Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Have You Been Searching for the Perfect Pipe Fusion Welder Tool?

You’re in for a treat with the CHONGHAN 63-160 2500W Pipe Fusion Welder Tool. This comprehensive review will walk you through its features, strengths, and potential weaknesses, so you can decide if it’s the right fit for your needs. If you’ve been on a mission to find the equipment that takes the hassle out of your pipe welding tasks, you’re in the right place. Let’s get into the nitty-gritty details of this powerful device.

Overview of the CHONGHAN Pipe Fusion Welder Tool

The CHONGHAN 63-160 is a versatile and powerful tool designed to connect various types of plastic pipes. This tool specializes in creating hot melt butt welding connections for PE, HDPE, PP, PB, and PVDF pipes. Its wide diameter range handles pipes from 63mm to 160mm, providing flexibility for different projects. The robust 2500W engine ensures you have the power needed to tackle even the toughest welding jobs.

Key Features and Design

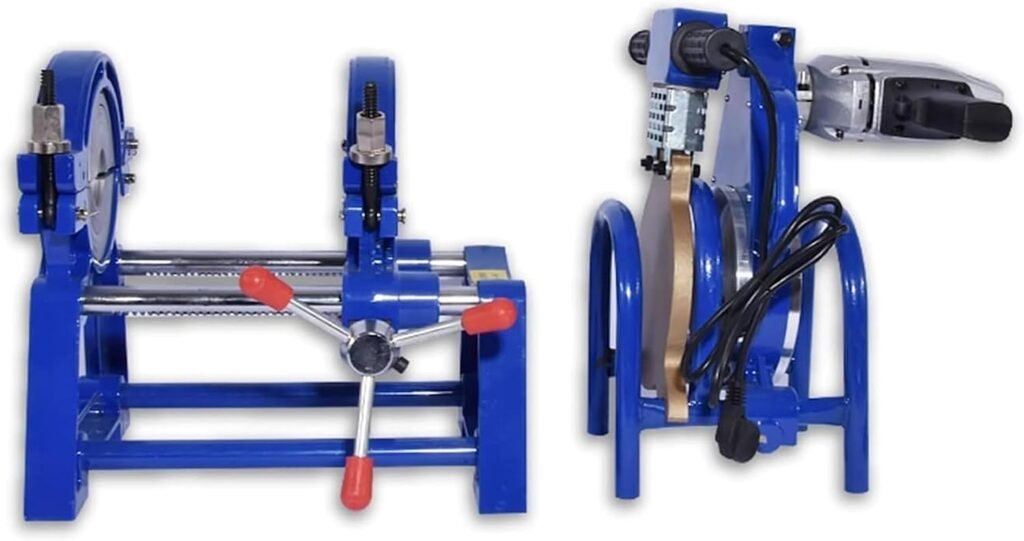

The CHONGHAN Pipe Fusion Welder is ingeniously designed to maximize efficiency and ease. It comprises three essential components for a successful welding process: the fixture rack, heating plate, and milling machine. Each plays a critical role in ensuring strong, reliable pipe connections.

- Fixture Rack: Provides stable support and alignment for pipes during welding.

- Heating Plate: Ensures even heat distribution for a strong fusion.

- Milling Machine: Prepares pipe ends for perfect joins by creating a clean and parallel surface.

This setup underscores a well-thought-out engineering design that enhances your welding experience by making tasks more convenient and flexible.

Specifications Table

To help you grasp the technical aspects quickly, here’s a handy table summarizing the specifications of this product.

| Feature | Details |

|---|---|

| Suitable Pipe Diameter | 63mm, 75mm, 90mm, 110mm, 125mm, 140mm, 160mm |

| Power | 2500W |

| Compatible Materials | PE, HDPE, PP, PB, PVDF |

| Main Components | Fixture Rack, Heating Plate, Milling Machine |

| Design Considerations | Engineering mechanics for flexibility and effectiveness |

| Special Structure | Card gland unilateral fixed clamshell for stability during welding |

Ease of Use and Setup

Setting up the CHONGHAN 63-160 Welder is straightforward, especially if you’re accustomed to working with industrial tools. The design of the tool is geared toward user convenience, with each component smoothly interlocking to form an efficient welding system. The tool’s intuitive structure means you spend less time struggling with complicated setups and more time focusing on welding.

User-Friendly Design

The welder is built with ergonomics in mind. It’s not just about getting the job done; it’s about ensuring you can do so safely and comfortably. The layout of the welding machine minimizes physical strain, allowing for prolonged use without discomfort. This is particularly beneficial for projects that require extended periods of welding.

Convenient and Flexible Engineering

The design’s practical aspect shines through its flexibility. Whether you’re working on-site or in a workshop, the CHONGHAN Pipe Fusion Welder adapts to the environment. The thoughtful engineering mechanics ensure you get effective assistance, making the welding process short and effective, as desired.

Performance and Reliability

When it comes to performance, the CHONGHAN delivers what it promises: robust and reliable pipe connections. The powerful 2500W engine provides the heat necessary for thorough and consistent welds across various pipe types and sizes.

Consistent Welding Results

The heating plate is engineered to distribute heat evenly, minimizing the risk of faulty welds. Consistent heat distribution means fewer imperfections, reducing the chance of leaks or weak points in your piping system. This reliability is crucial in applications where safety and efficiency are paramount.

Quality of the Butt Fusion Process

The butt fusion method employed by this tool is among the most reliable techniques for joining pipes. The milling machine component of the welder ensures pipe ends are adequately prepared, enhancing the quality and strength of the weld.

Pros and Cons of the CHONGHAN Pipe Fusion Welder

It’s essential to weigh the advantages against any limitations. Here’s a breakdown of what you might appreciate and what could be a concern with this tool.

Pros

- Wide Diameter Range: Works with a variety of pipe sizes, increasing its utility across different projects.

- Powerful Engine: The 2500W motor ensures you have the power needed for demanding tasks.

- Durability: Built to withstand tough conditions, ensuring longevity and value for money.

- Ease of Use: Intuitive setup and user-friendly design make it accessible to both novices and seasoned professionals.

Cons

- Weight and Portability: As an industrial-grade tool, it’s not the most lightweight option available, which could impact portability.

- Initial Learning Curve: While setup is straightforward, mastering the tool might take time for those new to pipe fusion welding.

Ideal Applications for the CHONGHAN Pipe Fusion Welder

This welder shines in various settings, from construction sites to maintenance work. Its adaptability is one of its major strengths. Here are a few applications where this tool can profoundly impact your work:

Construction Projects

The CHONGHAN is ideal for extensive plumbing installations on construction sites, where speed and reliability are crucial. Its ability to handle different pipe sizes makes it invaluable in diverse project scenarios.

Maintenance and Repairs

For maintenance professionals, this welder provides the precision needed to handle repairs efficiently. Its reliability means fewer call-backs for redo welds, saving time and resources.

Industrial Manufacturing

Industries that rely heavily on fluid transport systems can benefit immensely from the consistent and strong connections this tool provides. It minimizes downtime by ensuring rapid and secure pipeline assembly.

Tips for Optimizing Use and Maintenance

Like any tool, getting the best out of your CHONGHAN welder requires proper handling and maintenance. Here are some pointers to keep in mind:

Efficient Use Practices

- Always ensure that pipe surfaces are clean and free of debris before welding, as contaminants can weaken the weld.

- Pre-heat pipes and practice exact temperature control to achieve quality joints.

- Regularly check alignment to prevent any weld mishaps.

Maintenance Recommendations

- Clean the components of the welder after each use, especially the heating plate, to maintain optimal performance.

- Store the welder in a dry, cool place to prevent moisture damage.

- Periodically check and service the motor to ensure its longevity and consistent output.

Final Thoughts on the CHONGHAN Pipe Fusion Welder

The CHONGHAN 63-160 2500W Pipe Fusion Welder Tool stands out for its power, reliability, and versatility. It’s well-suited for professionals who demand quality and efficiency from their equipment. Despite its weight and initial learning curve, the tool’s advantages make it a strong contender for anyone serious about pipe fusion welding.

Every project may not require a tool of this magnitude, but when it does, having the CHONGHAN at your disposal ensures you’re well-equipped to tackle even the most challenging tasks. By investing time in understanding and mastering this tool, you pave the way for successful, high-quality pipe joints, embodying a blend of craftsmanship and technological prowess.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.