Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Want a reliable set of consumables for your MB15 MIG/MAG welding torch that won’t leave you guessing during a job?

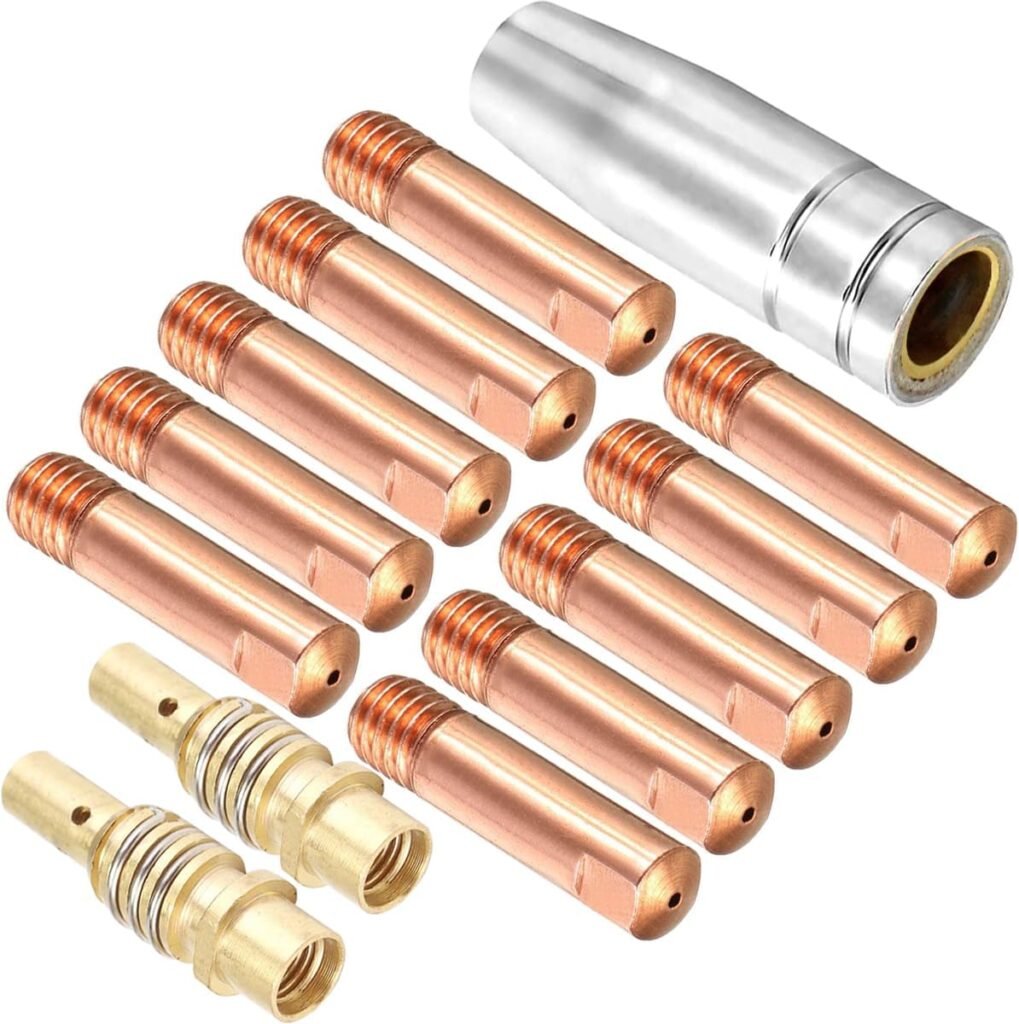

Overview of EATBALE MB15 15AK Nozzles Contact Tips Holders MIG Welder Consumable (13Pcs)

You’ll find this 13-piece set labeled “EATBALE MB15 15AK Nozzles Contact Tips Holders MIG Welder Consumable, Contact Tip 1.0mm M6, Tips Holder Difuser, Nozzles, Welding Gun Accessories for MB15 15AK MIG/MAG Welding Torch (13Pcs)” aims to cover most common needs for MB15/AK15-style welding torches. The set is positioned as a ready-to-use replacement pack containing contact tips, a gas nozzle, and tip holders so you can get back to work quickly when consumables wear out.

What the product is meant to solve

You want stable arc performance and consistent wire feeding while you weld, and worn nozzles or tips cause spatter, poor contact, and frequent downtime. This set is intended to restore the torch’s ability to deliver current smoothly to the arc zone and maintain consistent gas coverage so your welds improve and your efficiency increases.

What’s Included

You’ll appreciate knowing exactly what you get in the 13-piece package before you buy, so you can plan for replacements or backups.

- 10 x 1.0mm Contact Nozzles (Contact Tips)

- 1 x Gas Nozzle (conically pluggable)

- 2 x Contact Tip Holders

You’ll have spare tips ready for most small- to medium-gauge wire welding tasks and the nozzle and holders should fit standard AK15/MB15 torch heads.

Package quality and labeling

Each part is typically packaged together in a small box or blister pack; you should inspect them for correct thread size (M6) and tip diameter (1.0mm) before using. The labeling normally names the set and compatibility, but you should check the items visually to confirm the thread and fit to your torch model.

Compatibility and Fit

This set is described as “widely applicable” for AK15 MB15-style welding torches from various manufacturers. You’ll need to confirm physical compatibility before assuming a perfect fit.

Torch models and fit notes

If your torch is an MB15 or AK15 standard (often used on light-duty MIG guns), the M6 thread and 1.0mm tip should match. If your torch is a different standard (e.g., different thread pitch or tip dimensions), you should compare the existing parts on your torch to the new parts in this set to ensure fit.

Materials and Build Quality

Materials matter for conductivity and durability, and this set uses copper and brass—materials you’re used to seeing in contact tips and holders.

Copper and brass benefits

Copper provides excellent electrical conductivity which reduces resistance and heat buildup at the tip, improving welding stability. Brass in holders and diffusers offers good strength and wear resistance so your components last longer under regular use.

Manufacturing quality expectations

You should expect acceptable machining for the price range: smooth threads and a consistent bore are important for wire feeding. Inspect the tips for a centered hole and consistent diameter to reduce wire feeding issues.

Technical Specifications (Quick Reference Table)

Below is an easy-to-scan table breaking down the essentials so you can compare quickly.

| Feature | Detail |

|---|---|

| Product Name | EATBALE MB15 15AK Nozzles Contact Tips Holders MIG Welder Consumable (13Pcs) |

| Contact Tip Size | 1.0 mm |

| Thread | M6 |

| Quantity of Contact Tips | 10 |

| Gas Nozzle | 1 x conical pluggable |

| Contact Tip Holders | 2 |

| Materials | Copper (tips), Brass (holders/nozzle) |

| Compatibility | MB15 / AK15 MIG/MAG welding torches (common models) |

| Intended Use | MIG/MAG welding consumables and replacements |

| Typical Applications | Light to medium welding tasks, shop, hobby, maintenance |

Installation and Initial Setup

Changing consumables is straightforward if you follow a basic routine. You’ll be back to welding quickly when you know the right steps.

How to swap tips and nozzle

First, turn off and unplug your welder and allow the torch to cool. Unscrew the worn nozzle and tip holder, remove the old contact tip, screw in the new contact tip (ensuring the wire path is centered), attach the nozzle, and then tighten securely. Check for snug fit but avoid overtightening which could damage threads.

Things to check after installation

After installation, feed your wire manually through the gun to ensure the wire passes freely through the new tip. Run a short weld test at low current to confirm good arc stability and consistent gas coverage.

Performance: Arc Stability and Wire Feed

You’ll likely notice improvements if your previous tips were worn or clogged. Good contact tips and diffusers help create a steady, reliable arc and smooth wire feeding.

Electrical contact and arc behavior

Copper contact tips conduct electricity efficiently, so you should see a more stable arc with less erratic behavior as the current transfer to the wire becomes smoother. That means fewer burnbacks and a cleaner, more consistent arc.

Wire feeding reliability

A true-to-size 1.0mm bore should keep your wire centered and prevent drag. If you use 0.030” (0.8mm) to 0.035” (0.9mm) or 0.039” (1.0mm) wire, these tips should feed correctly, but confirm wire size compatibility before welding.

Gas Coverage and Nozzle Shape

The included conical pluggable gas nozzle may change your gas flow characteristics slightly depending on the shape compared to your original nozzle. You’ll want to ensure that the new nozzle provides consistent shielding to avoid porosity.

How nozzle shape affects welds

A conical nozzle can concentrate gas more directly on the weld pool, which is beneficial when you need focused shielding. If your welding environment has drafts, you should still ensure your gas flow settings are appropriate to maintain coverage.

Gas nozzle material impact

Brass diffusers and nozzles generally tolerate heat well and resist deformation better than cheaper alloys. You should find the nozzle keeps its shape under typical use so gas flow remains stable.

Durability and Longevity

You want components that can handle repetitive use; copper and brass parts usually offer that. Proper care will extend the life significantly.

Wear mechanisms to watch

Contact tips wear primarily from friction with the wire and from heat. If you weld abrasive wires or use high amperage settings, your tips will wear faster. Check tips regularly for enlargement of the bore or off-center holes.

How to maximize life span

Keep the torch clean, remove spatter build-up, use correct gas flow, and replace tips before they become excessively worn to maintain consistent weld quality and prolong both tip and nozzle life.

Maintenance and Cleaning

Routine maintenance keeps your torch performing and prevents small problems from becoming major headaches. You’ll want to establish a simple cleaning routine.

Regular cleaning steps

After welding, remove the nozzle and clean spatter using a nozzle reamer or pliers; use a wire brush to clean inside the nozzle area. Wipe the contact tip lightly and check for proper fit. Reassemble once everything is clean and cool.

When to replace instead of clean

If the contact tip bore has become oval or noticeably larger than 1.0mm, you should replace it. If the nozzle is warped or the holder threads are damaged, replacement is preferable to trying to repair it.

Troubleshooting Common Issues

Even with new parts, things can go wrong; knowing what to look for helps you fix issues quickly.

If wire jams or feeds irregularly

Check for a misaligned tip, an off-center hole, or debris in the nozzle. Confirm the liner is in good condition and that the drive rolls are correctly adjusted to your wire size and tension.

If you get excess spatter or porosity

Verify gas flow and gas type for the material and ensure the nozzle is clean and the diffuser is seated correctly. Also confirm you don’t have drafts affecting the shielding gas and that your tip-to-work distance is appropriate.

Safety Considerations

You’ll be working with high heat and electricity, so safety should be a priority when installing or changing consumables.

Basic safety steps

Always power down and unplug the welder, allow components to cool, and wear gloves when handling hot parts. Use eye protection and avoid touching conductors while the machine is energized.

Safe disposal and storage

Store spare tips and nozzles in a dry place to avoid corrosion. Dispose of severely damaged or deformed parts according to local regulations if they’re contaminated or unsafe to reuse.

Comparing to OEM and Other Aftermarket Options

You’ll want to know how this set stacks up versus original equipment manufacturer (OEM) parts and other aftermarket options.

Pros compared to OEM

This set is generally more budget-friendly and provides enough pieces to keep you running without ordering single replacements. The materials (copper/brass) are consistent with many OEM consumables.

Cons compared to OEM

Fit or finish might vary slightly versus OEM parts. You might need to clean burrs or slightly adjust fitment in rare cases; OEM parts sometimes have finer machining tolerances.

Value for Money

You’ll often weigh cost vs performance—this 13-piece set is positioned as an economical spare set for MB15/AK15 torch users.

Who benefits most from this price point

Hobbyists, small shops, and anyone who wants a ready set of spares without paying premium OEM prices will find value here. You’ll get multiple tips and holders to cover routine wear and tear.

When you might prefer to pay more

If you require top-tier precision for high-production welding where every part must meet strict tolerances, OEM or premium brand tips may be worth the extra cost.

Who Should Buy This

Think about your welding needs: frequency, wire size, and torch model.

Ideal users

You should consider this set if you use an MB15/AK15-style torch for hobby work, maintenance, light fabrication, or small shop jobs and you want economical, ready-to-install replacements.

When to skip it

If you run high-volume production or use unconventional wire sizes and need exact OEM tolerances, you might opt for an OEM pack or specialty tips matched precisely to your wire type.

Pros and Cons Summary

You’ll want a quick summary to decide fast—here are the main pros and cons to weigh.

Pros

- Affordable 13-piece set that covers common consumables.

- Copper and brass materials provide good conductivity and durability.

- Standardized M6 thread and 1.0mm tip fit many MB15/AK15 torches.

- Includes spare tip holders and a nozzle for quick replacement.

Cons

- Fit and finish may vary slightly compared to OEM parts.

- Only one nozzle included—if you use multiple nozzle types or sizes you may need additional purchases.

- Designed for a 1.0mm tip; if you commonly use a different wire diameter you’ll need different tips.

Practical Tips for Best Results

You’ll get the most out of this set if you follow a few practical tips during use and maintenance.

- Match wire diameter to the tip bore; 1.0mm tips work best with 0.035”/0.039” wires.

- Inspect tips under light for centered bore before installation to reduce feeding issues.

- Keep spare tips handy so you can swap quickly mid-job if wear affects performance.

- Clean the nozzle after each heavy spatter session to avoid gas flow disruption.

Frequently Asked Questions (Quick Answers)

You’ll likely have questions before buying—here are concise answers to common ones.

- Will these fit my MB15 torch? If your torch uses the AK15/MB15 standard with M6 threads and 1.0mm tip size, yes—verify by comparing your current parts.

- Can I use these with stainless or flux-cored wire? The physical parts fit, but for stainless and flux-cored wires you may need to check specific tip wear rates and gas settings.

- How often will tips wear out? It depends on wire type and amperage—check frequently and replace when the bore enlarges or the arc becomes unstable.

Final Recommendation

If you need an economical, practical replacement pack to keep your MB15/AK15 welding torch running, this EATBALE 13-piece set is a sensible choice. You’ll get a variety of consumables that restore arc stability and gas coverage, especially useful for hobbyists, maintenance workers, and light-fabrication shops.

Last considerations before buying

Confirm your torch thread and typical wire diameter before purchasing to ensure the 1.0mm M6 tips are the right match. Keep in mind that while these parts are cost-effective, you should inspect each piece on arrival for fit and finish to avoid surprises.

Closing Notes

You’ll find this set useful if your goal is to reduce downtime and keep commonly used spares on hand without spending much on OEM replacements. With proper maintenance and correct matching to your wire size, the EATBALE MB15 15AK Nozzles Contact Tips Holders MIG Welder Consumable set can be a practical addition to your welding toolkit.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.