Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for dependable nozzles that keep your flux core MIG welding safe, comfortable, and consistent?

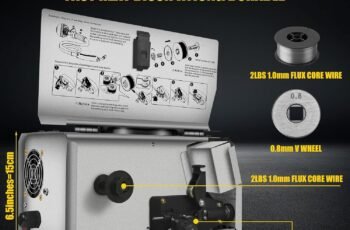

Product Overview: 4Pcs Flux Core Gasless Nozzle, MIG Welding Flux Core Gasless Nozzle Self Protection Welding Parts 100L MIG Welder Accessories

You’re looking at a set of four flux core, gasless welding nozzles designed to replace worn tips and protect the nozzle holder during MIG welding with flux core wire. These nozzles promise strong heat resistance, lightweight handling, and operator insulation, which should translate into steadier arcs and less downtime for swaps during your projects.

What you get in the box

When you buy this product, you receive four identical flux core gasless nozzles so you have spares ready when you need them. Having four nozzles in one package reduces the number of purchases you’ll make and gives you immediate backups when one becomes clogged, damaged, or excessively spattered.

Key specifications

Below is a concise breakdown so you can quickly scan the most important specs and features that determine fit and performance. This should help you confirm compatibility with your torch and decide whether these nozzles meet your expectations for durability and convenience.

| Feature | Specification / Notes |

|---|---|

| Product name | 4Pcs Flux Core Gasless Nozzle, MIG Welding Flux Core Gasless Nozzle Self Protection Welding Parts 100L MIG Welder Accessories |

| Quantity | 4 pieces per package |

| Primary function | Protects nozzle holder thread and opening; insulates operator from circuit |

| Material qualities | High strength, high heat resistance material (unspecified alloy/composite) |

| Compatibility | Designed for flux core (gasless) MIG welding setups — check specific torch model fit |

| Weight | Lightweight design intended to improve torch flexibility |

| Heat handling | Marketed as strong heat resistance to reduce arc heat loss |

| Safety | Insulates operator from circuit; intended to make welding safer |

| Typical use | Replacement nozzles for hobbyists, light shop use, and small production runs |

Build Quality and Materials

You’ll want nozzles that can tolerate the heat and spatter that come with flux core welding, and this product emphasizes high-strength, heat-resistant construction for that reason. The manufacturer doesn’t specify the exact alloy or coating, but the description suggests a material chosen to limit arc heat loss and resist rapid wear.

Heat resistance and durability

The nozzles are marketed to reduce arc heat loss and withstand higher temperatures, which helps maintain arc stability and extend nozzle life under typical flux-core conditions. While the marketing highlights heat resistance, you should still expect gradual wear from heavy spatter and adjust replacement intervals based on how aggressively you weld.

Weight and ergonomics

These nozzles are described as lightweight to improve torch flexibility and reduce wrist fatigue during extended sessions, which will matter if you weld for hours at a time on larger projects. A lighter nozzle also helps you maneuver tight spots more easily, so you’ll likely notice better control compared with heavier, bulkier aftermarket options.

Safety Features

Flux core welding generates a lot of molten spatter and can present electrical hazards, so well-designed nozzles should prioritize protection for both the torch internals and the operator. This set claims to provide effective insulation and protection, which is valuable when you want to keep things running without unnecessary risk.

Electrical insulation and protection

The nozzles are intended to insulate the operator from the circuit by providing a barrier between the handheld torch and the live components, which reduces the chance of electrical contact during use. That insulation is especially useful if you’re working in damp conditions or switching frequently between parts and tweaks while welding.

Protection of torch components

By shielding the thread and opening of the welding nozzle holder, these nozzles prevent excessive spatter and molten metal from fouling internal parts, which extends the lifetime of the holder and reduces maintenance downtime. If you’ve ever had to re-tap threads or replace a holder because spatter welded parts together, you’ll appreciate how protective nozzles can preserve your equipment.

Performance in Welding

Performance isn’t just about lasting longer; it’s about how much the nozzle contributes to a stable, controllable arc and how it affects the quality of welds. Expect better arc consistency when the nozzle prevents premature heat loss and keeps spatter from changing the gasless wire’s feed path.

Arc stability and heat management

These nozzles are designed to reduce arc heat loss and therefore can help maintain a more consistent arc when you’re welding with flux core wire. Consistent heat at the arc helps produce more even penetration and bead shape, which translates into fewer weak spots and less grinding or rework later.

Spatter management and consistency

Flux core welding typically produces more spatter than gas-shielded MIG welding, so nozzle shape and material play a role in how the spatter builds up and how often you’ll need to clear the nozzle. The set’s emphasis on effective protection implies it will reduce the rate at which spatter destroys threads and openings, but you should assume you’ll still clean nozzles regularly during heavy use.

Compatibility and Fit

Getting the proper fit is crucial, because a nozzle that’s too loose or too tight will hurt performance and could damage the holder or torch. You’ll need to verify the nozzle internal diameter, seat style, and thread compatibility (if applicable) against your specific torch model.

Which torches and wire sizes it suits

These nozzles are primarily for flux core, gasless MIG welding, typically used with 0.030 in (0.8 mm) to 0.035 in (0.9 mm) flux core wires in many hobby and light industrial setups. If your torch uses a unique seat or proprietary nozzle shape, check your torch manual or measure your current nozzle to be sure these will slide on and seat properly.

Checking fit before purchase

Prior to installing, compare the inner geometry and seat type of your existing nozzle to pictures and measurements if available, and if you’re ordering online, read other buyers’ comments about specific torch models that worked with the nozzles. If you can, have a caliper handy to measure your current nozzle’s outer and inner diameters; that extra accuracy saves you time and returns.

Installation and Replacement

Replacing a worn nozzle is a routine part of MIG welding maintenance, and these are designed to be swapped out quickly so you can get back to work with minimal interruption. Having four nozzles in the pack means you can stage replacements and not interrupt a job mid-weld when one becomes too fouled.

Step-by-step replacement guide

First, cut power and ensure the welder is off and cooled down, then remove the contact tip and sleeve as required by your torch model, clean debris from the holder threads, and slide the new nozzle into place, seating it firmly by hand or with the recommended tool. After installation, run a short test bead to check alignment, wire feed clearance, and arc behavior before re-starting your main project.

Common issues and troubleshooting

If you find the wire is rubbing or the arc is erratic after swapping a nozzle, make sure the contact tip is properly seated and not worn; sometimes poor performance is about tip wear rather than the nozzle itself. If spatter collects quickly on the new nozzle, consider adjusting your welding parameters slightly—reduce voltage or slow feed speed a little—and check that your wire type and diameter match recommended settings.

Maintenance and Cleaning

Keep your nozzles functioning longer by adopting a consistent cleaning routine; a little preventive maintenance reduces replacements and keeps weld quality high. Because these are flux-core nozzles, expect to remove spatter regularly and inspect for cracks or deformation that could indicate it’s time for a swap.

Cleaning tips to extend life

Use a dedicated wire brush, nozzle reamer, or a nozzle-cleaning tool to remove spatter after each shift or after extended bursts of welding, and avoid banging nozzles on hard surfaces which can deform the opening and affect shielding of the arc. For tougher buildup, a short heat cycle to burn off flux residue followed by brushing can restore function, but don’t overheat the nozzle as it can become brittle if repeatedly subjected to extreme cycles.

When to replace your nozzle

Replace a nozzle when the opening is deformed, when repeated cleaning doesn’t restore a clean, round aperture, or when spatter has compromised the nozzle’s ability to seat properly on the holder. Also consider replacement if you notice sudden changes in arc behavior or if the nozzle shows cracks or structural damage; those signs mean the protective function is reduced and your torch may suffer.

Practical Use Cases and Scenarios

These nozzles are practical for a variety of welding tasks where flux core is the preferred method—outdoor fabrication, farm repairs, and quick site work where shielding gas isn’t practical. You’ll get the most benefit when you use them with consistent wire sizes and maintain a regular cleaning schedule.

Hobbyist and light shop use

If you’re working on car frames, trailers, or home-built frames, these replacement nozzles give you the convenience of spares and a slightly more comfortable torch during longer sessions. Lightweight handling and heat resistance will make extended repair sessions less tiring while helping to preserve your torch internals.

Heavy-duty and production welds

For high-volume shops that weld all day, these nozzles can serve as economical, quick-replacement parts, but you should track replacement frequency and consider premium or OEM nozzles if you find you’re replacing them very frequently. Heavy production environments might still opt for more specific, higher-grade materials tailored to their exact wire types and amperage ranges.

Pros and Cons

You’ll want to weigh the advantages against limitations so you know whether this set is right for your work style and torch. Below are straightforward pros and cons to consider before you commit.

Pros:

- You receive four nozzles, reducing immediate re-purchase needs and giving quick spares.

- Lightweight construction improves torch maneuverability and operator comfort.

- Marketed heat-resistant material helps manage arc heat loss and prolong nozzle life.

- Designed to insulate the operator and protect torch threads/openings.

- Practical and affordable for hobbyists and small shops.

Cons:

- Exact material composition and detailed measurements aren’t specified, so fit needs verification.

- Flux-core welding inherently produces spatter, so you’ll still perform frequent cleanings.

- Heavy-duty or specialized welding environments may require OEM or premium nozzles for longer life.

- If your torch has unique seating, adapters or different nozzles may be required.

Comparison to Alternatives

It helps to understand how these nozzles stack up against OEM and other aftermarket options so you can balance cost, performance, and longevity. You’ll often find a trade-off between price and the precision of fit or composition offered by name-brand nozzles.

Gas-shielded vs flux-core gasless nozzles

Gas-shielded MIG nozzles are designed for use with shielding gas and often have different internal geometry and sometimes coatings tailored to reduce oxidation; these flux-core gasless nozzles prioritize protection against spatter and electrical isolation without relying on gas. If you occasionally switch between gas-shielded and gasless wire, you’ll need appropriate nozzles and torches for each method rather than expecting one nozzle to suit both perfectly.

OEM nozzles vs these aftermarket nozzles

OEM nozzles will typically offer explicit compatibility, precise tolerances, and sometimes superior material specs, but they cost more and you may buy multiple OEMs over time. These aftermarket nozzles give you a cost-effective solution and immediate spares, but you should check fit and monitor wear to make sure they meet your usage demands.

Price and Value

You’re investing not just in replacement parts, but in downtime reduction and consistent weld quality, and buying a 4-pack tends to reduce the per-nozzle cost compared with single purchases. If you’re a hobbyist or run a small shop, the value often comes from having multiple backups and acceptable performance at a reasonable price point.

Is this a good value for your needs?

If you need affordable, ready spares and aren’t welding at production volumes, these nozzles likely represent solid value, especially if your torch accepts the fit without modification. If you’re running high-output industrial operations, you should balance unit cost against replacement frequency and consider spending a bit more on specialized or OEM parts that can last longer under sustained use.

Frequently Asked Questions

These common questions address fit, maintenance, and expected life so you don’t get surprised after purchase.

Q: Will these nozzles fit my torch? A: They are designed for general flux core MIG torches, but you should compare the nozzle’s outer diameter and seating style to your existing nozzle. If your torch uses a proprietary seating or has an unusual geometry, check product pictures, specs, or seller notes before ordering.

Q: How often will I need to replace them? A: Replacement frequency depends on how much you weld, the amperage you run, and how often you clean spatter; light hobby use might mean months between changes, while heavy shop use could mean replacing nozzles weekly. Track your weld quality and visually inspect the nozzle aperture; replace when deformation or cracks appear or when cleaning doesn’t restore function.

Q: Do these nozzles reduce spatter? A: Nozzles themselves don’t stop spatter generation, but a properly shaped and seated nozzle can help manage spatter deposition so it doesn’t foul the holder as quickly. Regular cleaning and proper welding parameters are still necessary to minimize spatter buildup.

Q: Can I use these with gas-shielded welding? A: They are intended for flux core gasless welding, so while you might physically fit one on some torches, performance with gas-shielded MIG welding isn’t guaranteed and may be suboptimal. Use the nozzle type recommended for your welding mode to ensure correct shielding and arc behavior.

Q: Are these safe to use for outdoor welding? A: Yes, flux core is commonly chosen for outdoor welding because it doesn’t rely on external shielding gas; these nozzles will function in outdoor environments and help protect your holder from spatter and heat. However, you should still follow general safety guidelines, including PPE and checking for wind conditions that might affect arc stability if you ever use shielding gas.

Q: How do I clean them without damaging them? A: Use a brass or stainless steel wire brush, nozzle reamer, or purpose-made nozzle-cleaning tool and avoid striking the nozzle against hard surfaces which can deform the opening. If heavy buildup occurs, a brief controlled heat cycle followed by brushing can help, but avoid aggressive chemical cleaners unless the manufacturer endorses them.

Final Verdict

If you need a cost-effective set of flux core gasless nozzles that give you spares, reasonable heat resistance, and lighter handling for better maneuverability, this 4-piece pack is worth considering. Make sure to verify compatibility with your torch model and maintain a cleaning schedule so you get the best life and performance from each nozzle.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.