Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Have you ever found yourself staring at a project and wishing for a tool that promises precision and reliability, especially when it involves intricate piping systems? Enter the “63-160 2500W Pipe Fusion Welder Tool 63-160mm PE PPR PB PVDF Butt Fusion Welding Machine Piping Hot Melt Engine DIY & Tools” — quite a mouthful, but most importantly, it boasts a range of features that could be your next best friend in piping hot melt operations.

Understanding the Core Features

To truly appreciate what this welder tool offers, you need to dissect its core components and the value each brings to your projects.

Versatility Across Pipe Sizes

The tool’s capability to handle pipe sizes ranging from 63mm to 160mm is a testament to its versatility. Whether you’re working with PE, HDPE, or PP plastic pipes, the welder’s adaptability ensures you get consistent results across different projects. Imagine the convenience of not having to switch tools or attachments frequently.

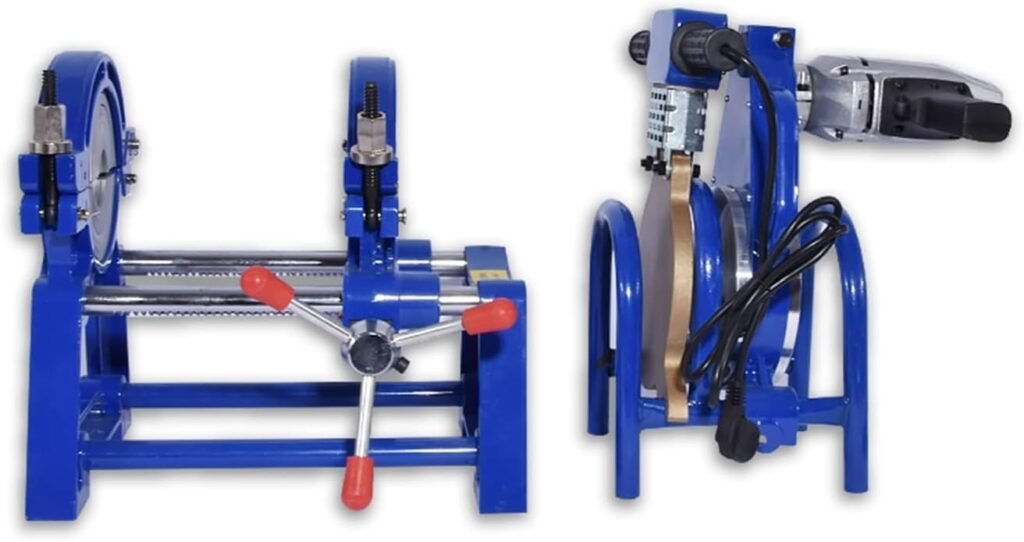

Three-Part Composition

The tool comprises three main components: a fixture rack, a heating plate, and a milling machine. This triplet forms the backbone of its functionality. The fixture rack secures your pipes, allowing for stable and precise operations. Meanwhile, the heating plate ensures consistent heat distribution for effective fusion, and the milling machine provides smooth alignment and surface preparation.

Engineering Mechanics Design

Its ergonomic engineering mechanics design is all about enhancing work convenience and flexibility. Position your projects more effortlessly and enjoy maneuverability that reduces fatigue. Engineering mechanics does not just make operations efficient; it ensures your safety by minimizing the risk of accidents linked to poor tool handling.

Innovative Locking Mechanism

What sets this tool apart is its ingenious locking mechanism. This feature aims to prevent any movement during the welding process, particularly from external forces that could compromise the quality of the weld. It’s like having a trusty assistant ensuring that everything stays in place until the job is done.

Clamshell Structure

The use of a clamshell structure with a card gland offers a unique unilateral fixed configuration. This design drastically shortens welding processes and enhances efficiency. It’s perfect for when you’re racing against time but don’t want to sacrifice quality.

The Practical Benefits for Users

Time-Saving Operations

The tool’s components and design work collectively to save you precious time. Picture less downtime, with efficient welding processes getting you through tasks faster. This is invaluable when project deadlines are tight but maintaining high-quality standards is non-negotiable.

Enhanced Project Quality

Precision is critical in your line of work, and inaccuracies can lead to costly errors. The welder’s reliability promises better quality control, ensuring that each joint is robust and long-lasting. Your projects not only progress quickly but also withstand the test of time.

User-Friendly Interface

Ease of use is heavily emphasized, making the machine accessible even to those who may not be seasoned professionals. The friendly layout and operational controls mean you don’t need to devote hours to learning curves or intricate setup processes.

Reliable for Professional and DIY Enthusiasts

Whether you’re a professional contractor or a do-it-yourself enthusiast, this tool’s durability makes it suitable for prominent industry applications and personal projects alike. Its ability to handle diverse piping materials and tasks means your investment pays off across multiple applications.

Detailed Product Specifications

| Feature | Description |

|---|---|

| Pipe Compatibility | 63mm, 75mm, 90mm, 110mm, 125mm, 140mm, 160mm |

| Material Compatibility | PE, HDPE, PP plastic pipes |

| Core Components | Fixture rack, heating plate, milling machine |

| Design Enhance | Ergonomic engineering mechanics design |

| Locking Mechanism | Innovative design to prevent external interference during welding |

| Structure Type | Unilateral fixed clamshell structure for efficiency |

| Power Output | 2500W |

| Application | Professional and DIY use |

Usage Tips for Optimal Performance

Preparing Your Workspace

Always ensure your workspace is clean and organized before commencing. Clutter-free environments contribute significantly to safe operations and prevent unnecessary disruptions that can affect precision.

Familiarize With Your Tool

Spend some time getting to know the components and settings. Adjust the fixture rack, heating plate, and milling machine as per your requirements to ensure a seamless workflow when you start welding.

Regular Maintenance Checks

Regular maintenance is key to extending the life of your tool. Make a habit of checking for wear and tear, ensuring that moving parts are lubricated, and that the heating plate is kept clean for consistent heat application.

Testimonials and Real-World Applications

Countless users have remarked on how the welder has transformed their projects. A mix of professionals and hobbyists praise not only the machine’s efficiency but also its robustness and reliability under intense workloads. They highlight how the tool has slashed both time spent on tasks and the likelihood of errors.

Final Thoughts

Your investment in the “63-160 2500W Pipe Fusion Welder Tool 63-160mm PE PPR PB PVDF Butt Fusion Welding Machine Piping Hot Melt Engine DIY & Tools” promises to yield significant dividends. Not only will your projects benefit from improved quality and reduced completion times, but you will also elevate your craft, whether that’s in professional piping work or passionate DIY projects. While the name might be long, the time you spend on learning and implementation will prove short and satisfying.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.