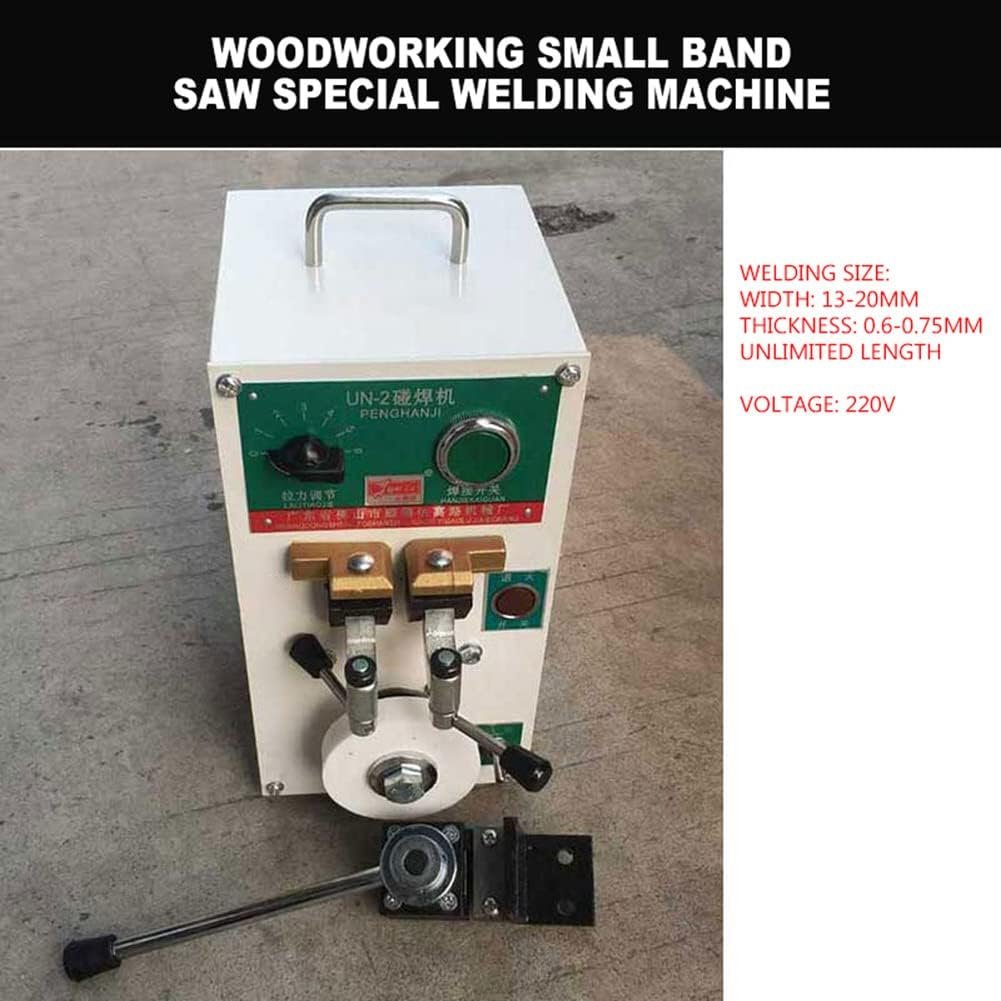

? Are you trying to decide whether the 3 in 1 Portable Electric Welder Band Saw Blade Welding Machine Grinder Cutter 0.6-0.75mm Thickness BandSaw Blade Butt Welder Tempering, Wood Pruning Saw Reciprocating Saw Blade Welder only woodworking is the right compact solution for repairing and maintaining your woodworking band saw blades?

Product overview

You get a compact, multi-function tool designed specifically for woodworking band saw blades. It combines a butt-welding unit with an integrated grinder and cutter so you can weld, temper, sharpen, and trim blades without needing separate devices or many additional consumables.

What it is

This is a 3-in-1 portable unit that forms band saw blade joints by resistance/butt welding, and it also includes a small grinding wheel and a cutter. It’s made to handle blades with thicknesses between 0.6 and 0.75 mm and to temper the joint so the weld holds up under tension after annealing.

Key features

The main selling points are speed, portability, and the built-in finishing tools that let you complete an entire repair cycle on the spot. You should expect welding within about 2 seconds, a tempering or annealing function, and the convenience of an integrated grinder and cutter so extra purchases aren’t necessary.

Technical specifications

Below is a detailed breakdown of the core technical numbers and limitations you’ll want to keep in mind before buying. These are what determine what blades you can repair, how fast you can work, and how durable the welds will be.

| Specification | Detail |

|---|---|

| Product Type | 3-in-1 band saw blade welder, grinder, and cutter (woodworking only) |

| Voltage | 4.8 V (low energy consumption) |

| Weldable Thickness | 0.6–0.75 mm |

| Maximum Welding Width | 20 mm (2 cm) |

| Welding Method | Resistance/butt welding with annealing/tempering |

| Welding Speed | Weld completes in around 2 seconds |

| Additional Tools | Small grinding wheel and a hacksaw-style blade for trimming |

| Material Compatibility | Woodworking band saw blades only (not metal blades) |

| Portability | Compact, lightweight design |

| Typical Use | Wood pruning saws, reciprocating and band saw blades for woodworking |

You’ll notice this machine is deliberately targeted: thin woodworking band saw blades only, compact power, and a quick weld cycle. If your blades fall inside the specified thickness and width, you can expect consistent results.

What’s in the box

You should receive the main welding body with integrated controls, a small grinding wheel, the included white hacksaw-style blade for cutting, and any clamping fixtures that come with the unit. The package is intended to make you ready for blade repairs out of the box, without needing additional grinders or cutters.

Accessories and consumables included

Expect the machine to come with the essential finishing tools so you don’t have to source separate equipment for trimming and dressing the weld. Keep spare grinding wheels and cutting blades on hand because those wear out over time and are the parts you’ll replace most often.

How it works

You set the two blade ends into the machine’s clamp, align them, and the unit applies a resistance current to form a butt weld between the ends. After the weld, the machine’s annealing/tempering function relieves stresses and strengthens the joint, then you use the grinder and cutter to finish the joint to the correct profile and length.

Welding process

The welding is done by bringing the blade ends into contact under pressure and applying a short burst of current — roughly a two-second weld for compatible blades — to fuse the steel. Immediately after fusion, tempering/annealing is applied to stabilize the joint and increase tensile strength, which helps the weld hold up to tension when the blade is in use.

Grinding and cutting process

Once welded and annealed, the integrated small grinding wheel removes excess flash and smooths the weld area so the blade runs cleanly on your saw wheels. The included white hacksaw-style cutter trims the blade to the correct length and square if needed, so you can reinstall the blade without additional tools.

Performance & welding quality

You can expect a firm weld if you follow the thickness and width specifications closely, and if you temper the joint properly after welding. The annealing treatment is a significant plus because it increases tensile resistance compared to a raw, untempered weld.

Weld strength and tempering

After the annealing step, the welded joint should withstand the tension and bending loads typical of woodworking band saw use, provided you stay within the recommended blade thickness range. The tempering reduces brittleness and improves reliability, so you won’t be surprised by premature joint failure when you run a welded blade at normal cutting speeds.

Speed and efficiency

The machine claims to weld a blade within about 2 seconds, which is fast and lets you get blades back into service with minimal downtime. Because it includes finishing tools, the whole repair cycle is efficient: clamp, weld, anneal, grind, and cut — done. For a shop or mobile technician who repairs blades frequently, the time savings add up quickly.

Usability & portability

You’ll like the lightweight, compact form factor if you need to move between benches, job sites, or a woodworking trailer. The design aims to minimize setup complexity so a single operator can complete repairs without extra helpers or large fixtures.

Controls and operation

Controls are straightforward: alignment clamps, a welding trigger or switch, and the anneal cycle control. The learning curve is relatively short, but as with any welding device, you should practice on scrap blades before working on your high-value blades so you learn alignment and pressure nuances.

Portability and setup

The unit’s small size and low voltage make it easy to carry and set up quickly, and it doesn’t demand bulky power delivery. That portability is useful if you service machines at remote sites or need a compact solution in a crowded shop where bench space is limited.

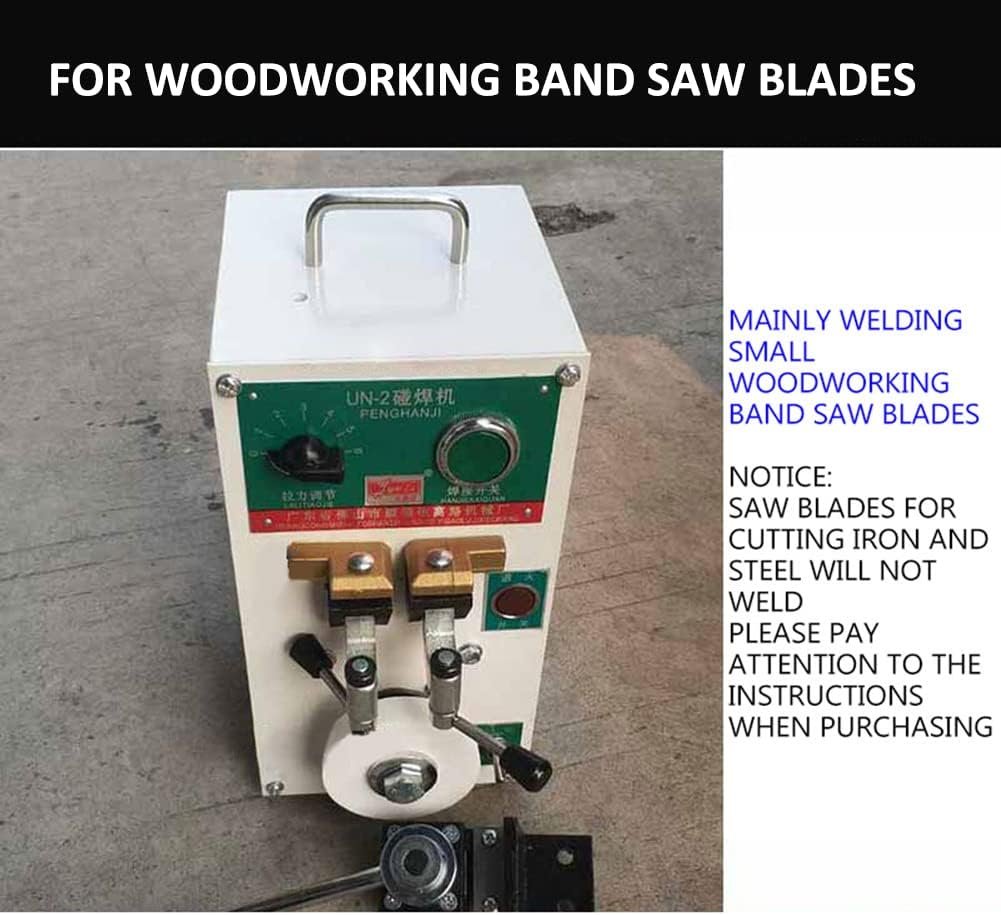

Safety & limitations

You must not use this machine for metal or heavy-duty industrial blades — it is explicitly designed for woodworking saw blades only. Also, follow standard safety practices for resistance welding, grinding, and cutting: eye protection, gloves, and an appropriate workspace.

Materials and compatibility

The welder supports blades 0.6–0.75 mm thick and up to 20 mm wide; outside of that range you risk weak welds or damage to the machine. It’s made for woodworking blades like pruning saws and reciprocating saw blades for wood; it is not intended for metal-cutting band saw blades or other thicker industrial materials.

Safety tips

Always wear eye protection and cut-resistant gloves during setup, welding, grinding, and cutting. Make sure your clamps are secure, keep the area free of flammable materials because welding generates heat, and avoid touching the weld area until it cools or is properly annealed.

Maintenance & care

Take care of the grinding wheel and cutting blade as consumables: keep them clean, replace them when they show wear, and check for balance to avoid vibration during finishing. Clean the unit’s contacts and clamps after use to ensure consistent electrical contact during future welds.

Cleaning and replacement parts

Wipe down the machine after use, remove metal filings from grinding operations, and inspect consumables frequently. Keep a small stock of replacement grinding wheels and cutting blades; these are the parts that wear down and will determine your ongoing repair quality.

Battery/power and long-term storage

The machine runs at low voltage (4.8 V) and is described as low energy consumption; check the manual to confirm whether it uses a rechargeable battery pack or an external adapter. Store it in a dry place, and if it uses batteries, follow recommended storage charge levels in the manual to preserve battery life.

Who should buy it

You should consider this if you regularly repair thin woodworking band saw blades and need a compact, portable, all-in-one solution. It’s a good fit for mobile blade sharpening services, tree pruning professionals who bring blades to a truck, or small woodworking shops that handle their own blade maintenance.

Use cases

You’ll find it useful for repairing band saw blades used in wood pruning, reciprocating saw blades for woodworking, and general light woodworking bands that meet the thickness specs. If you frequently replace blades because you can’t repair them quickly, this machine can save you money and time by letting you weld blades back together efficiently.

Not suitable for

You should not use this device if you need to weld thicker industrial or metal-cutting blades, or if your shop requires heavy production-level welding of blades outside the 0.6–0.75 mm range. It’s not a universal welder; using it on incompatible materials risks poor welds and possible damage to the machine.

Pros and cons

Here’s a concise table that sums up the main advantages and disadvantages so you can quickly weigh whether it matches your needs.

| Pros | Cons |

|---|---|

| 3-in-1 functionality (weld, grind, cut) reduces the need for extra tools | Only for woodworking blades — not compatible with metal blades or thicker industrial bands |

| Fast welding time (around 2 seconds) speeds up repairs | Limited to 0.6–0.75 mm thickness and up to 20 mm width |

| Annealing/tempering improves weld durability | Low voltage design may not suit heavy industrial use |

| Portable and lightweight for mobile use and small shops | Consumables (grinding wheel, cutter) will need periodic replacement |

| Low energy consumption and compact footprint | May require some practice to get consistent joints |

You should weigh these points against your workload: if you repair blades in the specified range frequently, pros will likely outweigh the cons. If your blades fall outside the specs or you need industrial strength welders, look elsewhere.

Tips for best results

Practice on scrap blades to dial in alignment, clamp pressure, and the timing of the weld and anneal cycles. Proper preparation — clean blade ends, square cuts, and correct alignment — is what determines a strong weld more than speed alone.

Clamping and alignment tips

Set the blade ends square and avoid overlaps; the machine works by butt welding, so a clean, flush joint is essential. Use the machine’s alignment guides and ensure the blades are held rigidly to prevent slippage, which will cause weak or uneven welds.

Grinding and finishing tips

Don’t over-grind the weld area; remove only the flash and shape the joint so it runs true on the saw wheels. After grinding, visually inspect and flex the joint gently to make sure the weld is smooth and free of cracks before installing the blade.

Comparison with alternatives

Compared to standalone welders or full-size industrial band saw welding machines, this unit trades heavy-duty capability for portability and convenience. You sacrifice universality and high-power output for integrated finishing tools and easy transportability, which is ideal for your woodworking-focused, lightweight blade repairs.

When to choose this unit over others

Pick this tool if your workload is primarily woodworking blades within the specified thickness range and you value rapid, on-site repairs without multiple tools. If you need to service heavy metal-cutting blades, a dedicated industrial welder would be a better long-term investment.

When to choose an alternative

If your application includes thicker blades, high-volume industrial forging, or metal-cutting blades for steel and other metals, a larger, more powerful welder is necessary. Also consider full-service blade specialists or benches with professional welders if you need certification-level consistency for industrial production.

Practical scenarios and workflow

Imagine you’re out on a pruning job and a band blade breaks; you can bring the blade back to your van, clamp it in the 3-in-1 unit, weld and temper it in a few minutes, grind the excess, trim the length, and reinstall. This minimizes downtime and reduces the need to carry spares or transport blades to a separate shop.

Mobile technician routine

If you work as a mobile technician, you’ll value the combination of low weight and integrated finishing. Keep a small kit of spare grinding wheels, replacement cutter blades, cleaning brushes, and a few alignment shims in your van so you’re ready for a variety of field repairs.

Small shop routine

In a small shop with limited bench space, this unit frees you from requiring a bench grinder or separate cutter nearby. Set up a dedicated corner for blade repair and make a quick workflow: belt out damaged blades, weld and temper, clean up the weld, and get back to cutting.

Frequently asked questions (FAQ)

You should find these answers helpful if you’re deciding on purchase or planning first use. If anything is unclear, always consult the supplied manual or contact the seller/manufacturer for safety-critical details.

Q: Can this weld metal-cutting blades or thicker blades?

A: No. This unit is designed for woodworking saw blades only and is limited to 0.6–0.75 mm thickness and up to 20 mm width.

Q: Do you need additional tools to finish the weld?

A: No. The unit includes a small grinding wheel and a cutter so you can grind and trim the joint without separate devices.

Q: How long does a typical weld take?

A: The welding cycle is fast—around 2 seconds—followed by an annealing/tempering step to strengthen the joint.

Q: Is the weld strong enough for production use?

A: For blades within the stated thickness and material type, the annealed weld offers strong tensile resistance suitable for regular woodworking tasks, though industrial heavy-duty applications might require more robust equipment.

Final verdict

If your work revolves around woodworking band saw blades in the 0.6–0.75 mm range and you need a portable solution that welds, tempers, grinds, and cuts, this product is a very practical and efficient choice. It gives you a near-complete repair cycle in a small package that saves time and reduces downtime, provided you respect its limitations and maintain the consumables.

You’ll appreciate the rapid weld times, integrated finishing tools, and the annealing feature that increases weld durability. Keep in mind the targeted nature of the machine — it’s a specialist tool for a specific class of blades — and if your needs match that class, it’s likely to become one of the most useful gadgets in your kit.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.