Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a versatile welding machine that can handle MIG flux-core, stick, and lift TIG tasks without breaking the bank?

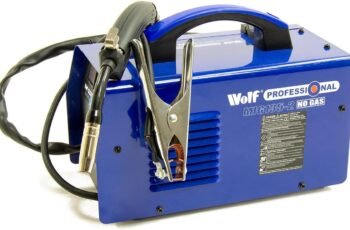

Product Overview: MIG Welder Flux Core Welder and Stick Welder 200A Machine Dual Voltage 110V 220V 200Amp Gasless MIG Welding ARC/MMA Lift TIG Welder Combo Machine

You’re looking at a multi-function welder designed for home shops, garages, and outdoor work. This machine promises three welding modes in one package so you can handle a variety of jobs without buying separate machines.

What this machine is designed to do

This combo unit gives you a gasless flux-core MIG mode for easy carbon steel and stainless work, a 200A MMA/stick mode for rod welding with hot arc starting and anti-stick features, and a lift TIG mode to let you TIG weld if you add a TIG torch. The idea is that you get flexibility: light fabrication, repair work, farm and ranch tasks, and hobby projects.

Quick specifications at a glance

Below is a condensed breakdown of the essential specs so you can quickly compare what matters to you. These are drawn from the product information and are the numbers you’ll reference when deciding if it fits your projects.

| Specification | Value |

|---|---|

| Model (as listed) | MIG Welder Flux Core Welder and Stick Welder 200A Machine Dual Voltage 110V 220V 200Amp Gasless MIG Welding ARC/MMA Lift TIG Welder Combo Machine |

| Welding modes | Flux-core MIG (gasless), MMA/Stick (ARC), Lift TIG (torch not included) |

| Max output current | 200A |

| Input voltage | Dual: 110V / 220V |

| Flux core wire sizes | 0.8 mm (0.03″), 1.0 mm (0.04″) |

| Electrode sizes supported | 1.6 mm to 4.0 mm |

| Wire feed control | Synergic control (knob adjusts current; wire feed speed auto-matched) |

| Included consumables | 0.030″ (0.8mm) / 2 lb flux-cored wire (one spool) |

| Package includes | Machine, MIG torch, electrode holder, ground clamp, 2lb flux wire, protective mask, brush |

| TIG torch | Not included (requires separate purchase) |

| Best use case | Home DIY, outdoor repairs, small shop work |

Package contents

You’ll get the main machine and a starter kit that lets you begin basic MIG and stick welding right away. There’s enough in the box to begin small projects without running to the store, but you should plan on buying extra consumables and a TIG torch if you want full TIG capability.

Items included:

- MIG200A machine

- MIG torch

- Electrode holder (stick)

- Ground clamp

- 0.030″ (0.8mm) flux-cored wire, 2 lb spool

- Protective mask

- Wire brush

These give you a convenient starter set. The lift TIG feature is still only functional after you buy a separate TIG torch, which is important to keep in mind.

Main features explained

Every mode and control feature serves a purpose depending on the job. You’ll appreciate the core design choices if you need an all-in-one welder that keeps things simple.

- Gasless MIG (Flux Core): Allows you to weld without shielding gas using flux-cored wire. Good for outdoor work and when portability matters.

- MMA/Stick Welding: Works with a wide range of electrode sizes and offers anti-stick and hot start characteristics for better arc initiation.

- Lift TIG Welding: Adds TIG capability but requires you to buy a TIG torch separately. It’s useful for precision welding once you add the torch.

- Synergic Control: A single knob to set current and have wire feed speed auto-adjust. That makes initial setup faster and reduces the learning curve.

Flux-core (Gasless MIG) mode — how it performs for you

You’ll find the flux-core MIG mode is the selling point for outdoor and quick repairs. Using flux-cored wire means you don’t need a gas cylinder, which simplifies setup and reduces the gear you carry to a job.

- Wire sizes included: 0.8 mm and 1.0 mm options are supported, with a 0.030″ (0.8mm) spool included.

- Materials: Works well for carbon steel and some stainless applications when using the appropriate flux-cored wires.

- Use cases: Sheet-metal repairs, fence fixes, farm equipment, and other on-site jobs where bringing shielding gas would be inconvenient.

This mode is forgiving for beginners because the flux core provides its own shielding and helps maintain arc stability in outdoor conditions.

MMA/Stick mode — useful details for your stick welding

When you switch to stick mode, you get an output capable of handling rods from 1.6 mm up to 4.0 mm. This gives you flexibility to work with different electrodes for varying penetration and joint thickness.

- Hot arc start: Helps you start quickly even on rustier surfaces.

- Anti-stick feature: Prevents the electrode from adhering to the workpiece as easily, saving electrodes and frustration.

- Welding surface: Expect a solid weld pool when you set parameters appropriately.

Stick welding is especially helpful for outdoor, dirty, or rusty surfaces and when you need deeper penetration on thicker materials.

Lift TIG mode — what you need to know

The machine offers lift TIG functionality, meaning it supports TIG welding using a lift-start method. However, no TIG torch is included, so you’ll need to buy that separately before you can TIG weld.

- Lift start: You’ll start the arc by touching the tungsten to the work and lifting, which is a simpler TIG start method for many users.

- Torch not included: Plan for the extra cost of a TIG torch and consumables if you want to use TIG.

- TIG capability: Useful for finer welds on thinner materials once you equip the torch and learn TIG technique.

If you want TIG welding regularly, invest in a quality TIG torch and practice the lift-start technique to get good results.

Synergic control and user interface — ease of use for you

One of the features aimed at simplifying welding is the synergic control system. Instead of adjusting wire feed speed and voltage separately, you set the current with a knob and the machine matches wire feed speed accordingly.

- Easy adjustments: Reduces the trial-and-error phase when setting parameters.

- Beginner-friendly: Makes learning MIG welding less intimidating because fewer settings are required.

- Quick setup: Saves time when switching between wire sizes or material thicknesses.

You’ll still need to match wire size and polarity correctly, but this control approach streamlines everyday adjustments.

Power and electrical requirements — running the machine safely

This unit supports dual-voltage input (110V and 220V), which gives you flexibility depending on what outlets you have available.

- 110V use: Great for household outlets and convenience, but expect lower performance on very thick materials.

- 220V use: Better for higher amperage work and thicker metals, making full use of the 200A capability.

- Plug requirements: Check the plug type and circuit capacity where you plan to operate. For heavy welding at 220V, ensure you have a compatible outlet and breaker.

Using the correct voltage is important for optimal weld quality and for avoiding electrical issues.

Performance expectations and real-world limits

The machine’s 200A output is solid for a compact combo unit and suits many hobbyist and light-professional jobs. You should keep realistic expectations about duty cycle and continuous heavy use.

- Best for intermittent work: Ideal for repairs, hobby projects, and small fabrication tasks.

- Duty cycle: The manufacturer doesn’t specify a detailed duty cycle in the provided info, so expect typical inverter-combo limitations—continuous heavy welds will require breaks to prevent overheating.

- Material thickness: With 200A, you can handle medium-thickness steel well, but for very thick structural work or production environments, a dedicated heavy-duty machine would be preferable.

If you need continuous production welding, confirm duty cycle details with the seller or manual before committing.

Setup and first-time use — what you’ll do when you unbox it

Getting started is straightforward if you follow basic steps and safety precautions. You’ll need to install the spool, feed the wire, set polarity, and verify connections before striking your first arc.

- Spool installation: The machine supports 0.8 mm and 1.0 mm flux-core wire; load the included spool and route the wire through the feeder.

- Polarity and connections: Set polarity according to the wire and electrode. Check connections for tightness.

- Test welds: Use scrap metal to dial in heat and travel speed before welding your actual piece.

Following these steps reduces mess and helps you avoid common beginner mistakes.

Portability and build quality — how easy it is to move and maintain

The unit is generally designed for home and portable use, making it easy to move around a shop or take out to a job. You’ll appreciate a compact footprint when storage space is limited.

- Carrying: Compact form factor makes it suitable for garage-based users and occasional outdoor work.

- Construction: Typical for machines in this class—solid enough for hobbyists but treat it well to extend life.

- Environmental considerations: Avoid operating in heavy rain or damp conditions; keep ventilation clear to prevent overheating.

For heavy daily use in a professional shop, evaluate build robustness and consider a commercial-grade unit if necessary.

Consumables and replacements you should stock

To keep welding without interruptions, it’s smart to keep extra consumables and replacement parts on hand. Flux-core welding, stick electrodes, and basic parts wear with use.

Recommended extras:

- Additional flux-cored wire spools (0.8mm and 1.0mm)

- Contact tips and nozzles for the MIG torch

- Extra stick electrodes in the sizes you use most (1.6mm–4.0mm)

- Tungsten and a TIG torch if you plan to TIG weld

- Replacement parts such as drive rollers and consumable kits

Having these on hand will save time and let you finish jobs without waiting for deliveries.

Safety considerations for you to follow

Safety is critical with any welding setup. Use proper protective gear and safe workspace practices to protect yourself and others.

Key safety items:

- Wear a proper welding helmet with the right shade for the process.

- Use flame-resistant clothing, gloves, and closed-toe shoes.

- Ensure good ventilation, especially with flux-core welding, which produces more smoke.

- Keep a fire extinguisher nearby and clear flammable materials from the area.

- Always ground the machine properly and check electrical connections.

Being cautious prevents injury and keeps your workspace functional.

Troubleshooting common issues and fixes

You’ll likely run into a few common problems as you learn the machine. Many are easy to fix once you know what to check.

- Wire feeding problems: Check drive roller tension and alignment; ensure the wire spool rotates freely and the liner is clear.

- Poor weld penetration: Increase current or switch to 220V for heavier materials; check tip size and travel speed.

- Spatter and porosity: Clean the base metal; adjust travel speed and polarity; ensure you’re using the correct flux-core wire type.

- Electrodes sticking: Use the anti-stick feature and double-check amperage and electrode type for compatibility.

If persistent issues continue, consult the manual or contact support for guidance.

Maintenance tips to keep it reliable

Regular maintenance extends the life of your welder and improves reliability. Keep things clean and check wear items frequently.

- Clean the machine exterior and ventilation ports to prevent overheating.

- Replace contact tips and nozzles as they wear to maintain arc quality.

- Inspect cables and connections regularly for damage or loose fittings.

- Store the machine and consumables in a dry place to prevent rust and contamination.

A little maintenance goes a long way in preventing downtime.

Accessories you might want to buy

To get the most out of the Lift TIG mode and to expand your MIG capabilities, consider some accessory purchases.

Useful accessories:

- TIG torch and consumables (if you want to TIG weld)

- Extra MIG torches or a longer lead for remote work

- Spare spools of flux-core wire in different chemistries

- Welding cart for mobility and storage

- High-quality welding helmet with auto-darkening feature

Investing in the right accessories makes the machine more versatile and enjoyable to use.

Who should buy this machine — is it for you?

This machine is a strong option if you’re a hobbyist, DIYer, or small-shop owner who needs a single unit for varied tasks. It’s particularly attractive if you want to avoid the complexity of gas cylinders when working outside.

You’ll like it if:

- You want a single, budget-friendly machine that does MIG, stick, and enables TIG after adding a torch.

- You do intermittent welding rather than continuous, high-volume production.

- You need portability and the convenience of gasless MIG for outdoor or remote jobs.

If your work is high-production or requires specialized capabilities like aluminum MIG welding without a spool gun, you may need a more specialized setup.

Who should not buy this machine

There are also situations where this combo might not be the best choice for you.

Avoid this machine if:

- You need continuous, heavy-duty welding for production shop work.

- You plan to weld large amounts of aluminum without purchasing a proper spool gun and gas setup.

- You require a precise, gas-shielded TIG experience out of the box (the TIG torch isn’t included).

For industrial, high-duty-cycle requirements, look at commercial-grade machines that specify duty cycle and industrial reliability.

Comparison: combo vs dedicated machines — what matters to you

Choosing a combo machine like this is a trade-off between versatility and specialization. You’ll save space and cost, but you’ll give up some single-function performance.

- Combo benefits: Lower overall cost, fewer machines to manage, good for mixed hobby and repair work.

- Dedicated machine benefits: Better duty cycle, refined controls, and often better long-term performance for a single welding type.

If your workload requires frequent switching and diverse tasks, a combo will likely serve you well. If you primarily do one type of welding at scale, a dedicated machine is the smarter investment.

Real-world tips to get better welds quickly

Once you have the machine set up, there are practical tips you can use to improve weld quality and reduce frustration.

- Practice on scrap before welding your project to set heat and travel speed.

- Clean the joint and remove paint, rust, or oil for fewer defects.

- Use the knob control to start conservative and increase current in small steps.

- Keep a consistent travel speed and angle—mechanical consistency matters more than exact numbers for many beginner-level welds.

These simple habits will give your welds a more professional look sooner.

Cost considerations and value

You’re getting multiple welding capabilities in a single package, which is cost-effective if you need versatility. Account for the initial outlay plus extra costs for consumables and a TIG torch if needed.

- Initial value: Good for users who want MIG and stick capability without separate machines.

- Ongoing costs: Flux-core wire and electrodes are consumables; budget for replacements.

- TIG upgrade: Add the cost of a TIG torch and consumables if you need true TIG capability.

When you add up the convenience of one machine versus buying separate units, the combo often wins for home users.

Frequently asked questions you might have

You’ll probably think of a few common questions when shopping—here are concise answers to typical concerns.

- Q: Does it come with a TIG torch? A: No. The lift TIG function requires a separately purchased TIG torch.

- Q: Can it weld aluminum? A: Flux-core gasless MIG is not suitable for aluminum. Welding aluminum typically requires a spool gun and shielding gas; check compatibility before attempting.

- Q: Is it good for outdoor use? A: Yes, the gasless flux-core mode is especially suited to outdoor conditions where shielding gas would be impractical.

- Q: Are replacement parts easy to find? A: Contact tips, nozzles, wire, and electrodes are common consumables and should be readily available; specific spare parts from the manufacturer may take longer.

If you have other questions, check the detailed manual or seller information to confirm specific technical details.

Final thoughts and recommendation

You’ll get a flexible, user-friendly machine that’s especially appealing if you want to handle a range of tasks without buying multiple welders. The synergic control simplifies MIG setup, the stick mode is robust for rough outdoor jobs, and lift TIG gives you the option to add precision welding later. Keep in mind the TIG torch is not included and continuous heavy industrial welding may push you toward a more specialized unit. For hobbyists, DIYers, and small-shop owners who value versatility and portability, this combo machine is a solid value and practical choice.

If you want, I can help you create a short checklist for the first-time setup, recommend consumables to buy next, or suggest TIG torches that are compatible with lift-start systems. Which would you like next?

Disclosure: As an Amazon Associate, I earn from qualifying purchases.