Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you looking for a reliable replacement nozzle for your Binzel MB25 MIG torch that won’t break the bank and is simple to install?

Product Overview

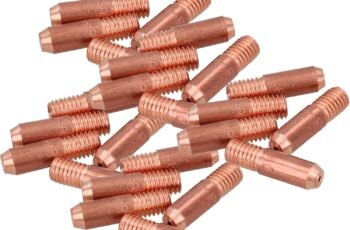

You want a straightforward part that keeps your welding setup running without fuss, and the 5PK Conical Nozzle Shroud Binzel Style Welding Welder MIG MB25 Gas Push On aims to deliver exactly that. This pack of five conical push-on nozzles is designed for MIG welding and is intended to fit Binzel MB25-style torches, giving you spare parts ready when you need them.

What it is

This product is a set of five conical push-on nozzles (shrouds) made for MIG welding torches that follow the Binzel MB25 style. You get multiple replacements at once so you can quickly swap worn nozzles during a job without downtime.

Key specifications

Below is a quick breakdown of the main specs so you can check fit and compatibility at a glance. These are the measurements and attributes you’ll want to confirm against your torch and your welding application.

| Feature | Detail | Notes |

|---|---|---|

| Product name | 5PK Conical Nozzle Shroud Binzel Style Welding Welder MIG MB25 Gas Push On | Pack of 5 |

| Style | Conical, push-on | Binzel MB25 style |

| Inner bore (ID) | 15 mm | Check against your contact tip and liner clearance |

| Outer diameter (OD) | 22 mm | Overall outside width of nozzle |

| Length | 58 mm | Depth of nozzle from front opening to back |

| Fitment | Binzel MB25-style torches | May fit other torches with similar dimensions |

| Material | Heat-resistant metal/plated alloy (typical) | Exact alloy varies by supplier |

| Quantity | 5 pieces | Useful spares for shops and hobbyists |

| Application | MIG welding with gas shielding | For gas-shielded welding processes |

Fit and Compatibility

You need to know whether this nozzle will actually fit your torch, and that’s where checking dimensions matters most. The push-on design is common and makes swaps quick, but small dimensional differences can affect fit and gas coverage.

Which torches it fits

This nozzle is made for Binzel MB25-style torches, so it should fit any torch built to that standard profile. If you’re using a genuine Binzel MB25 or another manufacturer’s torch advertised as MB25-compatible, this shroud will likely work.

How to check compatibility

Always compare the inner bore (15 mm), outer diameter (22 mm), and length (58 mm) to the nozzle and gas diffuser on your torch. You should also verify that the push-on seating diameter and tolerance match your torch’s stub or insulator so the nozzle seats firmly and doesn’t wobble while you weld.

Build Quality and Materials

You’ll want an answer to whether these nozzles will last under heat and repeated swaps. While aftermarket packs are generally economical, material and plating quality determine how long they serve you before replacement.

Materials used

Most push-on nozzles like these are constructed from heat-resistant metal, often with a nickel or chrome plating to provide some corrosion resistance. The plating helps reduce sticking and makes cleanup easier, but exact alloys and coating thickness can vary by supplier.

Durability expectations

For routine welding, these nozzles will hold up well, but you should expect some wear over time if you work with spatter-prone materials, high amperage, or poor gas coverage. Since you’re getting a pack of five, you can swap worn nozzles readily and keep working while one or more are cleaned or discarded.

Performance in Real Use

Performance isn’t just about fit and materials; you’ll feel it when you’re welding. Gas coverage, spatter control, and convenience during wire feeding are the practical metrics you’ll notice.

Gas shielding and arc stability

A correctly fitted conical nozzle gives you focused gas coverage over the weld pool, helping keep oxidization down and improving arc stability. If the nozzle size and shape match your torch and contact tip position, you’ll get consistent shielding and more predictable welds.

Contact tip and wire feed interaction

Because this is a push-on nozzle, make sure the inner bore clearance (15 mm) aligns with your contact tip placement and wire path. Too tight a clearance can restrict gas flow and cause turbulence; too loose a fit can allow the nozzle to wobble and disturb the arc or wire feed. You’ll want the contact tip centered and the nozzle seated snugly.

Installation and Removal

You don’t need a complicated procedure to use these nozzles, but handling them correctly ensures a good seal and safe operation. Here are some straightforward steps and tips you’ll appreciate.

How to install

- Turn off your welder and cut gas/wire feed if needed for safety.

- Slide the push-on nozzle over the torch’s insulator or gas diffuser until it seats firmly.

- Check that the contact tip and liner are properly centered and that the nozzle does not sit at an angle.

You should always make installation checks before welding to confirm proper alignment.

How to remove

To remove, simply grip the nozzle and pull it straight off the torch with a steady motion. If it’s stuck due to spatter buildup, apply a short blast of low heat and break the spatter loose, or use a non-damaging pliers wrap with cloth to get extra grip. Avoid prying sideways which can damage the insulator or diffuser.

Sizing and Dimensions Explained

You’ll want to understand the three main dimensions and why they matter: inner bore, outer diameter, and length. Each influences gas flow, coverage, and practical fit.

Inner bore (15 mm)

The inner bore determines how much space there is around the contact tip and wire as they exit the torch. This affects gas laminar flow and how well the shielding gas covers the weld pool. If you frequently use larger-diameter wires or special tips, check this measurement carefully.

Outer diameter (22 mm) and length (58 mm)

The outer diameter affects how much of the nozzle protrudes and how close you can get to tight joints. The length influences the gas cone and the physical protection around the contact tip. A 58 mm length provides a reasonable balance of coverage and access to confined joints.

Pros and Cons

When you’re choosing parts, clear pros and cons help you decide quickly. Here’s what you can typically expect from this five-pack of conical push-on nozzles.

Pros

- You receive five nozzles, so you’ll have spares ready during long projects.

- Push-on design makes for fast swaps and minimal downtime.

- Conical shape provides focused gas coverage for many MIG tasks.

Cons

- As an aftermarket pack, material and coating consistency can vary between batches or suppliers.

- Push-on nozzles may loosen slightly over time if subjected to repeated heavy impacts or excessive spatter.

- They may not be a perfect fit for torches that deviate from MB25-style tolerances.

Maintenance and Care

Taking care of your nozzles will extend their useful life and keep your weld quality consistent. Simple cleaning and storage habits go a long way.

Cleaning tips

After each welding session, remove spatter and built-up slag with a brass wire brush or nozzle reamer designed for MIG nozzles. Avoid aggressive grinding that can remove plating and change the nozzle shape. You should also inspect the inner bore for clogs and the seating area for nicks.

Storage and handling

Store unused nozzles in a dry, dust-free container to avoid contamination. When handling, avoid dropping them onto concrete or heavy surfaces which can deform the seating area. Label spare nozzles if you switch between nozzle types frequently to make it easy to grab the right one.

Troubleshooting Common Issues

If things don’t go smoothly, you’ll want a short list of troubleshooting steps to get back to welding quickly. These are practical fixes you can try on the job.

Spatter buildup

If spatter is sticking to the nozzle, check your gas flow and contact tip alignment first. Clean the nozzle with a brass brush and consider increasing gas flow slightly or switching to anti-spatter sprays suited for MIG use.

Poor gas coverage or porosity

If your welds show porosity, ensure the nozzle is seated properly and not damaged. Check for leaks in gas hoses and fittings, verify correct gas type and flow rate, and inspect the contact tip position relative to the nozzle inner bore.

Nozzle fits loosely or wobbles

If the nozzle wobbles, confirm you’re using an MB25-style consumable and that the nozzle seating surface isn’t damaged. Sometimes swapping in a new insulator or gas diffuser can restore correct seating. If the issue persists across multiple new nozzles, there may be a torch damage issue to address.

Comparisons and Alternatives

You’ll find several nozzle types on the market, and knowing the differences helps you pick what’s best for your work. Here’s how this conical push-on set compares to other common choices.

OEM vs aftermarket nozzles

OEM Binzel nozzles are made to strict tolerances and often come with better plating and finish consistency. However, aftermarket packs like this 5PK option are more budget-friendly and give you spares in bulk. If you want guaranteed fit and finish for high-stakes production work, OEMs may be preferred; for maintenance, hobbyist, or backup use, a 5-pack aftermarket is often a sensible choice.

Conical vs cylindrical nozzles

Conical nozzles focus gas centrally and are great for standard MIG welding applications, giving a narrower gas cone for improved penetration control. Cylindrical nozzles provide a wider gas umbrella and can be useful for larger diameter wires or when you need more overall coverage. Choose based on wire size, material thickness, and joint configuration.

Buying Guide and Tips

When you’re ready to purchase these nozzles, a few practical tips will help you avoid surprises and get the best value from your order. Here are factors and steps you should consider.

What to look for

Check the compatibility with your torch by measuring the seating diameter and comparing the inner bore, OD, and length with your current nozzle. Look for user reviews that mention fit on MB25 torches, and prioritize suppliers who clearly state material and plating details if longevity matters to you.

Where to buy

You can find these nozzles through industrial suppliers, online marketplaces, and welding specialty shops. When buying online, review seller ratings and return policies. If you need consistent quality for commercial use, purchase from a reputable supplier who offers guarantees or clear specs.

Safety Considerations

Safety matters every time you change a nozzle or perform maintenance. A few precautions will protect you and your equipment.

Personal safety

Always shut off the welding machine, gas supply, and disconnect power before removing or installing nozzles. Wear gloves and eye protection when handling hot parts, and allow components to cool before you touch them.

Equipment safety

Avoid using tools that could damage the insulator or diffuser seating when removing stuck nozzles. Damaging those parts can lead to gas leaks or poor nozzle seating, which in turn affects weld quality and can create safety hazards like gas escapes.

Frequently Asked Questions (FAQ)

You’ll likely have practical questions when choosing or using this product. Below are common Q&As that address fit, performance, and use.

Will this nozzle fit my genuine Binzel MB25 torch?

If your torch follows MB25 dimensions and specs, this nozzle is designed to fit. Confirm by comparing the inner bore (15 mm), OD (22 mm), and length (58 mm) to your existing nozzle measurements.

Can I use these nozzles with different wire sizes?

Yes, you can use these nozzles with various wire sizes, but you should ensure the contact tip setup leaves adequate clearance within the 15 mm inner bore. Very large wires or unusual tip positions might require a different nozzle profile.

How often should I replace nozzles?

Replacement frequency depends on usage, amperage, and spatter levels. In heavy production or spatter-heavy conditions you may replace nozzles frequently; for light hobby use, one nozzle could last a long time. Having five in a pack gives you flexibility.

Are these nozzles compatible with flux-cored welding?

These are designed for gas-shielded MIG welding. If you use flux-cored wire that relies on self-shielding, gas coverage and nozzle shape may be less relevant; however the nozzle still protects the tip and may still be usable depending on your specific torch and wire type.

How do I clean a nozzle effectively?

Use a brass wire brush or dedicated nozzle cleaning tool to remove spatter and buildup. Avoid grinding or using hard steel tools that can remove plating and alter the nozzle shape.

Troubleshooting Checklist

You’ll appreciate a concise troubleshooting checklist you can use on the job to solve common nozzle-related issues quickly. Follow this list step-by-step.

- Verify nozzle seating and alignment.

- Inspect contact tip and liner for wear or misalignment.

- Check gas flow rate and gas type.

- Clean spatter from nozzle and diffuser.

- Swap to a fresh nozzle from the pack to see if the problem resolves.

These steps will quickly tell you whether the nozzle or another part of the system is causing issues.

Final Verdict

If you want an economical, practical solution for replacing worn or lost nozzles, the 5PK Conical Nozzle Shroud Binzel Style Welding Welder MIG MB25 Gas Push On is a solid choice. You get five push-on conical nozzles sized to fit MB25-style torches (15 mm inner bore, 22 mm OD, 58 mm length), which makes them great for keeping spare parts on hand.

You’ll appreciate the value and convenience, especially if you do a lot of welding and need quick swaps. If you require the highest consistency and longest life from consumables, consider pairing these with OEM difusers or contacting the supplier for material details. Overall, this pack offers good utility for hobbyists, maintenance shops, and many production environments where cost-effective, ready-to-install spares are useful.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.