Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you looking for a single welding machine that can handle MIG, TIG, and ARC tasks without taking up a ton of space in your shop?

Overview of the MIG Welder 250A Welding Machine 3 in 1 Combo MMA MIG Lift TIG Welder Flux Core Portable Welding Equipment

This 3-in-1 combo unit aims to give you the flexibility to switch between MIG, TIG, and MMA/ARC welding with minimal fuss. You can use solid wire with gas or flux-cored wire without gas, which makes it useful whether you’re working on stainless steel or plain iron.

Who this machine is for

Whether you’re a weekend hobbyist, a mobile repair tech, or an experienced fabricator, this machine is built to suit a wide range of users. You’ll appreciate the portability and the ability to tackle a variety of materials and joint types without needing three separate machines.

Key features at a glance

You’ll get several standout features: solid and flux-core wire compatibility, gas and gas-free MIG welding, lift TIG capability, and MMA/ARC welding. The unit is built to be portable and robust so you can take it between job sites or keep it in your garage for general repairs.

What “3-in-1” means for you

The 3-in-1 label means the machine combines MIG, TIG (lift start), and MMA/ARC welding in one chassis. This saves you money and workspace, and lets you match the welding process to the task rather than the other way around. You’ll be able to switch modes depending on material thickness, joint style, and finish requirements.

Specifications breakdown

Below is a compact table to help you compare the machine’s primary specs at a glance. This should help you quickly decide whether it matches your power and duty-cycle needs.

| Specification | Detail |

|---|---|

| Model | MIG Welder 250A Welding Machine 3 in 1 Combo MMA MIG Lift TIG Welder Flux Core Portable Welding Equipment |

| Welding Processes | MIG (gas & gas-free/flux-cored), TIG (lift start), MMA/ARC |

| Output Current | Up to 250A |

| Wire Compatibility | Solid wire, Flux-cored wire |

| Gas Capability | Supports gas for stainless steel MIG; gas-free for iron with flux core |

| Portability | Built-in handle; compact design for portable use |

| Target Users | Hobbyists, mobile welders, small shops, professional users |

| Construction | Durable housing with cooling system |

| Typical Uses | Vehicle repair, metal fabrication, farm equipment maintenance, structural repair |

Design and build quality

The machine’s housing is designed to take a fair amount of daily abuse while protecting the internal electronics. You’ll find that the outer shell feels sturdy and the handles are practical for carrying the unit between jobs.

Cooling and durability

This welder uses active cooling to protect components during extended use. You’ll appreciate consistent performance and reduced risk of thermal shutdown because the thermal system is designed to maintain reliable operation under moderate workloads.

Controls and layout

Controls are grouped logically so you can dial in wire speed and current without fumbling. You’ll find straightforward knobs and switches with clear labels, which helps when you’re switching between modes or tuning for weld quality.

Performance by welding mode

Each welding mode has its own strengths and practical use-cases, and this machine delivers competent performance across all three.

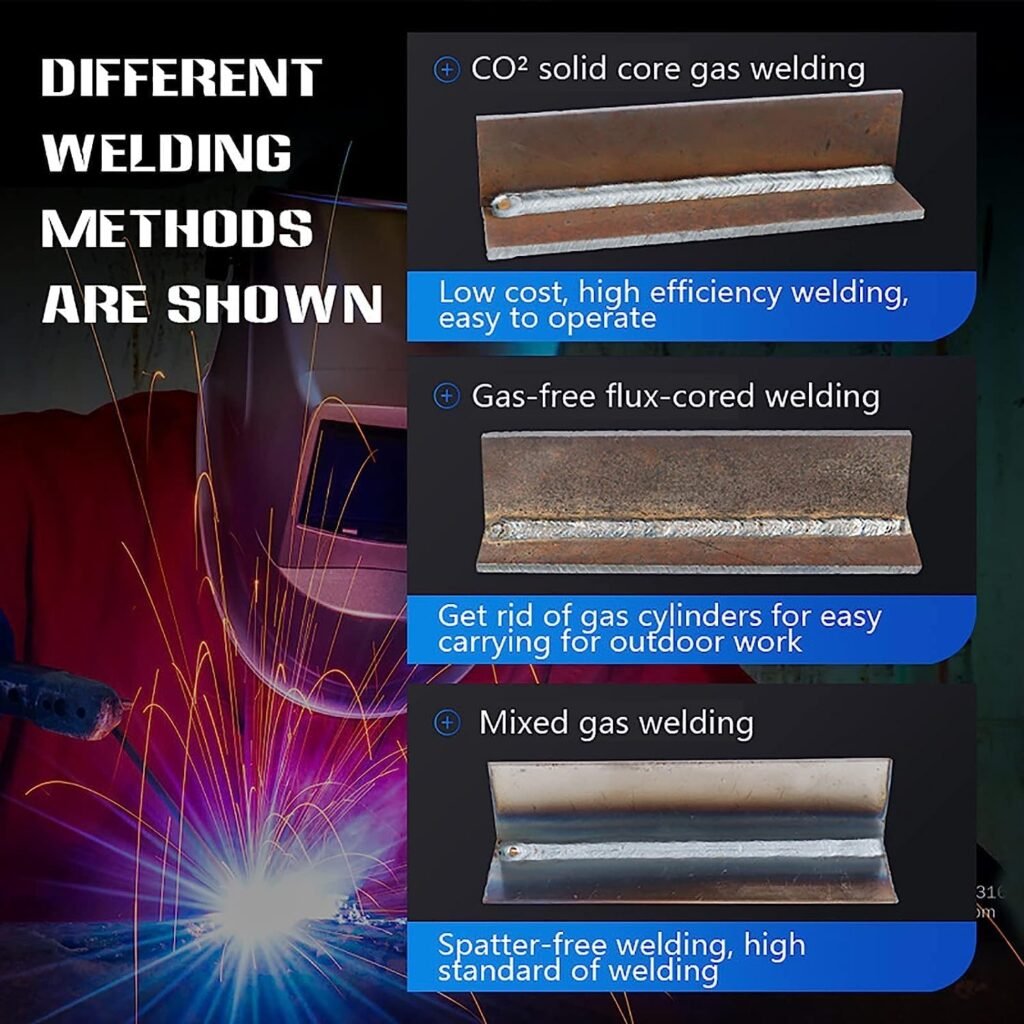

MIG welding performance

In MIG mode, you’ll be able to weld with either solid wire plus shielding gas or flux-cored wire without gas. The unit offers stable arc characteristics and reasonable penetration for its class, making it suitable for thin- to medium-gauge sheet metal and some heavier repairs when set to higher amperages.

TIG welding performance (lift start)

Lift TIG allows you to do TIG welding without high-frequency start, which is often preferred in workshops where HF interference is a concern. You’ll be able to achieve cleaner welds on stainless steel and thin materials by carefully dialing in current and using the proper filler rod.

MMA/ARC welding performance

MMA/ARC welding gives you the flexibility to use stick electrodes for repairs outdoors and on rusty or dirty surfaces. You’ll find it dependable for structural tack welds, field repairs, and heavier sections that require robust electrode options.

Wire compatibility and gas options

One of the practical advantages you’ll notice is the ability to use both solid and flux-cored wires. This versatility lets you adapt to your work environment without needing multiple dispensers.

Solid wire with gas

When using solid wire, you can attach shielding gas to get cleaner welds, reduced spatter, and improved appearance—especially important on stainless steel. You’ll need the proper regulator and gas hose to use the supplied gas port effectively.

Flux-cored wire gas-free option

If you’re working outdoors or don’t want to deal with a gas cylinder, flux-cored wire allows you to weld without gas. This is particularly handy for iron and mild steel where surface contamination or windy conditions would otherwise cause issues.

Set up and first-time use

Getting this machine ready is straightforward, and you’ll have it operational in a relatively short time if you follow the instructions and take basic safety steps.

Initial setup steps

You’ll install the wire spool, thread the wire through the drive system, connect your torch, and, if necessary, hook up the gas. After that, set your input voltage and tune wire feed speed and current according to the material thickness.

Safety checks before welding

Make sure you confirm correct polarity, check cable connections, test ground clamp contact, and make sure gas flows if you’re using MIG with shielding gas. You’ll also want to wear proper PPE: helmet, gloves, jacket, and ventilation.

Ease of use and learning curve

This machine is designed for both beginners and experienced welders, so you’ll find the controls approachable even if you’re new to multiple welding processes. With a little practice, you’ll be able to switch modes and get consistent welds.

Helpful features for beginners

The clear front-panel settings, straightforward wire speed/current knobs, and lift TIG start make it less intimidating for new users. You’ll gain confidence quickly because the machine reacts predictably to adjustments.

Advanced tuning for pros

If you’re more experienced, you’ll appreciate the control range and the ability to tweak settings for optimal bead profile and penetration. You’ll find it supports many professional techniques once you’ve mastered the arc characteristics.

Portability and shop use

You’ll notice that the machine’s relatively compact size and built-in handle make it easy to move between jobs. It’s designed with portability in mind, although it’s still a solid, well-built unit that feels like a professional tool.

Jobsite considerations

You can use MMA/ARC outdoors without shielding gas and use flux-core MIG welding for outdoor metalwork. You’ll still want to protect the machine from direct rain, dust, and extreme temperatures to preserve its electronics.

Workshop considerations

In a garage or small shop, this 3-in-1 combo saves space and gives you flexibility to tackle diverse projects without investing in separate machines. You’ll still want a dedicated space for cylinders and consumables.

Consumables and spare parts

You’ll need to keep a few consumables on hand—wire spools, TIG filler rods, stick electrodes, contact tips, nozzles, and possibly a replacement torch liner. Most consumables are standard and easy to source.

Recommended consumables

For MIG: solid wire (ER70S-6) and flux-core wires matched to your material. For TIG: appropriate filler rods and a compatible tungsten when required. For MMA: low-hydrogen rods or rutile rods depending on your material and desired weld properties.

Maintenance parts to stock

It’s smart to have spare contact tips, nozzles, a work cable, and replacement drive rollers. You’ll also want basic cleaning tools like a wire brush and tip cleaner to maintain consistent arc performance.

Common applications and use cases

You’ll be able to take on automotive bodywork, structural repairs, farm equipment fixes, metal artwork, and general fabrication tasks. The machine’s flexibility makes it a practical choice if you routinely switch between different types of welding.

Automotive and bodywork

For vehicle repair, you’ll appreciate the MIG mode for fast welding on panels and the TIG mode for cleaner stainless repairs. You’ll find the fine control helpful when working on thinner sections or when appearance matters.

Fabrication and structural repair

When working on frames, supports, or brackets, MMA and MIG flux-core modes give you the strength and versatility needed to handle thicker pieces. You’ll be able to select the process that best balances penetration with appearance.

Pros and cons

You’ll want to weigh the machine’s capabilities and limitations to make an informed buying choice. Below are the main benefits and potential drawbacks to consider.

Pros

- Versatile: MIG, TIG (lift), and MMA in a single unit allow you to match process to task.

- Wire flexibility: Uses both solid wire (with gas) and flux-cored wire (gas-free), giving you options for different environments.

- Portable: Compact and built with a carrying handle for job-site mobility.

- User-friendly: Intuitive controls make it approachable for beginners while still offering depth for experienced users.

- Durable: Robust construction helps it withstand regular use.

Cons

- Limited advanced TIG features: No high-frequency TIG start or pulse TIG options may limit some very fine TIG work.

- Duty cycle constraints: Like most combo machines in this class, sustained heavy-duty industrial use may push it beyond comfortable duty cycles.

- Accessories required: You’ll need to buy a gas bottle and regulator for MIG with solid wire, and some consumables may not be included.

- Learning curve for multi-process use: Switching between processes requires understanding different settings and techniques to get best results.

Real-world welding results and tips

You’ll get better results with small technique adjustments and process-specific tips that match settings to material and joint type.

MIG tips for cleaner welds

Set wire feed speed and voltage so that the arc is steady and the bead is neither too wet nor too cold. You’ll want to maintain a consistent travel speed and a slight push angle for better visibility and lower spatter when welding thin sheet metal.

TIG tips for improved finish

Use proper tungsten selection and a clean joint; lift start helps avoid HF interference. You’ll keep filler addition controlled and use shorter arc lengths to avoid contamination and porosity.

MMA/ARC tips for reliable starts

Strike the arc cleanly and control your travel speed to avoid undercut. You’ll choose electrodes appropriate for the metal and thickness to ensure proper penetration and mechanical strength.

Safety considerations

Welding safely protects you and extends equipment life. You’ll want to follow best practices each time you weld.

Personal protective equipment

Always wear an appropriate welding helmet with the correct shade, flame-resistant clothing, gloves, and eye protection. You’ll also need a respirator when working in poorly ventilated areas or when welding materials that produce hazardous fumes.

Workspace safety

Ensure proper ventilation, keep flammable materials away, and maintain a dry environment for electrical safety. You’ll also ground the machine properly and inspect cables for wear to reduce shock and fire hazards.

Maintenance and care

Regular maintenance extends the life of the machine and ensures consistent welding performance. You’ll want to do a few simple checks before each welding session.

Daily checks

Inspect cables, conditon of hoses, and consumables, and make sure the drive rollers and contact tip are clean and properly seated. You’ll also confirm the gas connections are leak-free and the ground clamp has good contact.

Periodic maintenance

Clean internal dust and debris periodically, inspect fans and vents, and replace worn drive rollers and liners when needed. You’ll also tighten electrical connections to prevent heat buildup and premature wear.

Accessories and optional add-ons

You’ll likely want a few additions to make full use of the machine: gas cylinder and regulator, welding cart, TIG torch accessories, spools of wire, and protective gear.

Useful accessories

A quality regulator and gas hose, an extra MIG torch, a TIG torch consumable kit, and a set of spare welding cables will reduce downtime. You’ll also benefit from a welding cart to move the unit and store consumables.

Comparison to standalone machines

If you already have a MIG-only or TIG-only unit, consider how often you actually use each process. The 3-in-1 gives you multi-purpose capability but might not match the heavy-duty performance of specialized commercial systems.

Advantages over single-process units

You’ll save money, space, and the hassle of learning multiple machines. The combo approach is ideal if you need process flexibility rather than specialized, high-end TIG features.

When a standalone machine makes sense

If your work is exclusively high-end TIG on exotic alloys or you need continuous high-current MIG production, a dedicated machine may serve you better. You’ll see improved duty cycles and specialized feature sets in those dedicated units.

Troubleshooting common problems

If you run into issues, many are solvable with simple checks and adjustments. You’ll most commonly encounter problems with wire feeding, spatter, or arc instability.

Wire feeding and drive issues

If the wire feeds inconsistently, check the drive rollers, tension setting, and liner for kinks or obstruction. You’ll also verify spool mounting and proper wire diameter selection.

Porosity and poor weld appearance

Porosity typically points to gas issues or contaminated metal. You’ll ensure proper gas flow, clean the workpiece, and check for drafts when welding with gas.

Inconsistent arc or stalling

If the arc fluctuates, inspect for grounding problems, worn contact tips, or incorrect polarity. You’ll also verify settings and ensure the power input is stable.

Price and value proposition

When you look at the features relative to price, the 3-in-1 machine is positioned as a value-packed option for users who need multiple processes without the footprint and cost of separate machines. You’ll find it delivers a strong mix of functionality and portability for the money.

Cost considerations

Besides the initial purchase, factor in the cost of consumables, gas bottles and regulators (if you plan to use solid wire), and any necessary cables or carts. You’ll end up with a flexible shop setup without building a large inventory of separate machines.

FAQs

You’ll likely have a few common questions when evaluating this welder. Below are short answers to issues most buyers ask about.

Can I use it outdoors?

Yes, especially in flux-core or MMA/ARC mode. You’ll avoid shielding gas MIG outdoors unless you have a protective wind screen, since wind can scatter gas and cause porosity.

Do I need a separate TIG torch or is it included?

Some packages include a TIG torch while others may require you to buy it separately; check the specific seller listing. You’ll also want appropriate TIG consumables and filler rods for TIG work.

Is gas required for MIG welding?

Not for flux-cored MIG. You’ll need shielding gas when using solid wire to achieve cleaner welds, especially on stainless steel.

What is the duty cycle?

Duty cycles vary by model and operating amperage. You’ll check the specification sheet for the exact duty cycle at different amperages; expect moderate-duty cycles typical for multi-process machines.

Final thoughts and buying recommendation

If you want a single machine that allows you to perform MIG, TIG, and MMA/ARC welding with the convenience of both solid and flux-cored wires, this is a compelling choice. You’ll gain the flexibility to handle many jobs—automotive repairs, fabrication, and fieldwork—without purchasing multiple dedicated machines.

You should consider this unit if you value portability, versatility, and a reasonable price-performance balance. If your work demands continuous, high-amperage TIG with advanced features, then a dedicated TIG machine might be a better fit. Otherwise, this 3-in-1 combo can be a practical, cost-effective addition to your toolkit.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.