Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

? Are you trying to find small, reliable contact tips that will keep your hobby MIG torch running smoothly without breaking the bank?

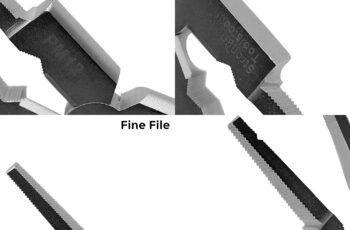

0.8mm Mini Contact Tips 10pk Hobby Welding Torch Welder MIG Gas M5 Thread — Quick Overview

You’ll get a compact pack of ten contact tips designed for hobbyists and light-duty welding tasks. These are labeled as 0.8mm contact tips with an M5 (5mm) thread and are intended to fit standard torches using 0.8mm wire.

What this product is meant for

These contact tips are purpose-built to provide electrical contact and guide the welding wire to the arc for MIG/GMAW setups that use 0.8mm welding wire. You’ll use them when you need consistent arc transfer and a snug fit in a torch with an M5 thread.

Who should consider these tips

If you do small-scale welding projects on mild steel, thin sheet metal repairs, hobby fabrication, or model and DIY work, these tips will suit your needs. You’ll especially benefit if your torch accepts the M5 thread size and you prefer buying spares in small packs.

Key Specifications

Here’s a simple breakdown so you can quickly see whether these match your equipment and needs. This table should make compatibility checking a little faster.

| Feature | Detail |

|---|---|

| Product Name | 0.8mm Mini Contact Tips 10pk Hobby Welding Torch Welder MIG Gas M5 Thread |

| Pack Size | 10 pieces |

| Wire Size Compatibility | 0.8 mm (approx. 0.030 inches) |

| Thread Type | M5 (5 mm) |

| Intended Use | MIG/GMAW welding, hobby & light-duty tasks |

| Torch Fit | Standard torches with M5 thread |

| Material | Typically copper or copper-plated (check seller notes for exact composition) |

| Typical Applications | Thin metal welding, small fabrication, repairs, hobby projects |

| Country of Manufacture | Varies by seller (check packaging or listing) |

Why these specifications matter

You’ll want to pay attention to thread type and wire size: the M5 thread and 0.8mm wire size must match your torch and spool wire choice to avoid misfit and feeding problems. Pack size matters because ten tips is a modest stock for hobby use — enough for several sessions if you don’t weld full-time.

Build Quality and Materials

You’ll typically see contact tips made from copper or copper-plated alloys. These conduct electricity well and tolerate heat reasonably, but they can wear quicker than premium alloy tips.

What to expect from the construction

The tips in this pack are small and simple. You shouldn’t expect exotic metallurgy — they’re manufactured for affordability and general-purpose use. That said, for hobby applications they tend to hold up adequately if you maintain proper welding parameters.

Common signs of wear

You’ll notice spitting, inconsistent arcs, or burnback when a tip is worn. Also watch for deformities around the threaded shank or the contact hole — these indicate you should replace the tip.

Compatibility and Fit

Compatibility is the most critical element you’ll check before buying these tips. If your torch’s nozzle and liner accept an M5 threaded tip and you use 0.8mm wire, you’re in the right place.

How to verify thread compatibility

You’ll want to look at your torch’s documentation or unscrew an existing tip to check the thread. If it’s marked M5 or measures roughly 5mm across the nut thread, the tips will likely fit.

Wire size and feeding considerations

Using a 0.8mm contact tip with 0.8mm wire ensures the wire runs smoothly through the tip without excessive play. If you try to use a different wire diameter, you’ll get poor contact, erratic arc, or feeding jams.

Installation and Replacement

Replacing contact tips is straightforward, but you’ll be glad you follow a few simple steps to avoid damage or cross-threading.

Step-by-step installation

- Turn off and unplug your welding unit. Let the torch cool if it’s hot.

- Remove the nozzle and gas diffuser to access the tip.

- Unscrew the old tip by hand or with pliers if it’s tight (use a cloth to avoid damaging the tip).

- Thread the new M5 tip in by hand to avoid cross-threading, then snug it up with a wrench — don’t over-tighten.

- Reassemble nozzle and diffuser, check wire feed alignment, and test weld on scrap.

Tips to avoid common installation problems

You’ll want to avoid over-tightening, which can strip threads or deform the tip. If the tip feels loose, check for damaged threads in the torch or leftover metal shavings. Always replace damaged liners or nozzles that might cause misalignment.

Performance and Welding Behavior

These tips perform suitably for general-purpose hobby welding. You’ll get stable arcs and predictable behavior when you match wire, gas, and machine settings.

Arc stability and contact

When new and properly installed, the 0.8mm tips deliver good electrical contact and a consistent arc for thin materials. They’re best used with appropriate wire speed and voltage settings for 0.8mm wire.

Heat tolerance and lifespan

Because these are economical tips, their heat tolerance and lifespan won’t match premium copper alloy tips. If you weld intermittently or on thin materials, you’ll find their lifetime acceptable. For extended or demanding use, plan to swap them more frequently.

Practical Applications and Use Cases

You’ll find lots of use cases where these tips shine, particularly in home workshops and for people doing light fabrication.

Typical projects you’d use them for

- Small car bodywork and patch panels

- Thin aluminum or mild steel repairs (when using appropriate shielding gas and settings)

- Model fabrication, garden equipment repairs, and DIY metal art

- Educational use for training and practice at home or in a classroom

Limitations in heavier applications

If you plan on thicker plate welding or continuous production work, these tips can overheat or wear quickly. For heavy work, you’ll want higher-grade tips, larger wire diameters, and a heavier-duty torch system.

Value for Money

You’ll likely find this 10-pack to be a cost-effective solution for hobbyists who want a steady supply of replacement tips without spending too much.

Cost-benefit considerations

Ten tips give you a modest stock, which is ideal if you weld occasionally. You’ll save money compared to buying branded or specialty tips, but you’ll trade off some longevity and performance under heavy loads.

When to consider upgrading

If you start doing more frequent welding or find yourself changing tips every session, it’s worth investing in higher-grade tips or buying larger quantity packs to reduce per-tip cost.

Pros and Cons

You’ll appreciate the straightforward pros and be aware of the limitations before you commit.

Pros

- Affordable and convenient 10-pack for hobbyists

- Correct fit for torches with M5 threads that use 0.8mm wire

- Easy to install and replace

- Good initial arc stability for light-duty welding

Cons

- Not as long-lasting as premium alloy tips

- May wear faster under heavy or continuous use

- Quality can vary between manufacturers — check seller reputation

Troubleshooting Common Issues

When things don’t go right, you’ll want to work through these common problems systematically.

Issue: Wire jams or inconsistent feed

- Check that you’re using 0.8mm wire that matches the tip hole.

- Verify the liner isn’t kinked or worn and the drive rolls are set to the correct pressure.

- Ensure the tip is threaded in straight and not blocked with spatter.

Issue: Poor arc or excessive spatter

- Confirm gas flow and shield gas type are appropriate for your material and wire.

- Replace a worn tip — a slightly enlarged or misshapen hole causes poor contact.

- Clean the nozzle and diffuser to ensure proper gas coverage.

Issue: Tip threads strip or won’t tighten

- Inspect torch threads for damage or contamination.

- Avoid cross-threading by starting the tip by hand.

- If threads are damaged, you may need a replacement gas diffuser or a torch repair.

Maintenance and Care

You’ll extend tip life by keeping the torch and consumables clean and by using correct welding parameters.

Cleaning regimen

- After each session, blow out the nozzle and clean spatter from the tip and nozzle.

- Use anti-spatter spray or a light coating designed for MIG welding to reduce build-up.

- Replace tips when you see misalignment, deformation, or frequent burnback.

Storage suggestions

Store unused tips in a dry container to avoid contamination or corrosion. Keep them separated from abrasive items that can damage threads.

Comparison with Alternatives

It helps to see how these tips stack up against other options so you can choose what’s right for you.

Budget vs premium tips

- Budget tips (like this 10-pack): cheaper, adequate for light use, variable quality.

- Premium alloy tips: more expensive but longer-lasting, better heat tolerance, ideal for higher duty cycles.

Pack sizes and buying strategy

If you weld more often, bulk packs (25/50/100) can be more economical. If you weld rarely or want to test fit, a 10-pack keeps upfront costs low while giving you a reasonable supply.

Practical Buying Tips

You’ll want to check a few things before finalizing your purchase to avoid returns or incompatibility.

Verify torch thread and wire diameter

Confirm the torch accepts an M5-threaded tip and that you use 0.8mm wire. Measure an existing tip if unsure.

Check product reviews and seller details

Look at user photos and reviews to confirm consistent quality from the seller. Some listings may use generic images, so buyer feedback can confirm fit and material.

Consider spare parts like liners and diffusers

If you’re replacing tips, you may also need a new liner or diffuser — check those components and stock them if they’re worn.

Real-world Testing (What You’ll Likely Experience)

If you run a few real welds with these tips, you’ll notice how they handle typical hobby tasks.

Typical setup and settings

- Material: 0.6–1.2 mm mild steel sheets

- Wire: 0.8 mm solid wire

- Gas: C25 (75% Argon / 25% CO2) or similar gas mix for good penetration and low spatter

- Settings: Moderate wire speed and low-to-medium voltage for thin sheets

Expected results

When matched correctly, you’ll get smooth wire feed and a stable arc suitable for tack welding and short seam work. For thicker or continuous seams, you’ll need longer runs and may see heat buildup.

Frequently Asked Questions (FAQ)

You’ll find answers to common buyer queries right here.

Will these tips fit my torch?

If your torch uses an M5 threaded tip and runs 0.8mm wire, yes. Always measure or check documentation if you’re unsure.

Can I use these for aluminum?

You can weld thin aluminum with MIG, but you’ll usually need a spool gun or push-pull feeder and a soft wire liner for aluminum wire. These tips are fine for aluminum only if your setup supports proper feeding and a suitable liner.

How often should I replace contact tips?

Replacement frequency depends on use. Occasional hobbyists might change them after many sessions; heavier users may need to replace them weekly or more often. Replace whenever you notice inconsistent arc, frequent burnback, or enlarged tip holes.

Are these tips universal?

They’re not universal; the M5 thread and 0.8mm compatibility are specific. They’ll fit many standard hobby torches but not all industrial models.

Safety Notes

You should always follow standard welding safety procedures when handling consumables and performing welding tasks.

Basic safety reminders

- Turn off and unplug welding equipment before changing tips.

- Wear appropriate PPE: welding helmet, gloves, jacket, and eye protection.

- Work in a well-ventilated area and use gas shielding properly.

- Keep flammable materials away and have fire safety equipment nearby.

Final Verdict and Buying Recommendation

You’ll find this 0.8mm Mini Contact Tips 10pk Hobby Welding Torch Welder MIG Gas M5 Thread pack to be a sensible choice if you’re a hobbyist or part-time welder using a torch with an M5 thread and 0.8mm wire. The pack offers affordability, convenience, and reasonably reliable performance for light-duty work.

Who should buy it

If you want a low-cost, easy-to-replace set of contact tips for occasional welding, these are a good match. You’ll appreciate the convenience of a ten-pack for practice and DIY projects.

Who should look elsewhere

If you weld daily, do heavy fabrication, or need the longest-lasting tips, you should consider premium contact tips in larger packs or different alloys designed for higher duty cycles.

Additional Tips and Tricks

Here are a few practical pointers that will help you get the most out of these tips.

Extend tip life

- Keep your nozzle clean and free of spatter using anti-spatter agents.

- Match your gas and settings to the material and wire.

- Avoid dragging the nozzle on the workpiece — mechanical stress shortens tip life.

Improve feed consistency

- Check and replace worn drive rolls and liners.

- Use proper wire tension: not too loose, not too tight.

- Ensure straight wire feed from spool to tip when possible.

You’ll find that with basic care and the right setup, the 0.8mm Mini Contact Tips 10pk Hobby Welding Torch Welder MIG Gas M5 Thread will keep you welding smoothly for a good number of projects. If you have specific torch model questions or want setup suggestions for a particular material, tell me the torch model and what you plan to weld, and I’ll give tailored guidance.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.