Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you looking for a compact, multiprocess welder that you can carry to small jobs or keep in your garage for DIY fixes?

Quick Verdict

You get a compact, lightweight unit that packs surprising capability for its size. If you need a portable machine for home repairs, auto bodywork, or hobby projects, this model gives you useful flexibility without overwhelming complexity.

Product Snapshot

This section summarizes the main specs so you can see the core details at a glance. The table below breaks down important numbers and features you’ll want to compare quickly.

| Specification | Details |

|---|---|

| Product Name | ANDELI 135Amp MIG Welder 110V Portable Gasless Welder Flux MIG/Lift Tig/Stick 3-in-1 Multiprocess Welder LED Digital Display Welding Machine IGBT Inverter Welder |

| Welding Modes | Flux Core Gasless MIG, Lift TIG (torch not included), MMA (Stick) |

| Input Voltage | 110V |

| Max Output Current | 135A |

| Recommended Steel Thickness | Up to 1/8 inch (3.0 mm) |

| Wire Size Compatibility | .030″ & .035″ flux core wire |

| Synergic Control | Yes — auto-matches voltage to wire feed speed |

| Display | LED digital display |

| Protections | Over-current, overload, overheat, over-voltage, automatic voltage compensation |

| Dimensions | 13″ x 6″ x 8″ |

| Weight | ~9 lbs |

| Included Items | MIG Welder, 3m MIG Torch, Ground Clamp, Electrode Holder, Nozzle, Flux Core Wire |

| Notes | Lift TIG torch must be purchased separately |

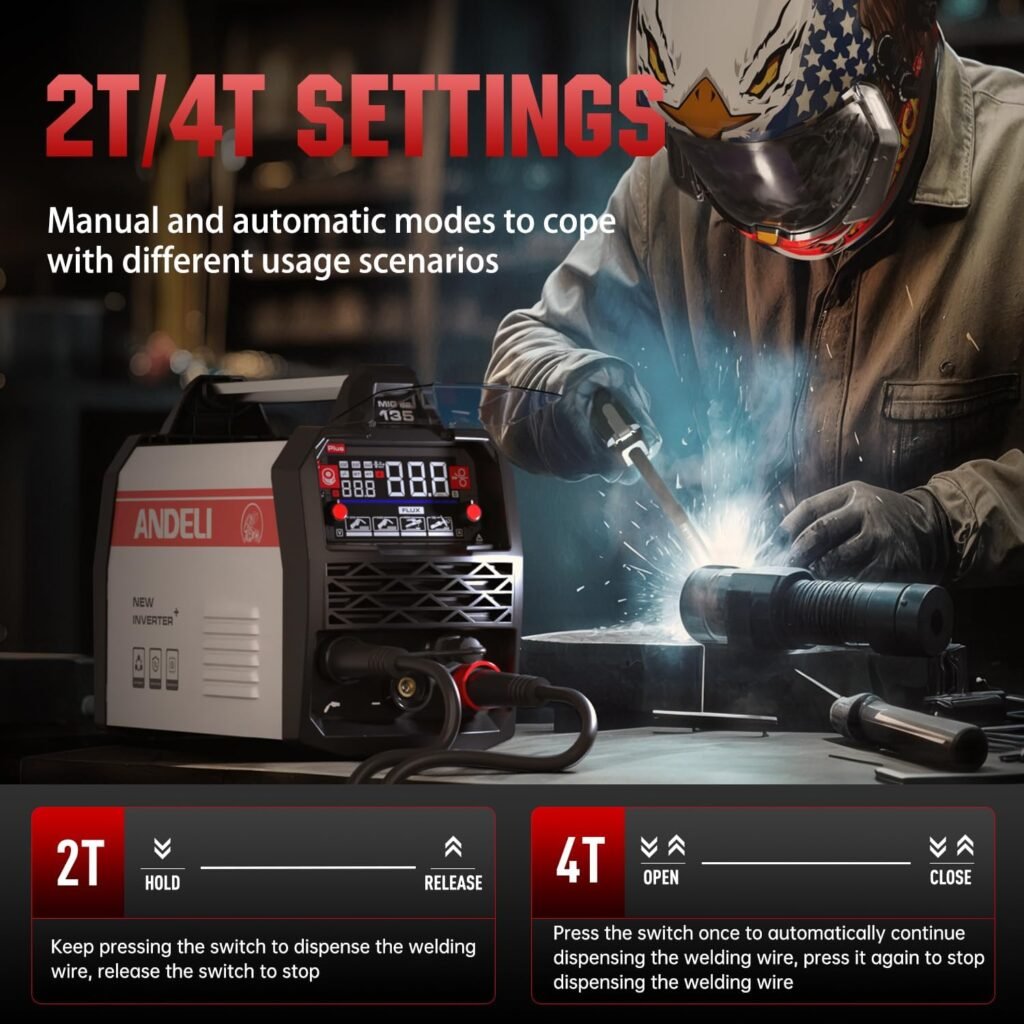

What Makes This Unit Stand Out

You’ll notice the multiprocess capability first, since getting MIG, TIG (lift), and Stick in one compact unit is convenient. The LED digital display and synergic control aim to make setup simpler and to reduce guesswork when you’re changing wire feed speed.

3-in-1 Welding Modes

The three supported processes let you tackle a variety of tasks without multiple machines. You can use flux core MIG for gasless welding, add a Lift TIG torch later for TIG capability, and switch to MMA for basic stick welding.

Flux Core (Gasless MIG) Performance

Flux core is ready-to-go since it doesn’t require shielding gas, which is ideal for outdoor or quick repair work. The unit supports .030″ and .035″ flux core wire, which covers most home and hobby projects and gives good deposition rates for thin to medium gauge steel.

Lift TIG Capability

You can perform Lift TIG welding, but you must buy the TIG torch separately. Lift TIG is useful for finer, cleaner welds compared with flux core, so adding the torch expands your options for precision work.

MMA (Stick) Welding Use

Stick welding is handy for thicker, rusted, or painted materials where shielding gas isn’t practical. The included electrode holder makes it possible to jump into basic stick welding right away, which helps when doing outdoor or maintenance tasks.

LED Digital Display

The digital readout makes it easier for you to see settings and monitor welding parameters while you work. Clear numeric feedback reduces the need for trial-and-error adjustments and helps you repeat setups for consistent welds.

Synergic Control Explained

Synergic control automatically matches the voltage to the wire feed speed when you make adjustments, simplifying the learning curve. That means you’ll spend less time finding the right voltage/wire speed combination and more time welding, which is especially helpful if you’re new to welding.

Power and Output

With a 110V input and up to 135A output, the welder can handle up to about 1/8″ (3.0 mm) mild steel. This power envelope is ideal for light fabrication, automotive repairs, and household metalwork, though it won’t replace a shop-grade machine for heavy industrial tasks.

Wire Size and Feed Compatibility

The unit supports .030″ and .035″ flux core wire, the most common sizes for gasless MIG. These sizes balance ease of feed with good material deposition rates, and they’re affordable and easy to source from local stores or online.

Protection and Stability System

The built-in protections—automatic voltage compensation, over-current, overload, overheating, and over-voltage—are designed to keep both you and the unit safe. The welder’s intelligent corrections help stabilize performance when input power fluctuates, extending the machine’s lifespan and reducing the risk of damage.

Portability and Build

Weighing about 9 lbs and measuring roughly 13″ x 6″ x 8″, this machine is genuinely portable and easy for one person to carry. Its compact housing and lightweight design make it convenient for garage work or carrying to small job sites where a full-size welder would be overkill.

Included Accessories

You get a 3m MIG torch, ground clamp, electrode holder, a nozzle, and a roll of flux core wire. The included kit gets you welding immediately with flux core MIG and MMA, though you’ll want to purchase a TIG torch separately if you plan to TIG weld.

What You’ll Need to Buy Separately

If you want to TIG weld, you’ll need to purchase a Lift TIG torch. You might also want additional items like a gas/regulator (if you ever use gas-shielded MIG/TIG with modifications), extra wire spools, different electrode types, and proper PPE such as a quality auto-darkening helmet and gloves.

Setup and First-Time Use

Setting up the welder is straightforward: mount the wire, thread it through the torch liner, attach the ground clamp, and adjust the wire feed speed and voltage. The LED display and synergic control will guide your initial settings, so you’ll spend less time guessing and more time establishing a workable arc.

Suggested Initial Settings

Start with moderate wire feed speed and mid-range voltage suggested by similar flux core welders for thin steel. From there, tweak wire feed and voltage incrementally until you see a stable arc and good bead appearance; the synergic control helps reduce how many iterations you’ll need.

Welding Performance by Material and Thickness

You’ll get good results on mild steel up to about 3.0 mm (1/8″). Thin sheet metal and automotive panels are well within its capabilities, but if you plan heavy structural welding or thick plate work, you’ll need a higher amperage machine. For rusted or painted metals, stick welding can compensate when surface prep is difficult.

Bead Quality and Appearance

When set properly, the flux core MIG mode produces solid, penetrative beads suitable for repairs and fabrication. You can achieve cleaner, more aesthetic beads with the Lift TIG option once you add a TIG torch, but that involves extra cost and slightly more skill.

Duty Cycle and Continuous Use

Smaller inverter welders like this one generally have modest duty cycles at max output, meaning you’ll need to allow cooling periods during heavy use. For intermittent repair and hobby tasks, the cycle is adequate; for production work, you should plan pauses or multiple units.

Noise and Smoke

Flux core welding produces more smoke and spatter than gas-shielded MIG or TIG, so you should expect to use ventilation or respirators in enclosed spaces. The unit’s inverter operation tends to be quieter and more efficient than older transformer-based machines, but proper PPE remains essential.

Ease of Use for Beginners

You’ll find the machine approachable if you’re new to welding thanks to the synergic control and digital readout. The included accessories let you get started quickly, and the forgiving nature of flux core welding helps you learn faster without a gas setup.

Training and Learning Curve

You’ll still need to practice basic techniques—travel speed, work angle, and joint prep—to make solid welds. The synergic feature shortens the technical setup learning curve, but mastering clean, strong welds requires time and practice.

Maintenance and Care

Basic maintenance includes keeping the wire feed and torch liner clean, checking cable connections, and ensuring vents are free of dust and spatter. Regular inspection and replacing consumables like contact tips and nozzles will keep your unit performing reliably.

Safety Tips

Always wear appropriate PPE: welding helmet, gloves, long sleeved clothing, and respiratory protection when needed. Ensure you work in a well-ventilated area and follow electrical safety practices since the machine runs on 110V and includes protection circuits but still requires safe handling.

Troubleshooting Common Issues

If the wire won’t feed, check tension, spool orientation, and liner obstructions first. If the arc is unstable, confirm ground clamp contact, clean work surfaces, and adjust wire feed speed/voltage; the LED display and synergic control can help you diagnose which parameter to tweak.

Consumables and Replacement Parts

Contact tips, nozzles, and drive rollers are common wear items you’ll replace over time. Keep a small stock of tips and a spare spool of wire to reduce downtime, and source parts that match the .030″/.035″ wire sizes for compatibility.

Use Cases Where This Unit Shines

You’ll find this welder great for automotive patch panels, light fabrication, trailer repair, metal art, and household maintenance. Its portability and gasless flux core capability make it particularly useful for outdoor repairs and small mobile jobs.

Use Cases Where It’s Less Ideal

If you plan heavy industrial work, thick plate welding, continuous production welding, or professional TIG fabrication, this unit’s 135A limit and duty cycle will be restrictive. For demanding shop environments, a higher-amperage, purpose-built machine will serve you better.

Comparison to Similar Machines

Compared with single-process budget welders, this machine adds value by bundling three processes and an LED display with synergic control. Against professional-grade multiprocess welders, it’s lighter on features and power, but it’s more affordable and more portable for casual users.

Pros

You’ll appreciate the compact, lightweight design, easy portability, and multiprocess flexibility. The LED display and synergic control make setup friendlier, while built-in protections help protect both you and the machine.

Cons

You’ll need to buy a TIG torch separately to use Lift TIG, and the power limit keeps it focused on light- to medium-duty tasks. For long continuous welds at full amperage, duty cycle limitations and heat management will require breaks.

Price and Value Assessment

For hobbyists or DIYers, the price-to-feature ratio is attractive given the multiprocess capability and included accessories. If you need a shop-rated, heavy-duty machine, investing more in a higher-spec unit is justified, but for occasional work the value here is solid.

Who Should Buy This

You should consider this machine if you need a portable, low-cost multiprocess welder for home repair, auto bodywork, or creative metalwork. It’s ideal if you want an easy start with gasless MIG and room to upgrade to TIG later without buying an entirely new welder.

Who Should Look Elsewhere

If your projects require sustained high amperage, thick plate welding, or professional TIG work with argon shielding, you’ll be better off with a full-size, higher-amperage machine that offers longer duty cycles. Professionals who weld continuously should look for industrial models with higher capacity.

Long-Term Durability

The built-in protection systems suggest good longevity if you follow recommended duty cycles and maintenance. Treating it as a workshop companion rather than a production workhorse will preserve performance and extend the unit’s life.

Practical Tips for Best Results

Use clean metal with proper fit-up and joint prep, and take time to dial in wire feed and voltage using the synergic control. Keep replacement consumables handy, and try some test beads on scrap to set parameters before working on your real project.

Warranty and Support

Confirm the seller-provided warranty coverage and support options to ensure you have recourse if anything fails. Manufacturer or retailer support can be crucial if you run into issues with the inverter electronics or included accessories.

Final Recommendation

If you want a versatile, portable machine for light- to medium-duty welding and easy-to-use features like synergic control and an LED display, this ANDELI 135Amp model is a solid choice. You should add a Lift TIG torch if you plan to TIG weld, and remember that this unit is best suited to hobbyists, DIYers, and those needing a versatile garage or mobile welder rather than a full-time professional shop tool.

Quick Buying Checklist

You should confirm the following before purchase: that 110V input suits your shop or household outlet, that you accept the 135A limit for your project needs, and that you’ll purchase a TIG torch separately if needed. Also check for included accessories and the warranty length to ensure you get everything required to start welding quickly.

If you want, I can draft suggested settings for common sheet thicknesses, list recommended consumables and suppliers, or help you pick a compatible Lift TIG torch. Which would you like to look at first?

Disclosure: As an Amazon Associate, I earn from qualifying purchases.