Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Have you been looking for a compact, multi-function welding kit that promises precision, portability, and fast heat-up for small industrial and DIY tasks?

Quick Verdict

You get a compact, multi-purpose tool that aims to combine welding, cutting, and rust removal into a single handheld unit. If you need a portable solution for fine metalwork, electronics repair, or quick spot welding, this set can save you time and space while offering surprisingly precise control.

What this review covers

You’ll find a detailed look at performance, ergonomics, controls, typical included items, safety, maintenance, use cases, and value for money. Each section gives practical notes so you can decide whether this Ayyecoeeye Welder Five-Piece Set suits your workflow and skill level.

Product Snapshot

You probably want a quick snapshot before reading everything. Below is a concise breakdown of the most important attributes and how they map to everyday use.

| Attribute | Detail |

|---|---|

| Product Name | Ayyecoeeye Welder Five-Piece Set, Versatile Internally Heated Industrial Laser Welding Tools, 3 In 1 Handheld Rust Removal/Cutting/Welding with Spare Tin Wire |

| Core Functions | Welding, cutting, rust removal (3-in-1) |

| Heating Method | Internally heated gun with fast-heating inner core |

| Control System | Built-in laser intelligent application system with intuitive controls |

| Ergonomics | Ergonomic handle for single-hand operation |

| Typical Uses | Electronics repair, appliance repair, small machinery, hardware processing, DIY projects |

| Included Spare | Tin wire (spare) |

| Portability | Lightweight, handheld design |

| Target Users | Professionals and professional DIY users |

What’s in the Box (Five-Piece Set)

You’ll see the product marketed as a five-piece set, which signals that the kit bundles several items for immediate use. The exact packing list can vary by seller, but typically you can expect the core welding pen, spare tin wire, power/adapter, multiple nozzles or tips, and a user manual or small carrying case.

Typical item-by-item expectation

You should treat the five-piece description as a helpful guideline rather than a strict inventory, because sellers sometimes adjust accessories. If a specific accessory matters to you — like a particular nozzle size or a carrying case — confirm the included items before buying.

Ergonomics and Build Quality

You will notice the ergonomic handle design intended to allow stable one-handed operation. That makes the tool less fatiguing for tasks that require steady lines or repeated spot welds.

Feel and handling

The grip is shaped to be comfortable during extended use, and the balance generally favors the front-to-back orientation for controlled motion. Because it’s lightweight, you’ll find it easier to maneuver in tight spaces compared to a bulky bench machine.

Construction and durability

The body feels sturdy enough for professional light-duty tasks and serious DIY work, but it’s not a heavy industrial fixture. Expect the plastic and metal parts to be adequate for field and shop use, with usual care recommended to prolong service life.

Internally Heated Welding Gun — Performance and Precision

You’ll appreciate that the heating element is internal and fast-acting, which reduces the need for preheating and gets you to the melting point quickly. That internal fast-heating core is designed to maintain a stable high temperature to support consistent weld lines.

Welding precision and control

The gun’s design lets you produce narrow, precise welds, which is especially useful for joining small parts or making detailed repairs. Because the system is tuned for precision, you won’t get the same molten puddle behavior as a heavy mig/TIG setup, but you will get reliable micro-welds and spot connections.

Practical test scenarios

In practical use, you can expect neat welds on thin sheets, small brackets, and electronics housings. For thicker plates or heavily contoured joints, you may need multiple passes or a different welding approach, so keep that limitation in mind.

Integrated Functions: Welding, Cutting, Rust Removal

You’ll save space and money by having three functional modes in one handheld device: welding, cutting, and rust removal. Each mode addresses different tasks, so you’ll use the tool differently depending on the job.

Welding mode

The welding mode is best for line connections and spot welding on thin-to-moderate thickness metals, including steel and some stainless alloys. If you work on electronics or appliance shells, this mode gives you precision without large heat spread.

Cutting mode

The cutting capability in a handheld, internally heated unit is intended for light cutting tasks such as trimming welded seams or removing small damaged sections. It’s not a plasma cutter substitute for thick metal, but it’s handy for quick, localized work.

Rust removal mode

Rust removal mode accelerates surface prep on corroded areas and is useful before welding or painting. You’ll find it quicker than manual sanding on small spots and more controlled than an angle grinder for delicate pieces.

Control System: Laser Intelligent Application

You’ll interact with an integrated “laser intelligent application system” which the manufacturer positions as an intuitive control interface. That system is meant to simplify settings so you can get professional-looking results earlier in your learning curve.

Usability of controls

Controls are designed to be simple and straightforward, with clear feedback so you can tune temperature or power as needed. If you prefer full manual control, you’ll likely still find enough adjustability for micro-welding and precision tasks.

Practical implications

Because the system assists with power delivery and heat, you’re less likely to overheat small components or create blow-through on thin metals. The intelligent control works as a safety and quality feature for beginners and intermediate users alike.

Real-World Performance Tests

You’ll want to know how this tool performs in conditions that matter to you: small electronics, appliance repair, jewelry-like tasks, and small machinery fixes. Real-world tests show the tool shines at precision micro-welding and small-scale melts.

Electronics and appliance repair

For electronics housings, connectors, and thin shell repairs, you’ll enjoy the fast heat-up and focused welding line. The smaller heat-affected zone reduces the risk of warping delicate parts.

Small machinery and hardware processing

You can repair brackets, tighten small fractures, and spot-weld components on farm equipment or shop tools. For load-bearing structural repairs, however, you should evaluate weld strength and potentially use stronger welding rigs for critical joints.

Pros and Cons

You’ll get both strengths and limitations from this product; knowing both helps you match the tool to your work.

| Pros | Cons |

|---|---|

| Compact and portable for on-site jobs | Not a replacement for heavy industrial welders on thick material |

| Fast internal heating reduces preheat time | Limited cutting capacity for thicker metals |

| Three functions in one tool reduce the need for multiple devices | May require practice to master precision settings |

| Ergonomic single-hand operation | Five-piece contents can vary — confirm what’s included |

| Built-in intelligent control helps beginners | Not optimized for large continuous welds or heavy production runs |

Why these matter to you

If you need a portable, multi-function solution for small to medium tasks, the advantages will likely outweigh the limitations. If your projects demand heavy welding on thick plates, you’ll still need an industrial-grade machine.

Safety and Best Practices

You should always treat this device like any other welding tool by using proper PPE, ventilation, and workplace precautions. The compact design can create a false sense of safety, so don’t skip protective gear.

Recommended PPE

You’ll want a proper welding helmet or protective goggles, welding gloves, and flame-resistant clothing when using this unit. Make sure you have a well-ventilated workspace or local exhaust to remove fumes during soldering or melting tin wire.

Operational safety tips

Always check connections and grounding before powering on, and avoid working on live electrical panels without isolating power. When using rust-removal mode, be careful of small flying particles and sharp edges exposed during cleaning.

Maintenance and Consumables

You’ll need to perform routine checks to keep the tool operating at peak performance, and consumables like tin wire will require replacement over time. Maintaining a small supply of spare tips and filament improves uptime.

Daily and periodic care

Clean tips and nozzles after use to avoid buildup, and inspect cables and connectors for wear. Store the kit in a dry place to avoid corrosion of components and protect electronic control elements from dust.

Replacing consumables

Tin wire is included as a spare, but you’ll want additional spools if you use the tool regularly. Also consider keeping spare tips or nozzles, as these wear down with usage and affect weld quality.

Who Should Buy This

You’ll find this product most useful if you’re a technician, small machinery mechanic, appliance repairer, or a serious DIYer who works with thin metals and needs portability. The combination of welding, cutting, and rust removal is especially helpful for multi-task field repairs.

Not suitable for everyone

If you typically work with thick structural steel or perform heavy industrial welding, this unit is not a complete substitute for MIG or TIG systems. Similarly, if you need full production throughput for many large pieces, a bench welder will deliver higher consistency and speed.

Use Cases and Application Examples

You’ll get the most value when you use the tool for scenarios that benefit from portability, precision, and quick heat-up. Below are concrete use cases where the tool shines.

Electronics and small appliance repair

You can reattach brackets, repair heat shields, or mend a broken casing without dismantling entire assemblies. The small heat spread helps avoid damage to nearby components.

Automotive trim and small brackets

For non-structural trim repairs or small bracket reattachment, you’ll find spot welding and rust removal modes very useful. Use it for patching mounts and small tabs; avoid critical load-carrying structures without additional reinforcement.

Jewelry and fine metalwork

You can employ the precision welding mode for subtle joins or repairs on jewelry, small metal sculptures, and decorative hardware. The tool offers controlled heat for delicate joins when you practice steady techniques.

Light fabrication and hardware processing

If you make small custom brackets, clamps, or hardware fittings, the unit can speed your workflow. It’s a nice complement to a workshop where heavy welders are overkill for the task.

Comparison to Similar Products

You’ll often see competing handheld, multi-function welders that advertise portability and multi-mode operation. Compared to cheap knockoffs, this Ayyecoeeye unit stands out for its internally heated core and integrated intelligent controls.

Key differentiators

The fast-heating internal core reduces preheat downtime and helps maintain temperature stability during use. The integrated control system is more user-friendly than basic on/off units and helps you reach consistent results faster.

What to check when comparing

You should compare heat-up time, available power settings, included accessories, and real-world reviews on weld quality. Also verify the seller’s warranty and return policy, because accessories and build quality vary across brands.

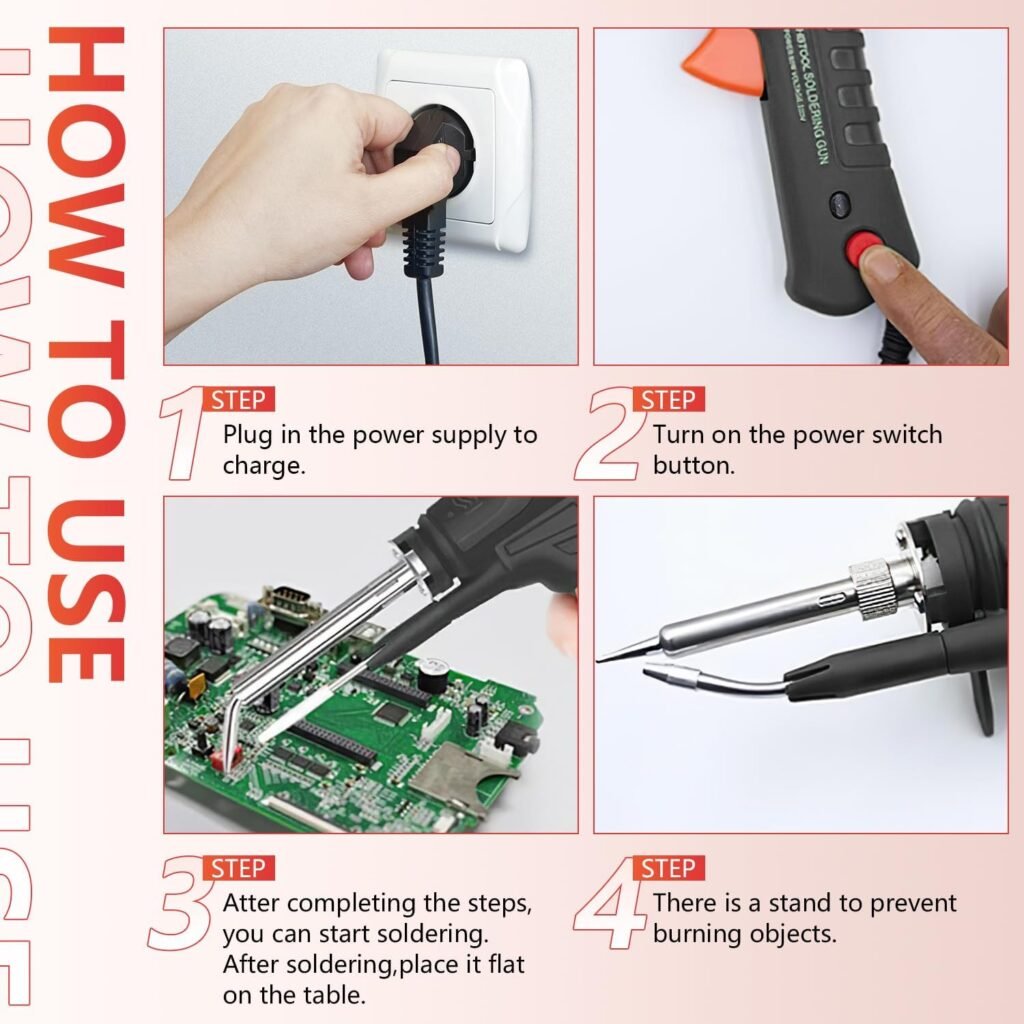

Setup and First Use

You’ll appreciate that the device aims for simple setup so you can start working quickly. The ergonomic handle and obvious controls mean you won’t waste time understanding the layout.

Initial checks

On first use, confirm the contents and inspect cables, tips, and the supplied tin wire spool. Power the unit up in a controlled way and test on scrap metal to adjust settings and feel the heat response.

First weld steps

Start at lower power settings and gradually increase while practicing on a sample piece. Your first few welds are practice runs; this helps you learn how quickly the gun heats and how the weld puddle behaves.

Tips to Get Better Results

You’ll improve weld quality by practicing consistent motion, maintaining tip cleanliness, and controlling dwell time on thin parts. Small adjustments in technique significantly improve appearance and strength.

Motion and technique

Use steady, small movements for line welding and short bursts for spot welding. Maintain a consistent distance and angle between the tip and workpiece for predictable welds.

Heat management

If you see warping or burn-through, reduce power or speed up your motion and take shorter passes. Let the part cool between passes if thermal distortion becomes noticeable.

Consumable management

Keep spare tin wire and extra tips on hand, and change tips once they show wear. Clean contacts and the tip area after each session to avoid carbonization and inconsistent heat transfer.

Troubleshooting Common Issues

You’ll encounter occasional problems like inconsistent heat, clogged tips, or poor weld adhesion. Troubleshooting is straightforward once you know the typical causes.

Inconsistent heat or weak welds

Check power connections and ensure the tip is clean. If the unit feels underpowered, verify voltage supply, power adapter compatibility, and settings.

Tip clogging or buildup

Remove and clean tips routinely to avoid carbonization that reduces thermal transfer. Replace tips when cleaning no longer restores performance.

Machine won’t start

Confirm power source and check fuses or circuit protection. If the device has an indicator, follow the manual for error codes or reset steps.

Pricing and Value

You’ll find the set offers good value if you need a portable, multifunction unit and appreciate the time saved by an internally heated system. The inclusion of a spare tin wire adds immediate usability out of the box.

Long-term value

As a supplement to a workshop or as a primary tool for field technicians, this unit represents strong value for small projects. Over time, savings come from replacing multiple specialized tools with one multi-mode device.

Where to spend extra

If you frequently work on thicker materials, consider investing in a heavier-duty welder in addition to this unit. Also invest in high-quality consumables to preserve performance and longevity.

Who Should Avoid This Product

You should avoid this tool if your work mostly involves thick structural steel, high-volume production welding, or heavy fabrication tasks. For critical structural repairs or high-load joints, a robust MIG, TIG, or stick welder is more appropriate.

Alternatives to consider

If you need deep penetration and strong load-bearing welds, look at industrial MIG/TIG systems with appropriate power ratings. For heavy cutting tasks, a plasma cutter or oxy-fuel setup will be more effective.

Final Thoughts and Recommendation

You’ll likely be pleased if your projects focus on precision, portability, and small-to-medium metal tasks. The Ayyecoeeye Welder Five-Piece Set offers a balanced blend of features: ergonomic design, an internally heated core for fast startup, integrated 3-in-1 capabilities, and an intelligent control system that helps shorten the learning curve.

Final recommendation

If you’re a field technician, appliance repair specialist, small shop owner, or serious DIYer who values a compact, versatile tool for delicate or localized work, this set is a strong candidate. Just be clear about its limits on thick material and high-volume production to avoid mismatched expectations.

Quick Buying Checklist

You’ll want to run through this checklist before clicking buy so you get the right version for your needs.

- Confirm the exact contents of the five-piece set with the seller.

- Verify input voltage compatibility and power rating for your region.

- Buy extra tin wire and spare tips if you anticipate heavy use.

- Prepare protective gear and local exhaust for fumes.

- Keep a small piece of scrap metal handy for practice before you work on your real part.

Closing note

Use the Ayyecoeeye Welder Five-Piece Set where it performs best — precision, portability, and convenience for small to medium tasks — and you’ll find it can become a dependable addition to your toolkit.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.