Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Curious whether the Sealey Tg100/4 Flux Cored Mig Wire 4.5Kg 0.9Mm A5.20 Class E71T-Gs is the right choice for your welding jobs?

Product overview

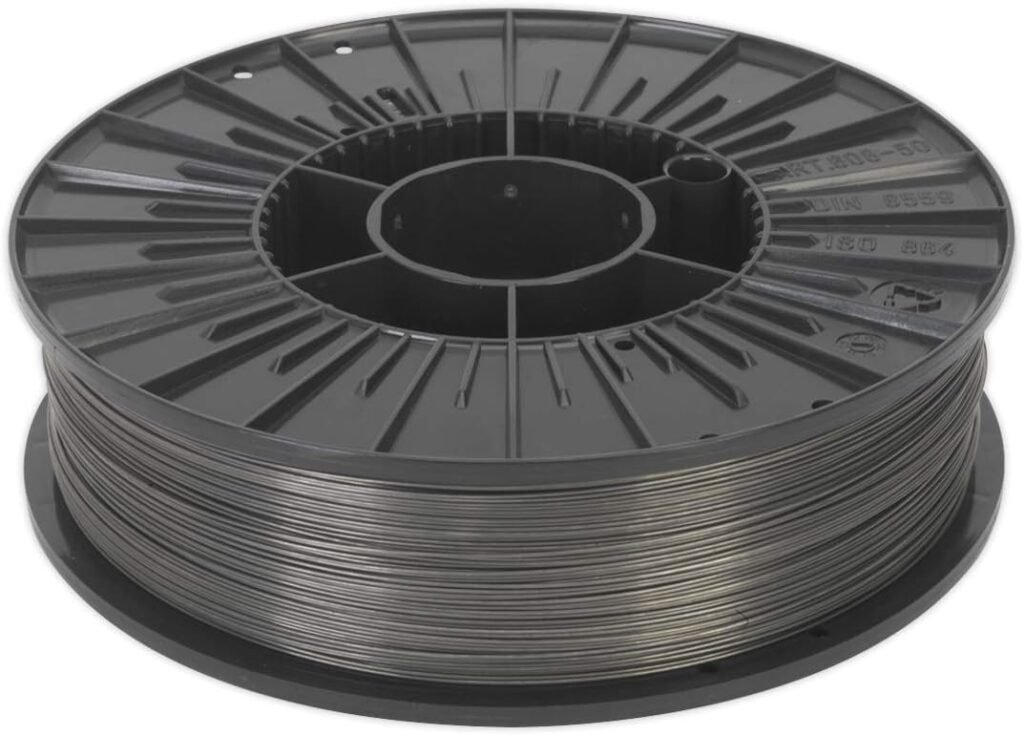

You’ll get a spool of flux-cored MIG wire designed to perform reliably for general-purpose carbon steel welding. The Sealey Tg100/4 Flux Cored Mig Wire 4.5Kg 0.9Mm A5.20 Class E71T-Gs is manufactured to industry standards and is aimed at both workshop and site use, especially where gas shielding isn’t practical.

What the product includes

You should expect a single 4.5 kg spool of 0.9 mm diameter flux-cored wire, ready for use with compatible MIG feeders. This product uses the E71T-GS classification, which is a common, self-shielding flux-cored wire type that handles a range of mild steel applications.

Official product details

The manufacturer lists the following details for quick reference. You can use this to confirm compatibility with your equipment and project needs.

- Top quality wound welding wire manufactured to BS EN ISO 14341:2008.

- Suitable for use with our MIGHTYMIG170/190/210 Gas/No-Gas MIG welders.

- See more product details via the retailer or Sealey’s documentation for additional specs.

Key specifications

You’ll want to check the core specs before you buy so you know the wire will match your machine and intended work. These key specifications summarize what you need at a glance.

| Attribute | Specification |

|---|---|

| Product name | Sealey Tg100/4 Flux Cored Mig Wire 4.5Kg 0.9Mm A5.20 Class E71T-Gs |

| Wire type | Flux-cored, self-shielding (E71T-GS) |

| Diameter | 0.9 mm |

| Spool weight | 4.5 kg |

| Standard | BS EN ISO 14341:2008 |

| Suitable welders | Sealey MIGHTYMIG170/190/210 (Gas/No-Gas) and other compatible MIG feeders |

| Typical materials | Mild steel, low-alloy structural steel |

| Shielding | Self-shielded (no external gas required) |

| Typical polarity | DCEP (electrode positive / DC+) |

| Typical uses | Fabrication, repair, maintenance, outdoor welding |

Performance and welding characteristics

You’ll find that flux-cored wire like this delivers strong deposition rates and good penetration on medium-thickness steel, and it performs especially well outdoors or in windy conditions where gas-shielded welding struggles. Expect higher spatter and slag than gas-shielded solid wire, but the trade-off is excellent productivity and tolerance to less-than-perfect conditions.

Penetration and bead quality

You’ll notice robust penetration with E71T-GS wires, which helps with joint strength and fusion on thicker materials. The bead profile is usually slightly convex and can be controlled with travel speed and voltage adjustments; slag must be removed after welding since the flux produces it during the process.

Deposition rate and efficiency

You’ll appreciate the relatively high deposition rate compared with solid wire of similar diameter, which means you can lay down more metal faster. That helps when you need to get through repair work or structural welding quickly, though you will have more cleanup afterwards due to slag and spatter.

Compatibility and fit

You’ll want to verify that the spool fits and feeds correctly on your machine before buying, since conduit diameter, spool hub sizes, and drive roll types vary. The product is specifically noted as suitable for the Sealey MIGHTYMIG170/190/210 Gas/No-Gas MIG welders, but it will also work with other MIG setups that accept 0.9 mm flux-cored wire on a 4.5 kg spool — just confirm physical fit and drive roll compatibility.

Drive rollers and contact tips

You’ll need drive rollers and contact tips sized for 0.9 mm wire; use knurled or V-groove rollers appropriate for flux-cored wire to avoid slippage. Contact tip internal diameter should match 0.9 mm wire (some people go for a 1.0 mm tip to reduce tip-seizing), and ensure your liner is suitable for flux-cored operation to reduce bird-nesting.

Spool and feeder considerations

You’ll want to check spool mounting and feeder tension settings; flux-cored wire can be softer or more flexible than solid wire, so feed tension and drive roll alignment are important for smooth continuous feeding. If your welder has a spool hub that’s not compatible with the Sealey spool dimensions, an adapter or different spool may be required.

Typical welding parameters

You’ll benefit from parameter ranges when setting up for your welds. These are typical starting points for 0.9 mm flux-cored wire on carbon steel; exact settings depend on the machine, joint geometry, and base material thickness.

| Material thickness | Voltage (approx) | Current (A) | Wire Feed Speed (m/min) | Suggested travel speed |

|---|---|---|---|---|

| 1.0–2.0 mm | 16–18 V | 80–120 A | 4–6 m/min | Fast, short bead |

| 2.0–4.0 mm | 18–22 V | 100–150 A | 5–8 m/min | Moderate travel speed |

| 4.0–8.0 mm | 20–26 V | 140–220 A | 7–12 m/min | Slower travel, multi-pass |

You’ll want to use DCEP (electrode positive) polarity on most machines for E71T-GS wires unless your welder documentation specifies otherwise. If your welder allows inductance or arc control settings, increasing inductance can soften the arc and reduce spatter.

Materials and applications

You’ll be able to use this wire primarily on mild steel and most low-alloy carbon steels. It’s suitable for many fabrication tasks, repair work, maintenance, and outdoor jobs where shielding gas is not feasible.

Common use cases

You’ll find it useful for general fabrication, structural steelwork, agricultural equipment repair, vehicle chassis repair (non-critical areas), and maintenance tasks. Its ability to perform outdoors in wind and its good deposition rate make it a go-to for on-site welding.

Limitations and unsuitable applications

You should avoid using this wire for stainless steel, aluminium, or high-alloy steels that require special filler materials. Also, for critical structural welds or cosmetic automotive bodywork where minimal spatter and a clean bead are essential, you might prefer gas-shielded solid wire.

Setup and practical tips

You’ll save time and frustration by preparing your machine and workspace correctly before you weld with flux-cored wire. A little attention to setup goes a long way in achieving consistent welds.

Pre-weld checklist

You’ll want to follow a quick checklist: confirm spool fit, install the correct drive rolls and contact tip, set polarity to DCEP, set initial voltage and wire feed speed within recommended ranges, and clean base material to remove heavy rust, oil, and paint that could cause porosity. Make sure your work clamping and grounding are solid to prevent intermittent arcs.

Torch handling and technique

You’ll control bead shape by adjusting travel angle, travel speed, and stickout. A short stickout (12–18 mm) tends to produce a stable arc and good transfer. Keep a steady travel speed and maintain a slight push or drag angle depending on desired bead profile — many welders prefer a slight forehand (push) technique for a flatter bead.

Bead cleanup and post-weld handling

You’ll need to chip away slag and brush the weld with a wire brush to reveal the final bead and check for defects. Slag removal is essential for additional passes; leaving slag can cause inclusions and poor fusion on the next pass.

Grinding and finishing

You’ll sometimes grind weld toes for cosmetic or fit reasons, but be careful not to remove excessive reinforcement that could weaken the joint. If you’re preparing the weld for painting or corrosion protection, clean off any residue, remove slag, and use appropriate primers to protect against rust.

Troubleshooting common issues

You’ll run into a few familiar issues with flux-cored welding, but most can be fixed quickly by tweaking settings or technique. Here are common problems and straightforward remedies.

Porosity

If you see porosity in the weld, you’ll first check for contamination on the material (oil, paint, rust) and the wire. Moisture in the wire or the workpiece and excessive travel speed can also cause porosity; store wire dry and slow your travel slightly.

Excessive spatter

If spatter is higher than expected, you’ll try adjusting voltage and wire feed speed slightly to rebalance the arc, and increase inductance if your machine has that control. Cleaning the tip and using the correct contact tip size also helps.

Burnback and bird-nesting

If the wire melts back into the contact tip (burnback) or nests at the feeder (bird-nesting), you’ll check feed tension, liner condition, and drive roll alignment. Reduce voltage slightly, increase wire feed speed incrementally, and ensure the liner is free of kinks or metallic debris.

Maintenance and storage

You’ll extend the life and performance of the spool by storing it properly and maintaining your feeder and torch components. Flux-cored wire is hygroscopic to varying degrees; moisture absorption affects weld quality.

Storing the spool

You’ll keep the spool in a sealed container or dry cabinet, ideally with desiccant packs, especially in humid environments. If the wire has absorbed moisture, some manufacturers recommend baking the spool at a specified temperature to restore condition — check Sealey’s documentation or retailer for exact instructions before attempting any baking.

Machine maintenance

You’ll regularly inspect drive rolls, contact tips, liners, and the torch nozzle for wear and contamination. Replace consumables when they show signs of groove wear, excessive spatter buildup, or tip deformation to maintain consistent feed and arc performance.

Health and safety

You’ll need to follow standard welding safety practices when using flux-cored wire, and there are a few additional considerations due to flux-generated fumes and slag.

Ventilation and fume control

You’ll ensure adequate ventilation or a fume extraction system, as flux-cored welding can generate more particulate and chemical fumes than gas-shielded solid wire. Use respirators rated for welding fumes in poorly ventilated areas.

PPE and arc protection

You’ll wear the usual PPE: welding helmet with correct shade, gloves, apron, and eye protection. Slag chips can be hot and fly unpredictably, so a full-face shield or goggles during slag removal is advisable.

Comparison with other wire types

You’ll want to compare flux-cored wire to solid wire and other filler types to choose the best tool for the job. Each wire class has trade-offs in performance, convenience, and finish.

| Feature | Flux-cored (E71T-GS) | Solid MIG wire (ER70S-6) | Flux-cored with gas (E71T-1) |

|---|---|---|---|

| Shielding | Self-shielding (no external gas) | Requires external shielding gas | Requires external gas |

| Outdoor use | Excellent (wind-resistant) | Poor in wind | Better than solid but still needs gas control |

| Deposition rate | High | Lower | Moderate to high |

| Spatter & slag | High spatter, slag forms | Low spatter, no slag | Moderate spatter, little slag |

| Bead finish | More cleanup required | Cleaner finish | Cleaner than self-shielded FCW |

| Ease of use | Good for site work, more cleanup | Preferred for precision and cosmetic work | Balanced performance |

You’ll choose self-shielded flux-cored when you need portability and production on site; choose solid wire with gas for cleaner welds and thinner material.

Pros and cons

You’ll find a clear set of strengths and trade-offs with this Sealey flux-cored wire. Knowing them helps you match product to task.

Pros

- You’ll be able to weld outdoors without external shielding gas, which is ideal for windy site work.

- You’ll get a good deposition rate for faster build-up and repair tasks.

- You’ll benefit from a robust wire classification (A5.20 E71T-GS) and manufacturing standards (BS EN ISO 14341:2008).

Cons

- You’ll have more spatter and slag to remove compared with gas-shielded solid wire.

- You’ll need careful storage and handling to avoid moisture-related porosity or weld defects.

- You’ll likely need to do more post-weld cleanup for cosmetic or precision work.

Price and value considerations

You’ll consider spool size, frequency of use, and project type when judging value. A 4.5 kg spool is a sensible middle-ground—large enough for multiple repairs or moderate production but compact enough for portability.

When it’s a good value

You’ll see value if you regularly work outdoors, do on-site repairs, or need a wire that performs without running gas lines. The reduced need for shielding gas and higher deposition rate often offset the extra cleaning time.

When another option might be better

You’ll prefer a gas-shielded solid wire if you do precision welding, thin sheet metal, or finish-critical work—this avoids slag and gives a cleaner appearance with less grinding.

Troubleshooting checklist

You’ll find it helpful to run through a short checklist if your welds aren’t turning out as expected. These checks cover the most common sources of trouble.

- Check base material cleanliness for oil, paint, rust, and mill scale.

- Verify spool fit, drive roll type, and feed tension.

- Confirm contact tip size and that the liner is free of debris.

- Adjust voltage and wire feed speed incrementally to stabilize the arc.

- Increase inductance or arc control to reduce spatter if available.

- Replace consumables that are worn or contaminated.

FAQ

You’ll likely have a few recurring questions before you commit to this wire. These quick answers should help.

Q: Can you use this wire with shielding gas? A: This wire is self-shielding (E71T-GS) and is designed to operate without external gas, but some flux-cored wires are compatible with gas for specific purposes. Check Sealey’s documentation; generally you won’t need external gas.

Q: Is 0.9 mm wire suitable for thin sheet metal? A: You’ll be able to weld thinner metals with 0.9 mm wire, but control and heat input are key. For very thin sheet (under 1 mm), you may prefer smaller diameter wire or a pulsed MIG setup to reduce burn-through.

Q: How long does the spool last? A: You’ll find that lifespan depends on how frequently you weld and your deposition needs. A 4.5 kg spool is enough for many repair jobs and moderate production runs, but heavy daily use will go through it faster.

Q: Can you use this wire in the Sealey MIGHTYMIG170/190/210? A: Yes, the product is specifically noted as suitable for those Sealey machines. You should still verify drive roll and contact tip compatibility.

Alternatives and when to choose them

You’ll pick different filler wires depending on environment, finish, and base material. Consider these alternatives for specific needs.

- Use ER70S-6 solid wire with shielding gas if you require cleaner beads and minimal post-weld cleanup.

- Use gas-shielded flux-cored (E71T-1) if you want the deposition advantages of flux-cored wire while still running gas for improved bead appearance.

- Choose stainless or aluminium-specific wires for corresponding base metals; this Sealey wire is for carbon steel only.

Real-world tips from welders

You’ll get better results faster by applying a few practical tips that experienced users rely on.

- Keep a spare spool and consumables on hand when working on-site to avoid downtime.

- Preheat thicker or contaminated steels if necessary to reduce the risk of hydrogen-induced cracking.

- Practice bead control on scrap pieces to dial in voltages and wire feed speed before committing to the actual joint.

Final verdict and recommendation

You’ll find the Sealey Tg100/4 Flux Cored Mig Wire 4.5Kg 0.9Mm A5.20 Class E71T-Gs to be a strong, practical choice if you need a versatile, self-shielded flux-cored wire for mild steel. It’s especially useful for outdoor work, repairs, and jobs where running shielding gas is inconvenient. If you prioritize a cleaner finish or work with thin-gauge sheet often, consider a gas-shielded solid wire instead. For general maintenance, fabrication, and site welding, this spool offers good value, solid performance, and the convenience of self-shielding.

If you want, you can tell me the type of projects you do most often and the machine you use, and I’ll recommend specific setup settings and consumable choices tailored to your gear and materials.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.