Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Ever found yourself stuck with a pesky dent on your car’s door or hood and wondered if there was a more savvy tool on the market to help fix it? Let’s dive into the world of the Spot Welding Machine, dent Puller Welder 2000Watt 3500A 220V, and see what makes it an ally for both professional auto body repair technicians and DIY enthusiasts alike.

Intelligent Induction Welding Technology

This device boasts cutting-edge intelligent induction welding technology, which is designed to provide superior precision in the auto body repair arena. With a tremendous current output of 3800A, achieving stable and robust welds, even as thin as 0.6 to 1.2mm (0.024 to 0.047 inches), becomes straightforward. This feature promotes efficient bonding without compromising the integrity of metal plating or corrosion-resistant paint on the reverse side. A task once daunting for low-thickness body components like hoods, doors, and roof panels has just been made simpler.

How Does it Preserve Your Car?

One of the standout attributes of this machine is its ability not to damage the opposite side’s metal plating or paint. This ensures that while you’re improving one side, the other remains untouched, essentially doubling the value of its use. Plus, it minimizes consumables, letting you save more over time.

Dual Mode Operations

The Spot Welding Machine is fitted with six distinct welding modes: Triangular meson pull, Round meson pull, OT meson pull, Wave line welding, Carbon rod to close the fire, and Single-sided spot welding. Whether you’re looking for a seamless finish or tackling a more challenging project, this machine offers the flexibility to adapt as necessary.

Automatic vs. Manual Welding

Do you prefer having control or letting the machine do its thing? You can switch between automatic and manual welding modes according to the condition of the car body. This customization ensures that you’re working in the best possible mode to achieve the finest results, taking care of both simple and intricate tasks.

Safety and Efficiency

Incorporating automatic overheat protection and fast heat dissipation ensures the machine stays cool under pressure. This smart design protects both the machine and user by pausing operation when overheated until it cools down, thereby prolonging the device’s life.

Efficient Design for Heat Management

Thanks to its unique hollowed-out panel design, heat dissipates swiftly, guaranteeing an extended operating time. This careful consideration in design ameliorates overheating issues faced by lesser machines.

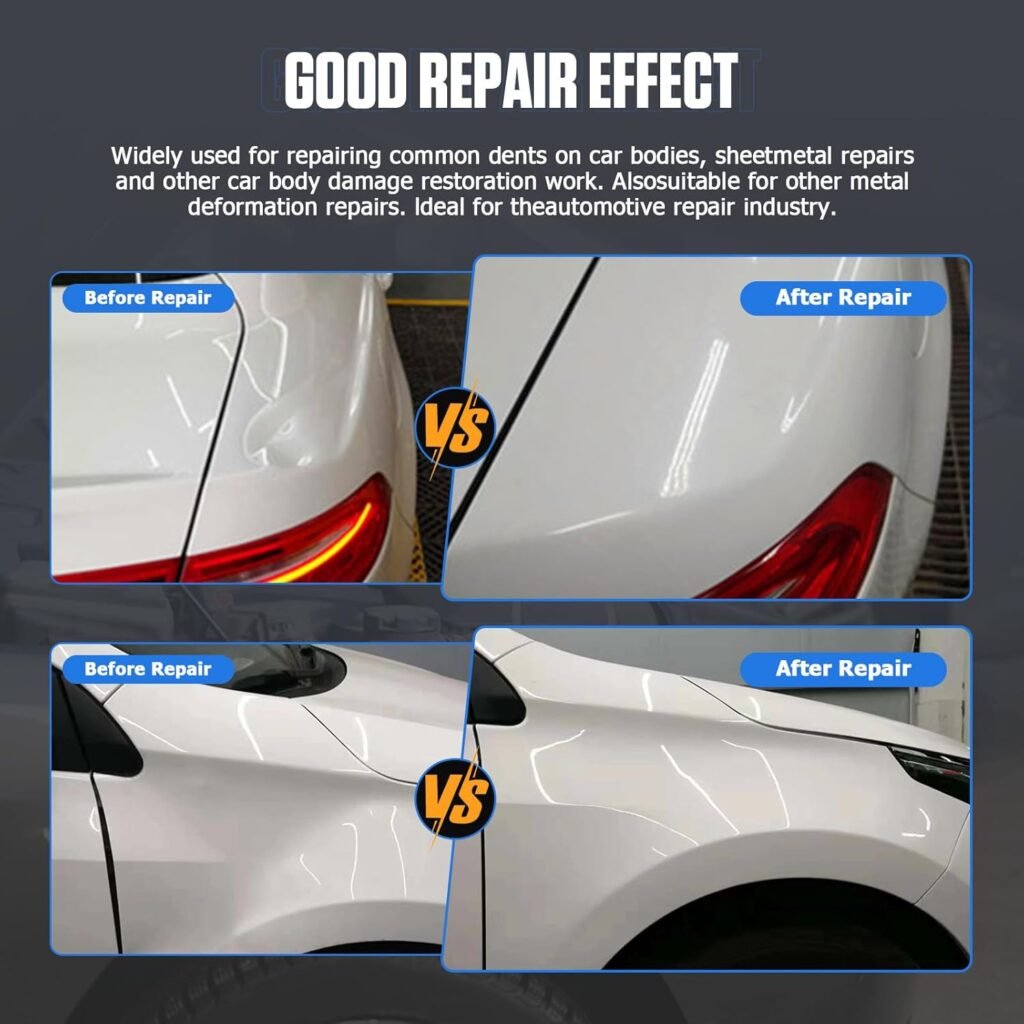

Versatile Applications

This tool isn’t solely for automotive repairs; it finds use in mending a range of metallic deformations beyond vehicles. Whether it’s an elastic, plastic, or direct damage, the dent puller is designed to work across a wide array of issues, making it a versatile addition to your toolkit.

What Kind of Damages Can It Handle?

From scratches and dents to rust damages, its ability to deal with both direct and indirect damage makes it an asset for comprehensive repair jobs. Avoid the costs of visiting an auto shop by having this at your disposal.

Energy Efficiency and Durability

By employing a pure copper core cable, the machine ensures stable current output with little heat generation, all while saving on energy costs. The smart design helps achieve a remarkable 70% saving in power usage.

Built to Last: Cold-rolled Steel Shell

Constructed with a cold-rolled steel shell, the machine’s robustness does not go unnoticed. This durable construction paired with metal body and shell shutters helps in prolonged service life and effective heat dissipation.

Important Usage Notes

Before diving into usage, understanding and adhering to the electrical requirements is key. It is recommended to operate this machine under voltage conditions below 240V for optimal performance.

Key Precautions

Removing a significant area of insulating coating around the negative connection is necessary for efficient operation. This ensures that the current moves effectively through and the machine functions correctly.

Specifications Breakdown

For a concise overview, here’s a table summarizing the critical specifications and operating modes:

| Feature | Details |

|---|---|

| Current Output | 3800A |

| Welding Material Thickness | 0.6 to 1.2mm (0.024 to 0.047 inches) |

| Welding Modes | Triangular meson, Round meson, OT meson, Wave line, Carbon rod, Single-sided |

| Operating Modes | Automatic, Manual |

| Safety Features | Automatic overheat protection, Fast heat dissipation |

| Construction Material | Cold-rolled steel shell, Pure copper core cable |

| Additional Notes | Use under 240V, Remove insulating coating for proper function |

The Spot Welding Machine, dent Puller Welder 2000Watt 3500A 220V offers a robust and versatile solution for those tackling various body repair challenges. Its intelligent design and efficient operation make it a tool worth considering for anyone in the field, whether professional or hobbyist.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.