Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

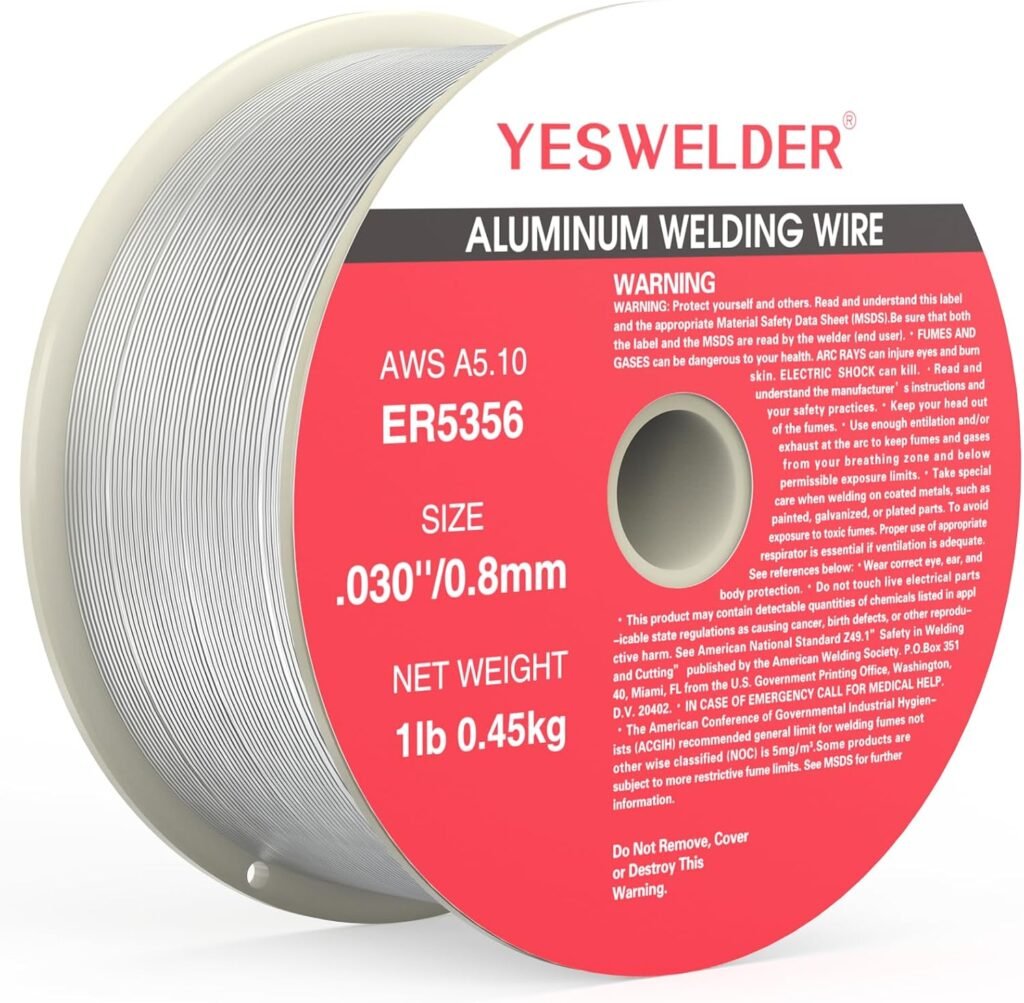

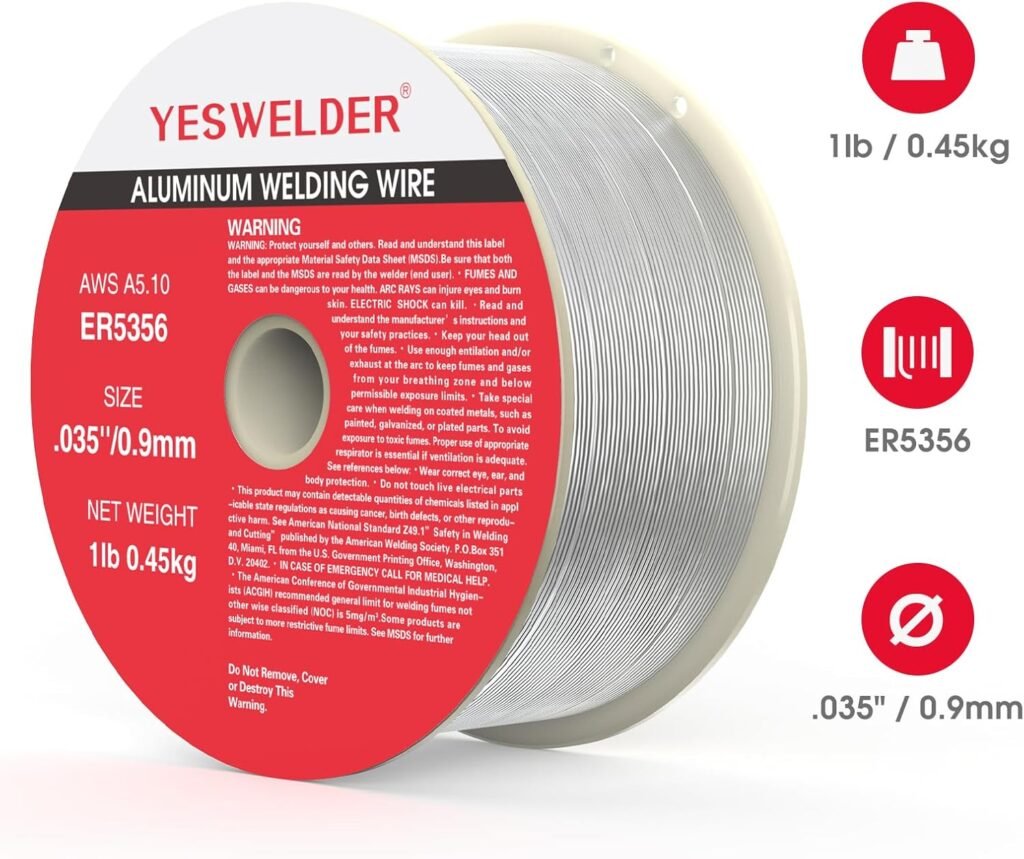

Introducing the YESWELDER Magnesium Aluminum Welding Wire ER5356 .030-Diameter, 1-Pound Spool, your go-to solution for dependable and versatile aluminum welding. This exceptional welding wire, with its 5% magnesium content, offers outstanding corrosion resistance and higher shear strength, making it ideal for a variety of applications. Whether you’re working on 5000 series aluminum base metals or need a weld that remains aesthetically pleasing after anodizing, this general-purpose alloy ensures a robust and visually consistent finish. With its exceptional performance and color-matching capabilities, the YESWELDER ER5356 is the perfect companion for your MIG welding projects. Have you ever found yourself needing a reliable and versatile aluminum welding wire that won’t let you down? If so, you’re in for a treat. The YESWELDER Magnesium Aluminum Welding Wire ER5356 .030-Diameter, 1-Pound Spool might just be the perfect fit for all your welding needs. Let’s dive into the specifics of this remarkable product and see why it’s worth considering.

What Makes YESWELDER Magnesium Aluminum Welding Wire ER5356 Stand Out?

With various welding wires available on the market, it can be challenging to zero in on the one that will serve you best. Here’s what sets the YESWELDER ER5356 apart:

Composition and General Purpose

The YESWELDER ER5356 welding wire contains 5% magnesium, making it a general-purpose aluminum alloy with a wide range of uses. Whether you’re working on marine applications, automotive projects, or general fabrication, this wire is up for the task.

Advantages

One standout advantage is its superior corrosion resistance, especially when exposed to saltwater. This makes it a wise choice for projects that demand durability. Coupled with its higher shear strength, thanks to the addition of magnesium, you get a dependable and flexible solution that won’t let you down even under challenging conditions.

Excellence in Color Matching

Another great feature is its exceptional color matching after anodizing. If aesthetics are a priority for you, the welded seam remains white, providing a better visual match with your base materials.

Application Range

ER5356 should be used for welding 5000 series aluminum base metals like 5050, 5052, 5083, 5356, 5454, and 5456. Whether you’re a seasoned welder or a DIY enthusiast, this welding wire gives you the versatility to tackle various projects.

Specifications in a Nutshell

To give you a clear idea of what you’re getting, here are the crucial specs:

| Specification | Description |

|---|---|

| Weight | 1 lb |

| Diameter | .030 inch |

| Material | 5% magnesium aluminum (AlMg5) |

| Process | MIG welding |

These specs ensure that you get a wire that’s easy to handle and perfect for different welding tasks, whether simple repairs or extensive builds.

Real-life Applications

Let’s delve a bit deeper into the practical applications:

Marine Industry

Given its excellent corrosion resistance in saltwater, the YESWELDER ER5356 is perfect for marine applications. From boat repair to constructing marine equipment, this wire performs consistently well.

Automotive Industry

When it comes to vehicle frames and other aluminum parts, the shearing strength and color matching capabilities of this welding wire make it a top choice.

General Fabrication

Whether it’s constructing aluminum structures, repairs, or custom fabrication, this wire’s flexibility makes it suitable for a range of general manufacturing needs.

Ease of Use

User-Friendly Design

This wire’s .030-inch diameter makes it user-friendly, even for those new to welding. The spool feeds smoothly, reducing the risk of jamming or other common issues.

Versatility and Compatibility

Since the YESWELDER ER5356 is designed for the MIG welding process, it is compatible with most MIG welding machines. Just make sure your setup is compatible with aluminum welding.

Detailed Review of Performance

Arc Stability

Arc stability is paramount for achieving smooth, clean welds. With the YESWELDER ER5356, you’ll find that it offers excellent arc stability, ensuring a consistent performance.

Weld Quality

Thanks to its composition, you can expect high-quality welds that are not only strong but also visually appealing. The welded seams blend well with the aluminum, making them almost seamless.

Color Anodizing

As mentioned before, this wire excels in maintaining its color even after anodizing. This is a significant advantage if the appearance is critical in your projects.

Corrosion Resistance

The 5% magnesium content adds a robust layer of corrosion resistance, especially crucial for projects exposed to elements like saltwater or harsh environmental conditions.

Tips for Getting the Best Results

Preparation

Proper preparation is key. Clean the aluminum surface thoroughly to remove any oxides or contaminants. This will help in achieving quality welds.

Settings

Ensure your welding machine is set up for aluminum welding. Consult your machine’s manual for the best settings for .030-inch aluminum wire. Typically, a higher voltage and faster wire feed speed will yield better results.

Practice

Especially if you are new to welding aluminum, take some time to practice on scrap pieces. This will help you get a feel for how the wire behaves and let you tweak your settings for optimal performance.

Pros and Cons

No product review would be complete without a balanced look at the pros and cons. Here’s what you can expect with the YESWELDER Magnesium Aluminum Welding Wire ER5356:

Pros

- Superior Corrosion Resistance: Perfect for projects exposed to harsh environments.

- Excellent Color Matching: The welded seam remains white after anodizing.

- High Shear Strength: Durable and reliable for demanding applications.

- Versatile: Suitable for a range of applications, from marine to automotive and general fabrication.

- User-Friendly: Easy to handle, even for beginners.

Cons

- Higher Cost: Generally, specialized aluminum welding wires can be more expensive.

- Machine Compatibility: Make sure your welding machine supports MIG welding for aluminum.

Safety Considerations

Protective Gear

Always wear appropriate protective gear, including a welding helmet with the proper shade, gloves, and long sleeves. Aluminum welding can generate a lot of heat and UV radiation.

Ventilation

Ensure you have adequate ventilation, especially when welding in confined spaces. Aluminum welding can produce hazardous fumes.

Fire Safety

Always keep a fire extinguisher nearby. Clear the area of any flammable materials before starting your project.

FAQs

Can I use this wire with any MIG welder?

While it is designed for MIG welding, ensure that your machine is capable of aluminum welding. Check your machine’s manual for specific compatibility.

How do I store the welding wire?

Store the wire in a cool, dry place. Make sure it’s sealed to prevent moisture contamination, which could affect the weld quality.

What’s the best way to clean aluminum before welding?

Use a stainless steel brush dedicated to aluminum to clean the surface. Additionally, a solvent like acetone can help remove grease and contaminants.

Final Thoughts

The YESWELDER Magnesium Aluminum Welding Wire ER5356 .030-Diameter, 1-Pound Spool is a fantastic choice for anyone looking to work with aluminum. Its excellent corrosion resistance, high shear strength, and ease of use make it a standout product. Whether you’re working on marine, automotive, or general fabrication projects, this welding wire offers quality and reliability that you can count on.

For those who need a versatile, dependable, and straightforward welding wire, the YESWELDER ER5356 is worth every penny. So, why not give it a try and see for yourself how it can enhance your welding projects?

Disclosure: As an Amazon Associate, I earn from qualifying purchases.