Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a reliable contact tip kit for your MB15 15AK welding torch that balances cost, performance, and ease of use?

Quick Verdict

You’ll find that the EATBALE 15AK MB15 Contact Tip Kit Conical Gas Nozzle M6 Copper Contact Tip 0.9mm/0.035″ Brass Holder Diffuser for MAG MIG MB15 15AK Welding Torch Consumables Shield Cup Welder Gun Accessories (13 Pcs) is a solid, no-frills consumable package. It gives you the basic parts you need to keep a MB15/15AK torch running smoothly, with good electrical conductivity and materials built to handle routine MIG/MAG work at common current ranges.

Short Summary of Strengths and Limitations

The kit’s strengths are clear: good fit for MB15/15AK torches, high-conductivity copper contact tips, and components designed for durability in general welding tasks. Its main limitation is the specified operating current range (below 100A), which means you shouldn’t expect it to perform well on heavy industrial or high-amperage welds.

What You Get in the Box

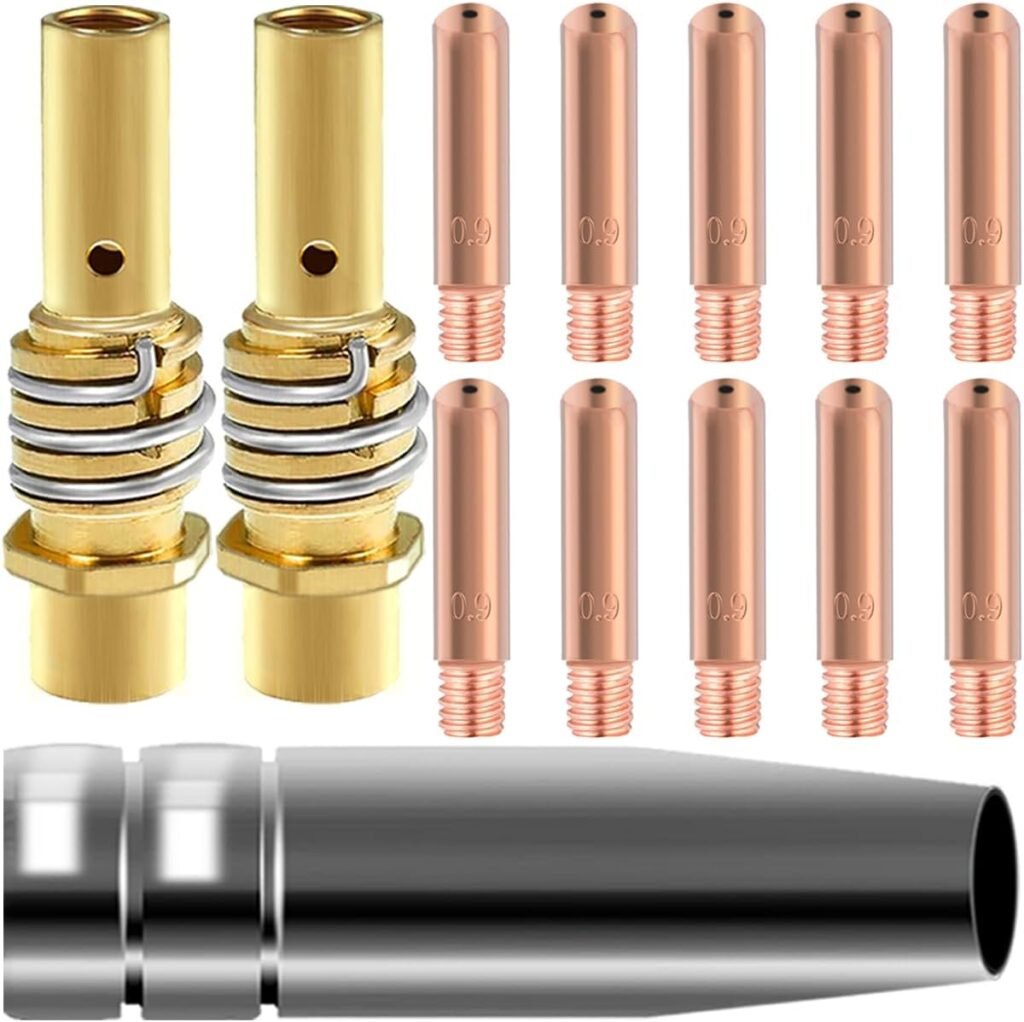

You’ll appreciate knowing exactly what arrives so you can plan your spares and workflow. The kit is straightforward: one conical gas nozzle, two gas diffusers, and ten M6 copper contact tips sized 0.9mm/0.035″.

Package Breakdown Table

Here’s a clear table that breaks down the supplied parts so you can quickly see quantities, sizes, and materials without hunting through the listing.

| Item | Quantity | Material | Size / Thread | Notes |

|---|---|---|---|---|

| Conical Gas Nozzle | 1 | Brass (or brass-plated) | Standard MB15/15AK fit | Conical shape for general shielding gas coverage |

| Gas Diffuser | 2 | Brass (diffuser design) | MB15/15AK compatible | Helps gas distribution and insulates inner components |

| Contact Tip (M6) | 10 | Copper | 0.9 mm / 0.035″ M6 thread | High-conductivity, recommended for wire diameter matching 0.9 mm feeders |

Why the Box Contents Matter

You’ll want multiple contact tips because they’re the consumable part that wears fastest due to wire feed friction and electrical arcing. The inclusion of diffusers and a nozzle means you can change everything that affects gas coverage and arc stability without scavenging parts from another torch.

Compatibility and Fit

Compatibility is crucial when you’re buying consumables, and you’ll like that this kit targets MB15/15AK torches. The M6 thread standard and conical nozzle shape are matched to common MB15-style MIG/MAG torches, so installation should be straightforward.

What This Means for Your Torch

If you already own an MB15 or 15AK torch, you’ll find these parts fit directly with minimal fuss, letting you swap worn parts quickly and get back to welding. If your torch uses a different thread or different nozzle geometry, you’ll need to double-check compatibility before purchasing.

Materials and Build Quality

You’ll notice a practical choice of materials in this kit: copper tips for electrical conductivity and brass components for the nozzle and diffuser. These materials are standard for MIG consumables because they balance conductivity, machinability, and heat tolerance.

Copper Tips: Conductivity and Wear

Copper contact tips give you the electrical conductivity needed for reliable arc transfer. You’ll still see wear on the tip bore over time, especially if you’re using abrasive wires or poor wire alignment, so the supply of ten tips is useful for routine replacement.

Brass Nozzle and Diffuser: Strength and Heat Handling

The brass nozzle and diffuser provide reasonable heat resistance and structural strength, which is appropriate for typical MIG/MAG tasks under the kit’s rated conditions. You’ll want to keep an eye on the nozzle for spatter buildup, which brass handles well but still needs cleaning.

Electrical Conductivity and Welding Performance

The contact tips’ superior electrical conductivity is a central selling point, and you’ll notice smoother arc transfer when the tip and wire match closely. Good conductivity reduces voltage drop at the contact point and creates a more stable arc.

How That Translates to Weld Quality

When electrical contact is consistent, your arc becomes steadier and your bead appearance improves with fewer burn-throughs or unstable arc events. You’ll also see better wire feeding consistency because the tip supports smooth contact and less friction at the feed point.

Heat Resistance and Durability

You’ll want consumables that tolerate repeated heat cycles without deforming or failing. This kit is designed for long-term reusability in typical MIG/MAG work, but keep the current limit in mind.

Performance Under Heat

The brass nozzle and copper tips hold up well under the moderate heat loads expected below 100A. For higher amperages or prolonged heavy welding, you’ll need to consider parts rated for higher temperatures and industrial duty.

Ease of Installation and Use

You’ll appreciate how user-friendly these parts are. Installation is typical for MB15/15AK consumables: unscrew the old nozzle and tip, replace the diffuser if needed, screw in the contact tip, and fit the nozzle back on.

No Adjustment of Welding Procedures Required

You won’t need to change welding parameters just to use this kit. The tips and nozzle are made to match torch geometry and wire sizes, so your existing settings should remain valid once you swap parts.

Welding Performance: Real-world Use

If you use this kit for common projects—sheet metal, light fabrication, frame repair, hobby automotive, or maintenance work—you’ll find it a reliable set of consumables. The 0.9 mm tip works well with 0.9 mm wire, which is a common diameter for medium-duty MIG welding.

How It Handles Different Tasks

You’ll get consistent results for general-purpose welding. For thin gauge steel, you’ll need to adjust amperage and travel speed appropriately; for thicker sections approaching the upper current limit, you might hit the practical ceiling where tip life shortens or gas coverage becomes marginal.

Current Range and Limitations

The kit specifies an operating current range below 100A. That’s fine for many repair jobs and hobbyist to light professional tasks, but it does define your workload envelope.

What Current Range Means in Practice

You’ll be fine for light- to medium-duty welding and for jobsite repairs that don’t require heavy penetration. If you typically run above 100A for thicker plates, heavy structural work, or long continuous welds, you should look for heavy-duty consumables rated for higher amperage and better heat dissipation.

When to Use This Kit (Use Cases)

You’ll find this kit best for maintenance shops, home garages, hobbyists, and light contractor work. It’s a good spare parts set for keeping an MB15/15AK torch operational without breaking the bank.

Specific Applications Where It Shines

Use this kit for automotive panel work, general fabrication up to light structural tasks, repair welds, and projects where you run moderate amperage. The set is also handy as an emergency rebuild kit if you need to change all consumables in the field.

Pros and Cons

You’ll want a clear snapshot before you buy, so here are the straightforward strengths and trade-offs of this kit.

Pros

- You get a complete basic set (nozzle, diffuser, tips) so you can replace all wear items quickly.

- Copper tips offer good electrical conductivity, which helps arc stability.

- Parts are precision crafted for MB15/15AK fit, minimizing installation headache.

- The kit is cost-effective for hobbyists and light professional use.

Cons

- The current rating (below 100A) limits use on heavier industrial tasks.

- Ten tips may still be fewer than you need for high-usage shops; heavy users will want more spares.

- The nozzle is a single conical shape—if you prefer different gas coverage profiles, you’ll need other nozzle types.

Comparison with Alternatives

When you’re choosing consumables, you’ll likely compare price, material quality, compatibility, and amperage rating. This EATBALE kit sits in the budget-to-mid-range of options, targeted at MB15/15AK owners.

How It Compares by Category

- Value: You’ll find this kit affordable and good value for light-to-medium work.

- Materials: Copper and brass are standard; higher-end kits may use special coatings or alloyed materials for extended life.

- Amperage: Many industrial-grade kits are rated for 150A+ or feature enhanced cooling; this EATBALE kit is intended for lower amperages.

- Fit: For MB15/15AK torches, the fit is right. For other torch families, make sure to match thread and nozzle geometry.

Maintenance, Care, and Tips

To get the best life from this kit, you’ll also need to keep consumables clean and aligned. Simple maintenance habits will extend tip life and improve weld consistency.

Practical Care Tips

- Clean spatter off the nozzle regularly with a wire brush or nozzle dip to maintain gas coverage efficiency.

- Inspect the contact tip bore for grooving or ovaling; replace if the wire feed becomes inconsistent.

- Make sure the diffuser threads and sealing surfaces are clean before assembly to prevent gas leaks.

- Keep the wire straight and properly tensioned in your feeder to reduce tip wear.

Installation Guide (Step-by-Step)

You’ll be able to swap these parts quickly with a few basic steps. This simple guide assumes you’ve powered down and unplugged your welding machine before working on the torch.

Step-by-Step Replacement

- Remove power and disconnect gas supply to ensure safety.

- Unscrew the existing conical nozzle and set it aside.

- Unscrew and remove the worn contact tip (M6 threaded) using a suitable wrench.

- Inspect the diffuser; replace it if it’s clogged or damaged.

- Thread in a new M6 copper contact tip and tighten snugly—don’t overtighten to avoid stripping threads.

- Reinstall the diffuser and then the conical nozzle, making sure the nozzle seats correctly and threads are clean.

- Reconnect gas and power, run a quick wire feed test, and adjust parameters if necessary.

Frequently Asked Questions

You’ll probably have a few common questions before buying; here are the ones people ask most often with straightforward answers.

Can I use larger wire sizes with these tips?

No, the included contact tips are 0.9 mm / 0.035″, so you should use 0.9 mm wire for optimal performance. If you want to run a different wire diameter, you’ll need tips sized for that diameter.

Are these parts compatible with non-MB15 torches?

They’re designed for MB15/15AK-style torches with an M6 thread. If your torch uses M6 tips and similar nozzle geometry, they may fit, but confirm the exact torch model before buying.

How long will the tips last?

Tip life depends on usage: wire type, amperage, feed tension, and cleanliness. Under normal use below 100A with proper alignment and care, you’ll get reasonable service life out of each tip, but heavy continuous welding will shorten it.

Do the diffuser and nozzle match OEM quality?

They’re built to match the function and fit of OEM parts for MB15/15AK torches. You’ll likely see comparable performance for general use, though OEM or premium-brand consumables may last longer under extreme conditions.

Practical Buying Tips

When you’re ready to buy, a few practical points will help you avoid common mistakes and maximize satisfaction with the kit.

What to Check Before Purchasing

- Verify your torch model is MB15 or 15AK and uses M6 threaded tips.

- Make sure you run 0.9 mm wire or plan to purchase tips for your preferred wire size separately.

- If you weld at higher amps regularly, look for consumables rated above 100A.

Real-World Scenarios Where This Kit Helps

You’ll find that the kit is especially useful for keeping a torch operational during small production runs, maintenance tasks, and when you don’t have immediate access to OEM parts. It’s a practical spares kit for home workshops and small fabrication shops.

Example Use Cases

- Auto bodywork where you’re running intermittent tack welds and finish beads.

- Small fabrication jobs and household repairs that require MIG welding of mild steel or similar materials.

- On-site maintenance where you need to replace consumables quickly and get back to work.

Final Recommendation

If you own an MB15/15AK torch and you weld at moderate amperages, you’ll likely find this EATBALE 13-piece kit to be a strong value buy. It gives you the key consumables you need—10 contact tips, 2 diffusers, and 1 nozzle—in materials and sizes matched to the torch for reliable welding sessions.

Bottom Line

You’ll want to buy this kit if you need a reasonably priced, compatible set of consumables for light to medium MIG/MAG work and you use 0.9 mm wire. If you operate at higher currents or need heavy-duty longevity, consider sourcing industrial-grade or OEM high-amp consumables tailored to those demands.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.