Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a reliable replacement nozzle shroud for your MIG MB15 torch that won’t break the bank?

Product overview

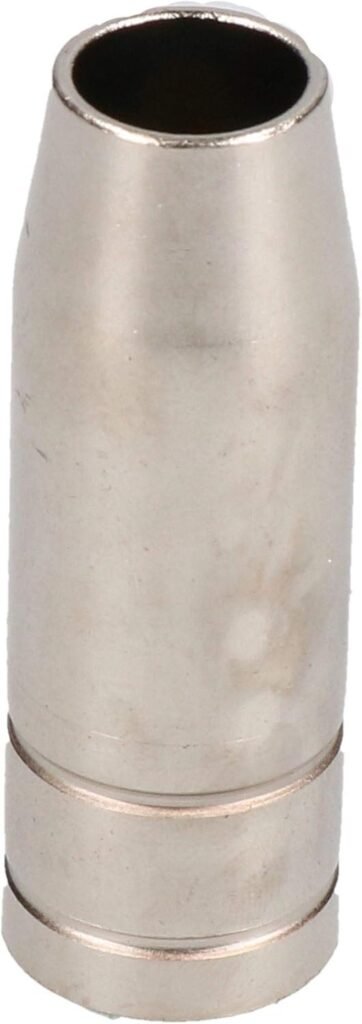

You want to know if the 5pk Conical Nozzle Shroud Binzel Style Welding Welder MIG MB15 Gas Push On is a solid choice for your welding setup. This product offers five conical push-on nozzles designed to fit Binzel MB15 style torches, giving you spares or replacements at a reasonable price so you can keep welding with minimal downtime.

You’ll find the nozzles are intended for typical MIG welding tasks, especially in light fabrication and hobbyist work. They’re meant to be simple to fit and replace, making them a practical option if you need quick swaps during a job.

Key specifications

You need the numbers to ensure fit and compatibility. Below is a clear breakdown of the most important measurements and features so you can quickly compare against your torch and current consumables.

| Feature | Specification |

|---|---|

| Product name | 5pk Conical Nozzle Shroud Binzel Style Welding Welder MIG MB15 Gas Push On |

| Quantity | 5 pieces per pack |

| Type | Conical push-on nozzle / shroud |

| Compatibility | Binzel MB15 style torches |

| Inner bore | 12 mm |

| Outer diameter (OD) | 18 mm |

| Length | 55 mm |

| Mounting style | Push-on (no threading) |

| Primary use | MIG welding gas nozzle / shroud replacement |

| Material | Metal alloy (plated/finished for wear resistance) |

You’ll appreciate that the table gives you the numbers you need at a glance, helping you decide whether these will fit your torch and your workflow.

What the specs mean for you

Those dimensions (12 mm inner bore, 18 mm OD, 55 mm length) will determine whether the nozzle sits properly on your MB15-style contact tip and gas diffuser. If you match the inner bore to your contact tip and the outer diameter to the shroud seat on your torch, installation should be straightforward.

You’ll also want to check the push-on style: it’s quick to install, but you’ll rely on a snug fit rather than threads, so keeping an eye on how firmly the nozzle seats matters for gas coverage and safety.

Design and build quality

You want durability without overpaying for consumables. These nozzles are made to be practical: conical in shape for focused gas flow, with a push-on design to speed up changes when you’re in the middle of a job.

The metal finish gives reasonable resistance to spatter and heat, but these aren’t premium copper nozzles designed for industrial heavy use. They strike a balance between cost and function so you can keep going when factory nozzles wear out.

Construction details

You’ll notice a simple, conical form that channels shielding gas toward the arc. The inner bore and length help you maintain proper gas coverage if matched to your tip and gas diffuser. The outer plating or finish reduces sticking and spatter buildup, making cleaning easier between uses.

Because the package includes five nozzles, you can rotate them, use them as backups, or stash them across different torches.

Compatibility and fitment

You’re likely asking if these will fit your torch and work with your current consumables. These nozzles are designed specifically for Binzel MB15-style torches, a widespread format used in many hobbyist and light industrial MIG setups.

Compatibility comes down to three things: the inner bore, the push-on seat, and the length. If your contact tip, gas diffuser, and torch neck align with those measurements, the fit should be reliable.

Checking your torch

You should measure the outer diameter of your contact tip and the internal diameter of your existing nozzle seat. If the contact tip OD is close to 12 mm and the torch neck accommodates an 18 mm OD nozzle with a 55 mm length, you’re in good shape.

Also check whether your torch expects a push-on shroud or a threaded one. These are push-on style, so they won’t work if your torch requires threaded nozzles.

What’s in the box

You want to know exactly what you’ll receive so you can plan. The packaging includes five conical push-on nozzles designed for Binzel MB15-style torches. That’s it—no contact tips, no diffusers, just the nozzles themselves.

Having five means you can replace worn nozzles without pausing your work to order replacements, or you can keep spares in different workstations.

Why a five-pack helps you

You’ll appreciate having multiple nozzles when you’re running through a welding day. Nozzle spatter and wear are normal, and a pack lets you swap quickly. You’ll also save money versus buying individual OEM nozzles every time one gets clogged or damaged.

Installation and removal

You’ll find installation is straightforward because these are push-on style nozzles. That simplicity is convenient when you’re changing tips between passes or dealing with a spattered nozzle.

To install, slide the nozzle over your gas diffuser and tip assembly until it seats snugly. For removal, grasp the nozzle and pull with a steady hand; if it’s hot, use pliers with a protective cover or wait until it cools to avoid burns.

Step-by-step: installing your nozzle

- Turn off the welder and let components cool slightly to avoid burns.

- Align the nozzle’s inner bore with your contact tip/diffuser assembly.

- Push the nozzle onto the torch neck until you feel it seat firmly.

- Check alignment and gas flow briefly with a short test weld to ensure proper coverage.

You’ll find this method is quick and low-tech, which is ideal for fast swaps on the job.

Dealing with stuck or spattered nozzles

If a nozzle gets stuck due to spatter, apply anti-spatter agent before welding sessions to ease removal later. If a nozzle is already stuck, allow it to cool and use a soft-jaw plier or a nozzle puller tool to avoid damaging the torch or the nozzle.

You’ll want to avoid excessive force that could bend the torch neck or damage the contact tip inside.

Performance in real use

You care about gas coverage, arc stability, and how long the nozzle lasts. These conical nozzles provide reasonably focused gas flow for general MIG work, helping you maintain a clean arc and consistent weld bead in common materials like mild steel and stainless in thinner gauges.

Expect good results in light to medium-duty applications. If your work pushes higher amperage for extended periods, you’ll notice faster wear and may prefer higher-grade nozzles.

Gas flow and arc control

You’ll notice more consistent shielding with a properly sized nozzle. The conical shape narrows the gas stream enough to protect the puddle without dispersing gas excessively, which is especially useful on out-of-position work or when you need a tighter arc.

However, if you change your contact tip or diffuser configurations significantly, you should re-evaluate nozzle choice to ensure gas coverage remains optimal.

Heat and spatter resistance

You’ll find these are fit-for-purpose for hobby and light production work. They’re finished to resist spatter sticking, but they’re still consumables. Expect some buildup over time that will require cleaning or replacement, particularly with frequent high-amperage runs.

If you’re working in a production environment or welding thick materials at high amps for long cycles, consider more robust OEM or copper nozzles for extended life.

Use cases and ideal users

You’ll want to know whether this product suits your needs. These nozzles are ideal if you’re a hobbyist, auto-body worker, small fabrication shop, or home welder using an MB15-style torch. The five-pack format makes them economical for anyone who needs quick replacements.

They’re less ideal as a long-term option for heavy industrial welders running continuous high-current cycles—but they serve well as backups or for intermittent use.

Typical applications

You’ll do well using these for:

- Light fabrication and assembly

- Auto-body repairs and patch panels

- Home and garage welding projects

- Maintenance tasks and spot repair They help you keep welding without frequent stops to clean spattered nozzles.

Not the best for

You should consider alternatives if you:

- Run continuous high-amperage welds in production

- Need maximum thermal conductivity and wear resistance for long duty cycles

- Require threaded OEM nozzles for a specific torch model

Pros and cons

You’ll want an honest assessment so you can weigh value versus performance. Below are the main advantages and drawbacks based on design, price, and user scenarios.

Pros

- Economical five-pack lets you stock spares and replace quickly.

- Push-on installation makes swaps fast and straightforward.

- Conical shape supports focused gas coverage for typical MIG tasks.

- Compatible with widely used Binzel MB15-style torches.

- Durable finish reduces spatter sticking and eases cleaning.

You’ll appreciate the low cost per piece and the convenience when you’re juggling multiple jobs or torches.

Cons

- Not premium copper; wear life is shorter under heavy use.

- Push-on fit might loosen over time compared to threaded nozzles.

- Limited to MB15-style torches; not universal for all MIG heads.

- Slight variability in fit across non-OEM parts can require a careful check.

You should expect to treat these as consumables—excellent for general use, but not a permanent upgrade for industrial workloads.

Maintenance and care

You’ll want to keep nozzles clean to extend life and maintain weld quality. Regular cleaning, anti-spatter application, and inspecting for wear will go a long way in keeping gas coverage consistent.

A quick wipe and light brush after each session prevents buildup and reduces the frequency of full replacements.

Cleaning tips

- Apply a commercial anti-spatter spray before welding to reduce adhesion.

- Use a soft steel wire brush or nozzle cleaning tool to remove spatter.

- Avoid using excessively aggressive tools that might deform the inner bore or scratch plating.

- Wipe down and inspect for cracks or deformation after cleaning.

You’ll save time and money by cleaning regularly rather than waiting until the nozzle is heavily fouled.

When to replace

Replace the nozzle if you notice:

- Significant spatter buildup that can’t be cleaned without damaging the nozzle.

- Deformation or cracking of the shroud.

- Poor gas coverage resulting in porosity in welds.

- The nozzle no longer seats snugly on the torch neck.

You’ll avoid rework and inconsistent welds by swapping nozzles at the right time.

Tips and tricks for getting the most out of your nozzles

You want practical tips to maximize performance, reduce wear, and cut costs. Small habits in your welding routine will translate into longer nozzle life and better welds.

Keep an anti-spatter bottle handy, rotate nozzles between jobs if you have multiple torches, and inspect alignments frequently.

Practical usage tips

- Apply anti-spatter before starting each weld session to reduce buildup.

- Rotate through the five nozzles: use one lightly while another cools to avoid continuous high-heat exposure.

- Check that the contact tip is centered and not protruding; a misaligned tip can accelerate nozzle damage.

- Use a nozzle puller or soft-jaw pliers when removing stuck nozzles to avoid damaging the torch.

You’ll reduce downtime and lengthen the usable life of each nozzle with these small steps.

Avoiding common mistakes

- Don’t force a push-on nozzle onto the wrong size torch—misfit causes poor gas coverage and can damage components.

- Avoid grinding or filing nozzle interiors; that can change gas flow characteristics and weaken the structure.

- Don’t ignore signs of poor gas coverage; address nozzle issues before weld defects become costly.

You’ll maintain weld quality and safety by paying attention to these details.

Troubleshooting common issues

You’ll likely run into a few small problems when using aftermarket nozzles; knowing how to handle them saves time and frustration.

If you experience porosity or inconsistent arc, check nozzle fit, tip condition, and gas flow before blaming wire or power settings.

Porosity and poor weld appearance

Porosity usually points to shielding gas problems. Check:

- Nozzle seats properly and isn’t clogged with spatter.

- Gas flow rate and regulator settings are correct.

- No drafts or air movement near the weld area.

You’ll often solve porosity by cleaning or replacing a fouled nozzle and verifying your gas setup.

Nozzle loosening or wobble

If the push-on nozzle starts to wobble, it may be worn or slightly distorted. Remove and inspect for deformation, and consider a replacement. Tightening by forcing a slightly oversized nozzle can cause damage, so match sizes properly.

You’ll avoid damaged torch components by using appropriately sized replacement nozzles.

Frequently asked questions

You want quick answers to likely questions—here are the top ones you’ll ask when considering this product.

Will these fit any Binzel torch?

These are designed for Binzel MB15-style torches, which covers a broad range of hobbyist and light industrial torches. You should confirm inner bore and outer dimensions before buying to ensure compatibility.

You’ll want to measure your torch specifics if you’re unsure.

Are these threaded or push-on?

These are push-on style nozzles. You’ll slide them into place rather than screw them on. This provides fast changes but relies on a snug fit for stability.

If your torch needs threaded nozzles, these will not work.

How many pieces come in a pack?

You get five nozzles per pack. That’s handy for rotating spares or for multiple torches around your workspace.

Having spares reduces downtime when one nozzle fouls.

Can I use them for high-amperage welding?

They’re suitable for typical hobbyist and light-duty commercial use, but you’ll see faster wear in sustained high-amperage applications. For continuous heavy work, consider OEM or copper options with better heat dissipation.

You’ll balance cost savings with expected wear rates when selecting nozzles.

Comparison with OEM and other aftermarket options

You’ll want to know how these stack up against OEM Binzel nozzles and other aftermarket products. OEM parts often offer premium materials and guaranteed fit, while aftermarket five-packs like this one trade some longevity for a lower price and quicker availability.

Consider whether you prefer lower upfront cost and stock spares or longer life with OEM parts.

Cost vs. longevity trade-off

You’ll save money with this five-pack, making it a practical choice when you need frequent replacements or backups. OEM nozzles typically last longer under heavy use but cost more per piece.

If you weld intermittently or do repair work, this product gives you good value. If you weld all day every day, OEM may be more economical in the long run due to reduced replacement frequency.

Safety considerations

You care about staying safe while welding. Nozzle condition affects gas coverage, which in turn impacts weld integrity and safety. A loose or clogged nozzle can produce poor welds or cause spatter hazards.

Always turn off equipment and wear proper PPE when installing or removing nozzles. Allow parts to cool or use insulated tools to avoid burns.

PPE and work practices

- Wear welding gloves, helmet, and protective clothing when working on the torch.

- Use pliers or nozzle pullers to handle hot or stuck nozzles.

- Inspect torch components regularly to ensure safe operation.

You’ll protect yourself and your equipment by following basic welding safety practices.

Final recommendation

You’re likely to find the 5pk Conical Nozzle Shroud Binzel Style Welding Welder MIG MB15 Gas Push On to be a practical, cost-effective choice for light fabrication, hobby projects, and small shop use. The push-on design, reasonable dimensions (12 mm inner bore, 18 mm OD, 55 mm length), and five-nozzle pack give you flexibility and spares to keep working with minimal interruption.

If you weld intermittently or need to replace worn nozzles quickly and economically, these will serve you well. If your work is heavy-duty, continuous, or requires exact OEM tolerances, you should weigh the benefits of more premium parts against the lower upfront cost.

Quick summary to help you decide

- Choose this product if you’re a hobbyist, small shop owner, or doing light production work and want an economical supply of replacement nozzles.

- Consider OEM or higher-grade copper nozzles if you need extended life under heavy, continuous welding cycles.

- Always verify the measurements and push-on compatibility with your torch before buying.

You’ll get good value from this five-pack if you match them properly to your torch and maintain them with basic cleaning and care.

Closing notes

You’ve seen the important specs, pros and cons, and practical guidance for using the 5pk Conical Nozzle Shroud Binzel Style Welding Welder MIG MB15 Gas Push On. With routine maintenance and the right fit, these nozzles will help you stay productive without constantly ordering replacements.

If you want, tell me the exact torch model and contact tip dimensions you’re using, and I’ll help confirm whether these nozzles will be a solid match for your setup.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.