Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you looking for a versatile welding machine that handles MIG, TIG, and ARC without forcing you to choose between solid wire or flux-cored wire?

Product overview: 250A MIG Welder, 3 in 1 Combo MMA/MIG/LIFT TIG Welder Machine, Flux Core Welder, MIG-130 Portable Welding Machine – MIG Welding Equipment

You’re looking at a 3-in-1 machine that promises MIG, TIG (Lift TIG), and ARC (MMA) functions in one package. The product also lets you choose between solid wire (with shielding gas) or flux-cored wire (gasless) for MIG-style welding, which gives you flexibility depending on the job and environment.

Who this machine is aimed at

This unit is positioned for both beginners and hobbyists as well as light-professional users who need a portable, multi-function welder. You’ll appreciate it if you want one tool for sheet metal, mild steel, and stainless steel projects without paying for separate machines.

Key features at a glance

This section summarizes the features you’ll interact with most often, so you can quickly decide whether it matches your needs. Each item below highlights practical benefits and typical use cases.

- 3-in-1 capability: MIG, LIFT TIG, ARC (MMA) welding modes. This saves you space and cost versus buying three separate machines.

- Compatible with both solid wire (requires shielding gas) and flux-cored wire (gasless). You can weld stainless steel with gas or iron without gas.

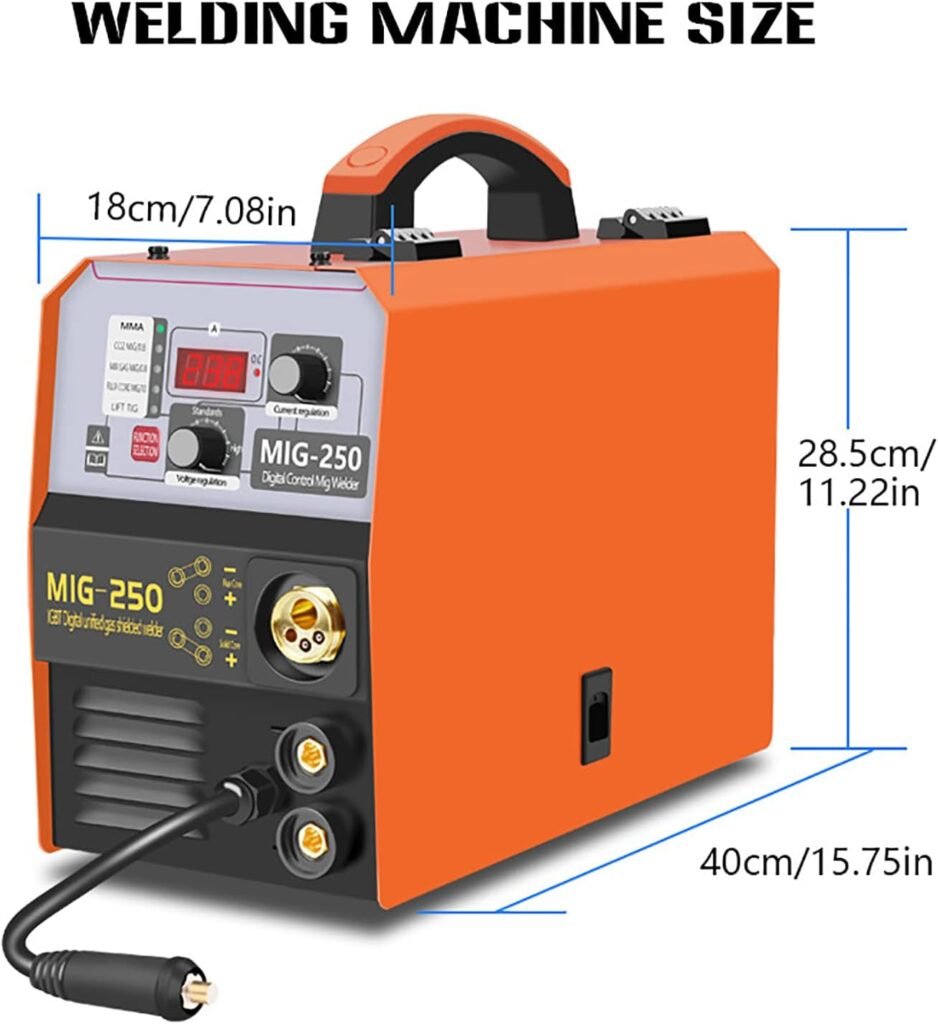

- Portable design with a carry handle—suitable for jobsite moves or garage storage.

- User-friendly controls intended for beginners while offering enough adjustability for experienced users.

- Designed for common DIY and light industrial tasks, including auto bodywork, farm equipment repairs, and metal fabrication.

Technical specifications (quick reference)

Below is a concise table to break down the most important technical details so you can compare at a glance. Refer to the manufacturer specs for absolute numbers and certifications if you need exact electrical parameters.

| Specification | Typical value / notes |

|---|---|

| Machine type | 3-in-1: MIG / LIFT TIG / ARC (MMA) |

| MIG wire | Solid wire or flux-cored wire supported |

| Welding current range (approx.) | Up to 250A peak (model rated as 250A) |

| Power supply | Commonly single-phase input (confirm model voltage: usually 110V/220V or switchable) |

| Duty cycle | Moderate (suitable for hobby and light-professional work) |

| Portability | Portable with handle; relatively lightweight compared to industrial units |

| Gas use | Required for solid MIG wire (shielding gas); not required for flux core |

| TIG type | Lift-TIG start (no HF) |

| Included accessories | Often includes torch, ground clamp, MIG gun, filler wire spool adapter, and basic consumables (varies by seller) |

| Recommended use | Stainless steel, mild steel, farm repairs, automotive, light fabrication |

First impressions and build quality

When you pick up this welder, you’ll notice it’s compact and designed for portability. The casing and controls are typically straightforward and functional rather than luxurious.

The machine is intended to be user-friendly. You’ll find knobs and switches laid out to let you change modes, adjust current, and set wire feed speed without reading a manual every time. While the build won’t match heavy industrial units, it’s ample for garage and jobsite use.

Exterior and ergonomic details

You’ll appreciate having an easy-to-grip handle and a relatively compact footprint that fits in a workshop or truck. The control panel is usually simple: mode switch, current/voltage and wire speed knobs, and a few indicator lights.

The knobs have enough tactile feedback to let you make adjustments with gloved hands. Expect plastic knobs and metal housing—good for portability but not for extreme environments.

Performance: MIG welding

MIG is often the feature people buy this unit for, because it’s fast, forgiving, and ideal for many common welding tasks. You’ll be able to run either gas-shielded solid wire or flux-cored wire for gasless MIG, which is useful outdoors or for quick repairs.

In practice, you’ll find MIG performance is good on thin to moderately thick steel (mild and stainless with gas), producing clean, consistent beads when settings are dialed in. Flux-cored MIG will be slightly messier with more spatter, but it’s convenient for outdoor work where wind could blow away shielding gas.

Wire feed and arc stability

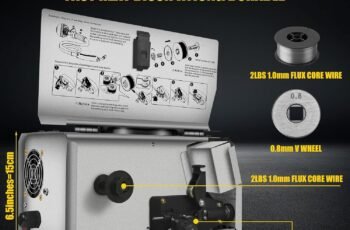

The wire feed mechanism on these combo machines is serviceable for small projects and occasional professional use. You’ll want to tune wire feed speed and voltage settings to match the wire diameter and metal thickness. Expect reliable arc starts once you find the sweet spot, though very long, continuous welds may begin to show the limits of duty cycle and cooling.

If you use good-quality wire and properly set tension, feed performance is dependable. For critical production work, an industrial-grade feeder might be preferable, but for general use this unit hits the mark.

Performance: Flux-cored welding (gasless MIG)

Using flux-cored wire means you don’t need external shielding gas, making your setup faster and more mobile. You’ll use this mode for outdoor repairs, farm equipment, and structural splices where traveling wind would make gas shielding impractical.

Expect more spatter and a slag layer that needs to be chipped away, especially compared to gas-shielded MIG on stainless or clean mild steel. If you keep your technique sound and adjust travel speed and wire feed properly, you’ll get strong, acceptable welds for many tasks.

Best practices for flux-cored MIG

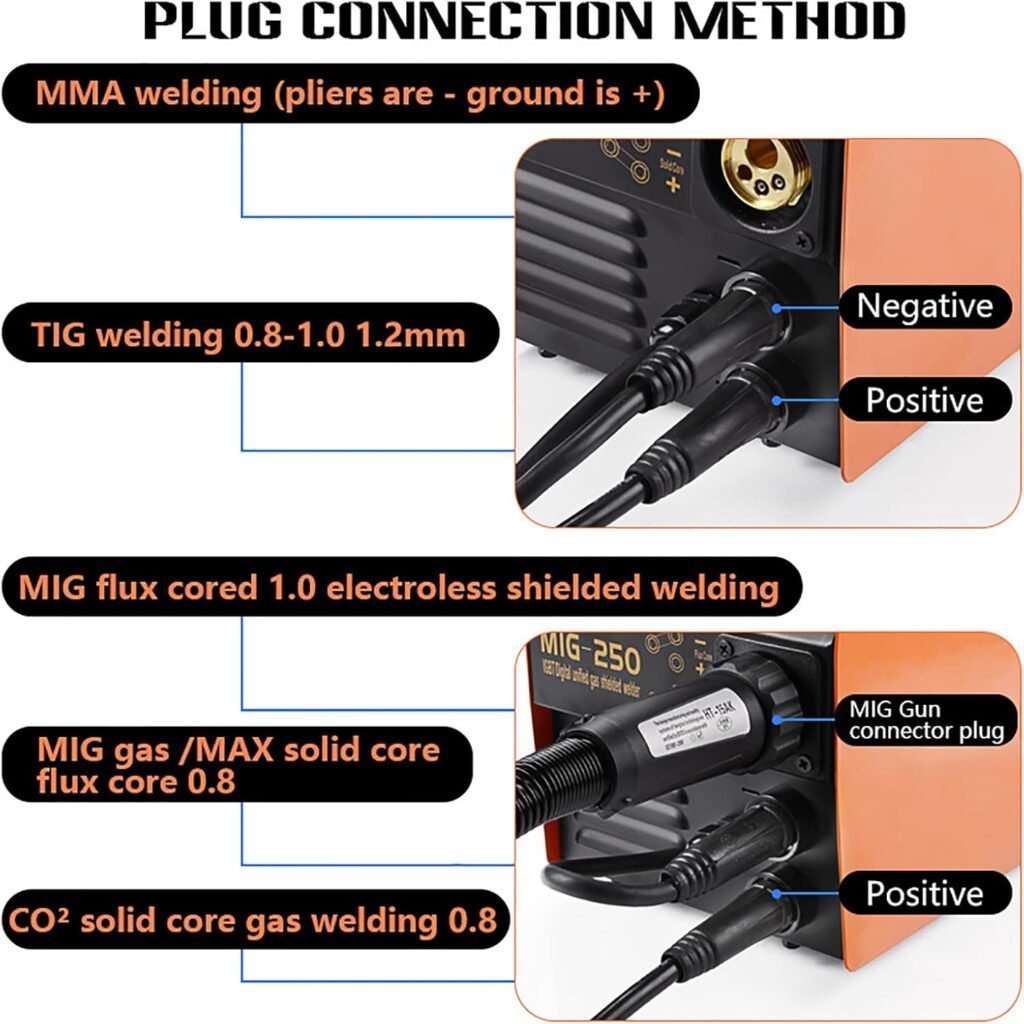

You should select the correct polarity, wire speed, and travel speed to reduce porosity and spatter. Clean your base metal where possible; flux-cored tolerates dirt better than gas-shielded MIG but benefits from cleaner surfaces. Use appropriate wire diameter (commonly 0.6–1.2 mm range) matched to your machine’s feed capability.

Performance: LIFT TIG (no-gas HF start)

Lift TIG provides a cleaner arc for thin materials and stainless steel, but it’s not as refined as high-frequency TIG start systems. You’ll touch the tungsten to the work, lift to initiate the arc, and then weld. This method reduces complexity and cost while still giving you a TIG-compatible option.

If you plan to TIG weld a lot of thin stainless steel or need high cosmetic quality, you’ll get decent results with proper tungsten prep and steady foot or fingertip control of current. However, for production TIG work or aluminum TIG, a full TIG machine with HF start and AC capability would be better.

Tips for LIFT TIG use

Use a sharp, properly ground tungsten and a steady hand for the best results. Keep gas flow set correctly and preflow/postflow times appropriate for cooling the weld and preventing oxidation. Practice the touch-and-lift start to minimize tungsten contamination in the weld.

Performance: ARC/MMA (stick welding)

ARC or MMA is the go-to for thick, dirty metals and outdoor conditions where other processes struggle. You’ll use coated electrodes to weld heavy sections and field repairs. This welder’s ARC mode provides adequate power and control for typical stick electrodes like E7018 or E6013.

Stick welding is forgiving for outdoor work, and you’ll find that the machine’s ARC performance is stable for light- to medium-duty jobs. Heavy industrial stick welding that requires long duty cycles might push the machine’s limits, but for most DIY and repair tasks it’s excellent.

Using the stick mode effectively

Choose the correct electrode size and set current according to the electrode specifications. Maintain consistent arc length and travel speed. If you weld in colder environments, preheat thicker sections to avoid cracking.

Setup and first-time use

When you unbox the machine, you’ll have to connect the MIG gun, ground clamp, torch leads, wire spool, and optionally a gas regulator if you plan to use solid wire with shielding gas. You’ll also choose the input voltage and verify the machine matches your outlet.

Follow the manual for installing wire and calibrating feed tension. If your unit includes both 110V and 220V capability, confirm wiring and plug type before powering up. Always secure the ground clamp to a clean metal surface for accurate results.

Step-by-step quick startup checklist

- Inspect all cables, connectors, and accessories for damage.

- Install the correct wire spool and set feed tension.

- Attach the ground clamp to clean metal.

- Set welding mode (MIG/TIG/ARC) and initial parameters for material thickness.

- If using gas, connect the regulator and confirm flow.

- Test on scrap metal and adjust wire speed/voltage (MIG) or current (TIG/ARC).

Consumables, wire, and shielding gas choices

You’ll need to pick the right wire type and gas depending on material and location. For stainless MIG with shielding gas, choose a stainless wire and a suitable argon/CO2 mix. For mild steel, a standard ER70S-6 solid wire with CO2 or argon/CO2 mix works well. Flux-cored wire like E71T-11 gives you gasless convenience but more cleanup.

Stock up on contact tips, nozzles, and a selection of wire diameters (0.8 mm and 1.0–1.2 mm are common). For TIG, have a selection of tungsten types (2% thoriated or ceriated for DC) and sizes. A small argon cylinder and regulator are necessary for gas-shielded welding.

Recommended gas mixes

- Mild steel with solid wire: 75–95% Argon / CO2 mixes, or straight CO2 for deeper penetration and lower cost.

- Stainless steel MIG: Argon with a small percentage of CO2 or Oxygen, or specialized stainless mixes.

- Flux-cored: No gas required for self-shielded flux-core; consider gas-shielded flux-core for cleaner welds.

Duty cycle and thermal performance

This machine is designed for hobbyists and light-professional use, so its duty cycle will be respectable but not industrial. You’ll be able to run mid-length welds, then allow time for cooling. For long continuous welding sessions on thick material, plan for cooling breaks or a larger industrial unit.

If you push the machine near its rated current for extended periods, thermal protection should kick in to prevent damage. Expect protective cut-offs and indicator lights that help you avoid overheating.

Managing heat and duty cycle

Monitor the welder’s temperature and keep an eye on duty cycle charts provided by the manufacturer. Use shorter welds and staggered passes to prevent overheating. If frequent long welds are part of your workflow, consider upgrading to a higher-duty-cycle model.

Safety considerations

You’ll need standard welding PPE: helmet with appropriate shade, gloves, jacket, and respiratory protection when welding stainless and flux-cored wires. Ensure good ventilation, especially for flux-cored or stainless welding, to limit exposure to fumes.

Keep the work area free of flammable materials and inspect leads regularly for wear. Use properly rated extension cords if needed, and never bypass safety interlocks.

Essential PPE and shop setup

- Auto-darkening helmet with appropriate shade settings.

- Leather gloves and jacket for spatter protection.

- Respirator or local exhaust for stainless steel and flux-cored welding.

- Fire extinguisher nearby and a clear workspace.

Common issues and troubleshooting

You’ll encounter a few common problems typical of multi-process welders but they’re usually solvable with simple checks. If you get wire feeding issues, check feed tension, drive roll alignment, and contact tip wear. Spatter and porosity often come from incorrect gas settings, dirty base metal, or improper wire feed.

If the TIG arc won’t start, ensure correct ground connection and confirm you’re using a Lift TIG touch technique. For random shutdowns, check duty cycle limits and cooling fan operation.

Quick fixes for common problems

- Wire slipping: Re-adjust tension and clean drive rolls.

- Burn-through on thin metal: Lower current, increase travel speed, or use pulse if available.

- Porosity: Check gas flow, gas type, and base metal cleanliness.

- Overheating: Allow cooling breaks and verify ventilation around the unit.

Maintenance and care

You’ll keep this machine running smoothly with periodic maintenance. Clean dust from vents, inspect cables and connectors, replace worn consumables, and keep the wire path free of debris. Lubricate moving parts lightly if specified by the manual.

Store the unit in a dry place and protect it from excessive dust or moisture. Replace contact tips and nozzles as they wear to maintain arc quality.

Regular maintenance checklist

- Clean vents and fans every few weeks depending on use.

- Replace contact tips and nozzles that show wear.

- Inspect cables and clamps for damage.

- Check wire feed tension and alignment monthly.

- Verify regulator and gas lines for leaks if using gas.

Portability and storage

You’ll find this machine easy to move around thanks to its compact size and handle. It’s lighter than industrial welders, so you can take it to the jobsite or store it in a small garage without special equipment.

Keep in mind that portability sacrifices some heavy-duty features, so if you need continuous high-current welding on thick sections you may prefer a permanent shop-mounted unit.

Tips for transporting and storing

Use original packaging for long-term storage or a padded bag to prevent scrapes. Secure torches and cables during transport so they don’t get stressed. Keep spare consumables in a labeled container for quick changeovers.

Accessories and extras you should consider

You’ll want to invest in a few extras to get the most from the machine. A quality gas regulator and cylinder, extra wire spools, an auto-darkening helmet, and a set of tungsten electrodes will keep you welding without delays.

Consider a cart with storage if you’ll use the welder frequently in your shop. A welding table, clamps, and magnets will help you set up workpieces quickly and accurately.

Suggested accessory list

- Argon regulator and cylinder (if welding with solid wire or TIG).

- Extra consumables: contact tips, nozzles, liners, tungsten.

- Auto-darkening helmet and leather gloves.

- Wire of multiple diameters and types (ER70S-6, E71T-11, stainless rods).

- Welding cart or stand for mobility and storage.

Value for money

This combo machine tends to offer excellent value if you need multiple welding processes in one package. You’ll save space and money versus buying three separate machines, and you’ll gain flexibility for varying jobs.

If your workload is industrial and continuous, an industrial single-process machine could be a better long-term investment, but for most DIYers, hobbyists, and light pros, this welder gives a strong balance of capabilities and cost.

Who gets the best value

You’ll see greatest value if you:

- Need occasional TIG and MIG without buying two separate machines.

- Perform outdoor repairs where flux-core gasless welding is handy.

- Are starting out and want a single, versatile unit to learn multiple processes.

Comparison with similar welders

Compared to single-process machines, this unit is more versatile but slightly less specialized. Versus other multi-process cheaper combos, quality of wire feed and TIG start method are key differentiators. You’ll want to compare actual duty cycle ratings, input voltage options, and included accessories when choosing between brands.

In short, this model competes well on price and versatility, but you’ll sacrifice the pure performance and duty cycles of dedicated machines.

Key comparison points to watch for

- Duty cycle at rated amperage.

- Wire feed quality and spool capacity.

- TIG capabilities (Lift TIG vs HF start and AC capability for aluminum).

- Included accessories and warranty.

Tips and tricks to get better results

Practice on scrap first to find optimal settings for wire speed, voltage, and travel angle. Use a short stick-out for MIG to reduce spatter, and keep steady travel speed for consistent penetration. For TIG, master the lift-start technique and practice rhythmic filler addition.

Keep a notebook of settings for common material thicknesses so you can reproduce good results quickly when switching jobs.

Quick practical tips

- Mark settings for common thicknesses on a cheat sheet.

- Keep contact tips and nozzles clean for consistent arc behavior.

- Use anti-spatter spray sparingly to protect nozzles and parts.

- Preheat thick or cold workpieces to reduce cracking.

Pros and cons

You’ll want to weigh the benefits and trade-offs to see if this welder fits your shop or jobsite.

Pros:

- Versatile 3-in-1 capability reduces equipment needs.

- Supports both solid and flux-cored MIG wire for flexibility.

- Portable and user-friendly for beginners and pros alike.

- Cost-effective for DIY and light-professional use.

Cons:

- Duty cycle and cooling are limited compared to industrial machines.

- Lift TIG is useful but not a full TIG replacement for aluminum work.

- Wire feed and consumables are not as heavy-duty as dedicated high-end feeders.

- Long continuous heavy welding will push limits.

Who should buy this welder?

You should consider this machine if you’re a hobbyist, small fabrication shop, auto-body enthusiast, or a maintenance technician who needs a single, flexible welding solution. It’s particularly apt if you prefer the option to weld outdoors without gas using flux core, but also want gas-shielded MIG and the occasional TIG or stick capability.

If you primarily weld aluminum or run continuous production welds every day, you might prefer dedicated, higher-end machines.

Ideal user profiles

- DIY small projects and home repairs.

- Mobile repair techs and farmers needing a portable machine.

- Beginner welders who want to learn multiple processes.

- Small shops with diverse welding needs but limited budget.

Final verdict and buying advice

You’ll get a lot of functionality for the price with the “250A MIG Welder, 3 in 1 Combo MMA/MIG/LIFT TIG Welder Machine, Flux Core Welder, MIG-130 Portable Welding Machine – MIG Welding Equipment.” It’s a strong choice if you want flexibility, portability, and the ability to switch between solid wire and flux-cored MIG options while also having TIG and stick capabilities on standby.

Before you buy, confirm the exact voltage and duty cycle for the specific model you’re considering, check included accessories, and read customer reviews related to longevity and after-sales support. If those align with your needs, this unit will likely serve you well for a wide range of projects.

Final purchase checklist

- Confirm input voltage compatibility with your workspace.

- Verify duty cycle for your typical welding tasks.

- Ensure seller includes necessary accessories or plan to buy them.

- Budget for gas if you’ll be doing gas-shielded MIG or TIG often.

- Check warranty and spare parts availability.

If you want, tell me what types of projects you’ll be working on (material types and thicknesses) and I’ll suggest recommended settings, wire sizes, and accessories tailored to your needs.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.