Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you looking for a reliable, budget-friendly gas regulator and flow meter for your TIG or MIG welding setup?

Product overview

You’ll find the BO WELD Argon CO2 Regulator Flow Meter Gas Regulator with 6.8ft Gas Hose for TIG MIG Welder is designed to be a straightforward, no-frills solution for controlling shielding gas on a range of welding machines. It combines a pressure regulator, a square flow tube, and a hose in one package so you can get set up quickly without buying separate parts.

What the unit includes

When you open the box, you get a complete set that lets you hook up to most common cylinder fittings and start welding. The package contains the regulator, a hose clamp and mounting nut, and a 6.8ft gas hose — enough to cover a typical bench or small shop layout.

Intended users and applications

This product is made with MIG and TIG welding in mind, so if you use Argon, CO2, or Helium for shielding gas, this unit fits your needs. You’ll appreciate the simple controls whether you’re hobby welding, doing automotive work, or handling light production tasks.

Compatibility and fittings

You’ll want to know whether the regulator will fit your gas cylinders and torch connections before buying.

Tank compatibility

The regulator uses a CGA-580 inlet connector, so you can attach it directly to standard Argon, Helium, and CO2 tanks with CGA-580 fittings. That means less fuss and fewer adapter purchases if your tanks conform to this common standard.

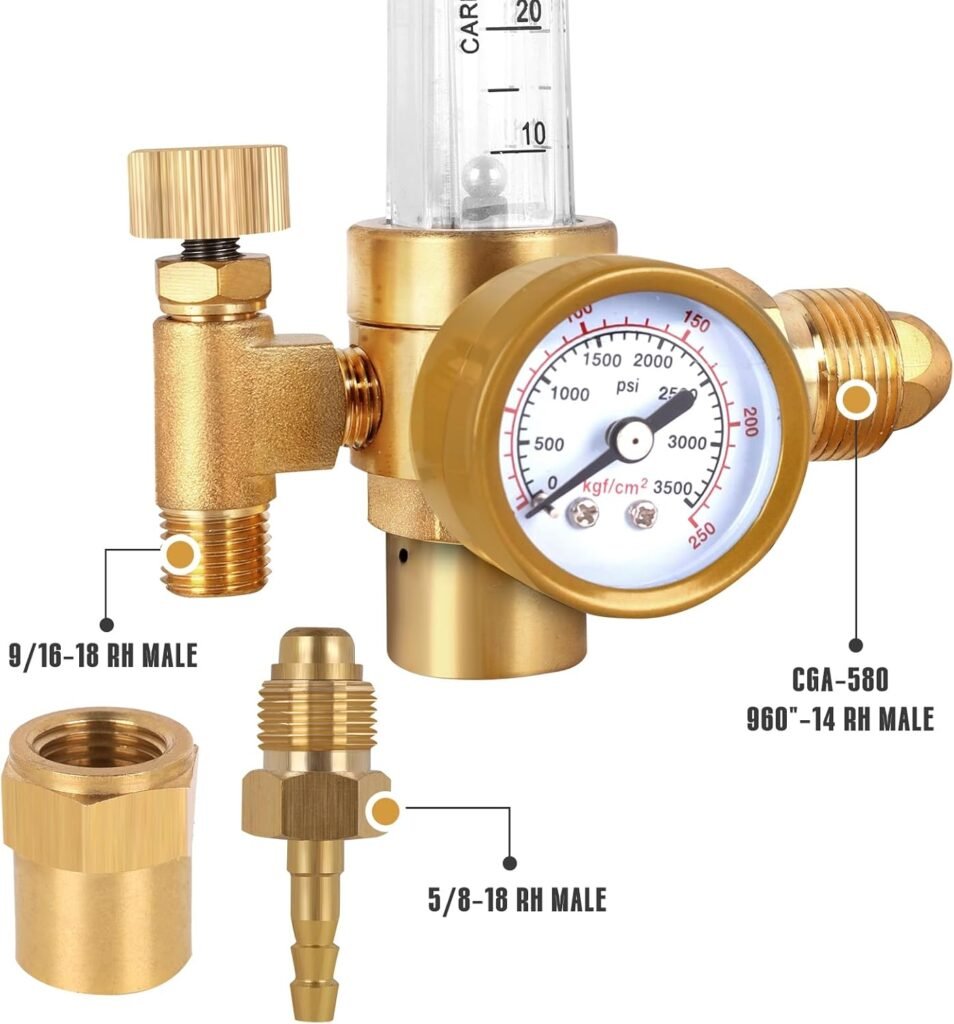

Outlet connectors and hose compatibility

You’ll be able to connect to both female 9/16″ x 18 nut fittings and male 5/8″ x 18 fittings, and it also includes a standard 1/4″ barbed fitting for the hose. This flexibility lets you use the unit with a broad range of torches and hoses without hunting for special connectors.

Gauges and measurement

Accurate flow and pressure readings give you better control over shielding gas, and this unit provides two key indicators.

Flow meter details

The square flow tube gives you a readable range from 0 to 60 CFH, marked by a ball that moves up and down the tube as flow changes. You’ll find it easy to see at a glance what your gas flow is set to, which helps you repeat setups and maintain consistent welds.

Pressure gauge details

The large 1 1/2″ diameter pressure gauge reads from 0 to 3500 PSI, so you can monitor the cylinder pressure and know when the tank needs replacing. The gauge size helps with visibility across the workbench, reducing eye strain when you’re adjusting settings.

Physical design and build quality

You’ll want the regulator to be durable and simple to use. The BO WELD unit aims to strike that balance without pushing the price up.

Materials and construction

The regulator body appears to be made from common brass and plated components, with plastic and acrylic components in the flow tube area. You should handle it carefully, but it’s built to withstand routine shop use rather than heavy industrial abuse.

Controls and ergonomics

The adjustment knob is straightforward and gives you fine control of flow rate. The dual gauges are oriented for quick reading, and the included hose is long enough for flexible placement of your tank relative to the welding station.

Installation and setup

You’ll be able to install this unit with minimal fuss if you follow a few basic steps and safety checks.

Step-by-step hookup

First, ensure the cylinder valve is closed. Attach the CGA-580 inlet to the tank and tighten the mounting nut. Connect the 1/4″ barbed fitting to the hose and secure it with the hose clamp. Finally, perform a leak test with soapy water at all connections before opening the cylinder valve fully.

Common issues during setup

If you get a leak or poor flow, double-check that the inlet connector is seated properly and that the hose clamp is tight on the barbed fitting. Cross-threading the tank connection is the most common setup error, so take your time and hand-start threads before final tightening.

Performance in welding

You’ll notice how consistent gas delivery affects bead quality and penetration when welding.

MIG welding performance

For MIG, the ability to set flow up to 60 CFH gives you ample range for different wire types and currents. You’ll see fewer porosity issues when you maintain stable gas coverage, especially when using CO2 or Argon/CO2 mixes on mild steel.

TIG welding performance

TIG welding relies heavily on shield quality, and the clear flow meter helps you dial in the low flow rates often used with TIG. You’ll appreciate the improved arc visibility when flow is steady and not fluctuating.

Accuracy and reliability

You’ll want the meter to be accurate enough for repeatable welds and reliable over time.

Flow accuracy considerations

The square flow tube and ball indicator offer decent accuracy for a budget flowmeter. While it may not match higher-end mass-flow meters, it typically gives you consistent, repeatable readings that are adequate for shop and hobby use.

Gauge reliability

The pressure gauge provides a large, readable face, but like other economical gauges, it can lose calibration over long periods or after strong impacts. It’s a good idea to check readings occasionally against a known reference if absolute precision is critical.

Safety and maintenance

You’ll be handling pressurized gas, so safety is mandatory. Regular maintenance keeps performance steady and hazards low.

Safety checks to perform

Always check for leaks with soapy water after installation, ensure hoses are free from cuts and kinks, and replace any damaged components immediately. Close the cylinder valve when not in use and relieve line pressure before disconnecting the regulator.

Routine maintenance tasks

Clean the exterior of the flow tube and gauges to keep readings legible. Periodically inspect the hose and clamps for wear and tear, and replace the hose if it shows signs of cracking or bulging. Have the regulator serviced or replaced if internal seals begin leaking.

Package contents and value

You’ll want to know exactly what comes in the box and whether that represents a good value for the money.

Included items

The box contains 1 x Argon Regulator, 1 x Hose Clamp and Mounting Nut, and 1 x 6.8ft Gas Hose. That’s a compact kit designed to get you started with minimal additional purchases.

Value proposition

If you need a low-cost, complete regulator setup with a long-enough hose and flexible fittings, this package delivers solid value. You’re getting a regulator, flowmeter, pressure gauge, hoses, and fittings for a price that typically undercuts individual component purchases.

Specification table

You’ll find this quick reference helpful when deciding if the unit meets your technical needs.

| Item | Specification |

|---|---|

| Product name | BO WELD Argon CO2 Regulator Flow Meter Gas Regulator with 6.8ft Gas Hose for TIG MIG Welder |

| Inlet connector | CGA-580 (compatible with Argon, Helium, CO2 tanks) |

| Flowmeter range | 0 – 60 CFH (square flow tube, ball indicator) |

| Pressure gauge | 1.5″ diameter, 0 – 3500 PSI |

| Included hose | 6.8 ft (1/4″ ID barbed fitting) |

| Outlet fittings | Female 9/16″ x 18 nut, male 5/8″ x 18 fitting, 1/4″ barbed |

| Package contents | Regulator, hose clamp, mounting nut, 6.8ft hose |

| Intended use | MIG and TIG welding |

| Typical construction | Brass/plated components, plastic/acrylic flow tube |

| Calibration | Factory-calibrated (check against reference if needed) |

Pros and cons

You’ll weigh the advantages and what to look out for before making a purchase.

Pros

You’ll benefit from straightforward installation, a readable flow meter, and a large pressure gauge, all packaged with a hose and fittings. The multiple outlet connector options give you flexibility with standard torch and hose threads.

Cons

You might notice the build quality isn’t like high-end industrial regulators, and long-term calibration drift is possible. If you require laboratory-level precision or heavy industrial durability, you may want a higher-end unit.

Real-world use cases

You’ll find that this regulator is useful in a broad set of scenarios, particularly when cost and simplicity are important.

Hobby and DIY welding

For home projects, automotive bodywork, and metal art, the unit gives you reliable shielding gas control without large expense. The included hose length and fittings typically cover small shops without extra purchases.

Light production and small shop use

In small fabrication shops you’ll appreciate the quick setup and easy gauge readings. It’s a practical option for lower-volume professional work where extreme precision isn’t required.

Troubleshooting common problems

You’ll be able to fix most common issues with basic checks and adjustments.

If the flow is unstable

Check for leaks at all connections and ensure the inlet is seated properly on the cylinder. Also confirm the hose isn’t kinked and that the adjustment knob is not damaged.

If the gauge reads zero or erratic

Make sure the gauge isn’t stuck from debris; close the cylinder valve, release line pressure, and gently tap the gauge to free any stuck mechanism. If readings remain off, consider having the gauge checked or replaced.

Comparisons with alternatives

You’ll want to know how this model stacks up against other regulators in the same price bracket and above.

Versus budget competitors

Compared with other affordable regulators, you’ll get similar functionality but with the advantage of included hose and multiple fittings. The square flow tube and ball indicator are common at this price point, and the larger pressure gauge is a practical plus.

Versus higher-end regulators

Higher-end regulators offer more precise mass-flow measurement, better internal materials, and often longer service life. You’ll pay significantly more for those features, so choose based on how critical absolute accuracy and durability are for your work.

Buying considerations

You’ll want to make an informed buying decision based on the specifics of your welding needs.

What to check before buying

Confirm your cylinder valve is CGA-580 compatible and decide if the included 6.8ft hose length suits your workshop layout. If you need adapters for different outlet thread sizes, verify what’s included or whether you need additional fittings.

When to opt for a pricier model

If you perform high-precision welding where gas flow stability down to tiny increments matters, or if your environment is hard on tools, consider investing in a higher-tier regulator. For general shop work and hobby welding, this BO WELD unit is typically sufficient.

Tips for getting the best results

You’ll get better performance and longer life from your regulator if you follow a few easy practices.

Setup and break-in tips

Check all connections for leaks before use, and don’t overtighten the inlet nut. Let the regulator sit under pressure for a short period and re-check for leaks — this helps seats and seals bed in.

Usage tips during welding

Keep the flow meter visible and avoid sudden adjustments mid-weld. Consistent flow settings for a given material and process will help you replicate successful welds.

Maintenance and storage

You’ll preserve the regulator’s function and safety by maintaining it properly.

Long-term storage suggestions

Store the regulator with the protective cap on the inlet and in a dry, dust-free place. Make sure to relieve pressure and close the cylinder valve before storing.

Parts to replace periodically

Replace the hose if it shows signs of cracking or stiffness, and replace the hose clamp if it loses tension. If the pressure gauge becomes inaccurate, replace the gauge or the entire regulator if parts aren’t serviceable.

Frequently asked questions (FAQ)

You’ll find answers to common concerns before you buy or while you’re using the product.

Can I use this with non-CGA-580 tanks?

If your tank has a different outlet standard, you’ll need an appropriate adapter. The unit is designed for CGA-580, which covers most Argon, Helium, and CO2 cylinders in common use.

Is the flow meter accurate for TIG at low CFH?

Yes, the flow tube provides reasonable accuracy at the lower end of the scale for TIG tasks, but if you require extremely precise low-flow control, consider a dedicated mass flowmeter.

Does the regulator require professional calibration?

No — it’s factory-calibrated and ready to use, but you should verify readings against a known reference if you need high precision.

Final verdict

You’ll appreciate the BO WELD Argon CO2 Regulator Flow Meter Gas Regulator with 6.8ft Gas Hose for TIG MIG Welder if you want an affordable, complete gas control kit for general welding tasks. It offers the practical combination of a readable 0–60 CFH flowmeter, a large pressure gauge, and flexible fittings that make setup easy.

Who should buy it

If you’re a hobbyist, small-shop fabricator, or a light-production user who values cost-effectiveness and convenience, this regulator is a solid pick. It balances performance and price without unnecessary complexity.

Who should consider something else

If your work demands laboratory-grade flow precision, heavy industrial duty, or extremely long service intervals under harsh conditions, you should look at higher-end regulators and mass flowmeters.

If you want, you can tell me about your welding setup (tank type, torch fitting, and workstation layout), and I’ll help you confirm whether this regulator will match your needs or suggest specific alternatives.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.