Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you looking for a compact, high-frequency TIG/Stick welder that promises professional-looking welds without weighing you down?

Quick Verdict

You get a versatile 2-in-1 machine with the AIXZGLOBAL TIG Welder 200A, High Frequency TIG/Stick 2 in 1 Welder Machine 110V/220V Dual Voltage Post Gas Function Welding Machine with IGBT Portable Welding Equipment that targets hobbyists, beginners, and many pros who need portability and dependable TIG performance. It blends HF TIG ignition, stick capability, post-gas control, and dual-voltage flexibility into a lightweight package that’s easy to carry and set up.

Product Overview

This unit gives you both HF TIG and Stick (SMAW) welding modes with a claimed 200A peak, and a solid 80% duty cycle rating that’s impressive for its size. The machine’s IGBT electronics and cooling design aim to deliver steady current and longer service life, while the post-gas timer protects your torch and weld after you release the trigger.

What this product aims to solve

You’ll appreciate a machine that reduces spatter, stabilizes the arc, and protects torch consumables with post-gas flow — especially when you want cleaner welds and less downtime. The dual-voltage capability means you can work from standard household outlets or 220V shop supplies.

Key Features

You’ll notice several clear selling points when evaluating this welder: HF TIG ignition for non-contact arc starts, stick welding capability for versatility, a post-gas timer to protect consumables, an 80% duty cycle to keep you welding for longer stretches, and a very portable form factor that makes job-site movement easy.

- HF TIG for smoother arcs and less spatter

- Stick mode for basic carbon steel welding and outdoor use

- Post-gas timer adjustable 1–10 seconds

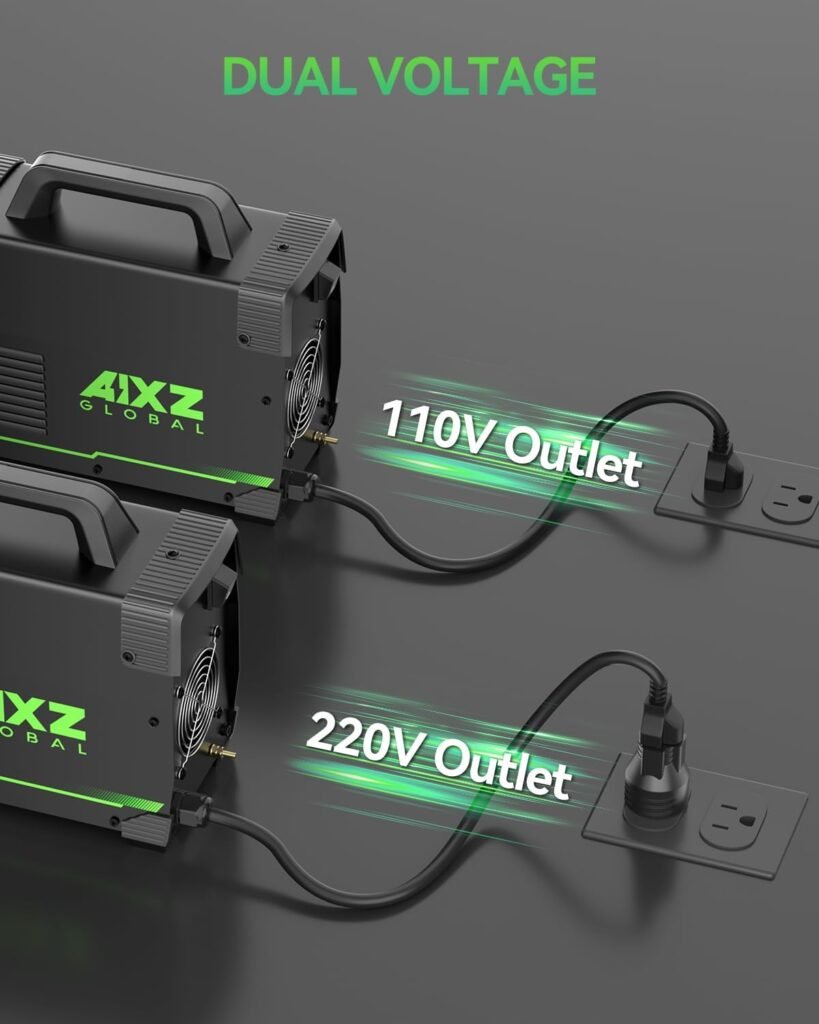

- 110V/220V dual voltage for broad power compatibility

- IGBT-based inverter for efficient power delivery

- Portable at roughly 12 pounds

Specifications

Here’s a compact table that breaks down the major specs so you can scan what matters most quickly.

| Specification | Details |

|---|---|

| Product Name | AIXZGLOBAL TIG Welder 200A, High Frequency TIG/Stick 2 in 1 Welder Machine 110V/220V Dual Voltage Post Gas Function Welding Machine with IGBT Portable Welding Equipment |

| Welding Modes | HF TIG (DC), Stick (SMAW) |

| Rated Current | Up to 200A (peak) |

| Duty Cycle | 80% (specific at rated output — check manual for exact amperage/duty pairing) |

| Voltage | Dual: 110V / 220V |

| Post-Gas Timer | Adjustable 1–10 seconds |

| Torch | TIG torch included |

| Weight | Approximately 12 pounds |

| Cooling | Forced-air cooling, designed for longer continuous use |

| Technology | IGBT inverter, HF ignition |

| Portability | Handle-mounted, compact case |

| Recommended Use | Hobbyists, beginners, light-to-moderate professional use |

What’s in the Box

You’ll typically receive the TIG machine itself, a TIG torch (as the listing states), grounding clamp/cable, electrode holder for stick welding, power cable(s) for dual-voltage operation or a single cable with switchable input (check the labeling), and a user manual. Consumable spares may or may not be included, so plan to have extra tungsten, collets, and cups on hand.

Items to make sure you have

You’ll want to double-check that you’ve got shielding gas (argon) and appropriate regulators/hoses, filler rod, and the correct tungstens for the metals you plan to weld. If the package doesn’t include a regulator or gas hose, you’ll need to source them separately.

Design and Portability

The housing is compact and light, making it easy to move between jobs. At roughly 12 pounds, you can carry it like a small backpack or set it on a cart. The handle is an obvious convenience, and the overall footprint keeps it easy to store when you don’t need it.

Build Quality

You’ll find a typical inverter-style case that balances weight and protection. The IGBT electronics are more efficient and lighter than older transformer-based designs. For the price point, the unit tends to offer a good fit-and-finish — but remember that portable, budget-friendly welders require careful handling and occasional maintenance.

Portability and Use Cases

You’ll be able to use this machine for light to medium fabrication tasks, automotive repair, maintenance, and hobby projects. Its portability makes it excellent for mobile techs, small shop owners, or makers who move between job sites.

Power, Voltage, and Cooling

The dual-voltage input allows you to work from standard household 110V outlets or 220V shop outlets for heavier tasks. The cooling system is designed to keep the machine running longer, helping you take advantage of the claimed 80% duty cycle.

Dual Voltage: 110V/220V

You’ll appreciate having both voltage options. Running on 110V lets you work in areas without 220V service, while 220V supply allows you to run closer to the machine’s higher output for thicker materials. Make sure you understand how to switch voltages or plug the unit correctly — the manual should give you clear instructions.

Cooling System

The forced-air cooling system protects internal components during extended use. You’ll need to keep air vents clear of debris to maintain optimal airflow; blocking vents or operating in dusty environments without filtering will shorten component life.

Welding Modes and Performance

The key functional split is HF TIG and stick welding. Each mode offers distinct advantages, and you’ll switch depending on the task.

HF TIG Mode

You’ll get non-contact arc starts with HF ignition, which reduces tungsten contamination and makes arc starts smoother. HF TIG produces fewer spatters and a stable arc that helps you create neat, high-quality weld beads when you dial in proper settings.

Stick (SMAW) Mode

You’ll get the classic stick capability that’s useful outdoors or where gas shielding isn’t convenient. Stick mode is robust for thicker steels and situations where portability and simpler gear are prioritized.

Duty Cycle and What It Means for You

An 80% duty cycle suggests the unit can weld longer before needing a cooldown period, but remember that duty cycles are often measured at a specific amperage — typically not at full 200A. You’ll want to check the manual for the exact amperage/duty pairing. In practice, this rating helps reduce downtime and improves productivity on longer weld runs.

Post-Gas Function Explained

You can set a post-gas time of 1–10 seconds, which means the shielding gas will continue to flow after you release the torch. You’ll find this especially useful when welding thinner materials or when the torch needs cooling; continuous gas flow reduces oxidation, helps keep the weld bead clean, and extends the life of your consumables.

Welding Materials and Applications

This machine is well suited for common shop materials like mild steel and stainless steel when using DC TIG. It’s also effective for welding nickel alloys and copper in some cases, but you’ll need to check compatibility and settings.

Steel and Stainless Steel

You’ll get good results on mild steel and stainless using DC TIG with appropriate filler and tungsten. The stable HF arc will help you make attractive beads with minimal spatter. Use lower amps for thin gauge steel and higher amps for thicker pieces, and ensure you choose appropriate shielding gas (argon for TIG on steel/stainless).

Aluminum and Limitations

You’ll want to be cautious with aluminum: most HF TIG machines that offer only DC output will not be ideal for aluminum welding because aluminum typically requires AC TIG (alternating current) to clean the oxide layer and produce a quality weld. Unless the unit explicitly lists AC capability, assume it’s DC only and plan to use this machine primarily for steel, stainless, and other DC-compatible metals. If you need to weld aluminum often, confirm the model supports AC TIG or consider a machine designed for AC TIG.

Thin Metal Work and Aesthetic Welds

You’ll find the HF ignition and stable arc helpful for thin metalwork because you can produce smoother starts that reduce burn-through risk. The post-gas feature helps prevent oxidation on the cooling joint, preserving weld aesthetics and strength.

Torch, Accessories, and Consumables

The listing notes that the TIG torch is included, which means you have an immediate path to start TIG welding once you secure gas and filler. You’ll want to maintain and equip the torch with spare cups, collets, and tungstens.

TIG Torch and Torch Care

You’ll want to keep the torch head clean and replace worn consumables. After long runs, allow the post-gas to cool the torch, and periodically inspect cables for wear. Good torch handling and maintenance will extend consumable life.

Electrodes, Filler, and Gas

You’ll typically use thoriated, ceriated, or lanthanated tungsten types for DC TIG on steel and stainless, choosing diameters based on amperage. For shielding gas, argon is the usual choice for TIG on most steels and stainless. Make sure you stock the correct filler rods for the metals you plan to join.

Setup and First Weld — Step by Step

You should approach setup methodically to avoid common mistakes. The following sequence gives you a straightforward path to your first weld.

- Inspect all components and read the manual for safety and wiring specifics.

- Connect the machine to the correct input voltage according to instructions and ensure proper grounding.

- Attach the ground clamp to clean metal and connect the TIG torch and stick electrode holder as needed.

- Install the correct tungsten (sharp point for DC), set the gas flow (typically 10–15 CFH for argon), and choose the proper filler rod.

- Set your starting amperage based on material thickness (see cheat sheet below).

- Turn on shielding gas flow, wait a few seconds for purge, then perform a test arc on scrap to fine-tune settings.

- Use the HF start to initiate the arc and make test beads, adjusting travel speed and filler addition for best results.

Recommended Settings Cheat Sheet

This general guide helps you pick starting points. Adjust based on experience, joint type, and material condition. These values are approximate; you’ll want to refine them through practice.

| Material | Thickness | Suggested Amps | Tungsten | Shielding Gas | Filler Rod |

|---|---|---|---|---|---|

| Mild Steel (DC) | 0.5–1 mm (thin) | 25–60 A | 1.0–1.6mm lanthanated | Argon 10–15 CFH | ER70S-2 (thin) |

| Mild Steel (DC) | 1–6 mm | 60–160 A | 1.6–2.4mm lanthanated | Argon 10–15 CFH | ER70S-2 |

| Stainless Steel (DC) | 0.5–3 mm | 20–120 A | 1.6–2.4mm lanthanated | Argon (maybe with small He mix) | ER316, ER308 |

| Aluminum (if AC supported) | 1–6 mm | 40–200 A | 2% Thoriated (or lanthanated for AC) | Argon 15–20 CFH | ER4043/5356 |

| Stick (SMAW) | Various | See electrode rating | N/A | Flux-covered electrodes (no gas) | E6010/E6013/E7018 as needed |

Note: If your unit is DC-only, omit aluminum AC rows. Always confirm the machine manual and test on scrap.

Tips for Getting Clean TIG Welds

You’ll improve weld quality faster if you keep a few habits:

- Clean the metal surfaces thoroughly to remove oil, paint, or oxidation before welding.

- Use the HF start to avoid tungsten contamination from touching the work.

- Maintain a consistent travel speed and filler rod angle for uniform beads.

- Set appropriate gas flow and use post-gas time to protect the weld until it cools.

- Keep spares of collets, cups, and tungstens for quick replacement on the job.

Safety and Maintenance

You’ll want to follow standard welding safety protocols: wear appropriate PPE (helmet with correct shade, gloves, long-sleeve flame-resistant clothing), ensure ventilation, and follow electrical safety guidelines when working with dual-voltage equipment.

Basic Maintenance Checklist

You should perform regular checks:

- Inspect power cables and connections for wear.

- Keep cooling vents and fans free of dust and debris.

- Replace consumables that show wear or damage.

- Check gas hoses and regulator for leaks.

- Verify tightness of electrical connections periodically.

Troubleshooting Common Problems

You’ll encounter issues occasionally, but many are easy to fix:

- No arc on TIG start: Confirm gas flow, ground connection, tungsten condition, and HF functionality.

- Tungsten contamination: Avoid touching tungsten to the workpiece or filler; re-grind the tip to a clean point.

- Porosity: Check gas flow, purge the gas lines, and ensure joint cleanliness.

- Overheating/shutdowns: Verify duty cycle conditions and cooling vents; allow machine to rest if thermal protection kicks in.

Pros and Cons

You’ll find many strengths in this unit as well as a few limitations to be aware of.

Pros:

- Strong mix of HF TIG and stick modes for versatility.

- Portable and lightweight at around 12 pounds.

- Post-gas timer improves torch life and weld quality.

- Dual-voltage operation increases utility across job sites.

- IGBT inverter tech improves efficiency and size.

- 80% duty cycle minimizes interruptions for many typical tasks.

Cons:

- If the unit is DC-only, aluminum welding will be limited or require a separate AC-capable machine.

- Kit may not include gas regulator or hoses — check what’s shipped.

- Portability can mean smaller internal components with some trade-offs in absolute heavy-duty use compared with larger stationary welders.

- You’ll need consumables on hand; check the included torch consumables upfront.

Who Should Buy This

You should consider this machine if you’re a hobbyist, small shop owner, mobile repair technician, or a beginner who wants a capable TIG that is easy to move. You’ll also like it if you need stick capabilities for rougher outdoor work but prefer TIG for clean, aesthetic joints in steel and stainless.

Comparison With Similar Units

You’ll find other compact inverter TIG/Stick combos on the market. Compared with many competitors, this unit stands out for its advertised 80% duty cycle and included post-gas feature. If you need AC for aluminum, you should compare models explicitly labeled with AC output. For portability and HF TIG performance in DC applications, this model is competitive.

Practical Projects You Can Tackle

You’ll be able to handle a variety of projects, such as:

- Auto body repair (panel patching on steel).

- Stainless trim and decorative pieces.

- Small fabrication work for frames and brackets.

- Welding repairs on farm implements and tools.

- Teaching TIG basics in a small class or for a maker’s workshop.

Final Thoughts

You’ll find the AIXZGLOBAL TIG Welder 200A an appealing balance of features, portability, and TIG performance for its class. Its HF ignition, post-gas control, and 80% duty cycle make it a practical choice for cleaner welds and longer working periods. Just confirm whether your aluminum needs require AC capability, and prepare the basic consumables and gas gear to get the most from the machine. If you value a compact, multi-mode welder that travels easily and produces tidy results on steel and stainless, this unit should meet your needs well.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.