Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

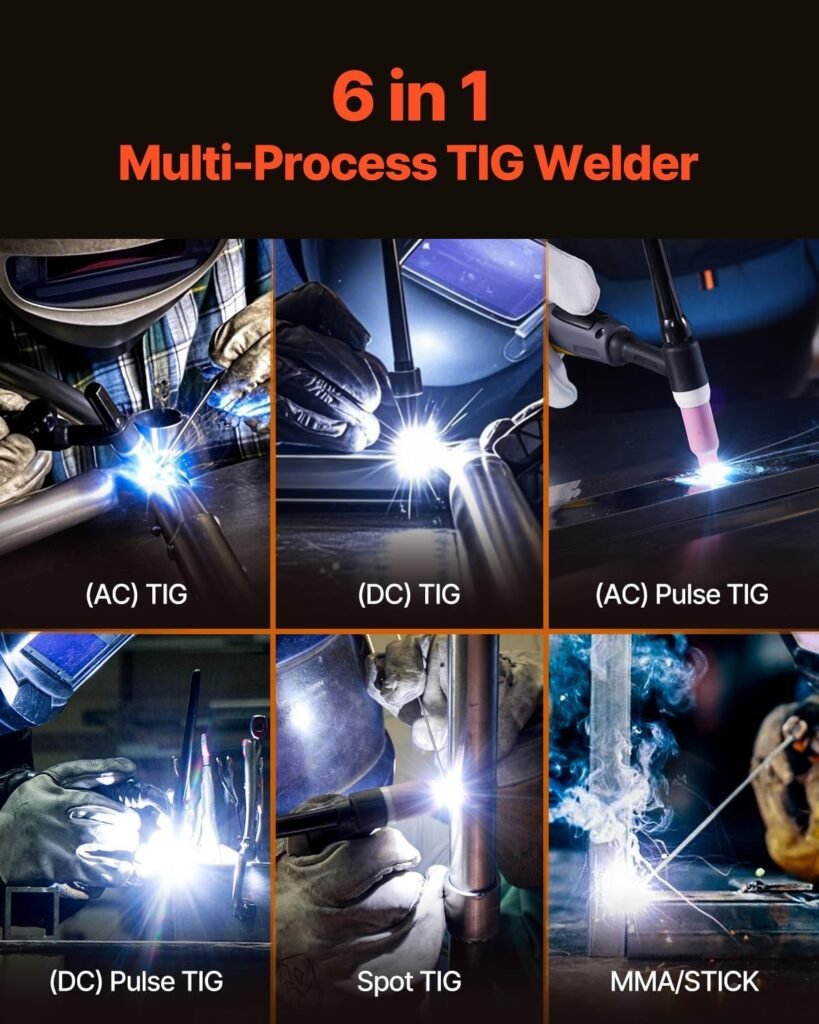

Are you trying to decide if the VEVOR TIG Welder, 200A 6-In-1 Aluminum Welding Machine (LED Display) – AC TIG/DC TIG/AC Pulse TIG/DC Pulse TIG/Spot TIG/MMA(Stick), 110&220V Dual Voltage Electric Welder with Synergic Control IGBT is the right tool for your projects?

Product Overview

You’ll find that the VEVOR TIG Welder, 200A 6-In-1 Aluminum Welding Machine is designed to be a versatile, all-in-one solution for a variety of welding tasks. It combines multiple welding modes, dual voltage capability, and a user-friendly LED display so you can tackle both home and professional projects with confidence.

What the 6-in-1 Means for You

The six modes — AC TIG, DC TIG, AC Pulse TIG, DC Pulse TIG, Spot TIG, and MMA (Stick) — let you switch processes depending on the metal and the joint you’re working on. This flexibility means you won’t need separate machines for aluminum, steel, or light fabrication jobs.

Who This Welder Is For

If you’re a DIYer working on garage repairs, a professional fabricator needing a compact backup unit, or someone who wants to weld different materials without buying multiple welders, this machine fits those needs. Its features make it suitable for welding aluminum, stainless steel, copper, and other alloys, so you can apply it across projects.

Key Specifications

The core technical specs shape how the machine performs under real conditions, and they also tell you what kind of power and duty cycle to expect. Below is a table breaking down the main specifications so you can quickly compare them to your requirements.

| Specification | Detail |

|---|---|

| Product Name | VEVOR TIG Welder, 200A 6-In-1 Aluminum Welding Machine (LED Display) – AC TIG/DC TIG/AC Pulse TIG/DC Pulse TIG/Spot TIG/MMA(Stick), 110&220V Dual Voltage Electric Welder with Synergic Control IGBT |

| Welding Modes | AC TIG, DC TIG, AC Pulse TIG, DC Pulse TIG, Spot TIG, MMA(Stick) |

| Peak Output Current | 200A |

| Input Voltage | 110V / 220V dual voltage |

| Display | Smart LED display |

| Control | Synergic control; adjustable welding current |

| Waveform Options | 9 waveform options (for AC TIG/aluminum) |

| Materials Supported | Aluminum (up to 1/4″), Low carbon steel (up to 3/8″), stainless steel, copper, magnesium alloy, titanium |

| Electrode Compatibility | 6010, 6011, 6013, 7018 |

| Protection Features | VRD, overcurrent, overload, overheat protection |

| Cooling | Forced air cooling with fan |

| Technology | IGBT (insulated-gate bipolar transistor) |

| Typical Uses | Home DIY, garage projects, outdoor repairs, professional fabrications |

Why These Specs Matter

Knowing the peak current, voltages, and protection features helps you match the machine to your materials and working environment. The presence of IGBT technology, dual voltage support, and a smart LED display improves reliability and usability across different job sites.

Build and Design

You’ll notice the unit is built with portability and practicality in mind, balancing rugged components with an accessible control panel. The chassis and handles are designed to move between job sites without requiring excessive effort.

Front Panel and Controls

The LED display and control knobs/buttons let you dial in parameters quickly and visually monitor settings. Synergic control simplifies setup by automatically adjusting multiple welding parameters based on one primary input, which saves time and reduces setup errors.

Cooling and Durability

An integrated fan cooling system helps maintain stable operation under load, and the IGBT modules offer efficient power conversion for reliable arcs. You’ll appreciate these features when working in hotter conditions or during longer welds where thermal protection prevents damage.

Performance: TIG Welding (AC and DC)

This welder delivers solid TIG performance in both AC and DC modes, and the AC TIG mode is especially useful for aluminum welding. The machine’s waveform options and pulse capabilities give you a fine degree of control over arc characteristics.

AC TIG for Aluminum

AC TIG stabilizes the arc when welding aluminum, which helps reduce porosity and produces cleaner weld beads. The included 9 waveform options allow you to tailor the output to thin or thicker aluminum, which means better penetration and less risk of burn-through when you set the machine properly.

DC TIG for Steel and Exotic Metals

DC TIG mode provides a smooth, controllable arc for carbon steel, stainless steel, copper, and titanium. You’ll find the arc stability and current control effective for both thin gauge and thicker plates when you adjust the current to suit the material.

Pulse TIG Modes

AC Pulse TIG and DC Pulse TIG can reduce heat input and improve bead appearance by modulating the current at set intervals. You’ll use pulse modes to control heat for thin materials, minimize distortion, and achieve visually pleasing welds with better control of puddle behavior.

Spot TIG and MMA (Stick)

Spot TIG is ideal when you need concentrated welds such as tack welds or repetitive spot joins. MMA (Stick) mode allows you to continue work in sites where TIG torches aren’t suitable or consumables are limited.

Spot TIG

You’ll use Spot TIG for small, precise spots where timing and localized heat are critical. This is helpful on sheet metal fabrication and automotive frame repairs where clean, repeatable spot welds are necessary.

MMA (Stick) Mode

MMA extends the unit’s usefulness for outdoor and windy conditions where TIG shielding gas could be problematic. You’ll appreciate the ability to use common electrodes (6010, 6011, 6013, 7018) for maintenance and field repairs.

Power and Duty Cycle

Knowing how much current you can run for how long determines whether the machine can handle continuous professional work or occasional hobby tasks. The 200A peak output gives you strong capability for a range of materials.

Dual Voltage Flexibility

You’ll benefit from 110V/220V dual voltage support because it allows you to operate at home on standard outlets or on job sites with 220V. This flexibility means fewer limitations when choosing locations to do your work or when transporting the machine between jobs.

Duty Cycle Considerations

The duty cycle varies with output current and ambient temperature, so you need to plan weld sequences accordingly. When you set higher currents for thicker materials, you’ll run into the welder’s duty cycle limits sooner, so understanding those limits prevents overheating.

Materials and Thickness Capability

The VEVOR TIG Welder supports a broad array of metals and thicknesses, which expands the range of projects you can work on. You’ll still need to match settings and filler materials to the metal being welded.

Aluminum Welding Limits

The AC TIG mode can handle aluminum up to about 1/4″ in thickness with the right technique and filler rod. You’ll get cleaner beads and reduced porosity compared to DC-only machines, but for very thick castings or heavy structural pieces, a higher-amperage unit could be preferable.

Carbon Steel and Stainless Steel

This machine will weld low carbon steel up to about 3/8″ reliably when you use proper settings and electrode selection. You’ll also be able to weld stainless steels effectively in DC TIG or MMA modes by adjusting current and gas shielding.

Controls and User Interface

The smart LED display and synergic control reduce guesswork and make changes quicker while you’re working. You’ll be able to monitor parameters at a glance and fine-tune the machine as the job requires.

LED Display

The LED display provides clear feedback on current, mode, and other settings which reduces guesswork and improves workflow. You’ll find it particularly useful when switching between welding modes mid-job.

Synergic Control and Settings

With synergic control, changing one parameter can automatically adjust related settings, so you can get close to an optimal starting point quickly. You’ll save time on trial-and-error setups, especially if you’re moving between different thicknesses or metals.

Welding Waveform Options

The 9 waveform choices let you balance penetration, cleaning action, and arc stability for aluminum welding. You’ll find the ability to customize the waveform helpful for fine-tuning the machine to suit specific alloys and thicknesses.

What Waveforms Influence

Waveform shape affects how the arc transfers heat and how cleaning action works on aluminum oxide. You’ll adjust waveforms to get the right mix of penetration and cleaning action for the exact joint and alloy you’re welding.

Practical Use of Waveforms

In practice, you’ll try a few waveform settings on scrap material until you find the one that gives the best balance of bead appearance and penetration. The machine’s LED and synergic settings make iteration faster, so you can lock in the best waveform quickly.

Safety and Protections

Safety features like VRD (Voltage Reduction Device), overcurrent, overload, and overheat protection keep both you and the machine safer during operation. These protections matter when you work in variable conditions or push the machine hard.

VRD and Overcurrent Protection

VRD reduces the output open-circuit voltage for improved safety when the torch is not in use, which matters especially in damp or confined environments. Overcurrent protection ensures the machine trips or limits output before damaging components or creating unsafe conditions.

Thermal Management and Overheat Protection

The welder’s internal sensors and fan cooling help prevent thermal runaway by reducing output or shutting down when temperatures get too high. You’ll avoid damage and downtime by allowing the unit to cool before resuming heavy-duty welds.

Accessories and Consumables

The package may include commonly used accessories, and you’ll want to confirm what’s included before purchase or plan to acquire necessary extras. Consumables such as TIG torches, collets, gas lines, and proper filler rods are essential for optimal results.

Typical Included Items

You’ll often receive a TIG torch, grounding clamp, and cables, but confirm whether gas regulators or additional consumables are included with your purchase. Buying a good set of tungsten electrodes, filler rods, and a regulator will make your first welds smoother.

Recommended Consumables

Buy argon gas for TIG operations, and choose filler rods appropriate to the metal you’re welding (aluminum rod for aluminum, ER70S for carbon steel, etc.). Keep a stock of spare collets and tungsten tips since they wear down during use and affect arc stability.

Setup and First Welds

Setting up properly makes your first welds far more predictable and helps you avoid errors that could damage the machine or the workpiece. You’ll want to read the manual carefully and practice on scrap pieces first.

Gas and Current Setup

For TIG welding, set argon flow and ensure the regulator and hose connections are leak-free before striking an arc. You’ll then set current based on material thickness and run a test bead to tweak pulse, waveform, and travel speed.

Safety Checks Before Welding

Check the grounding, cable integrity, and electrode condition before starting. You’ll also ensure proper PPE, adequate ventilation, and a stable work surface to maintain safety during operations.

Portability and Workspace Considerations

The welder is portable enough for garage work and moderate job site use, but it’s not as light as dedicated inverter-based mini welders. You’ll find it convenient to transport in a vehicle or move around a shop, but consider a helper for long transports.

Power Access and Cables

Because it supports both 110V and 220V power, you’ll have options for where you run your work, but you’ll still need appropriate cables and connectors. You’ll also plan your workspace with ventilation and fire safety in mind.

Workspace Requirements

A stable bench, metal clamps, and proper lighting improve your weld quality and reduce rework. You’ll need gas cylinders secured and a safe storage plan for electrodes and filler rods.

Troubleshooting and Maintenance

Knowing a few common troubleshooting steps and maintenance routines will keep the machine reliable and extend its lifespan. You’ll address common issues quickly by checking connections, consumables, and settings.

Common Issues and Fixes

If the arc is unstable, check tungsten condition, gas flow, and grounding. You’ll also verify that mode and waveform selections match the metal and joint type; many arc problems come from incorrect setup rather than hardware faults.

Regular Maintenance

Keep the fan inlets and outlets free of dust, inspect cables for wear, and replace consumables as needed to preserve performance. You’ll also periodically check internal connectors and ensure firmware or controls haven’t developed faults from heavy use.

Comparative Context

Compared to single-function TIG machines, the VEVOR 6-in-1 offers significant versatility, though it balances that against complexity. You’ll gain the advantage of one machine for multiple processes but should expect some trade-offs in extremes of industrial performance.

Versus Dedicated High-End TIG Units

Dedicated high-end TIG machines may offer higher duty cycles and more refined arc control for continuous industrial use. You’ll find the VEVOR excels in mixed-use environments, but production shops welding thick plate all day might choose a more industrial-rated unit.

Versus Budget Single-Mode Welders

Compared with bare-bones budget welders, this unit gives you more features like AC TIG for aluminum and pulse control. You’ll pay more for that flexibility, but the time saved and quality gained on tricky metals often justify the investment.

Pros and Cons

Summarizing strengths and weaknesses helps you evaluate whether this unit suits your needs and preferences. You’ll use this list to weigh the unit against specific project demands.

Pros

- Very versatile 6-in-1 modes that cover most common welding tasks.

- AC TIG with multiple waveform options for strong aluminum performance.

- Dual voltage support helps you work in more locations.

- Smart LED display and synergic control make setup easier.

- Built-in safety features like VRD, overcurrent, overload, and overheat protection.

Cons

- For extreme industrial continuous duty, a higher-duty industrial machine may be preferable.

- You’ll need to verify which accessories are included and may have to buy additional consumables.

- Learning all modes and waveform options adds a slight learning curve for beginners.

Practical Tips for Best Results

Small technique adjustments and setup choices will dramatically improve your weld quality. You’ll find faster progress and cleaner welds by practicing a few focused skills.

Aluminum Welding Tips

Use AC TIG with appropriate waveform and ensure clean joint surfaces free of oxide for best results. You’ll also choose the right tungsten (usually zirconiated or ceriated for AC) and adjust balance and frequency for cleaning action and arc focus.

General TIG Technique

Maintain a steady torch angle, consistent travel speed, and suitable filler rod placement to avoid contamination and achieve uniform penetration. You’ll also practice foot pedal control if available, which gives you dynamic control over heat.

When to Choose This Welder

Pick this machine if you want a flexible tool that handles both aluminum and steel, supports fieldwork with stick welding, and includes protective features for safer operation. You’ll find it especially valuable for hobbyists, shop owners, and contractors who need to switch tasks often.

Ideal Use Cases

Use it for automotive repair, fabrication of metal furniture, light structural work, and home projects involving multiple metals. You’ll also find it beneficial for small fabrication shops needing a versatile secondary machine.

When Another Option Might Be Better

If your work is exclusively heavy industrial welding with extended continuous duty, you may be better served by a high-capacity industrial TIG with higher amperage and duty cycle. You’ll want to match the machine to the intensity of your workload.

Final Verdict and Buying Advice

If you want a single machine that brings AC aluminum welding, DC TIG, pulse modes, spot welding, and stick capability, the VEVOR TIG Welder, 200A 6-In-1 Aluminum Welding Machine (LED Display) – AC TIG/DC TIG/AC Pulse TIG/DC Pulse TIG/Spot TIG/MMA(Stick), 110&220V Dual Voltage Electric Welder with Synergic Control IGBT is a solid candidate. You’ll get a flexible, feature-rich tool that saves you from buying multiple machines and offers good safety and control features for a range of projects.

Purchase Checklist

Before you buy, confirm what accessories come in the package, ensure a suitable gas regulator and hoses are available, and consider a starter kit of tungsten and filler rods. You’ll also want to check warranty details and local service options to keep your unit in top condition.

Final Recommendation

If your projects require multi-material capability and you value flexibility over extreme continuous duty, this welder is likely to serve you very well. You’ll benefit from its AC aluminum capability, pulse control, and safety features across a wide range of practical applications.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.