Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a reliable Plastic Welding Kit to fix bumpers, dashboards, or household plastics yourself?

First impressions of the Allturn Plastic Welder,Plastic Welding Kit 3 in 1

You’ll notice the kit feels complete and purpose-built the moment you open the box. The red Allturn Plastic Welder looks professional and the components are laid out so you can identify tools and consumables quickly.

What’s included in the Allturn Plastic Welder kit

You’ll appreciate a clear parts list when you want to start a repair without guessing what’s missing. Below is a compact table that breaks down the core items, quantities, and what you’ll typically use each part for.

| Item | Quantity (approx.) | Purpose / Use |

|---|---|---|

| Allturn plastic welding gun (110V) | 1 | Main heating tool for melting staples and rods into thermoset plastic joints. |

| Plastic welding staples | 1000 pcs | Used as internal reinforcement for cracks and breaks in rigid plastics. |

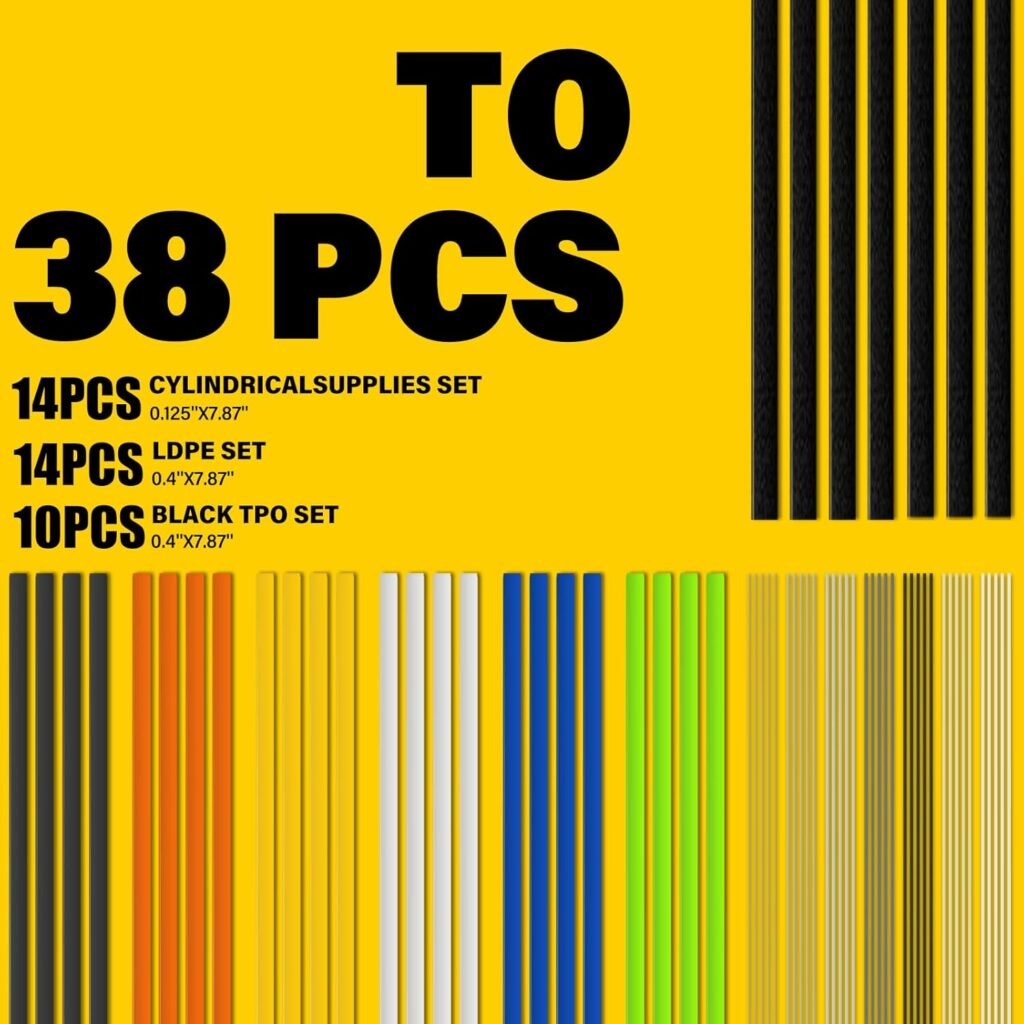

| Plastic welding rods | Assorted qty | Used to fill gaps, rebuild missing sections, and fuse repaired seams. |

| Rubber handle / ergonomic grip | Built-in | Provides comfortable hold for longer repair sessions. |

| Replacement tips/nozzles | Several | For different welding styles: spot reinforcement, rod feeding, and smoothing. |

| Instruction manual & safety info | 1 | Quick-start guidance and safety precautions for proper use. |

You’ll find this table helps you decide which parts you’ll use most and what you might run out of first. The kit focuses on practical consumables, so staples and rods are the items you’ll likely replace most often.

The kit components in more detail

You’ll get a heating gun designed for 110V outlets and a mix of welding staples and rods intended for thermoset plastics. The kit’s components are organized with repair workflow in mind: reinforcement first, then filler material, and finally finishing.

Packaging and presentation

You’ll see the product is presented in a way that suggests it’s ready for immediate use, with consumables visible and tools laid out for quick access. The red color and molded parts give the kit a distinct appearance that’s easy to spot in a workshop.

Key features and specifications

You’ll want to know what technically sets this kit apart before committing to a purchase. The main headline features include a 110V power rating, patented appearance, internal overheating protection, and a 3-in-1 approach to plastic welding.

Power and performance

You’ll plug the welder into a standard 110V outlet, giving you sufficient heat for most thermoset plastics typically found in car bumpers, lamp holders, and household items. The heat output is tuned for rapid heating so you can get repairs done faster, but you should still practice on scraps to find the right temperature for each plastic type.

Versatility and materials supported

You’ll be able to use this kit on many thermoset plastics—common automotive and household plastics that respond to staple reinforcement and rod bonding. Keep in mind that thermoplastics and some composite plastics can behave differently, so double-check material compatibility before major repairs.

Durability and repair strength

You’ll restore broken parts so they can handle shock and twisting loads better than a simple glue repair. The combination of internal staple reinforcement and surface rod filling produces a mechanical bond that often outperforms adhesive-only fixes, helping extend the part’s service life.

Ergonomics and ease of use

You’ll appreciate the rubber handle and ergonomic design if you’re working on repairs that take time or awkward positions. The tool is designed for quick and straightforward operation, so you can learn effective techniques without formal training.

Safety features and patented design

You’ll benefit from built-in overheating protection that shuts down the unit if internal temperatures become too high, and it will restart when the device cools. The kit also carries a patented appearance (Patent Number D970324), meaning its design is unique and offers recognizable styling.

How to use the Allturn Plastic Welder

You’ll get better results when you follow a step-by-step approach instead of improvising. Below are practical steps that take you from assessment to final finish.

Preparing the broken parts

You’ll start by cleaning the area thoroughly with isopropyl alcohol or a similar solvent to remove grease and dirt. Then you’ll sand or roughen the surface around the break so staples and welding rods have better mechanical adhesion, and clamp the pieces in alignment before you begin reinforcement.

Setting up the welder

You’ll plug in the welder to a stable 110V outlet and allow it to warm up according to the instructions; warm-up times can vary but are typically a few minutes. Choose the appropriate nozzle or tip for the application, and have the staples and rods ready in order of use so you can work efficiently.

Welding techniques and best practices

You’ll start by inserting staples across the crack on the inside of the broken piece for structural reinforcement; these staples are melted into place by the heated tip. Then you’ll feed welding rod or melted plastic across the seam to bond and fill gaps, feathering out edges for a smoother finish. Work in small sections, allow each to cool briefly, and avoid overheating to prevent material degradation.

Finishing and cleanup

You’ll trim excess filler material with a utility knife or sand it down to shape once the repair has fully cooled and solidified. Finish with progressively finer sandpaper for a smooth surface, then paint if cosmetic matching is required. Dispose of scrap and used consumables responsibly.

Pros and cons of the kit

You’ll want to balance the positives and negatives before deciding if this is the right kit for your toolbox. Below I summarize the areas where it shines and where you might expect limitations.

Pros

You’ll find the kit to be highly practical for common automotive and household plastic repairs. The internal overheating protection improves safety, the ergonomic handle makes longer sessions more comfortable, and the 3-in-1 approach (staples, rods, and welding gun) gives you a full repair system in one purchase. The kit’s ability to reinforce and rebuild plastic parts makes it more robust than adhesive-only solutions, and the included staples (1000 pcs) are a generous supply for many repairs.

Cons

You’ll need to be cautious about material compatibility; not all plastics will weld effectively with this method. You’ll also find that mastering technique takes a few practice repairs, so expect some trial and error. If you need a kit for professional high-volume use, you might prefer a more industrial-grade welder with variable temperature control and higher duty cycles.

Comparison with similar products

You’ll likely compare this kit to compact plastic welding guns, spot welders, and adhesive-based repair systems. Understanding the differences will help you choose the best tool for your needs.

What makes the Allturn stand out

You’ll notice the integrated safety shutdown and the complete consumable package as key advantages, along with an ergonomic grip that makes longer repair jobs less tiring. The patented design and the large staple count mean you’re getting a ready-to-use solution for many household and automotive tasks.

When you might choose something else

You’ll consider a different product if you need adjustable temperature control for delicate plastics, or if you require a 220V model for faster heating in industrial environments. You’ll also pick a different system if you rarely work on plastics and prefer a one-off adhesive fix rather than investing in welding tools and consumables.

Maintenance and care

You’ll keep the welder functioning reliably through a few basic maintenance steps. Regularly inspect tips and nozzles for wear, clean them after each use to prevent buildup, and store the kit in a dry area away from excessive humidity or dust.

You’ll also watch for frayed cords or loose connections, and if the overheating protection trips frequently, let the unit cool fully and check for blocked vents or accumulation of debris. Always follow the manual for recommended cleaning methods and replacement parts.

Real-world use cases and applications

You’ll find plenty of occasions to use this kit, from automotive repairs to household DIY fixes. Below are common scenarios where the Allturn kit provides value.

Automotive repairs

You’ll repair cracked bumpers, broken mounting tabs, and interior plastic trims using staple reinforcement and rod rebuilding. For many minor to moderate bumper repairs, this kit lets you avoid costly body shop visits by restoring structural integrity and appearance.

Household and DIY projects

You’ll fix lamp holders, plastic rings, garden tools, and even appliance housings that often break along stress points. The kit is handy for quick, durable repairs around the house where a glued joint would be too weak.

Professional and hobbyist use

You’ll appreciate the cost-efficiency and control if you’re a hobbyist or small shop technician who handles occasional plastic repairs. While it may not replace industrial welders in high-volume body shops, it serves well for light professional use and dedicated DIYers who want reliable results.

Buying guide and tips

You’ll make a smarter purchase when you check key details before ordering. Consider compatibility, accessories, safety features, and the amount of consumables.

What to check before buying

You’ll want to confirm that your primary repair materials are thermoset plastics compatible with staple-and-rod welding techniques. Also check your power availability (110V) and whether the kit includes enough staples and rods for your anticipated workload.

Accessories and extras you might want

You’ll consider buying additional tip sets for finer work, extra welding rods in specific colors for better cosmetic matches, and supplementary clamps to hold parts securely during repair. You’ll also appreciate replacement tips and a storage case if you plan frequent use.

Troubleshooting common problems

You’ll encounter a few predictable hiccups as you learn plastic welding; addressing them quickly helps maintain good results. Below are common issues and practical fixes.

You’ll find poor adhesion if surfaces are dirty or improperly prepared; clean and sand the area to improve bonding. You’ll notice weak bonds if you’re not using enough staple reinforcement or if you overheat and degrade the plastic; practice on scrap pieces to dial in heat and pressure.

You’ll also deal with tip clogging if melted rod material accumulates; clean tips regularly and replace worn nozzles to keep flow consistent. If the welder shuts down due to overheating protection, let it cool and reduce continuous run time or work in shorter segments.

Safety reminders you should follow

You’ll want to take standard safety precautions whenever you work with a hot tool and molten plastic. Use heat-resistant gloves, eye protection, and good ventilation to minimize fumes from heated plastics. Keep the welder away from flammable materials, and never leave it unattended while powered on.

You’ll also follow the manual’s guidance about duty cycles and cooling times to avoid triggering the overheating protection frequently, and make sure children or pets won’t come into the workspace.

Tips to get professional-looking repairs

You’ll get neater results by taking your time on prep and finish. Clamp and align parts perfectly before placing staples, use small incremental welds to avoid warping, and sand progressively from coarse to fine to blend the repair into the surrounding material.

You’ll paint or use a matching plastic filler after sanding to get a near-factory appearance, and you’ll consider practice pieces to refine your hand control before you touch a visible part.

Environmental and disposal considerations

You’ll be mindful that welding plastics can create fumes and generate scrap material. Use the kit in well-ventilated areas and consider a respirator if you work indoors for long periods. Dispose of used scraps and consumables according to local regulations for plastic waste, and avoid burning or melting scraps in open air.

Frequently Asked Questions

You’ll likely have specific questions before and after purchase. Below are common questions with brief, helpful answers.

Q: Can this kit repair any plastic? A: You’ll be able to repair many thermoset plastics commonly found in automotive and household applications. You’ll still want to test a small area because some plastics and blends don’t weld well or may require different techniques.

Q: Is the kit safe for beginners? A: You’ll find the kit designed for easy use, and the ergonomic handle plus basic instructions make it approachable for beginners. You’ll still need to practice and follow safety precautions, as the tool reaches high temperatures.

Q: How long do the staples and rods last? A: You’ll get a large starter supply—1000 staples—which will last through many small to medium repairs. You’ll likely use rods and staples at different rates depending on the size and number of projects you undertake.

Q: What is the overheating protection and why does it matter? A: You’ll benefit from internal overheating protection that automatically stops operation if internal temperatures exceed safe levels. You’ll find this feature reduces fire risk and prolongs the device’s lifespan by preventing thermal damage.

Q: Will the repaired area be as strong as new? A: You’ll often achieve structural strength suitable for normal use, especially when you combine staple reinforcement with rod filling. You’ll keep in mind that results vary with material type and repair quality, so some high-stress parts may still require replacement.

Q: Do I need special safety gear? A: You’ll want basic PPE such as heat-resistant gloves, eye protection, and good ventilation. You’ll also consider a respirator if you’re working indoors with a lot of heated plastic.

Q: Can you use this for thermoplastic repairs too? A: You’ll find the kit is optimized for thermoset plastics; thermoplastics can behave differently and sometimes respond better to other heat-based methods. You’ll test and research the specific plastic type before committing to a major repair.

Final verdict

You’ll find the Allturn Plastic Welder,Plastic Welding Kit 3 in 1,Plastic Repair Welder Kit,1000pcs Plastic Welding Staples,Plastic Welding Rods Kit,Repair for Most Thermoset Plastics (Red) to be a practical and cost-effective solution for many automotive and household plastic repairs. You’ll appreciate the combination of a well-designed heating gun, generous consumable supply, and safety features that make it approachable for both DIYers and light professional use.

You’ll still need to practice and be mindful of material compatibility, but if you want to avoid frequent part replacements or costly shop repairs, this kit gives you a powerful way to restore broken plastic parts and extend their useful life.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.