Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a sturdy welding cart that keeps your welder, plasma cutter, and accessories organized and easy to move?

First Impressions

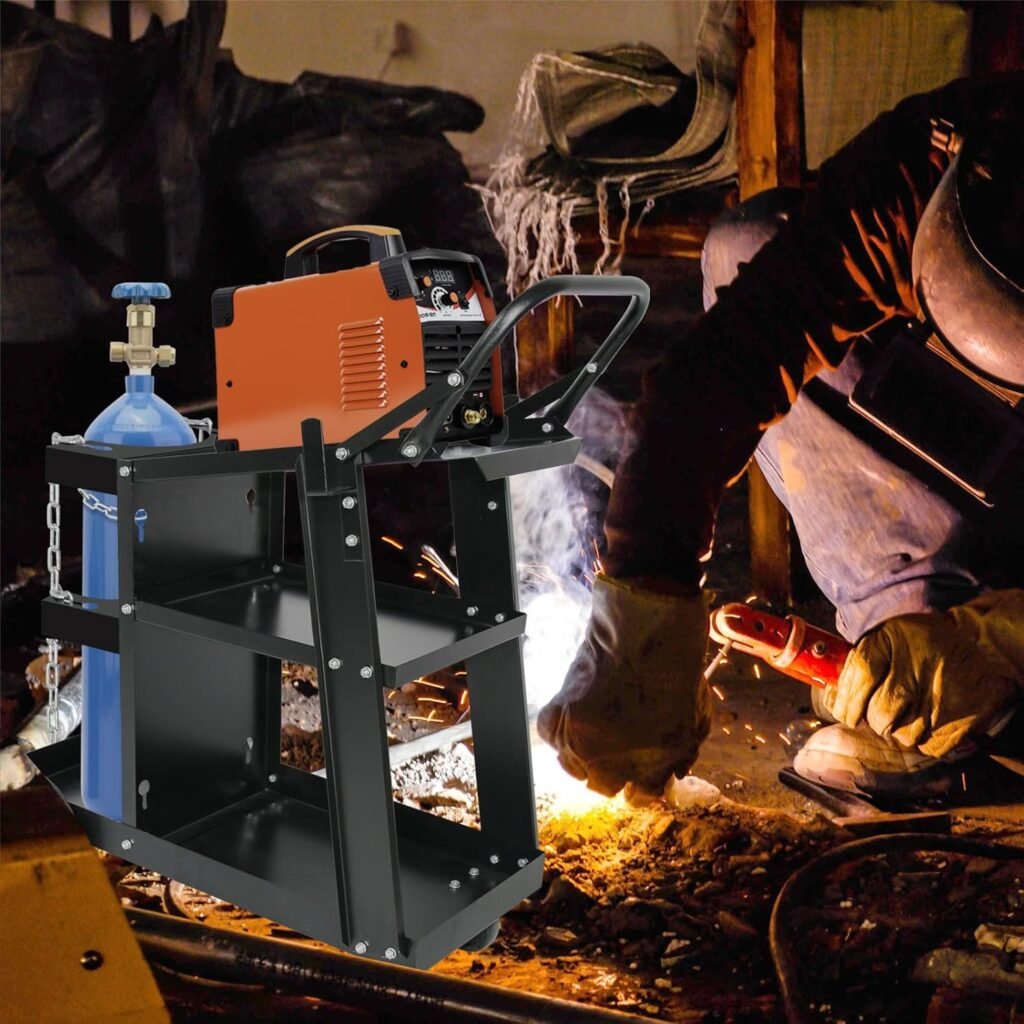

When you first see the MAYNIYJK Welding Cart Heavy Duty Welder Cart for MIG/TIG Welder and Plasma Cutter, 3-Tier Welding Cart with Wheels Handles and Gas Tank Holder, Black, 27.7″ x 11.4″ x 29.7″, you’ll notice the straightforward, utilitarian design. The black finish gives it a professional look, and the steel construction feels solid in your hands, which builds confidence that this cart was made to last.

The proportions are compact enough for tighter workshop spaces while still offering three tiers of storage. You’ll appreciate that it looks like a purpose-built solution rather than a repurposed dolly, which matters when you want tools and gas cylinders accessible and secure.

Product Overview

This cart is presented as a heavy duty solution for moving and storing welders, plasma cutters, and their associated gear. It’s made of high-quality steel that’s treated to resist rust and promises a long service life. The manufacturer rates it to carry 180 pounds while moving, which is enough for a wide range of bench and portable welders plus tools.

The cart dimensions are 29.7″ (height) x 27.75″ (length) x 11.42″ (width), which gives you a narrow footprint but vertical storage that keeps your work area uncluttered. You’ll find three shelves, a gas cylinder holder with safety chains, an ergonomic handle, side hooks, and a set of four casters designed for both mobility and stability.

Key Specifications

Below is a compact breakdown of the most relevant specs so you can quickly see if it matches your needs. This should help you verify fit, capacity, and compatibility with your equipment.

| Feature | Details |

|---|---|

| Product Name | MAYNIYJK Welding Cart Heavy Duty Welder Cart for MIG/TIG Welder and Plasma Cutter, 3-Tier Welding Cart with Wheels Handles and Gas Tank Holder, Black, 27.7″ x 11.4″ x 29.7″ |

| Material | High-quality steel (rust-resistant finish) |

| Color | Black |

| Overall Dimensions | 29.7″ (H) x 27.75″ (L) x 11.42″ (W) |

| Load Capacity | Up to 180 pounds while moving |

| Shelves | 3-tier storage shelves |

| Gas Tank Holder | Rear shelf with 2 safety chains |

| Casters | 4 heavy-duty casters (2 front 360° swivel, 2 large fixed rear wheels) |

| Side Hooks | 2 hooks for tools/welding guns |

| Assembly | Hardware and illustrated instructions included |

| Suitable For | Most MIG, TIG, ARC welders and plasma cutters |

| Warranty/Support | Contact seller for installation issues |

What You Get In the Box

You’ll receive the disassembled cart parts, the hardware pack with bolts and nuts, and an illustrated instruction manual. Everything necessary to assemble the cart is included, so you won’t be scrambling for special bolts or washers.

The manual includes diagrams and indicates the recommended assembly order. If anything is missing or you run into trouble, the product page suggests contacting the seller for help, which is useful if you’d rather not improvise.

Performance and Build Quality

The steel construction gives the cart a reassuring heft and rigidity that you’ll notice when you load heavy gear on the shelves. The rust-resistant finish helps keep the cart looking good even in a humid garage environment, and the welds and bent metal parts look clean and properly aligned when you inspect them.

Given the 180-pound moving capacity, the cart works well for portable welders and their accessories. You’ll still want to be mindful of weight distribution—placing the heaviest item on the lower shelf and centering loads will help keep things stable while you move the cart.

Frame and Shelves

The frame is welded and bolted in sections to create a rigid skeleton for the three shelves. Each shelf has a lip to help keep small items from sliding off when you push or pull the cart. You’ll find the rear shelf designed specifically with gas cylinder support in mind, which makes sense because those cylinders are tall and need to be secured vertically.

The shelves feel capable of handling grinders, helmets, clamps, and spools of wire without sagging. If you plan to store very heavy bench machines on the upper shelves, consider reinforcing or keeping the heaviest items down low.

Wheels and Mobility

The cart uses four heavy-duty casters—two front swivel wheels that rotate a full 360° and two larger fixed rear wheels that give you directional stability. This combination means you can steer the cart easily in tight spaces while still having a stable pull/drive when it’s loaded.

You’ll also appreciate that the wheels are designed to move quietly and be gentle on floors, helping to protect your workshop surface from gouges. The casters’ quality makes it practical to move the cart over shop-floor debris and small obstacles without having to lift it.

Gas Cylinder Security

The rear shelf comes with two safety chains to secure gas cylinders and prevent slippage. When you’re handling cylinders, that security is crucial to avoid tipping hazards and potential damage. You’ll want to make sure the chains are snug and the cylinder base is sitting properly against the rear support when you move the cart.

Additionally, because the cart positions the cylinder behind the main load, you reduce the chance that an uneven load will press the cylinder against other items. Still, always check that the chains are in good condition and not overly worn before every transport.

Storage and Organization

This cart is designed to keep the tools you use most often within arm’s reach. The three-tier design creates dedicated places for your welder on one shelf, accessories on another, and consumables like wire and tips on the third. You’ll find that having a predictable spot for each item speeds up your workflow.

The layout is especially helpful if you move from job to job or work on multiple small projects, because you can prepare the cart and take the whole setup with you.

3-Tier Shelving Layout

The three-tier arrangement provides clear organization opportunities. You can place the welding machine on the middle shelf for balance, put gas or heavier items on the bottom shelf for low center of gravity, and reserve the top shelf for lighter tools and consumables that you need quick access to.

Because the shelves are open, you’ll be able to see what’s stored at a glance and grab items without opening drawers or compartments. If you want more organization, adding small bins or magnetic holders on the shelves is an easy upgrade.

Side Hooks and Accessories

Two side hooks let you hang welding guns, pliers, lead wires, or bags. These hooks remove clutter from the shelves and keep tools from getting tangled. You can also hook gloves, face shields, or extension cords here, which makes preparing for a job faster.

If you tend to misplace small tools, you might add labeled pouches or small baskets to the hooks to keep everything tidy and in one place.

Assembly Experience

You’ll likely complete assembly in under an hour if you follow the instructions and have common hand tools on hand. The accurate hole positioning makes alignment straightforward, and the parts are lightweight enough to handle solo if needed.

The instructions recommend not tightening bolts fully at the beginning; that allows you to adjust parts for perfect alignment before locking them down. That small tip makes the whole process smoother and prevents frustration from trying to force misaligned holes together.

Tools Required and Instructions

Basic tools like a wrench and screwdriver will get the job done. Depending on whether bolts use hex heads or nuts, a socket set or adjustable wrench will speed things up. The manual indicates which bolts go where with illustrations, so you can follow step-by-step without needing a mechanic’s skillset.

You’ll find it’s better to partially assemble all components first—frames, shelves, casters—then tighten hardware after confirming everything lines up. This approach prevents cross-threading and makes for more accurate final assembly.

Common Assembly Mistakes and Tips

A common mistake is overtightening bolts too early, which can make it hard to align other parts. Follow the manual’s guidance to hold off on final tightening until everything is in place. Also, take care to attach casters in the correct orientation: swivel casters should go on the front for easier maneuverability.

Another tip: keep all small fasteners in a tray so they don’t roll away, and work on a soft but flat surface to avoid scratching the finish as you build the cart.

Use Cases and Compatibility

You’ll find this cart suits a variety of welding and cutting setups. Whether you own a small MIG welder for auto body work, a TIG unit for precision jobs, or a plasma cutter for metal fabrication, the cart provides a stable platform and storage solution for portable equipment.

It’s particularly useful when you need to move gear between different spots in a shop or take your setup along to a job site. If you work with heavy, stationary welders full-time, you might prefer a floor-mounted setup—but for mobility and organization this cart is a practical choice.

Home Workshop Use

If you do hobby welding, restoration, or small fabrication projects at home, the cart helps keep your space organized and your welder protected. You’ll appreciate the compact footprint that leaves room for a workbench and gives you mobile storage for spools, clamps, and safety gear.

The quiet wheels are also a plus in a residential setting where you want to avoid too much noise when moving equipment around.

Professional Shop Use

In a professional environment, the cart can function as a mobile station for service work, layout tasks, or spot repairs. You’ll find it handy for quick jobs where you don’t want to set up a permanent station, and the safety chains give you confidence when transporting gas cylinders.

However, if you move extremely heavy industrial welding machines frequently, confirm the machine weight and consider a cart with higher load capacity or motorized movement.

Compatibility with Welders and Plasma Cutters

The cart is advertised as suitable for most MIG, TIG, and ARC welders and plasma cutters. You’ll want to measure your machine footprint and weight and compare it to the cart’s shelf dimensions and 180-pound moving capacity. In many cases the cart will fit mid-sized portable welders and cutters comfortably.

If your machine is very wide or has a nonstandard base, you may need to adapt the mounting or keep it on the lowest shelf only.

Pros and Cons

You’ll want a balanced view of what the cart does well and where it might not meet every need.

Pros:

- Sturdy steel construction with rust-resistant finish gives long-term durability.

- 3-tier shelving provides flexible storage for tools and consumables.

- Gas cylinder chains secure tanks safely during movement.

- Swivel front casters and large rear wheels offer a good balance of maneuverability and stability.

- Side hooks and compact footprint improve workflow in small shops.

- Hardware and illustrated instructions included for relatively easy assembly.

Cons:

- 180-pound moving capacity is suitable for many but not all machines; very heavy welders may exceed this limit.

- Assembly requires basic tools and some patience to align parts properly.

- If you need enclosed or lockable storage, this open design won’t provide that.

- The top shelf may not be ideal for very heavy equipment due to center-of-gravity concerns.

Maintenance and Care

Keeping the cart in good condition is straightforward. Periodic checks of fasteners, caster bearings, and the condition of the safety chains will prolong service life and prevent surprises during use.

A light oil on moving parts and keeping the cart clean from weld spatter will also help maintain both function and appearance.

Cleaning and Rust Prevention

Wipe the cart down regularly to remove dust, metal filings, and spatter. If the finish gets chipped, consider touching it up with spray paint designed for metal to prevent rust in exposed areas. In humid or outdoor environments, a thin coat of rust inhibitor on vulnerable spots will help.

If you notice any surface rust, remove it promptly with a wire brush and apply a rust-converting primer before repainting.

Wheel and Fastener Maintenance

Check casters for debris and remove any wire, string, or grit that could impair rotation. Lubricate caster swivel bearings as needed and ensure mounting bolts remain tight. Inspect the safety chains for wear and replace them if they show significant degradation.

Tighten bolts according to a periodic schedule—after heavy use, vibration can loosen hardware, so give the cart a quick inspection before each major move.

Customization and Upgrades

You’ll likely want to tweak the cart to suit your workflow. Fortunately, the open design lends itself well to simple upgrades that can make your setup more efficient and personalized.

Common upgrades include adding magnetic tool holders, bins, cable wraps, and drawer modules. You can also attach pegboards or shelves to the frame to expand storage options.

Adding Additional Storage

You can mount small plastic bins or metal trays to the underside of shelves for fasteners, tips, and small consumables. Magnetic strips on the sides make for fast tool placement and removal. If you frequently use grinders and angle tools, adding a small dedicated hook with a retention clip keeps them secure.

When adding storage, be mindful of weight distribution so you don’t overload one side of the cart.

Upgrading Casters or Handles

If you’ll be moving the cart over rough terrain or you need locking casters for safety, you can replace the factory casters with heavy-duty or lockable models. Swapping in pneumatic casters can smooth movement over gravel or uneven floors, though you’ll want to verify bolt patterns before purchasing replacements.

Upgrading the handle to a thicker, rubber-coated grip can improve ergonomics if you frequently push or pull the cart.

Safety Considerations

Safety should be your priority when transporting gas cylinders, heavy equipment, and hot tools. Use the safety chains for your gas cylinders every time, and make sure the cylinder valve is capped or closed during movement.

Keep the cart’s center of gravity low by placing the heaviest items on the bottom shelf and avoid overloading any single shelf. If you’ll be transporting the cart in a vehicle, secure it to prevent tipping.

Gas Cylinder Safety

Always position gas cylinders upright and secure them with the provided chains. Use cylinder caps or valve protection when transporting to prevent accidental release. Check compatibility of cylinder size with the cart’s rear shelf—oversized tanks may not be stable even when chained.

If you frequently carry oxygen and acetylene cylinders together, separate them when possible and follow local regulations about transport and storage.

Load Limits and Safe Movement

Do not exceed the specified 180-pound moving capacity; static storage might tolerate slightly more weight, but movement introduces dynamic forces that can cause instability. Push the cart rather than pull it when possible to maintain better visibility and control.

Make sure the pathway is clear of obstacles and avoid sudden turns when the cart is fully loaded to prevent tipping.

Comparison with Similar Carts

There are many welding carts on the market with varying features. What sets this cart apart is the combination of a compact footprint, three-tier storage, and a dedicated gas cylinder holder with safety chains—all at a competitive price point for hobbyists and light professionals.

Other carts might offer enclosed drawers, higher load capacity, or more specialized mounting brackets. Compare the carts based on the machines you own and the way you work rather than on price alone.

When to Choose This Cart Over Others

Choose this cart if you want a solid, affordable, and mobile storage solution for a wide range of portable welders and tools. It’s especially good if you need a compact footprint with multiple shelves and a secure cylinder holder.

If you value easy maneuverability in a small shop and need a simple, rugged platform, this cart is a strong candidate.

When You Might Want a Different Option

If you need locked storage, built-in cable management, or extremely high load capacity for heavy industrial machines, consider a cart with enclosed drawers or higher-rated construction. Similarly, if you require heavy-duty transport over uneven terrain on a regular basis, look for carts with industrial-grade casters or a larger base.

Frequently Asked Questions

You’ll likely have a few questions before buying—here are the common ones people ask about this cart.

Q: Will my specific welder fit? A: Measure your welder’s base and weight, then compare it to the cart’s shelf dimensions and 180-pound moving capacity. If the base fits within the shelf footprint and the weight is below the limit, it should work.

Q: Can the cart hold two small machines? A: It depends on combined weight and dimensions. You’ll want to place heavier items on the bottom shelf and ensure total moving weight doesn’t exceed 180 pounds.

Q: Are replacement parts available? A: Contact the seller if parts are missing or damaged. Common replacements like casters or bolts are widely available at hardware stores.

Q: Can you lock the casters? A: The stock configuration doesn’t specify locking casters, but you can upgrade to lockable casters if you want the cart to stay put during use.

Q: Is the cart suitable for outdoor use? A: The finish is rust-resistant, but prolonged outdoor exposure can accelerate wear. Use sheltered storage or periodic touch-ups to maintain corrosion resistance.

Final Recommendation

If you want a functional, compact welding cart that organizes your gear, secures a gas cylinder, and moves smoothly around a shop, the MAYNIYJK Welding Cart Heavy Duty Welder Cart for MIG/TIG Welder and Plasma Cutter, 3-Tier Welding Cart with Wheels Handles and Gas Tank Holder, Black, 27.7″ x 11.4″ x 29.7″ is a solid choice. You’ll get a durable steel frame, three useful shelves, safety features for cylinders, and casters that balance maneuverability with stability.

This cart is particularly well suited for hobbyists, small shops, and on-site technicians who need a mobile workstation without the complexity or cost of larger, enclosed carts. With a few simple upgrades and regular maintenance, it can become the backbone of your mobile welding station and make your workflow smoother and more efficient.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.