Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you trying to decide if the RX WELD Dual Output Argon Regulator, Flow Meter Mig Tig 0-60CFH CGA580 Inlet 5/”8 UNF-18RH Outlet is the right choice for your welding setup?

Product Overview

You’ll find this regulator marketed for both MIG and TIG welding, offering dual outputs and a flow meter designed to suit argon, helium, and CO2 tanks. It’s built to attach to CGA-580 style cylinders and aims to give you more precise gas metering than simple diaphragm flow-gauge units.

What this product is meant to do

You’re getting a pressure regulator with an integrated flowmeter so you can reduce tank pressure and measure gas flow at the point of use. The dual output design allows you to run two lines or to use a backup line without swapping fittings, which can be handy in busy or multi-station environments.

Key Specifications

You should know the important numbers and fittings before buying, since compatibility matters for safe and effective operation. Below is a concise breakdown of the key specs so you can match the regulator to your tank, hoses, and welding torch.

| Specification | Detail |

|---|---|

| Product name | RX WELD Dual Output Argon Regulator, Flow Meter Mig Tig 0-60CFH CGA580 Inlet 5/”8 UNF-18RH Outlet |

| Compatible gases | Argon, Helium, CO2 (CGA-580 inlet) |

| Pressure gauge range | 0–4500 PSI (inlet tank pressure) |

| Flow range | 0–60 CFH (cubic feet per hour) |

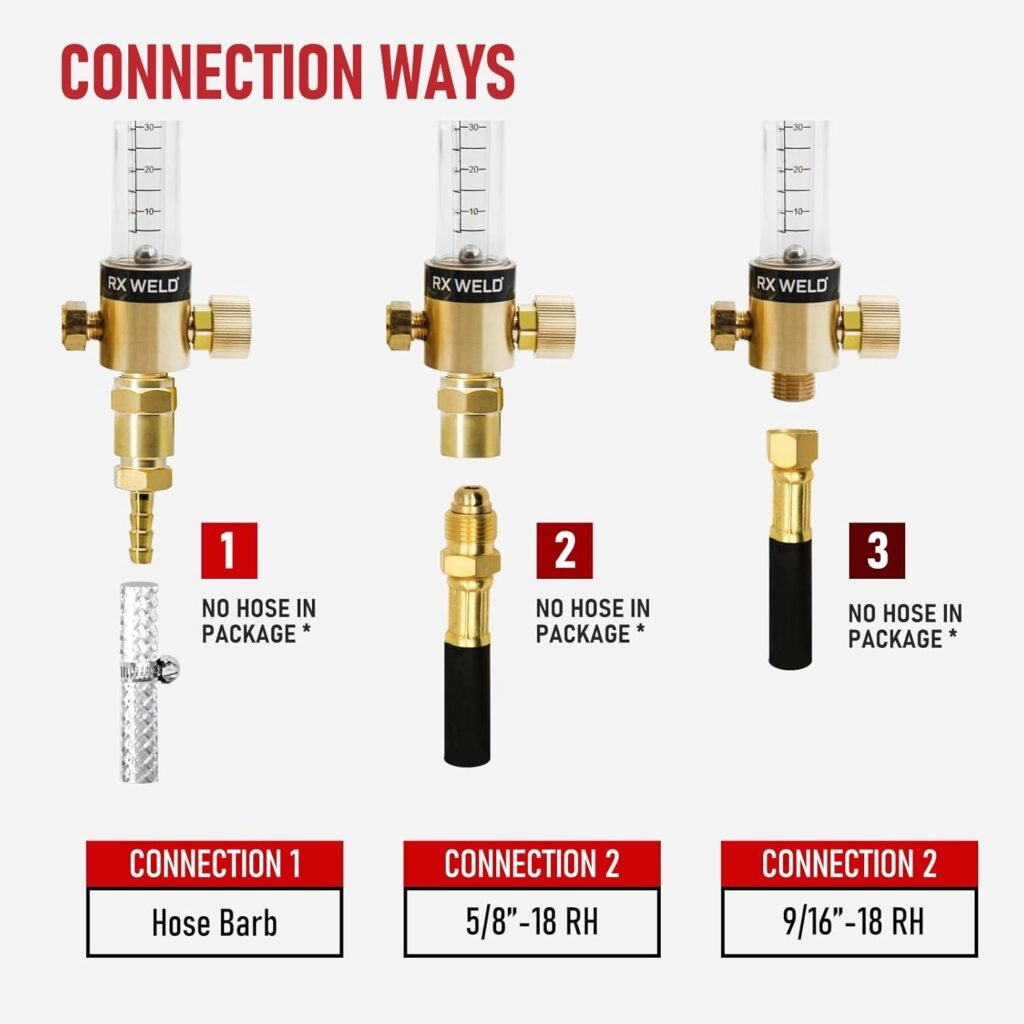

| Output fittings | Female 9/16″ x 18 nut and male 5/8 UNF-18RH fitting |

| Hose adapter included | 1/4″ hose barb adapter |

| Material | Brass construction |

| Application | MIG and TIG welding |

| Flow measurement type | Non-diaphragm flowmeter (reliable design) |

Why these specs matter to you

You’ll want to match the CGA-580 inlet to your tank valve and confirm the outlet fittings adapt to your hose or torch. The listed flow range 0–60 CFH is typical for many welding tasks, and the gauge range up to 4500 PSI covers common cylinder pressures. The brass body promises durability for regular shop use.

Design and Build Quality

You’ll immediately notice that the regulator uses brass for most components, which gives it a solid, traditional feel. Brass is corrosion-resistant and able to take the abuse of shop environments better than cheaper plated alloys or plastics.

Physical layout and ergonomics

The face of the regulator has a pressure gauge and a clear vertical flow tube so you can read flow at a glance while you’re welding. The dual-output ports are positioned to let you route hoses neatly without too much twisting, and the included 1/4″ hose barb adapter helps you adapt to common hoses easily.

Materials and durability

You should expect a long service life from the brass body and metal fittings as long as you protect the gauges from impacts and avoid cross-threading connections. The solid brass construction also limits corrosion where moisture or contaminants could shorten component life.

Flowmeter and Pressure Control

You’ll see two important control elements: the regulator for reducing tank pressure to a usable value, and the flowmeter for metering shielding gas to your weld area. The product claims a non-diaphragm flowmeter design, which tends to be more stable and reliable over time.

How accurate is the flow reading?

The flowmeter is calibrated to the 0–60 CFH range, suitable for most MIG and TIG applications. You’ll get repeatable readings and better control than you would with an inexpensive diaphragm-type flow gauge, especially at low flow rates where precision matters for TIG welding.

Inlet and outlet arrangement

You’ll connect the CGA-580 inlet to your cylinder valve, which is standard for argon/argon blends and helium cylinders in many regions. For outlet connections, the product supplies both a female 9/16″ x 18 nut and a male 5/8 UNF-18RH fitting, giving you flexibility to match a variety of torch or hose connectors.

Installation and Setup

You’ll find installation straightforward if you follow basic regulator safety and installation steps. The fittings are standard, and the package normally includes the hose barb adapter for 1/4″ internal diameter hose.

Step-by-step setup tips

You should attach the regulator to the closed cylinder valve, hand-tighten the CGA-580 nut, and then tighten with an appropriate wrench without over-torquing. Open the cylinder slowly, watch the inlet gauge rise, then adjust the output pressure while monitoring flow. Always check for leaks with a leak-detection solution or soapy water.

Common installation pitfalls

You’ll want to be careful not to cross-thread the inlet nut and to avoid forcing incompatible fittings together. If you try to use the regulator on a cylinder without a CGA-580 valve, you’ll need an adapter; never force mismatched fittings. Also, make sure you orient hoses so they don’t kink or strain the fittings.

Compatibility with Gases and Tanks

You’ll appreciate the regulator’s compatibility with argon, helium, and CO2 when you’re working on different welding jobs. The CGA-580 inlet is the common standard on many argon and helium cylinders, but you should double-check your cylinder valve type before ordering.

Which gases can you use safely?

The regulator works with argon, helium, and CO2 as advertised. If you plan to use other gas mixtures, verify chemical compatibility and pressure ratings; for specialty blends or mix-specific regulators, a dedicated product might be safer.

Matching with your tank

You’ll need a cylinder that uses a CGA-580 valve. If your tank uses a different CGA or a DIN-style valve, use the appropriate adapter or purchase a regulator specifically matched to your tank. Using the wrong inlet connection is both unsafe and ineffective.

Performance in MIG and TIG Applications

You’ll see the most benefits in TIG welding where precise low-flow control of argon is critical for shielding and heat management. For MIG applications, the regulator delivers steady flow for consistent shielding, which helps reduce porosity and inconsistent welds.

TIG-specific behavior

You’ll be able to set low CFH flow rates consistently, which matters when welding thin materials or performing delicate work. The stable non-diaphragm flowmeter design helps you keep a steady shielding envelope, improving weld appearance and reducing oxidation.

MIG-specific behavior

You’ll have adequate flow range for most MIG welding tasks, from light sheet metal to thicker steel when you need higher flow. The dual output can be handy if you want a second feed for a backup torch or pre-purge/flow-through setup.

Readability and Controls

You’ll know your flow and tank pressure quickly thanks to a reasonably sized pressure gauge and a visible flow tube. The controls are intuitive, with a main regulator knob for pressure and a flow adjustment for the output.

Gauge clarity and illumination

You’ll appreciate that the gauge is large enough to read from a short distance, which is useful in busy shops or when you’re wearing gloves. There’s no built-in light, so you’ll rely on ambient shop lighting; good shop lighting is recommended for precise adjustments.

Adjustment responsiveness

You’ll find the regulator responds smoothly to adjustments without jerky movement of the flow indicator. This helps when you’re fine-tuning flow rates for TIG work, where small changes can make a noticeable difference.

Safety Considerations

You should always follow standard gas cylinder and regulator safety practices. A regulator is a pressure control device; misuse can create unsafe conditions.

Safe operating practices

You’ll want to open cylinders slowly, never use oil or grease on fittings, and keep the regulator protected from impact. Always check for leaks and ensure the outlet pressure never exceeds the ratings of your hoses or torch components.

Maintenance for safety

You’ll need to inspect seals, O-rings, and the body periodically. Replace any components that show wear, and have gauges recalibrated or replaced if they become inaccurate. If the regulator is damaged or you suspect internal failure, stop using it immediately and replace it.

Maintenance and Longevity

You’ll get better lifetime performance if you treat the regulator like any precision tool—clean, protect, and inspect. Brass resists corrosion but can still suffer from dirt, physical damage, or contaminated gas.

Routine maintenance tasks

You should wipe the exterior, keep dust and debris out of the flow tube, and store the regulator with protective caps on fittings. If you detect inconsistent flow or abnormal gauge readings, investigate and service the unit rather than continuing to use it.

Troubleshooting common issues

You’ll most commonly see leaks (fix with correct sealing or replacement parts), stuck or noisy flow indicators (clean or replace the flow tube), or gauge failures (replace gauge). If flow is inconsistent, check for line obstructions and confirm the tank pressure is sufficient.

Pros and Cons

You’ll want to weigh the advantages and limitations so you can decide if this regulator matches your priorities. The list below summarizes the practical strengths and weaknesses.

Pros

- You’ll get dual outputs for more flexible hose routing and multi-line use.

- You’ll enjoy a robust brass construction that resists shop wear.

- You’ll see reliable flow metering without a diaphragm, improving stability at low flows.

- You’ll receive common fittings including a 1/4″ hose barb adapter to quickly connect standard hoses.

- You’ll be compatible with argon, helium, and CO2 (CGA-580 cylinder connection).

Cons

- You’ll need to verify fitting compatibility with your specific torch and hose configurations.

- You’ll have to protect the gauges from impacts, since they can be vulnerable in rough environments.

- You’ll need to confirm the CGA-580 inlet is correct for your cylinder or get an adapter if it’s not.

Comparison with Similar Products

You’ll find regulators at various price points and feature sets. This RX WELD unit aims to balance economy with better-than-basic flow control, making it a middle-of-the-road choice for many users.

How it stacks up on accuracy and durability

You’ll likely find it more accurate than cheap diaphragm-style flow gauges and roughly comparable to other brass-bodied, non-diaphragm regulators in its price range. For professional shops that need industrial-grade performance and certification, higher-end alternatives may offer finer tolerances and replaceable gauge options.

Value for the price

You’ll typically see this model priced as an economical solution for hobbyists, small shops, or those who need a backup regulator. It provides solid features for the money without the premium cost of heavy-duty commercial regulators.

Who Should Buy This Regulator

You’ll benefit from this regulator if you’re a home welder, hobbyist, small fabrication shop, or a shop needing an additional station. The dual output and included adapter are conveniences that appeal to users managing multiple torches or setups.

Scenarios where it’s ideal

You’ll find it particularly useful if you do both MIG and TIG work and want one regulator that handles argon and CO2 reliably. If you’re running occasional production or multiple hobby projects, the cost-to-feature ratio is attractive.

Scenarios where you might upgrade

You’ll want to consider upgrading if you need certified industrial-grade regulators for heavy continuous use, or if you need digital readouts, multiple precision outlets with separate gauges, or specific certifications for regulated industries.

Practical Tips for Everyday Use

You’ll get the best results if you keep certain practical habits. Small habits make a big difference in reliability and weld quality.

Quick setup and adjustment tips

You’ll open the cylinder slowly and let the regulator settle before making fine flow adjustments. Set your flow with the torch flowing at welding position, since local conditions and hose length affect required CFH.

Storage and transport tips

You’ll store the regulator with protective caps on both inlet and outlet fittings to avoid dirt and damage. During transport, brace gauges and fittings against bumps; consider a padded case if you move gear frequently.

Installation Accessories and Add-ons

You’ll sometimes need a few extras to integrate the regulator perfectly into your setup. The included 1/4″ hose barb helps, but other accessories might be handy.

Useful accessories

You’ll consider a short quality hose with correct fittings, a shutoff valve for convenience, and a flow-control valve at the torch if you want more localized control. A regulator cover or protective cage also protects gauges in rough shop environments.

When to use adapters

You’ll use adapters when your cylinder or torch fittings don’t match the regulator’s female 9/16″ x 18 nut or male 5/8 UNF-18RH outlet. Use only appropriate threaded or specialty adapters to avoid leaks and ensure safe operation.

Common Questions (FAQ)

You’ll likely have practical questions about real-world use and compatibility. Below are concise answers to common concerns.

Can this be used with mixed gas blends?

You’ll use it with argon, helium, and CO2 as stated. For specialty mixes or flammable gas blends, check compatibility and safety requirements; this regulator is not rated for oxygen or acetylene.

Is the flowmeter accurate for TIG welding?

You’ll find it accurate enough for typical TIG work because the non-diaphragm design provides stable readings, especially at lower flows.

How do I check for leaks?

You’ll apply a leak-detection solution or soapy water to all connections, pressurize the system, and look for bubbles indicating leaks. Tighten fittings or replace seals until leaks stop.

Can the gauges be replaced?

You’ll replace gauges if they fail, provided you have compatible replacement gauges and the right tools. If unsure, consult a qualified technician or replace the unit.

Final Verdict

You’ll find the RX WELD Dual Output Argon Regulator, Flow Meter Mig Tig 0-60CFH CGA580 Inlet 5/”8 UNF-18RH Outlet to be a capable, budget-friendly regulator that balances practical features with durable construction. It’s well-suited to hobbyists and smaller shops that need reliable flow control across MIG and TIG tasks without paying for high-end industrial options.

Who should buy it now

You’ll be happiest with this purchase if you’re outfitting a home shop, adding a second workstation, or need a dependable, reasonably priced regulator for argon, helium, or CO2. The included 1/4″ hose barb and dual outlets give you immediate flexibility out of the box.

Final recommendations

You’ll verify tank compatibility, inspect threads and seals on arrival, and practice safe installation and maintenance. With proper care, this regulator should serve you well for many welding sessions and give you the flow control needed for consistent weld quality.

Additional Resources and Next Steps

You’ll want to keep learning about safe gas handling and regulator care to maximize life and performance. Seek manufacturer instructions, shop safety standards, and local cylinder regulations for the best long-term results.

Where to look for more information

You’ll consult the product manual, vendor Q&A, and reputable welding forums for user experiences and troubleshooting tips. If you run into persistent issues, contact the seller or a qualified service technician.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.