Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a reliable regulator for your TIG and MIG welding work?

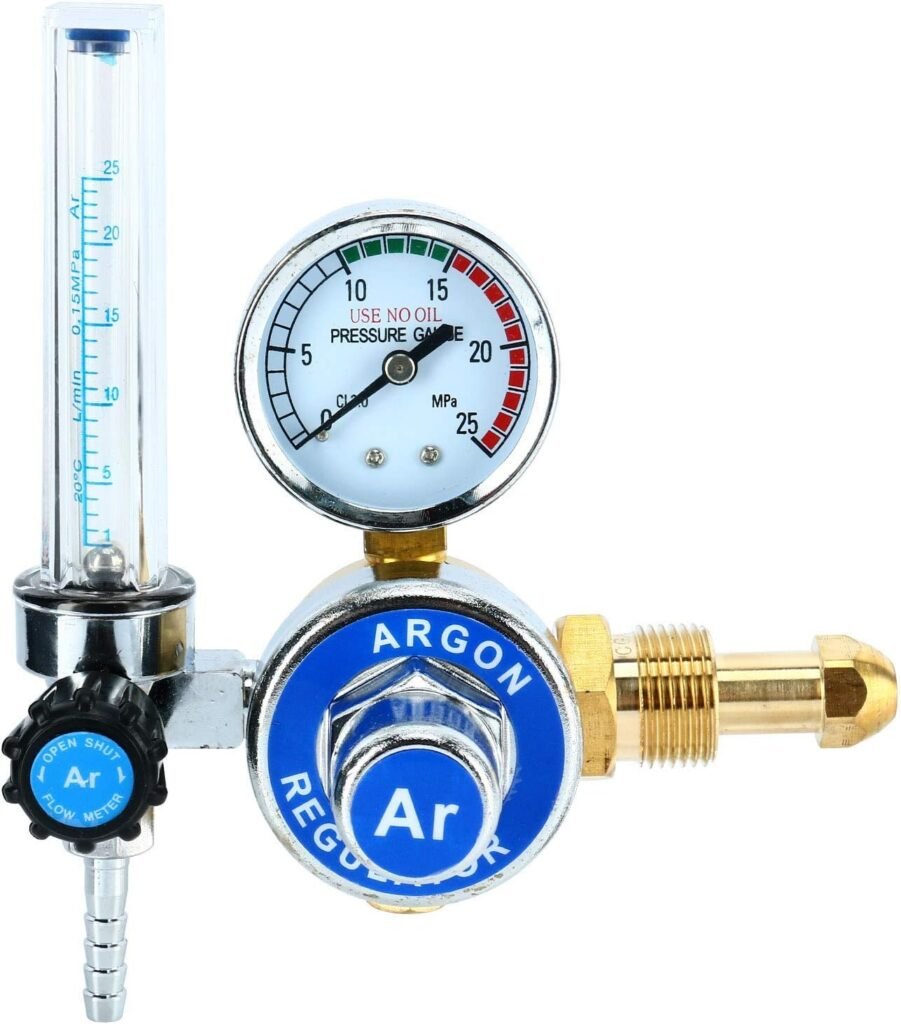

Product overview: Argon Regulator with Flowmeter TIG Welder MIG Welding CO2 Regulator 0 to 25 L/MIN – 0 to 25 MPA Pressure Gauge CGA580 Inlet Connection Gas Welder Welding Regulator with Built-in Flow Meter

You’ll find this regulator marketed specifically for MIG and TIG applications, and the name says it all. It’s designed to give you accurate gas flow control for Argon, Helium, and Carbon Dioxide, with a built-in flowmeter and a 2-inch pressure gauge for easier reading.

Who this product is for

If you’re doing hobbyist or professional MIG/TIG work and need a simple, compact gas regulator with visual flow control, this unit is meant to fit that role. It’s particularly useful if you switch between Argon and CO2 or need a durable flow tube on the job.

Key specifications

Below is a concise breakdown of the crucial specifications so you can quickly compare features before you buy.

| Specification | Details |

|---|---|

| Product name | Argon Regulator with Flowmeter TIG Welder MIG Welding CO2 Regulator 0 to 25 L/MIN – 0 to 25 MPA Pressure Gauge CGA580 Inlet Connection Gas Welder Welding Regulator with Built-in Flow Meter |

| Flow range | 0 to 25 L/min |

| Pressure gauge range | 0 to 25 MPa (gauge size: 2 inches) |

| Inlet connection | CGA580 |

| Calibrated gases | Argon, Helium, Carbon Dioxide |

| Flowmeter tube | Polycarbonate (impact resistant) |

| Flowmeter type | Built-in, back pressure compensated |

| Typical applications | MIG, TIG, CO2 shielding |

| Material highlights | Metal regulator body with polycarbonate flow tube and outer cover |

| Readability | 2-inch pressure gauge, transparent flow tube for visual flow reading |

Why these specs matter to you

These figures translate into how much control and visibility you get during welding, and whether the regulator will physically connect to your gas cylinder or system. The CGA580 inlet is commonly used for argon and related gases, so it’s important that your cylinder valve is compatible.

Design and build quality

You’ll notice the regulator is built around a metal body with a clear polycarbonate flow tube and protective outer cover. The combination gives you the ruggedness of metal for pressure handling with visual access to flow readings and resistance to impacts on the tube.

How it feels and handles

When you take it in hand, the unit is compact and feels solid. The flow tube’s polycarbonate and outer cover are helpful if you’re moving between the shop floor and field jobs where accidental knocks happen.

Flowmeter performance and accuracy

The built-in flowmeter measures from 0 to 25 L/min and is calibrated specifically for Argon, Helium, and CO2; that means you’ll get better accuracy for these gases versus a generic meter. It’s also back pressure compensated, so if you have restrictions downstream, the readings stay truer to actual flow.

What that means for your welds

Accurate flow control improves shielding performance, which can reduce porosity and contamination in your welds. You get a clearer visual on gas usage too, which helps when you’re dialing in settings for different materials and welding positions.

Pressure gauge and readability

A 2-inch pressure gauge is fitted for clear, fast reading of cylinder pressure and system pressure. The larger gauge face is a practical touch when you’re working in low-light conditions or at awkward angles.

Why gauge accuracy is important

Knowing your cylinder pressure tells you how much gas remains and whether you’re operating safely within recommended pressures. Consistent, readable gauges cut down on downtime for re-checking or swapping cylinders.

Gas compatibility and calibration

The regulator is calibrated for Argon, Helium, and Carbon Dioxide, which are the shielding and purge gases most commonly used in TIG and MIG processes. That calibration means the flowmeter’s scale and float behavior are tuned to those gases’ densities and flow characteristics.

How to use that knowledge

If you use mixed gases or different blends, you may need to confirm compatibility or be aware that the flow reading might not be exact for mixtures. For straight Argon or straight CO2, you can expect dependable readings as designed.

Installation and connection (CGA580 inlet)

The CGA580 inlet connection is a common fitting for Argon cylinders. If your cylinder valve uses CGA580, the regulator will thread on and seal as intended; if not, you’ll need the correct adapter or a different regulator.

What to check before installation

Always verify that the thread type and cylinder valve are compatible before attempting to fit the regulator. A mismatched connection can cause leaks, poor pressure control, or damage to fittings.

Usability and controls

Controls are straightforward: you have a main pressure adjustment knob plus the visible flowmeter to adjust and monitor flow. The clear flow tube gives you an intuitive, immediate readout of the flow rate without needing to rely on electronic displays.

How that affects workflow

You’ll spend less time guessing and more time welding, because you can visually confirm your flow setting and quickly tweak it. For repetitive setups, the tactile knob and visible flowmeter make it easy to return to the same settings.

Durability and maintenance

The flow tube is polycarbonate with an outer cover for impact resistance, and the regulator body is metal-built for pressure durability. Regular maintenance is limited to visual inspection, cleaning, and checking seals, which keeps the unit functional for many cycles.

Routine checks you should do

Check the flow tube for cracks, ensure the gauge lens is clear, and inspect the inlet seal for wear whenever you change cylinders. Small preventive steps go a long way toward ensuring consistent performance.

Safety considerations

This regulator is used with high-pressure gas cylinders, so you must handle installation, pressurizing, and storage using proper safety practices. The 2-inch gauge helps with visibility, but you should still ensure pressure settings fall within the gas and torch manufacturer’s recommendations.

How to keep your workspace safe

Keep the regulator and cylinder upright and secure, avoid exposing the regulator to direct heat sources, and ensure fittings are tightened and leak-tested after installation. If you suspect damage to the regulator or see irregular pressure behavior, remove it from service until verified safe.

Performance in MIG welding

For MIG applications, consistent CO2 or Argon/CO2 blend flow is critical for stable arcs and bead appearance. This regulator provides you with the visibility and control needed to maintain stable shielding, especially at the typical flow rates used in MIG welding.

What you’ll notice in your welds

If you’re moving from a less precise regulator, you may see reduced spatter and more stable arc behavior as you’re able to fine-tune the gas. The back pressure compensation helps when you’re using longer or narrower hoses that otherwise create restrictions.

Performance in TIG welding

TIG welding often requires precise Argon flow for shielding, and the fine control in the 0–25 L/min range covers most TIG setups. The clear flowmeter enables you to set low flows for thin materials or purge flows for pipework.

How it improves TIG results

You can expect cleaner weld beads and fewer oxidation issues when your shielding is correctly tuned. The visual flowmeter is especially valuable when you need to set low, steady flows that are harder to feel than high-volume flows.

How it handles back pressure and line restrictions

The flowmeter is back pressure compensated, which means it’s designed to maintain accurate readings even when there’s a restriction downstream. That matters if you use narrow hoses, anti-siphon devices, or long runs that might otherwise alter the meter’s accuracy.

Practical implications for your setup

If your shop layout forces longer hose runs or you attach additional devices between the regulator and torch, you won’t need to guess whether the flow reading matches actual flow at the torch tip. The compensation improves reliability.

Compatibility with mixed gases and blends

The manufacturer calibrates the flowmeter for specific gases—Argon, Helium, and CO2. If you use blends (like Argon/CO2 mixtures), you should verify whether the meter’s calibration is sufficiently accurate for your mix or if you’ll accept a small margin of error.

How to approach blends

For common Argon/CO2 mixes, many welders find the reading adequate for practical use, but if you require laboratory-level precision, consider a flowmeter specified for your particular blend or verify with a secondary measurement.

Pros and cons

You’ll want a balanced look at advantages and potential limitations before you decide.

Pros:

- Built-in flowmeter calibrated for Argon, Helium, and CO2 gives reliable visual flow control.

- Polycarbonate flow tube and cover provide impact resistance for tougher shop environments.

- Back pressure compensation helps maintain accuracy with line restrictions.

- 2-inch pressure gauge offers clear readability for quick checks.

- CGA580 inlet fits commonly used Argon cylinders, making installation straightforward when compatible.

Cons:

- Calibration is limited to Argon, Helium, and CO2—accuracy may vary for other blends.

- If your cylinder uses a different inlet standard, you’ll need an adapter or a different regulator.

- Polycarbonate, while durable, can scratch or cloud over time; careful handling helps preserve clarity.

- Gauge range and markings might be denser than some users prefer for ultra-precision work.

How these pros and cons affect your purchase

If you prioritize visual control and ruggedness with common welding gases, the pros likely outweigh the cons. If you need ultra-precise measurement for unusual gas blends or a different inlet standard, you might need to look at alternative models.

Comparison with similar regulators

Compared to entry-level regulators with no flowmeter or smaller gauges, this unit gives you immediate visual flow control and better gauge readability. Versus high-end digital flowmeters, this analog unit is simpler, more rugged, and less expensive but lacks digital precision and data logging.

Which scenario fits this regulator best

This regulator is a good mid-tier option if you want reliable analog control and durability without the extra cost and complexity of digital regulators. For production lines requiring tightly logged gas usage, you might add electronics or choose a different model.

Price and value for money

You’ll typically find this regulator priced competitively in the mid-range of welding regulators. Considering the built-in flowmeter, back pressure compensation, and larger gauge, it represents solid value for many fabrication and repair shops.

How to justify the cost

If you regularly set flows or switch between TIG and MIG, having a visible, accurate flowmeter saves time and reduces gas waste—factors that quickly offset the purchase price over weeks and months of use.

Who should buy this regulator?

If you’re an amateur fabricator, small shop owner, or a pro who needs a dependable analog regulator for Argon, Helium, or CO2, this product fits the bill. It’s especially useful when you need a compact, rugged regulator that gives you intuitive flow control without electronics.

Who should look elsewhere

If you need calibration for exotic gas blends, digital readouts, or a different inlet standard without adapters, consider higher-end or more specialized regulators. Similarly, if you’re outfitting a production line that requires traceable data, a digital solution may be preferable.

Tips to get the best results from the regulator

- Always confirm the CGA580 inlet matches your cylinder valve or get a verified adapter before use. Incorrect connections are the leading cause of leaks or poor performance.

- Bleed the line and check for leaks after installation with a leak-detection fluid or soapy water—no open flame tests. If bubbles appear, stop and re-tighten connections.

- Keep the polycarbonate flow tube clean and free from solvents that could fog or damage it. Wipe with a soft cloth and mild soap if needed.

- Use a regulator wrench or proper tools when tightening, but avoid over-torquing which can damage seats or threads.

Small habits that extend product life

Store the regulator in a clean, dry place when not in use, and protect the flow tube from impact. Regular inspections before each job save you from surprises mid-weld.

Common issues and troubleshooting

If the flow reading doesn’t change when you adjust the knob, check for clogged or kinked hoses and verify cylinder pressure. If you see erratic gauge behavior, ensure the gauge is properly seated and that there are no severe shocks or impacts to the unit.

When to service or replace

If the flow tube cracks, the gauge fails to hold pressure, or you detect persistent leaks you can’t fix with seals, replace or have a qualified technician service the regulator. Never attempt to use a damaged regulator.

Maintenance checklist

- Inspect flow tube and outer cover for cracks or clouding every month if used frequently.

- Check gland seals and inlet fittings for wear and perform leak tests after any cylinder change.

- Clean the gauge face and flow tube with mild soap and soft cloth as needed; avoid aggressive solvents.

- Store disconnected from the cylinder in a protective cover or dry toolbox.

Minimal maintenance, good longevity

The unit is designed to require minimal upkeep beyond these checks, so habitually performing them will maximize the regulator’s service life and safety.

Environmental considerations

The materials—metal body and polycarbonate tube—offer durability, but extreme UV or chemical exposure can degrade plastics over extended periods. Keep the regulator away from direct heat and corrosive chemicals.

How to protect the regulator

If you work outdoors, consider a shaded, dry storage option and inspect the flow tube more frequently. For corrosive or marine environments, more frequent maintenance and protective measures will prolong performance.

Final verdict

If you need a sturdy, straightforward regulator with a built-in flowmeter calibrated for Argon, Helium, and CO2, the Argon Regulator with Flowmeter TIG Welder MIG Welding CO2 Regulator 0 to 25 L/MIN – 0 to 25 MPA Pressure Gauge CGA580 Inlet Connection Gas Welder Welding Regulator with Built-in Flow Meter is a practical choice. It brings readable gauges, back pressure compensation, and a durable flow tube into a package that suits most hobbyists and many professional welders.

Bottom line for your purchase decision

You’ll get good value if your priorities are visual flow control, durability, and compatibility with standard Argon cylinders. For niche requirements—exotic blends, data logging, or a different inlet standard—look carefully at alternatives.

Frequently asked questions (FAQ)

Is this regulator compatible with Argon/CO2 mixes?

Yes, the flowmeter is calibrated for Argon and CO2 individually and will generally give usable readings for common Argon/CO2 blends. If you need laboratory-level flow precision for specific blends, you should verify with a flow calibrator or consider a meter specified for your blend.

What does CGA580 mean for my equipment?

CGA580 is a standard cylinder inlet connection for Argon and some inert gases. If your cylinder uses CGA580, the regulator should thread on directly; if not, you’ll need the correct adapter or a regulator with the matching inlet.

Can I use this regulator outdoors?

You can use the regulator outdoors, but protect it from direct sunlight, extreme weather, and corrosive elements. Store it indoors when not in use and inspect it frequently if exposed to harsh conditions.

How do I check for leaks after installation?

After attaching the regulator to the cylinder, open the cylinder valve slowly, then spray a leak-detection fluid or soapy water on connections; watch for steady bubbles. Do not use a flame for leak checks.

What should I do if the flowmeter becomes cloudy or scratched?

Try cleaning with a mild soap and soft cloth first. If scratching or clouding affects readability, consider replacing the flow tube or the entire regulator, depending on availability of service parts.

Is the gauge replaceable if it fails?

In many cases, pressure gauges can be replaced, but replacement depends on the regulator design and availability of compatible parts. If unsure, consult a qualified service technician.

If you want, I can summarize key buying points into a short checklist tailored to your welding setup, or compare this regulator directly against a specific model you’re considering.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.