Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Want to check your gas flow quickly and accurately when you’re using a Mig or Tig torch?

Product Overview

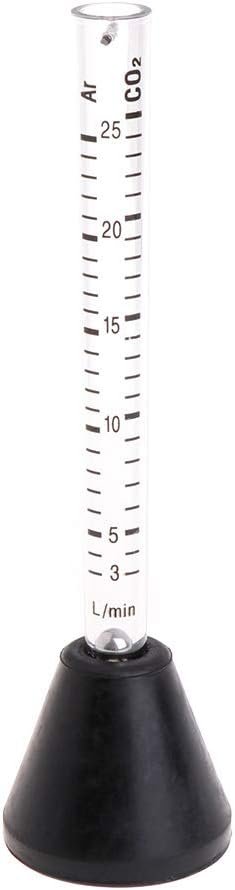

You’re looking at the JENOR Argon Co2 Gas Flow Meter Peashooter Scale Tester Measure for Mig Tig Welder Welding. This handheld flowmeter is designed specifically to check gas flow at the torch, giving you a fast way to confirm that shielding gas is actually reaching the weld zone. You’ll like that it is simple by design and gives readable measurements in litres per minute.

What this tool is meant for

This tester is intended to measure gas flow at the Mig or Tig torch nozzle rather than at the regulator or the gas cylinder. You’ll use it to verify that gas is present and flowing correctly where it matters most—at the point of welding. That can save you time and frustration when you suspect poor shielding gas coverage.

Who should consider this product

If you weld with Mig or Tig and you need to confirm gas delivery without guessing, this is a handy tool to own. You’ll find it useful whether you’re a hobbyist, a small shop operator, or a professional fabricator who wants quick confirmation of torch gas flow.

Key Features

You’ll appreciate several core features that make this product practical for field checks and bench use. These features are simple, but intentionally so—this isn’t a complex instrument, it’s a practical tester.

Flow range and graduations

The flowmeter tester is scaled from 0 to 25 litres per minute with one-litre graduations. You’ll be able to see small changes in flow visually through the ball indicator. The one-litre increments make it straightforward to confirm that your flow is within an expected range.

Peashooter design and usage

The peashooter style means you place the tester over the torch nozzle and read the flow from the top of the small floating ball. You’ll simply slide it onto the nozzle and watch the ball settle to indicate flow rate. That design is quick to use when you want a fast check without tools or disassembly.

Compatibility with Mig and Tig torches

This unit is made to test both Mig and Tig torches, so you won’t need different testers for different processes. You’ll still want to ensure the fit is good for your specific torch nozzle before relying on the reading for precision work.

Design and Build Quality

You’ll notice the tester is compact and lightweight, designed for workshop use and easy storage. It’s not a precision lab instrument, but it’s purpose-built for on-the-job verification.

Materials and durability

The materials are basic and functional, typically clear plastic tubing with a small ball inside and printed graduations. You’ll find it durable enough for routine checks, but treat it like a simple inspection tool and avoid rough handling or exposure to welding sparks.

Size and portability

Because it’s small and hand-held, you can carry it in your toolbox or in a welding cart compartment. You’ll appreciate the convenience when you need to run a quick check on a jobsite or in a tight workspace.

How It Works

Understanding how this peashooter tester works helps you use it reliably and interpret readings properly. The operation is mechanical and visual, with no electronics.

Reading the flow

You place the tester over the gas nozzle and the gas pushes the small ball upwards. You’ll read the flow rate from the top of the ball against the graduated scale; the ball’s position equals the litres per minute (L/min) flowing through the nozzle.

Testing procedure step-by-step

You’ll want to follow a simple sequence: (1) turn on your gas at the regulator, (2) disable HF on Tig welders to prevent shock, (3) release the Mig wire tensioner to stop wire feed when testing Mig torches, (4) place the tester over the nozzle, and (5) observe the ball position. You’ll get a fast confirmation of gas flow with this straightforward procedure.

Safety Considerations

Safety matters when you’re working around welding equipment and pressurized gas. You’ll need to take specific precautions to avoid injury or damage.

Disable HF on Tig welders

If you use a Tig machine that uses high frequency (HF) ignition, you must disable HF when placing the tester over the torch. You’ll risk an electrical shock or damaging the tester if HF remains active. Turning HF off ensures you can safely read the flow without stray voltage.

Stop wire feed on Mig machines

When testing a Mig torch, release the wire tensioner or otherwise stop the wire feeding mechanism before placing the tester over the nozzle. You’ll prevent the wire from being pushed into the tester and potentially causing a jam or damaging the unit. This simple step keeps both you and the gadget safe.

Accuracy and Performance

You want to know whether the readings you get are meaningful. This device provides practical, visual confirmation rather than laboratory-grade accuracy.

Practical accuracy for field checks

The one-litre graduation gives you a useful ballpark reading that’s typically accurate enough for ensuring effective shielding gas flow. You’ll be able to confirm whether you have near-zero flow, adequate flow, or an obviously incorrect flow—sufficient for troubleshooting.

Limitations you should know

This tester is not a precision meter for calibration tasks or detailed flow profiling. You’ll not get sub-litre resolution or certified accuracy for regulatory measurements. Use it primarily for quick performance checks and troubleshooting rather than official calibration.

Ease of Use

You’ll find that the JENOR peashooter is straightforward to operate and requires minimal setup. Its simplicity is an advantage for quick checks and repeated use.

Setup and first use

On first use, you’ll remove it from packaging, ensure it’s clean, and practice placing it over a few different torch nozzles. You’ll make sure the ball moves freely and that the scale is easy to read in your workspace lighting conditions.

Reading in varied conditions

In bright shop lighting you’ll have no problem reading the scale; in low light, you might move to a brighter area or use a flashlight. You’ll want to avoid fogging or condensation inside the tube, so store it in a dry place.

Compatibility and Fit

Because torches vary, you’ll want to check how the unit fits your specific torch. A good fit produces a better reading; a poor fit can allow gas to escape and give an inaccurate lower reading.

Torch nozzle sizes

Most common Mig and Tig nozzles will accept the peashooter tester, but you may find some specialty nozzles or gas cups that don’t seat perfectly. You’ll want to test the fit on your torch before relying on it for important checks.

Adapters and alternatives

If you have an unusually sized nozzle, you’ll either need an adapter or you’ll take an approximate reading by loosely seating the tester. You’ll still get a general sense of flow, but not a tight, highly accurate reading without a match-fit.

Pros and Cons

You’ll appreciate the strengths and want to be aware of the limitations before you buy.

Pros

- You’ll get a quick, on-the-spot check of gas flow at the torch, where it matters most.

- The 0–25 L/min scale with 1 L graduations is easy to read and covers typical welding flow ranges.

- It’s portable, inexpensive, and simple to use with minimal training.

Cons

- You’ll not get laboratory-grade precision or certification for calibration.

- A poor nozzle fit can cause readings to be lower than the actual flow.

- Plastic construction means you must avoid heavy impacts or exposure to sparks.

Table: Quick Specification Breakdown

You’ll appreciate this table that condenses the key information for fast scanning. It helps you compare the most relevant details quickly.

| Attribute | Details |

|---|---|

| Product name | JENOR Argon Co2 Gas Flow Meter Peashooter Scale Tester Measure for Mig Tig Welder Welding |

| Flow range | 0 – 25 L/min |

| Graduations | 1 L increments |

| Design | Peashooter/ball float type |

| Compatibility | Mig and Tig torches (fit-dependent) |

| Materials | Clear plastic tube, internal ball float |

| Use case | On-torch gas flow verification |

| Safety notes | Disable HF on Tig welders, stop wire feed on Mig before testing |

| Accuracy | Practical field checks; not laboratory precision |

| Portability | Handheld and lightweight |

Using the Tester: Step-by-Step Guide

You’ll get the best results if you follow a reliable sequence of steps when testing. This section gives you a clear checklist to follow each time.

Pre-test checks

Confirm that regulator settings are as usual and that you’ve turned the gas on at the cylinder or supply source. You’ll also check that the tester is clean and the ball moves freely.

Safety setup

Turn off HF on Tig machines and stop Mig wire feed by releasing the wire tensioner. You’ll then don appropriate PPE like gloves and safety glasses before proceeding.

Performing the test

Place the tester over the torch nozzle and hold it steady while the ball rises to its stable position. You’ll read the flow from the top of the ball against the printed scale.

Interpreting results

If the reading is within your expected flow range (for example, 8–15 L/min for many Tig applications), you can proceed. You’ll troubleshoot if you see near-zero flow or a reading significantly different from your typical value.

Troubleshooting Common Issues

If you get an unexpected reading, there are a few likely causes and easy checks you can do. You’ll find these steps help you narrow down problems quickly.

Low or zero reading

Check that the gas is actually turned on and the regulator is open. You’ll ensure the tester is seated properly over the nozzle and that HF is disabled or wire feed stopped, as applicable.

Erratic ball movement

Make sure the ball inside can move freely and that there’s no debris or oil blocking it. You’ll also check that the nozzle is clean and not partially obstructed, which can cause pulsating or irregular flow.

Inconsistent readings between sessions

Confirm consistent testing conditions like regulator pressure and hose condition; leaks or pressure drops can change readings. You’ll also inspect for wear or damage to the tester that could affect the seal or ball movement.

Maintenance and Care

Treating the tester with basic care will keep it useful for a long time. You’ll want to avoid contamination and mechanical damage.

Cleaning and storage

Wipe the exterior clean after use and store in a dry place away from direct welding sparks. You’ll keep it in a protective compartment or toolbox so the tube doesn’t get crushed or scratched.

Inspecting for damage

Periodically check the tube for cracks, the graduations for fading, and the ball for free movement. You’ll replace the tester if you find mechanical damage that could affect readings or safety.

Comparison with Other Flow Measurement Options

You’ll find different types of flow measurement tools on the market, each with trade-offs. This tester is a practical choice in certain contexts.

Regulator-mounted flowmeters

Regulator-mounted meters give continuous readings at the regulator but don’t confirm flow at the torch. You’ll use the peashooter tester when you want to confirm flow exactly at the nozzle.

Digital flowmeters

Digital meters can offer more precision and logging, but they’re more expensive and sometimes overkill for quick checks. You’ll choose the JENOR peashooter for fast, inexpensive verification rather than data logging or high precision.

When to Use This Tester vs When to Calibrate

Knowing when a quick check suffices and when you need professional calibration will save you time and money. You’ll want to be pragmatic about the tool’s role in your workflow.

Routine checks and troubleshooting

Use this tester for routine pre-weld checks, troubleshooting suspected gas flow problems, and quick validation after equipment changes. You’ll benefit from its speed and simplicity for everyday tasks.

Calibration or certification needs

If you need certified, traceable measurements for regulatory compliance or precision processes, you’ll seek a calibrated instrument or professional service. You’ll not rely on this tester where certified accuracy is required.

Buying Tips

You’ll want to pick up a tester that suits your torches, shop habits, and budget. These tips help you make a smart purchase decision.

Confirm compatibility

Check your torch nozzle sizes and types to ensure a good fit, or plan to use the tester for approximate checks if fit is loose. You’ll test the fit immediately upon receipt.

Budget and value

This tester is low-cost and provides good value for quick checks. You’ll weigh cost versus frequency of use; if you test gas flow frequently and need higher accuracy, consider a pricier option.

Real-World Use Cases

This section shows you where this tester will actually help in day-to-day welding scenarios. You’ll see practical examples of problems it helps find and prevent.

Spotting gas supply issues on-site

When a weld looks porous or you suspect contamination, you’ll use the tester to confirm gas is flowing at the torch. You’ll often find simple supply or regulator issues that are easy to fix once identified.

Checking after maintenance or hose changes

After swapping gas hoses, fittings, or regulator components, you’ll verify flow at the torch. You’ll avoid rework by confirming gas flow before you weld critical joints.

Final Thoughts and Recommendation

You’ll find that the JENOR Argon Co2 Gas Flow Meter Peashooter Scale Tester Measure for Mig Tig Welder Welding is a practical, no-nonsense tool for quick on-torch gas checks. It’s designed for convenience and speed rather than laboratory precision, and it performs that role well.

Who should buy it

If you weld regularly and want a simple way to confirm gas flow at the torch, this tester is a good buy. You’ll especially appreciate it if you troubleshoot gas delivery, work on multiple machines, or need a lightweight tool to carry to jobs.

Final safety reminder

Always disable HF on Tig welders and stop wire feeding on Mig torches before testing to avoid shocks and damage. You’ll keep yourself and your equipment safe by following these simple precautions.

If you want, I can summarize this into a short checklist you can print and keep in the welding area for quick reference. Would you like that checklist?

Disclosure: As an Amazon Associate, I earn from qualifying purchases.