Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a reliable flowmeter regulator for your MIG and TIG welding setup?

Product at a glance

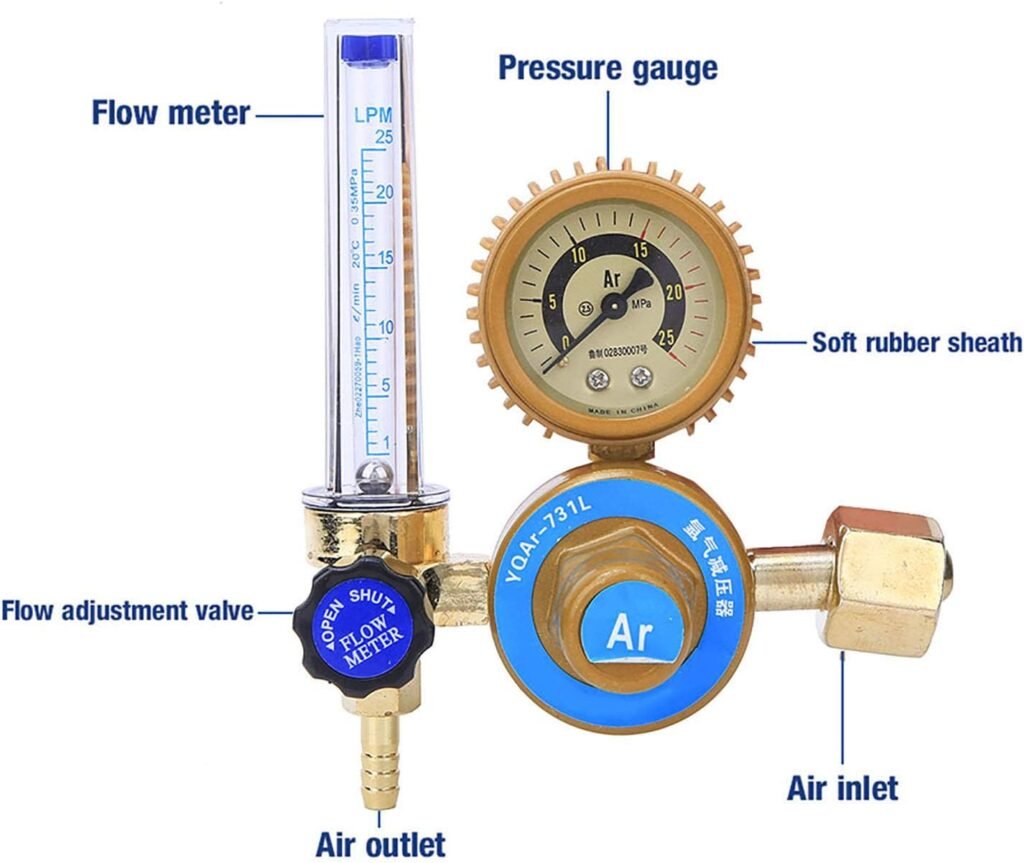

You should know what this Flowmeter Argon Co2 Regulator, Argon CO2 Mig Tig Flow Meter Regulator Pressure Gauge Welder Parts, Tig Mig Welding Pressure Reducer Flow Gauge is meant to do before you commit to it. The unit aims to combine pressure regulation with a readable flowmeter for Argon, CO2, and other inert or semi-inert gases commonly used in welding.

This section gives a compact summary so you can quickly see if it matches your needs. Below, the table breaks down the main specs and intended uses so you can compare at a glance.

| Item | Details |

|---|---|

| Product name | Flowmeter Argon Co2 Regulator, Argon CO2 Mig Tig Flow Meter Regulator Pressure Gauge Welder Parts, Tig Mig Welding Pressure Reducer Flow Gauge |

| Primary use | Regulating and metering Argon, CO2, Helium for MIG/TIG welding |

| Gauge type | Pressure gauge + flowmeter |

| Safety feature | External safety pressure relief design |

| Flow tube | Polycarbonate, impact resistant |

| Calibration | Calibrated for Argon, Helium, Carbon Dioxide |

| Readability | Clear scales for easy reading |

| Compatibility | MIG/TIG welding machines and gas cylinders |

| Durability notes | Impact-resistant outer cover for protection |

What’s in the box?

You’ll typically find the regulator assembly with the flowmeter attached and at least one pressure gauge included. Depending on the seller, the package may also include mounting hardware, sealing washers, or basic instructions to help you get started.

Having the right accessories in the box saves you from an extra trip to the store and speeds up setup. If a specific adapter or fitting is required for your cylinder valve type, confirm that it’s included or that you already have one on hand.

Design and build quality

You’ll notice the Flowmeter Argon Co2 Regulator’s practical, workshop-ready design as soon as you pick it up. It’s built to be utilitarian and focused on function, with reinforced components where you need them most.

The external safety pressure relief design is a visible aspect of the build and speaks to conscious safety engineering. You’ll also appreciate that the flow tube and outer cover use impact-resistant polycarbonate to stand up to accidental knocks and drops.

Materials and durability

You’ll find that the regulator body is typically brass or a similarly robust metal, which is standard for pressure regulation components. Brass gives reliable corrosion resistance and a secure threaded connection to cylinders and hoses.

The flow tube being polycarbonate provides a balance between impact resistance and clarity for reading the scale. You can rely on the outer cover to protect the tube during everyday shop use, but you should still avoid deliberate heavy impacts.

Safety pressure relief design

You’ll appreciate the external safety pressure relief because it helps vent pressure away from sensitive components if the regulator experiences an overpressure event. This reduces the chance of internal damage and adds a layer of safety for you and your equipment.

That external design also makes inspections and maintenance easier since you can visually check the relief area for signs of use or discharge. Always keep it clear of obstructions and check it regularly as part of your safety routine.

Impact-resistant components

You’ll get increased longevity from polycarbonate flow tubes and protective outer covers compared to glass or thin plastic alternatives. Polycarbonate resists shattering, which matters in busy welding environments where tools and parts are frequently bumped.

Still, impact resistance doesn’t mean indestructible; you should handle the regulator with care during transport and while mounting it on the tank to avoid cracking the flow assembly.

Performance and accuracy

You’ll want consistent, stable flow and reliable readings to produce quality welds, and this regulator aims to provide exactly that. The clear scales and calibrated flowmeter make monitoring easy, especially when you’re switching between different gases or welding processes.

Accurate flow reading directly affects weld quality; too much gas wastes consumables and can create turbulence, while too little gas invites porosity and poor arc stability. This model is calibrated for Argon, Helium, and Carbon Dioxide to help you get correct flow settings for each gas.

Flow measurement and clear scales

You’ll find the flowmeter’s clear scales helpful when setting precise flow rates for MIG and TIG work. The readability is a major selling point because it reduces time spent squinting under poor lighting and decreases the chance of misreading the flow.

Make sure to read the scale at eye level and account for any parallax if your viewing angle is off. Small errors in reading can translate to noticeable differences in weld behavior, especially on thinner materials.

Calibration for Argon, Helium, and Carbon Dioxide

You’ll appreciate that the unit is pre-calibrated for common welding gases so you don’t have to guess conversion factors. Calibration means the float position or scale corresponds to typical flow behavior for those specific gases, making your settings more reliable.

If you use mixed gases or specialty blends often, verify whether the regulator’s calibration will still be suitable or whether a gas-specific calibration chart is needed. For most hobbyists and many professionals, the provided calibrations will be adequate.

Pressure regulation and stability

You’ll notice consistent pressure regulation if the regulator is installed correctly and the cylinder is in good condition. A steady output pressure helps maintain constant flow and good weld bead formation, which is essential for repeatable results.

If you see fluctuations in output while your cylinder valve and hoses are secure, consider checking the inlet pressure and the internal seat for wear; regulators can fail slowly, showing minor instabilities before a complete malfunction.

Installation and setup

You’ll be able to install the regulator with basic hand tools if you follow straightforward steps and safety precautions. Always make sure your cylinder is secured and valves are closed before connecting or disconnecting regulators.

Begin by using the correct thread connection and a clean sealing washer or tape where applicable to avoid leaks. Once attached, slowly open the cylinder and monitor the inlet and outlet gauges as you set the desired working pressure.

Connecting to your gas cylinder

You’ll want to ensure the regulator threads match your cylinder valve, which is typically standard—but confirm before forcing anything. Use the included sealing washer or an appropriate fitting to get a tight, leak-free seal, and avoid cross-threading by starting connections by hand.

Open the cylinder valve slowly and watch the high-pressure gauge to make sure it reads correctly, then depressurize and re-tighten if any irregularities appear. Working methodically reduces the risk of damage to the regulator or the cylinder valve.

Adjusting flow rate and reading the gauge

You’ll set the flow using the adjustment knob—turn slowly and watch the float in the flow tube reach the desired mark on the clear scale. For TIG welding, you’ll often run lower flows than for MIG, so take your time dialing in the correct rate.

After setting the flow, run a short purge to confirm the flow is stable and that there are no leaks in your lines or torch. If you notice inconsistent float behavior, check for obstructions, proper gas selection, and regulator seating.

Compatibility and uses

You’ll find this regulator is primarily intended for MIG and TIG welding, which use Argon, CO2, Helium, or blends thereof. It’s broadly compatible with standard welding cylinders and a variety of torch setups when appropriate fittings are used.

Beyond welding, you can use similar regulators for laboratory or light industrial tasks that require controlled flow of inert gases—just ensure the calibration suits the gas and purpose. Always double-check material compatibility and certification if you plan to use it outside welding.

MIG and TIG welding

You’ll get the most value from this flowmeter when you pair it with MIG or TIG processes where shielding gas consistency is critical. For MIG, CO2 or Ar/CO2 blends are common, and for TIG, you typically run pure Argon or Argon/Helium mixes depending on the workpiece and desired arc characteristics.

Adjust your flow and pressure according to torch type, nozzle size, and material thickness. Proper shielding ensures cleaner welds and reduces post-weld cleanup and rework.

Other applications (Argon, Helium, CO2)

You’ll be able to use this unit for Helium when you need higher heat input or different arc characteristics, and for Carbon Dioxide where cost and penetration are priorities. Each gas behaves differently in the flowmeter, which is why calibration per gas is mentioned in the product details.

If your application calls for specialty gases or very precise laboratory-grade flow control, consider whether this welding-oriented regulator offers the level of precision you need. For general shop use and most welding tasks, it will be appropriate.

Pros and cons

You’ll find that every tool has trade-offs, and this regulator is no exception—balancing durability, readability, and price. Knowing the pros and cons helps you weigh whether it fits into your workflow and budget.

Overall, the unit’s clear scales, impact-resistant construction, and safety design are strong positives for workshop use. On the other hand, specialized applications or extremely high-precision requirements might point you toward a higher-end or digital regulator.

Pros

You’ll benefit from clear, easy-to-read scales that speed up setup and reduce guesswork, which is a big advantage in a busy shop. The external safety pressure relief and impact-resistant polycarbonate components increase safety and longevity during everyday use.

It’s also versatile in that it’s calibrated for several common gases, saving you the trouble of conversions. For cost-conscious buyers who need reliable functionality rather than advanced features, the price-to-performance ratio is attractive.

Cons

You’ll notice the design is focused on practical performance rather than precision instrumentation, which means it may not meet laboratory-level accuracy demands. If you require digital readouts, data logging, or ultra-fine control under changing ambient conditions, this mechanical regulator might feel limited.

Additionally, polycarbonate, while impact-resistant, can scratch and degrade over very long periods under UV exposure or chemical contact. Keep it clean and stored properly to extend its life.

Maintenance and troubleshooting

You’ll extend the life of your regulator with a few routine checks and a basic maintenance habit. Regular inspection is inexpensive and can prevent safety incidents or wasted materials.

Keep the inlet filter clean and watch for signs of wear around seals and hoses. If you notice leaks, pressure inconsistencies, or odd noises during operation, address them promptly rather than continuing to use the regulator.

Routine maintenance

You’ll want to periodically inspect the sealing surfaces, O-rings, and the flow tube for cracks or clouding. Clean the exterior with mild soap and water—avoid harsh solvents that could damage the polycarbonate parts or seals.

Store the regulator in a dry place and protect it from freezing conditions or prolonged sunlight exposure. Replace worn seals and washers with compatible parts as needed to maintain a proper seal.

Common issues and fixes

You’ll sometimes encounter a stuck float or a leaking connection; fixing those issues is usually straightforward. For stuck floats, depressurize the system and check for debris that may have been introduced from the cylinder—cleaning or gently tapping the tube can free the float.

For leaks, tighten fittings, replace deteriorated washers, and ensure threads are not cross-threaded. If pressure regulation is failing or the gauge reads erratically, consider a repair or replacement of the internal diaphragms or seats—these parts wear out after extended service.

Comparison with alternatives

You’ll want to compare this mechanical flowmeter/regulator with other options including digital regulators, single-stage vs. dual-stage models, and more premium brands. Each category has strengths: mechanical units often deliver rugged reliability, while digital units bring precision and logging features.

Consider the cost, the degree of precision you need, and how much maintenance and calibration you’re willing to manage. For many welders, a well-built mechanical regulator calibrated for common gases provides the best mix of value and performance.

Price vs performance

You’ll generally find that this Flowmeter Argon Co2 Regulator offers competitive performance for a mid-range price point. It’s a sensible choice if you want dependable performance without the premium cost of specialized lab-grade regulators.

If you need the absolute best stability under varying cylinder pressures and temperatures, a dual-stage regulator or a high-end digital regulator might be worth the extra expense. For most shop and hobbyist environments, the balance here is appropriate.

When to choose something else

You’ll consider alternatives if you require features such as digital flow readouts, remote monitoring, ultra-fine flow resolution, or regulatory certifications specific to your industry. In those contexts, shop-grade mechanical regulators can be limiting.

If your work involves exotic gases or very sensitive welding processes (e.g., aerospace or high-value medical device fabrication), opt for a regulator with the required certifications and traceable calibration.

Buying tips and what to look for

You’ll save yourself headaches by checking a few key details before purchasing: compatibility with your cylinder, included fittings, warranty, and seller reputation. Small differences in fittings and thread type can cause delays if you don’t confirm them ahead of time.

Look for clear documentation on calibration and the gases covered, and ask whether spare parts like O-rings, washers, and gauge replacements are available. A unit with accessible service parts will save money over the long haul.

Questions to ask the seller

You’ll want to ask whether the regulator is new or refurbished, whether it includes the proper washer and fittings for your local cylinder type, and the length of any warranty. Clarify return policies and whether technical support is available if you run into setup issues.

Also verify exact calibration details for the gases you intend to use and whether replacement parts are sold separately. Prompt responses from the seller are a good sign of post-purchase support.

Accessories and spare parts

You’ll find value in having spare sealing washers, thread adapters, and replacement O-rings on hand. Keeping a basic spares kit in your workshop minimizes downtime if something wears or gets damaged.

If you prefer additional protections, consider a regulator guard or case that shields the flow tube during transport. Also think about hose quality and fittings—high-quality hoses and secure connections make a big difference in consistent performance.

Frequently asked questions (FAQ)

You’ll often have specific questions before and after buying; these FAQs address common concerns and provide quick guidance. If your question isn’t covered, checking the seller’s product page or contacting support is a good next step.

How accurate is the flow reading?

You’ll generally get accuracy suitable for welding tasks where visual float-based flowmeters are standard practice. While not as precise as lab instruments, the calibration for Argon, Helium, and CO2 gives readings that are adequate for controlling weld shielding and penetration.

Is it safe for high-pressure tanks?

You’ll be safe using the regulator with standard welding cylinders when it’s installed correctly and the safety relief is clear and functional. The external safety pressure relief design is intended to manage overpressure scenarios, but always follow cylinder safety protocols.

Can you use it with mixed gases or specialty blends?

You’ll be able to use it with certain gas blends, but you should verify whether the calibration applies directly or whether you need to adjust your settings. For precise mixtures or non-standard blends, consult the vendor or perform small test welds to confirm the ideal flow.

How do I know if the regulator needs replacement?

You’ll suspect replacement is needed if you encounter persistent leaks, unstable pressure control, or if the gauges fail to respond accurately. Regular maintenance may extend service life, but functional failure of internal components usually calls for replacement.

Are replacement parts available?

You’ll want to check the seller’s parts policy—many manufacturers and resellers offer O-rings, washers, and gauge replacements. If parts aren’t available, consider whether the overall cost of replacement versus a new regulator makes sense for your needs.

Practical tips for using this regulator in your workshop

You’ll get the most out of the Flowmeter Argon Co2 Regulator by combining proper setup with a few habits that protect the unit and improve weld outcomes. Small changes in how you handle and store the regulator can pay dividends in reliability and consistent welding.

Always purge the line briefly before welding to clear out air and check the flow is steady. Keep the regulator covered when not in use and periodically tighten fittings to guard against slow leaks.

Lighting and reading the scale

You’ll find reading the flow easier under good lighting and from eye level; poor lighting increases the chance of mistakes. Consider mounting a small task light near your welding station to illuminate gauges and flow tubes.

If you frequently work in varied lighting, a backlit or digital option might be worthwhile later, but for many users the clear polycarbonate tube on this model is perfectly adequate.

Storage and transport

You’ll increase longevity by storing the regulator upright in a dry place and protecting the flow tube during transport. Using a padded case or a regulator guard reduces the chance of physical damage.

When transporting, secure the regulator so it doesn’t rattle against other tools, and label any cases clearly so hoses and fittings stay together.

Final verdict and recommendation

You’ll find the Flowmeter Argon Co2 Regulator, Argon CO2 Mig Tig Flow Meter Regulator Pressure Gauge Welder Parts, Tig Mig Welding Pressure Reducer Flow Gauge to be a practical, cost-effective option for many welders. Its combination of clear scales, impact-resistant construction, and safety-oriented design makes it a solid choice for workshop environments where reliable shielding gas flow matters.

If your priority is rugged, readable, and straightforward flow metering for Argon, Helium, or CO2 in MIG/TIG applications, this regulator should meet your needs without excessive expense. For users who require ultra-precise digital control, specialized certifications, or advanced logging features, consider a higher-end alternative, but for most standard welding applications this product delivers good value and dependable performance.

If you’d like, I can help you compare this regulator to specific models you’re considering, or suggest a checklist to use when verifying compatibility with your cylinder and hoses.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.