Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a reliable MIG wire that gives low spatter and solid all-position welds?

Product at a Glance

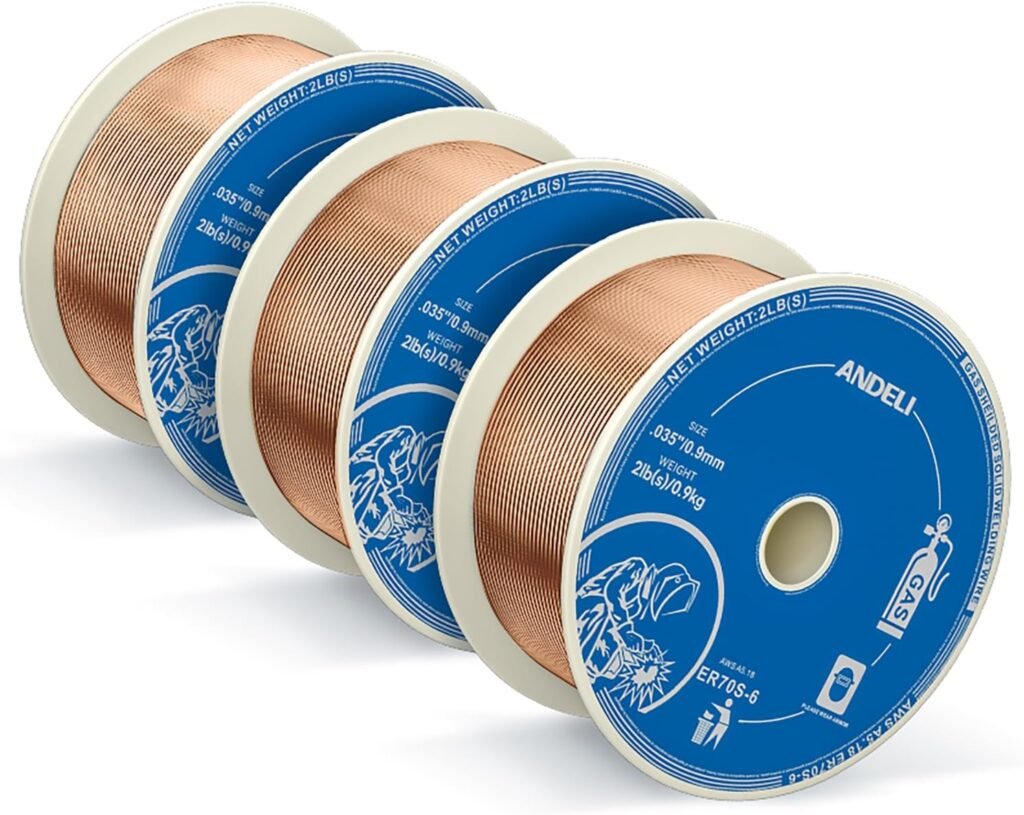

You want a wire that feeds smoothly, delivers consistent welds, and minimizes cleanup. The ANDELI Carbon Steel Solid MIG Welding Wire, ER70S-6 .035-Inch 2-Pound 3-Packs Gas Mig Welding Wire with Low Splatter and High Levels of Deoxidizers – For All Position Gas Welding is designed to meet those needs with copper coating, high deoxidizer content, and careful packaging.

What this product promises

You’ll get three 2-pound spools of .035″ ER70S-6 wire, packed to avoid tangles and designed for 100% CO2 or mixed shielding gases. The manufacturer highlights low spatter, high tensile strength, and stable feeding for long uninterrupted weld runs.

Key Features and Benefits

You care about features that save time and reduce frustration at the bench. These highlights show how the wire helps you finish jobs faster and with fewer defects.

High deoxidizers for tougher conditions

This wire contains higher levels of manganese and silicon compared to many plain carbon wires, which lets you run higher welding currents with 100% CO2 shielding gas. That composition reduces porosity and promotes smoother, cleaner beads so you can spend less time grinding and reworking.

Low spatter performance

Low spatter means less cleanup and fewer blown fumes to manage. You’ll notice fewer spatter globules sticking to adjacent surfaces and a cleaner weld area when settings are matched properly.

Smooth feeding and packaging

Consistent core feeding reduces snags and interruptions, and the three-pack packaging is specifically designed to prevent annoying tangles. That careful packaging helps you avoid wasted time and damaged wire that can ruin a shift.

All-position capability

You can weld flat, horizontal, vertical, and overhead positions with this wire when you match welding technique and parameters. The combination of composition and wire diameter helps maintain a stable arc across different positions and joint types.

Specifications Table

You’ll find the crucial specs below so you know exactly what you’re buying and can plan your setups accordingly. This table gives an at-a-glance look at weight, diameter, and quantity.

| Specification | Detail |

|---|---|

| Product Name | ANDELI Carbon Steel Solid MIG Welding Wire, ER70S-6 .035-Inch 2-Pound 3-Packs Gas Mig Welding Wire with Low Splatter and High Levels of Deoxidizers – For All Position Gas Welding |

| Wire Type | Solid copper-coated mild steel (ER70S-6) |

| Diameter | .035″ (0.9 mm) |

| Spool Weight | 2 lbs per spool |

| Quantity | 3 spools (total 6 lbs) |

| Shielding Gas Compatibility | 100% CO2, Ar/CO2 mixes (e.g., C25), other mixed gases |

| Main Benefits | Low spatter, high deoxidizer content, smooth feeding, all-position welding |

| Typical Tensile Strength | Approx. 70,000 psi (70 ksi) as-welded (typical for ER70S series) |

| Packaging | Tangle-resistant, careful packing |

Performance Overview

You want predictable arc behavior and welds that meet strength and appearance expectations. This wire is tuned to deliver consistent results when your machine and technique are set up correctly.

Arc stability and bead appearance

You’ll notice a steady arc that’s forgiving across a range of voltages when you use correct shielding gas and travel speed. The bead tends to be smooth with good wetting and minimal undercut if you maintain correct travel angle and speed.

Penetration and joint strength

This wire produces deep penetration with 100% CO2, and slightly softer penetration profiles with mixed argon/CO2 blends. You can expect welds that meet typical structural and fabrication strength requirements for mild steel when you follow recommended parameters.

Porosity and x-ray quality

Because of the higher manganese and silicon content, the wire reduces oxygen-related porosity and can produce x-ray quality welds in controlled conditions. You’ll see fewer pinholes and inclusions if you keep base material clean and gas coverage consistent.

Recommended Welding Parameters

You need practical settings so you can start welding faster and with confidence. These ranges reflect common conditions for .035″ ER70S-6 and cover material thicknesses and typical gas choices.

General setup guidance

Start with manufacturer-recommended voltage and wire feed speed curves on your welder and fine-tune based on bead shape and spatter level. Keep a log of your best-performing setups so you can repeat them when similar jobs return.

Sample parameter ranges

You can use the table below as a starting point for common thicknesses. These are approximate values; adjust for joint fit-up, position, and machine characteristics.

| Material Thickness | Shielding Gas | Voltage (V) | Wire Feed Speed (ipm) | Approx Amperage | Travel Tips |

|---|---|---|---|---|---|

| 18 ga (0.8 mm) | C25 (75/25 Ar/CO2) | 14–16 V | 150–200 ipm | 60–80 A | Lower heat, steady travel |

| 16 ga (1.2 mm) | C25 | 16–18 V | 180–240 ipm | 80–100 A | Faster travel, maintain arc gap |

| 14 ga (1.8 mm) | C25 or CO2 | 18–20 V | 220–300 ipm | 90–120 A | Moderate travel, watch for burn-through |

| 1/8″ (3.2 mm) | 100% CO2 | 20–22 V | 300–350 ipm | 120–140 A | Controlled travel, deeper penetration |

| 3/16″ (4.8 mm) | 100% CO2 | 22–24 V | 350–425 ipm | 140–180 A | Multiple passes often required |

| 1/4″ (6.4 mm) | 100% CO2 | 24–26 V | 400–450 ipm | 160–200 A | Multi-pass, good joint fit-up needed |

Compatibility and Machine Setup

You want to know whether this wire will play nice with your equipment and what consumables to choose. Proper setup ensures the best feed and arc behavior.

Drive rolls, liners, and contact tips

Use U-groove or knurled drive rolls designed for soft copper-coated wire to avoid deforming the wire. Match contact tip internal diameter to the wire (.035″) and keep liners clean and free of flattened wire buildup for consistent feeding.

Welding power sources

This wire works with standard MIG/GMAW power sources that support .035″ wire and the amperage ranges listed above. You’ll get the best results on machines with stable voltage control and reliable wire feed motors.

Shielding gas choices

You can run 100% CO2 for deeper penetration and cost savings, or a blended gas like 75/25 Ar/CO2 (C25) for smoother beads and less spatter. The ER70S-6 composition allows you to use CO2 more effectively than lower deoxidizer wires without paying the penalty of extra porosity.

Applications and Use Cases

You plan to use your welding wire where it pays off the most. This wire is versatile for fabrication, repair, and hobby work on mild steel.

Fabrication and structural welding

You’ll find it well-suited to welding frames, brackets, and general structural components where strength and penetration matter. When you follow recommended parameters, welds will meet typical structural requirements for many projects.

Automotive repair and bodywork

For many repairs on mild steel panels and structural components, you’ll appreciate the low spatter and ease of grinding. Use cautious heat input control on thin panels to avoid warping or burn-through.

Maintenance and hobby projects

You can use this wire for shop repairs, metal art, and DIY builds where consistent feeding and clean beads save you cleanup time. The three-pack gives you multiple spools to keep on hand for different machines or jobs.

Packaging, Handling, and Storage

You want spools that uncoil reliably and a storage approach that preserves wire quality. Packaging and handling directly affect feed reliability and arc stability.

Packaging quality

These spools are packaged to reduce tangles, which means fewer stoppages and less wasted time re-spooling. You’ll appreciate the tidy packaging if you frequently change spools during the day.

Handling guidelines

Keep the spool in a dry, clean place and avoid bending the wire at sharp angles between the spool and drive mechanism. Use a spool cradle or holder that allows smooth, trouble-free rotation during welding.

Storage best practices

Store wire in a dry environment and, if possible, keep unopened spools in their original packaging. If moisture exposure occurs, consider baking the wire per manufacturer recommendations before use to avoid hydrogen-related porosity.

Pros and Cons

You want the bottom line — what this wire excels at and where you might need to take extra care. This straightforward list helps you weigh tradeoffs.

Pros

- You’ll get low spatter and cleaner welds, particularly with proper gas selection.

- The high deoxidizer levels allow you to run 100% CO2 at higher currents with reduced porosity risk.

- Packaging reduces tangles and makes spool changes less of a hassle.

- All-position welding capability and common .035″ size make it a versatile shop staple.

Cons

- You’ll need to tune parameters for each thickness and joint to avoid excessive penetration or undercut.

- If stored improperly, any mild steel wire can pick up rust or contaminants that harm weld quality.

- For specialty alloys or stainless, this wire is not suitable — it’s strictly for mild carbon steels.

Troubleshooting Common Issues

You’ll inevitably face setup issues; quick diagnostics can get you back to welding fast. These steps address the frequent problems users report.

Wire feeding problems

If feeding is inconsistent, check the drive roll pressure, groove type (U-groove recommended), and liner condition. Replace worn drive rolls, clear or replace the liner if the wire has flattened spots, and ensure the spool unwinds freely.

Excessive spatter

If spatter is high, reduce voltage slightly, slow travel speed, or switch from 100% CO2 to a mixed gas like C25 for a smoother arc. Clean any built-up spatter from the nozzle and replace contact tips if pitting or wear is visible.

Porosity or gas shielding issues

You’ll see porosity if shielding gas flow is inadequate, wind is disturbing the gas, or base metal is contaminated. Increase gas flow slightly, provide wind breaks, and clean weld surfaces before welding.

Burn-through or lack of fusion

If burn-through occurs, reduce heat input by lowering voltage or travel speed on thinner material. If lack of fusion appears, increase voltage slightly and reduce travel speed while ensuring proper joint fit-up.

Tips and Best Practices

You want practical tips that help you get optimal results more often. The following recommendations come from common shop experience and manufacturer guidance.

Cleanliness matters

Always remove mill scale, rust, oil, and paint from weld areas for consistent penetration and minimal porosity. Even a small layer of contamination can cause poor fusion or trapped gases.

Keep a welding log

Record your voltage, wire feed speed, contact tip size, gas type, and observed bead quality for recurring joints. You’ll save time later by repeating settings that worked well.

Match consumables

Use contact tips, nozzles, and liners designed for .035″ copper-coated wire. Proper consumables protect the wire and prevent erratic feeding and short circuits.

Mind your travel angle and speed

Maintain a slight push or drag angle depending on the joint, and keep travel speed steady to produce uniform puddle and bead shape. Inconsistent travel causes undercut and inconsistent penetration.

Comparison with Similar Wires

You want to know how this wire stacks up against other common choices. This comparison focuses on ER70S-6 versus similar ER70S options and flux-cored alternatives.

ER70S-6 vs ER70S-3

ER70S-6 generally contains higher manganese and silicon than ER70S-3, which helps when using CO2 shielding and higher currents. You’ll choose ER70S-6 for tougher conditions and applications where CO2 is preferred or where contamination might be higher.

ER70S-6 vs flux-cored (FCAW) wires

Flux-cored wires offer better performance in windy conditions and sometimes faster deposition rates, but they produce more smoke and slag to clean. You’ll prefer solid ER70S-6 when you want cleaner beads and are welding in controlled environments with shielding gas.

Cost vs performance

You’ll often find solid ER70S-6 wires to be cost-effective for general fabrication and repairs; they balance lower wire cost, acceptable spatter, and good mechanical properties. Flux-cored wires might cost more per pound but can reduce welding time in specific scenarios.

Safety Considerations

You want to stay safe while getting the job done. Proper PPE and ventilation are crucial when welding any consumable.

Basic PPE

Wear a properly rated welding helmet with appropriate shade, flame-resistant clothing, welding gloves, and boots. Eye and skin protection is non-negotiable when you’re exposed to UV and infrared radiation.

Ventilation and fume control

Use adequate ventilation or local exhaust to remove welding fumes, especially when welding with CO2 or mixed gases. If you’re welding in tight or poorly ventilated spaces, use respirators rated for welding fumes.

Electrical and gas safety

Make sure connections are tight, inspect cables and torch liners for damage, and secure gas cylinders to prevent tipping. You’ll want to check regulators and hoses for leaks before starting.

Frequently Asked Questions (FAQs)

You’ll likely have a few practical questions before buying or using this wire. These answers address common concerns users have.

Will this wire work with my MIG welder?

If your MIG welder supports .035″ wire and can deliver the amperage ranges listed earlier, this wire should work well. Verify spool adapter compatibility and that your drive rolls and contact tips are correct.

Can I use this wire without shielding gas?

No, this is a solid MIG wire designed for GMAW with shielding gas. If you need no-gas capability, you’ll want a flux-cored self-shielding wire instead.

Is this wire good for outdoor welding?

You can use it outdoors if you protect the weld area from wind and drafts that would disperse shielding gas. If wind is a factor and you can’t provide protection, consider flux-cored wire for more reliable shielding.

How long will the spools last in storage?

Stored in a dry, controlled environment, these spools will last many months or even years. Always inspect for rust, and if any moisture exposure occurred, consider baking the wire or discarding it if contamination is severe.

Buying and Value Considerations

You want value — not just the lowest price. This three-pack gives you multiple spools, which lowers downtime and keeps a steady supply in the shop.

Cost per pound and practicality

Buying three 2-pound spools often saves you time and keeps spools replaced less frequently compared to buying single spools. You’ll find the packaging and consistent quality add value beyond raw price per pound.

When to choose alternatives

If you need stainless, aluminum, or specialized alloy welds, this wire isn’t appropriate. Likewise, if you routinely weld outdoors in high wind, you may prefer flux-cored alternatives for reliable shielding.

Final Thoughts and Recommendation

You want a clear verdict to guide your purchase decision. The ANDELI Carbon Steel Solid MIG Welding Wire, ER70S-6 .035-Inch 2-Pound 3-Packs Gas Mig Welding Wire with Low Splatter and High Levels of Deoxidizers – For All Position Gas Welding is a solid choice for general-purpose mild steel welding.

You’ll appreciate the low spatter, good feeding behavior, and the flexibility to use CO2 or argon/CO2 blends. If you match machine setup, consumables, and welding parameters to your material and position, this wire will deliver reliable, strong welds with minimal cleanup.

Quick Checklist Before You Weld

You want a last-minute checklist so you don’t forget the essentials. Use this brief list to confirm readiness before striking an arc.

- Verify wire diameter (.035″) matches contact tip and drive rolls.

- Confirm shielding gas type and flow rate appropriate for the job.

- Clean base metal and joint area to remove oil, rust, and paint.

- Ensure drive roll pressure and liner condition allow smooth feeding.

- Set initial voltage and wire feed speed from the parameter table and adjust to bead appearance.

If you follow these steps and use the guidance in this review, you’ll get the most from your ANDELI ER70S-6 spools and produce strong, clean welds that stand up to real-world use.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.