Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a compact welding machine that can handle MIG, MMA, and TIG tasks without breaking the bank?

Overview of the HYQNG Portable MIG Welder, 3 in 1 Combo MMA/MIG/LIFT TIG Welding Machine, Flux Core Welder, MIG-520 Welder Machine, mig welding equipment

You’re reading about a 3-in-1 welding machine that promises versatility by combining MIG, MMA (stick), and Lift TIG functions into one portable unit. This model aims to be a good fit whether you’re a hobbyist, a small shop owner, or someone who needs a flexible machine for repairs and light fabrication.

Why this model might matter to you

If you need one machine that covers multiple welding processes, you’ll appreciate avoiding the cost and storage of separate welders. The HYQNG Portable MIG Welder gives you the option to weld with shielding gas for stainless and gasless for iron, which increases your range of applications.

Key features at a glance

You should know the major selling points so you can decide quickly whether it meets your needs. The main features include selectable MIG flux-cored or solid wire, MMA mode for stick welding, Lift TIG capability, and a compact design intended for portability.

Important functional highlights

You can switch between gas and gasless MIG depending on the metal and job setup, which makes your workflow more flexible. It’s marketed as beginner-friendly while retaining enough control to satisfy experienced welders doing light industrial tasks.

Technical specifications (quick reference table)

Below is a table that breaks down core specs so you can quickly scan what the machine offers. Use this table to compare with other welders or to confirm it meets the electrical and performance requirements of your workspace.

| Specification | Detail |

|---|---|

| Product Name | HYQNG Portable MIG Welder, 3 in 1 Combo MMA/MIG/LIFT TIG Welding Machine, Flux Core Welder, MIG-520 Welder Machine, mig welding equipment |

| Welding Modes | MIG (gas/gasless), MMA (stick), Lift TIG |

| Wire Compatibility | Solid wire (with gas), Flux-cored wire (gasless) |

| Materials | Suitable for stainless steel and iron |

| Intended Use | Hobbyists, small shops, light fabrication, repair |

| Controls | Adjustable current and voltage settings (model dependent) |

| Portability | Compact and portable design with carry handle |

| Ease of Use | Marketed as easy to operate for beginners and professionals |

| Power Source | Typical input: household/220V variants (check specific model) |

| Accessories Included | Often includes torch, ground clamp, electrode holder, and regulator (verify package contents) |

| Weight | Varies by configuration; designed to be portable |

| Safety Features | Standard protections (thermal overload, short-circuit protection may be present) |

| Special Notes | Gas for stainless welding; gas optional for iron when using flux core wire |

What’s included and packaging

You’ll usually receive the welding machine itself plus the common accessories needed to start basic welding. Typical packages include a MIG torch, electrode holder for MMA, lift TIG torch or TIG adapter, ground clamp, consumable parts, and sometimes a regulator for gas welding.

Things to verify in the box

Before you start, make sure you have the correct torch connectors, a working ground clamp, and the right plug for your outlet if the unit isn’t universal. Also confirm whether shielding gas and welding wire are included or if you must supply them separately.

Setup and first-use checklist

You want a smooth first run, so follow a checklist: confirm correct power supply, inspect cables and connections, set the wire type and feeder, attach gas if you’ll MIG with shielding gas, and test on scrap metal. Taking a few moments for setup saves time and prevents mistakes that could damage the machine or cause poor welds.

Step-by-step basics for initial setup

Connect the unit to the appropriate voltage outlet, install the wire spool and route the wire through the feeder, adjust polarity if needed for wire type, set initial current and voltage based on wire diameter and material, and if using gas, attach the regulator and hose to a properly secured cylinder. Your first welds should be short tacks on scrap to dial in settings and ensure the arc behavior is stable.

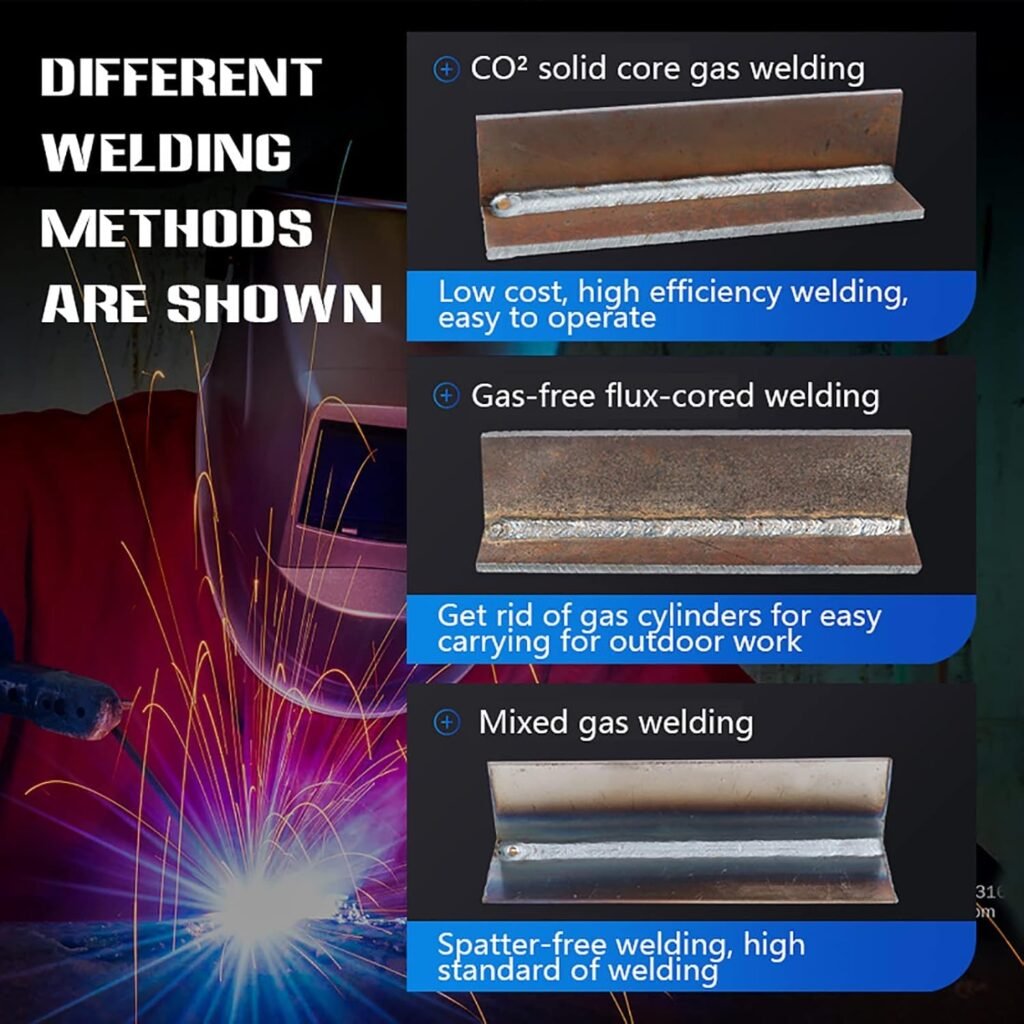

MIG welding performance

When you use MIG mode you can choose solid wire with gas for cleaner stainless welds or flux-cored wire for gasless iron welding. For thinner materials and aesthetic stainless welds, gas-shielded solid wire provides the best control and reduced spatter, while flux-cored wire is convenient outdoors and for thicker, dirty metal where shielding might be compromised.

How the MIG mode handles different materials

You’ll find that with the appropriate wire and gas, you can weld stainless steel effectively by maintaining clean joints and correct shielding gas choice (commonly argon or argon blends). For iron and mild steel, flux-cored gasless welding is handy because you don’t need to carry or set up a gas cylinder, though you may tolerate more spatter and clean-up.

MMA (Stick) welding performance

MMA mode gives you the flexibility to weld outdoors, on rusty or painted surfaces, and in locations where gas or wire feed isn’t practical. Stick welding is forgiving on poor surface conditions and is a great backup mode when the job calls for robust, quick repairs.

Use cases where MMA shines

If you’re repairing heavy equipment, working on farm gear, or welding in windy environments, MMA will help you get solid penetration where MIG might struggle. Make sure you have the appropriate electrode size and current settings for the rod type and thickness you’re welding.

Lift TIG capability and limitations

Lift TIG is useful for TIG-style welding without requiring a full HF start; you lift the torch to touch and then slowly increase current to strike the arc. This makes TIG welding of thin stainless steel achievable with a single machine, though Lift TIG on combo units is usually not as refined as on dedicated TIG machines.

Practical expectations for the TIG function

You can perform precise welds on thinner stainless with careful control, but if you need advanced TIG features like AC for aluminum or pulse TIG for fine control, you may find this unit limited. For light stainlesswork and occasional TIG use, the Lift TIG capability is quite practical and adds valuable versatility.

Gas vs gasless welding: which should you choose?

You’ll choose gas-shielded MIG for cleaner stainless steel welds and gasless flux-cored MIG for iron or outdoor work where wind or portability makes gas impractical. Gas welding produces less spatter, cleaner seams, and better overall cosmetic results, while gasless offers convenience and fewer setup requirements.

Making the right selection for your project

For workshop fabrication and stainless projects, invest in shielding gas and the required regulator and hoses to maximize weld quality. For maintenance, fieldwork, or jobs where speed and portability are key, flux-cored gasless welds are a sensible choice.

Wire selection and feeding behavior

The machine lets you select between solid and flux-cored wire, and proper feeding setup is critical to consistent welds. You’ll need to match wire diameter, polarity, and feed tension to the material and job to avoid bird-nesting, burnback, or uneven deposition.

Tips for consistent wire feed

Use the correct drive roller type for wire diameter, set the feed tension so the wire moves smoothly without slipping, and keep the liner clean and straight to prevent snags. If you experience inconsistent feeding, check for kinks in the wire spool, worn drive rollers, or a dirty liner.

Power, duty cycle, and electrical considerations

You should verify whether your model requires a 110/120V household outlet or a 220/240V supply, because this affects portability and where you can run the machine. Duty cycle determines how long you can weld before the machine needs to cool; for light fabrication and hobby use, moderate duty cycles are usually adequate, but repetitive heavy use may overtax smaller combo units.

What to watch for in power requirements

If you work primarily in a home garage, ensure the welder’s voltage and plug match your outlet to avoid using unsuitable adapters. For longer weld periods, pay attention to duty cycle charts in the manual so you can plan pauses to prevent overheating.

Controls, display, and ease of use

You’ll find basic knobs and switches to control current, voltage, and possibly wire speed, with some models offering digital displays for more precise adjustments. The design aims to keep things simple so beginners can start quickly while still allowing experienced users to fine-tune settings.

User interface and adjustability tips

Start with manufacturer-recommended settings for material thickness and wire diameter, then adjust incrementally while tacking on scrap to find the sweet spot for bead shape and penetration. Clear labeling and a logical layout make the control panel easier to learn when you’re new to multi-process machines.

Portability, weight, and build quality

This HYQNG model is advertised as portable, with a compact form factor and carry handle, which helps if you move between job sites or need versatile storage. Build quality on portable combo machines is often a balance between weight and ruggedness, and you should inspect welding torches and connectors for durable construction.

How portability affects your workflow

If you do a lot of mobile repair or need a welder in different parts of a shop, you’ll appreciate a lighter unit you can carry easily. However, remember that lighter often means less thermal mass and potentially lower sustained duty cycles, so plan breaks during heavy use.

Safety features and recommended practices

You must follow standard welding safety practices: use a welding helmet with appropriate shade, wear flame-resistant clothing, gloves, and eye protection, and ensure adequate ventilation for fumes. The machine may include overload protection and short-circuit safeguards, but these don’t replace safe operation and proper setup.

Fume control and workspace safety

When you weld stainless steel or flux-cored wires, fumes can be hazardous, so local exhaust or respirators are recommended for prolonged work. Keep flammable materials away from your weld area and inspect cables and connectors for damage before each session to prevent electrical hazards.

Maintenance and consumables

Regular maintenance will keep the machine reliable: clean the wire feed path, check drive rollers and contact tips, replace consumables as they wear, and inspect the torch liner and cables. Proper storage and occasional inspection of internal components (if you’re qualified) will extend lifespan and performance.

Routine tasks to keep the machine healthy

Wipe down the unit after heavy use, remove spatter from nozzle and tip, and ensure the ventilation openings are unobstructed to avoid overheating. Replace worn contact tips, nozzles, and liners promptly to maintain weld quality and prevent feeding issues.

Troubleshooting common issues

If you experience erratic wire feed, check the spool tension, drive roller condition, and liner cleanliness; for inconsistent arc or porosity, examine shielding gas flow or switch wire type and polarity. When TIG mode won’t strike, verify that the Lift TIG connections are correct and that the torch and ground are making proper contact.

Steps for diagnosing performance problems

Start with the basics: verify power input, check ground clamp contact, inspect consumables for wear, and test with scrap to isolate whether the issue is consumable-related or machine-related. If electrical faults persist, consult a qualified technician rather than attempting internal repairs if you’re not trained.

Accessories and add-ons worth considering

You’ll likely want spare contact tips, extra nozzles, a selection of wire diameters and types, different electrode rods for MMA, and possibly a dedicated TIG torch if you plan frequent TIG work. If your model didn’t include a gas regulator, you’ll need to purchase one for gas-shielded MIG or TIG welding.

Helpful accessories for improved results

Invest in a quality gas regulator with flow meter, a reliable welding helmet with auto-darkening lens, and a wire spool rack or storage to keep consumables organized. A welding cart can also make portable use more convenient by keeping gas cylinders and accessories together.

Comparisons with similar 3-in-1 machines

When you compare the HYQNG MIG-520 to other combo units, consider duty cycle, build quality, included accessories, and whether the Lift TIG function meets your TIG needs. Some other brands may offer more advanced TIG features or higher duty cycles, but this model aims to balance cost and versatility.

How to pick between combo welders

Focus on your primary use cases: if most of your work is TIG on delicate stainless, a dedicated TIG or a high-end combo with AC capabilities might be better. If you need a general-purpose machine for MIG and stick with occasional TIG, the HYQNG model is a compelling value proposition.

Practical project examples you can do with this machine

You can handle repair work on farm equipment, motorcycle frames, small stainless projects, home metal furniture, and light fabrication tasks. You’ll find that flux-cored MIG is convenient for quick structural repairs, while gas-shielded MIG and Lift TIG let you do cleaner stainless joints.

Real-world scenarios to try

Try building a small steel table using flux-cored MIG for the frame, then practice stainless TIG on a decorative trim piece to appreciate the machine’s range. Use MMA mode for farm or outdoor repairs where gas setups would be impractical.

Pros and cons summary

You should weigh the strengths—portability, multi-process capability, and budget-friendly price—against limitations like potential duty cycle constraints and less advanced TIG features. This balanced view helps you set realistic expectations and match the machine to the right tasks.

Quick pros and cons list

Pros: versatile 3-in-1 functions, gasless flux-core option, suitable for beginners and pros, portable design. Cons: Lift TIG not as advanced as dedicated TIG units, potentially limited duty cycle for heavy industrial use, possible need to buy gas/regulator and spare consumables separately.

Who should consider buying this unit

You should consider this machine if you want a single compact welder to handle a variety of tasks around a shop or home and you appreciate the convenience of switching between MIG, MMA, and Lift TIG. It’s also a good choice if you work in different locations and need something portable that still covers the major welding processes.

Who should look elsewhere

If your work is heavy production, requires long continuous welds, or needs advanced TIG capabilities (AC for aluminum or high-end pulse functions), you should consider a dedicated, higher-duty-cycle machine. Professionals with specialized requirements may prefer separate machines tuned to each process.

Value for money and long-term ownership

You’ll likely find the HYQNG Portable MIG Welder provides strong value for occasional to moderate welding needs because it reduces the need to buy multiple machines. Long-term ownership depends on maintenance, how intensively you use it, and whether you invest in high-quality consumables and accessories.

Cost-saving considerations

Buying this combo machine saves space and initial purchase cost, but budget for replacement consumables and possibly additional accessories like a regulator or extra torches. If you plan to grow into more demanding work, consider whether upgrading later will be cost-effective.

Final verdict

You can rely on the HYQNG Portable MIG Welder, 3 in 1 Combo MMA/MIG/LIFT TIG Welding Machine, Flux Core Welder, MIG-520 Welder Machine, mig welding equipment for versatility and portability at an accessible price, especially if your projects are light to moderate in scope. It’s a sensible choice if you want one machine to handle gas and gasless MIG, stick welding, and occasional Lift TIG on stainless and iron.

Bottom line recommendation

If you want flexibility in a compact package for home, small shop, or field repairs, this machine is worth serious consideration. For specialty industrial work or high-duty TIG needs, you should weigh dedicated machines against the convenience of a combo unit.

Frequently asked questions (short answers)

You’ll likely have a few questions before buying; here are clear answers to common concerns so you can feel confident about how this unit will fit your needs. These FAQs cover basics like gas requirements, wire compatibility, and maintenance.

Does this unit need gas to weld?

You don’t always need gas; you can weld iron with flux-cored wire in gasless mode. For stainless steel and cleaner MIG welds you’ll want a shielding gas such as argon or an argon/CO2 blend.

Can it TIG weld aluminum?

The Lift TIG function is not designed for AC TIG welding and therefore is not suitable for aluminum, which typically requires AC balance control. For aluminum work, you’ll need a machine with AC TIG capability.

Is it good for beginners?

Yes, you’ll find it relatively user-friendly, with simple controls that let you start quickly while offering enough control to learn. Beginners should still practice on scrap and follow safety guidance to build skill and confidence.

What maintenance does it need?

Perform regular cleaning of the wire feed path, replace worn contact tips and nozzles, and inspect cables and connectors for wear. Keep ventilation paths clear and store the unit in a dry, dust-free environment.

How portable is it?

The unit is designed to be portable and lighter than dedicated heavy-duty welders, with a carry handle for transport between jobs. Portability may come with compromises in continuous duty cycle compared to larger stationary machines.

If you want, you can tell me which specific tasks or materials you plan to weld and I’ll recommend exact settings, consumables, and accessories to get you started confidently.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.