Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

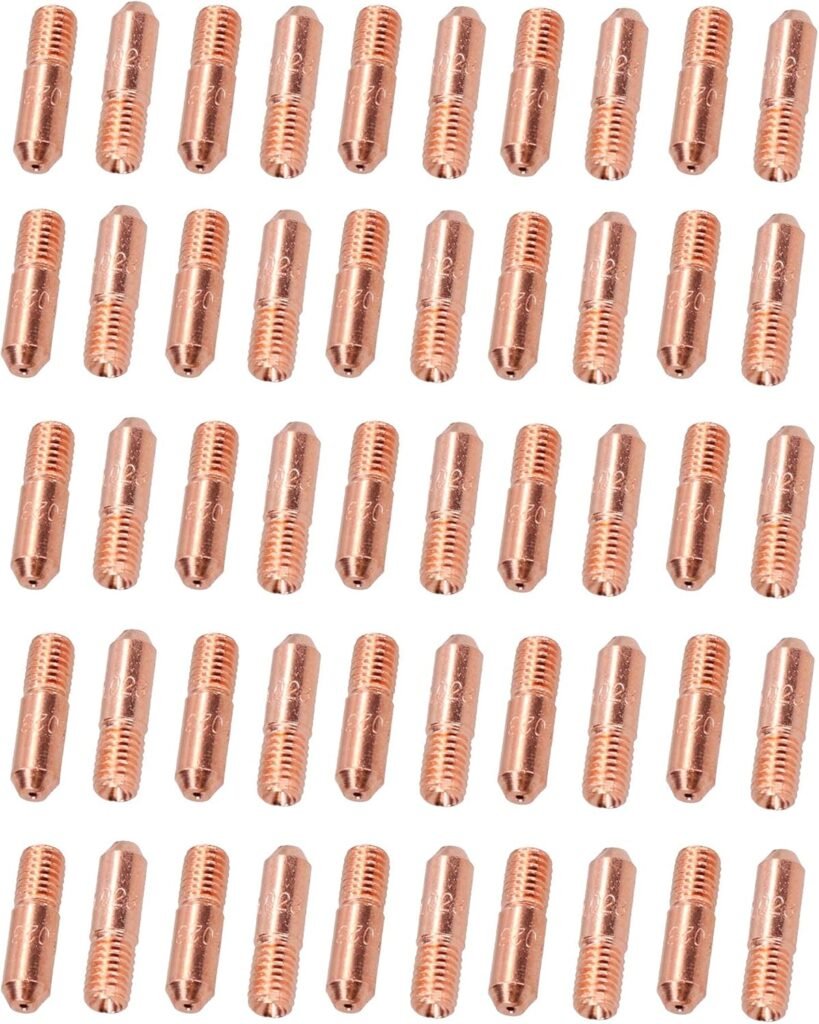

?Are you trying to decide if the 0.8mm Mini Contact Tips 10pk Hobby Welding Torch Welder MIG Gas M5 Thread are the right consumable for your next MIG project?

Product overview

You’ll find that the 0.8mm Mini Contact Tips 10pk Hobby Welding Torch Welder MIG Gas M5 Thread is targeted at hobbyists and light-duty users who need a reliable, affordable set of replacement contact tips. The pack contains ten tips and is designed for use with standard torches using an M5 (5mm) thread and 0.8mm welding wire. You can expect straightforward compatibility with many small MIG torches and budget hobby machines.

What’s in the pack?

You get 10 contact tips per pack, each intended to be a direct replacement for worn or damaged tips on compatible torches. The packaging is simple and compact, so you can keep spares in your toolbox without taking up much space. Since these are consumables, having a 10-pack helps you change tips as often as your welding routine requires.

Key specifications

Below is a concise table that breaks down the most important specs so you know exactly what you’re buying and how it fits into your setup.

| Attribute | Details |

|---|---|

| Product name | 0.8mm Mini Contact Tips 10pk Hobby Welding Torch Welder MIG Gas M5 Thread |

| Pack size | 10 pcs |

| Thread | M5 (5mm) |

| Wire diameter supported | 0.8mm |

| Use case | Hobby / light-duty MIG welding |

| Compatibility | Standard small torches with M5 thread |

| Material (typical) | Copper or copper-plated brass (varies by vendor) |

| Typical lifespan | Dependent on amperage, wire type, and usage frequency |

| Common applications | Thin sheet, light repairs, hobby projects, small fabrication |

Design and build quality

You’ll notice the design is simple and focused: a short, precision-formed tip with an M5 thread for screw-in mounting. Because contact tips are consumables, manufacturers emphasize consistent inner diameters and reliable threading rather than decorative finishes. The interior bore needs to be smooth and concentric to feed the 0.8mm wire consistently, and these tips are manufactured to that standard for hobby-grade use.

Material and finish

Most tips in this category are made from copper or copper-plated brass to balance electrical conductivity and mechanical durability. You’ll find that copper gives excellent electrical transfer, helping maintain a stable arc, while brass (or plated tips) can increase hardness and reduce wear. The finish is usually plain metal; you should not expect a high-gloss or treated exterior, but you’ll get a functional finish that performs well in everyday use.

Threading and fit

The M5 thread standard is common on many small torches and hobby units, which makes these tips a fit for a wide variety of equipment. The threading should seat securely to prevent gas and current leakage at the joint. You’ll want to hand-thread and then slightly snug with a spanner; over-tightening risks stripping the finer M5 threads. If the fit feels loose or cross-threaded, stop and check compatibility and alignment before forcing it.

Compatibility and fitment

You should confirm your torch uses an M5 thread and that it supports 0.8mm wire before ordering. These tips are meant for smaller MIG torches—commonly the handheld hobby units and compact gas-shielded torches used in light fabrication.

- If your machine uses 0.6mm or 1.0mm wire, these 0.8mm tips won’t be optimal.

- If you have a gun with a different thread size (e.g., 7/16-28, 5/8-18, or larger metric threads), these won’t screw in.

- If you have a proprietary quick-change tip system, double-check whether the M5 threaded tip is compatible.

You’ll reduce frustration by measuring the thread or checking your torch manual. If you’re unsure, take your existing tip to a hardware store or compare it visually to line drawings online.

Installation and replacement

Changing contact tips is one of the simplest maintenance tasks you’ll perform. Here’s a practical, step-by-step guide to get you back to welding quickly.

- Turn off the power and gas supply, and disconnect the torch if possible.

- Allow the torch and consumables to cool, especially after a recent session.

- Remove the nozzle to access the contact tip—twist or pull depending on your torch model.

- Unscrew the old tip by hand; use a small wrench if it’s seized, but avoid excessive force.

- Clean the contact area and internal thread on the gas diffuser (if present).

- Hand-thread the new M5 tip to ensure proper alignment, then snug with a wrench—about a quarter to half-turn beyond finger-tight is usually enough.

- Reinstall the nozzle and reconnect gas/electric, then run a quick wire-feed test at low current to verify feed and arc stability.

Tools needed

You don’t need fancy tools to replace these tips. Keep the following on hand:

- Small adjustable wrench or dedicated spanner

- Needle-nose pliers (for nozzle removal in some designs)

- Soft cloth to clean mating surfaces

- Wire feed alignment tool (optional but helpful)

Performance in use

When you use the 0.8mm Mini Contact Tips, you’ll likely notice stable wire feeding for light-duty operations and a generally consistent arc. These tips perform best in the amperage ranges typical of hobby machines—think low to moderate currents where 0.8mm wire is appropriate. The electrical conductivity of copper-based tips helps reduce resistance at the contact point, which in turn helps maintain steady current and arc behavior.

You’ll experience fewer wire burnbacks and more predictable feeding if the tip bore is concentric and free of obstructions. With 0.8mm wire, expect smoother deposition on thin to medium-gauge materials and better handling of slightly higher currents than 0.6mm wire would allow.

Welding scenarios where this pack shines

You’ll get the most value from these tips in the following situations:

- Automotive patching and small bodywork repairs where 0.8mm wire is commonly used for slightly thicker panels.

- Home and hobby projects like brackets, frames, and light structural welds.

- Thin to medium gauge steel where you need a steady arc without aggressive penetration.

- Situations where you need multiple tips on hand so you can swap out when one clogs or wears.

If you perform heavier production welding or daily industrial work, you may outgrow these tips faster and want a higher-grade or factory-specified consumable.

Wire feeding and arc stability considerations

You’ll want to tune wire feed speed and voltage to the characteristics of 0.8mm wire and your machine. These tips will generally support smoother feeding than undersized or oversized tips, but the following will help you maximize performance:

- Keep the liner clean and matched to the 0.8mm wire to avoid feeding friction.

- Ensure the drive rollers are set to the correct groove for 0.8mm wire.

- Keep contact tips free of spatter and wire burrs by replacing or cleaning them when feed becomes inconsistent.

- If you get burnback, check contact tip-to-wire contact; worn tips cause more resistance and can lead to burnbacks.

Pros and cons

You should weigh the strengths and limitations before purchasing. Below are the main points to consider.

Pros:

- Affordable pack with ten tips gives you spares for ongoing use.

- M5 thread fits many hobby torches, making them versatile for small setups.

- Designed for 0.8mm wire, which balances feedability and penetration for many DIY tasks.

- Easy to replace—no special tools required beyond a small wrench.

- Good electrical conductivity if tips are copper or copper-plated.

Cons:

- Consumable quality varies by supplier; some units may have slight variances in bore tolerances.

- Not suitable for industrial heavy-duty welding or high-amperage production work.

- May wear faster under heavy use compared to higher-end, hardened tips.

- Limited to M5 thread and 0.8mm wire, which reduces compatibility with some torches.

Comparison with other contact tip sizes and types

If you’re unsure whether to choose 0.8mm or another size, here’s a quick comparison to help you decide.

| Tip size | Typical use | Advantages | Considerations |

|---|---|---|---|

| 0.6mm | Very thin sheet metal, fine work | Less spatter, finer arc, good for very thin materials | Lower deposition rate, may require slower travel speed |

| 0.8mm (this product) | General hobby and light repair | Balanced penetration and feedability, good for thin-medium sheet | Slightly more heat and penetration than 0.6mm |

| 1.0mm | Thicker panels, heavier repairs | Higher deposition rate, better for thicker metals | Requires higher current, more heat input, less control on thin metal |

You’ll find 0.8mm to be a middle ground: a good compromise between control and productivity for small to medium hobby tasks.

Longevity and maintenance

Your contact tips won’t last forever. How often you replace them depends on current level, wire composition, and the amount of spatter you produce. Under light hobby use, a contact tip might last several hours of cumulative welding; under heavy or high-amperage use, it will wear faster.

- Replace tips if you see signs of erosion or an irregular bore.

- If wire feeding becomes jerky, check the tip before suspecting the liner or drive mechanism.

- Keep spatter minimized with anti-spatter sprays or gels, but use them sparingly and clean tips occasionally to prevent buildup.

Cleaning tips

If you prefer to extend a tip’s life by cleaning:

- Remove the tip and soak briefly in a mild solvent to remove oil and debris.

- Gently use a fine pick or dental tool to clear the bore if it’s partially blocked—but be careful not to enlarge or scratch the bore.

- Use a soft brass brush to remove external spatter; avoid aggressive grinding or filing that can change the bore diameter.

Storage and handling

You should store spare tips in a dry container to avoid contamination and physical damage. Keep them away from abrasive surfaces and magnetic fields that might cause metal shards to adhere. Labeling spare packs with wire diameter and thread type helps avoid mistakes when you’re in the middle of a job.

Common problems and troubleshooting

You’ll likely encounter a few common issues with contact tips. Here’s practical troubleshooting so you can get back to welding quickly.

Problem: Wire feeding inconsistently

- Check the tip bore for obstructions or wear.

- Verify the liner is clean and correctly sized for 0.8mm wire.

- Confirm drive rollers are adjusted properly for the wire.

Problem: Burnback (wire fusing to the tip)

- Ensure correct contact tip-to-wire contact; worn tips increase resistance.

- Check voltage and wire feed settings; reduce feed speed or adjust voltage per the wire/metal combination.

- Inspect for contamination in the tip bore that could cause arcing.

Problem: Excessive spatter

- Use correct shielding gas and flow rate for your wire and base metal.

- Clean or replace a tip with spatter built up in the bore.

- Fine-tune voltage and wire-feed speed to match material thickness.

Problem: Tip loosening or gas leakage

- Avoid over-tightening; you’ll strip M5 threads if you force them.

- Inspect the mating threads on both the tip and diffuser for damage or dirt.

- Make sure the nozzle seats properly over the tip to maintain gas coverage.

Safety considerations

You must always prioritize safety when welding. Even though contact tips are small, they contribute to the overall function of the torch, and improper use can create hazards.

- Wear appropriate PPE: helmet with correct shade, gloves, long sleeves, and closed-toe shoes.

- Ensure good ventilation; even light welding produces fumes.

- Turn off power and gas before replacing tips.

- Avoid touching the tip right after welding; it gets very hot.

- Keep a fire extinguisher or sand bucket nearby when welding in a confined workspace.

Who should buy these tips

You should consider this 10-pack if you’re a hobbyist, a DIYer, or someone doing occasional light repairs who needs an affordable supply of consumables. If you own a small MIG torch with M5 threaded tips and you use 0.8mm wire, this product saves you the trouble of sourcing single tips and keeps replacements on hand.

If you’re a professional doing daily production or high-amperage work, you’ll likely prefer industrial-grade tips engineered for high duty-cycle environments.

Practical tips for best results

Use these quick, user-focused tips to get the most from your purchase:

- Keep multiple tips ready so you can swap without downtime when one clogs.

- Match the liner, wire, and tip inner diameter carefully for smoother feeds.

- Periodically inspect the tip for tapered wear; a slightly flared bore can cause erratic feeding.

- Don’t over-tighten the M5 thread—snug is sufficient.

- Keep spatter to a minimum with anti-spatter or optimized welding settings.

Frequently asked questions (FAQ)

Q: Will these tips fit my MIG torch? A: They’ll fit if your torch accepts an M5 (5mm) thread and uses 0.8mm wire. Check your torch manual or existing tip for thread size.

Q: Can I use these for flux-cored wire? A: In many cases yes, if the wire diameter is 0.8mm and your torch is set up for flux-cored welding. Flux-cored wire produces more spatter, so maintenance frequency may increase.

Q: Are these tips copper or brass? A: Many hobby contact tips are made from copper or copper-plated brass to combine conductivity and wear resistance. The exact material can vary by supplier, but both are common in this form factor.

Q: How long do they last? A: Lifespan depends on amperage, wire, and usage. For hobby use, expect several hours of cumulative welding; high-amperage use will shorten life.

Q: Can I resize the bore for different wires? A: You should not attempt to resize the bore. The internal diameter is engineered for 0.8mm wire, and altering it can cause poor feed and increased burnback or spatter.

Common alternatives and when to choose them

If you’re considering other options, here are a few situations and what to choose:

- If you need finer control on very thin sheet metal, consider 0.6mm tips.

- If you do heavier repairs on thicker steel, 1.0mm tips or larger consumables will be better.

- If your torch has a different thread pattern, check for tips matching that thread rather than trying to adapt an M5 tip.

- If you need industrial endurance, look for hardened or wear-resistant contact tips designed for high duty cycles.

Real-world use cases and examples

You’ll find these tips particularly useful in practical scenarios such as:

- Repairing a rusted section of a car’s floor pan where you’re welding patch panels with 0.8mm solid wire and gas.

- Building garage shelving or brackets out of thin-medium gauge steel where you need consistent feed and a predictable arc.

- Hobby projects like building a small metal frame or art pieces that require occasional welding with a hobby MIG torch.

- Practice sessions where you’re learning bead control and don’t want to spend a lot per consumable.

Pricing and value

You’ll often find these packs at budget-friendly price points. The value comes from getting ten tips in one purchase, which reduces per-tip cost compared to buying singles. For a hobbyist, the price-to-lifespan ratio is attractive—especially if you practice regularly and go through tips often. Keep in mind that higher-priced tips from major brands may offer tighter tolerances and longer life, but at a higher unit cost.

Environmental and disposal considerations

Contact tips are small metal parts and should be disposed of or recycled according to local metal recycling guidelines. You’ll minimize waste by replacing only when necessary and by cleaning tips that are still serviceable. If you end up with many used tips, consider taking them to a scrap metal recycler rather than placing them in regular household waste.

Final verdict

If you’re running a small MIG torch with an M5 thread and you use 0.8mm wire, you’ll find the 0.8mm Mini Contact Tips 10pk Hobby Welding Torch Welder MIG Gas M5 Thread to be a practical, cost-effective choice. The pack gives you multiple spares, reasonable performance in hobby contexts, and straightforward compatibility with many small torches. These tips are not meant for heavy industrial workloads, but for DIYers, tinkerers, and occasional welders they strike a good balance of affordability and function.

You should buy this pack if you want easy-to-install, reliable replacements for routine welding tasks and if you prefer to have spares on hand so downtime is minimized. If you demand the longest possible life and maximum precision, you may want to compare premium branded tips, but for general hobby use these do the job well.

Rating summary (based on hobby use): 4 out of 5 — solid value and functionality for the price, with the caveat that higher-end tips will outlast them under heavy use.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.