Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you trying to find a reliable argon flowmeter regulator that gives you precise control during MIG and TIG welding?

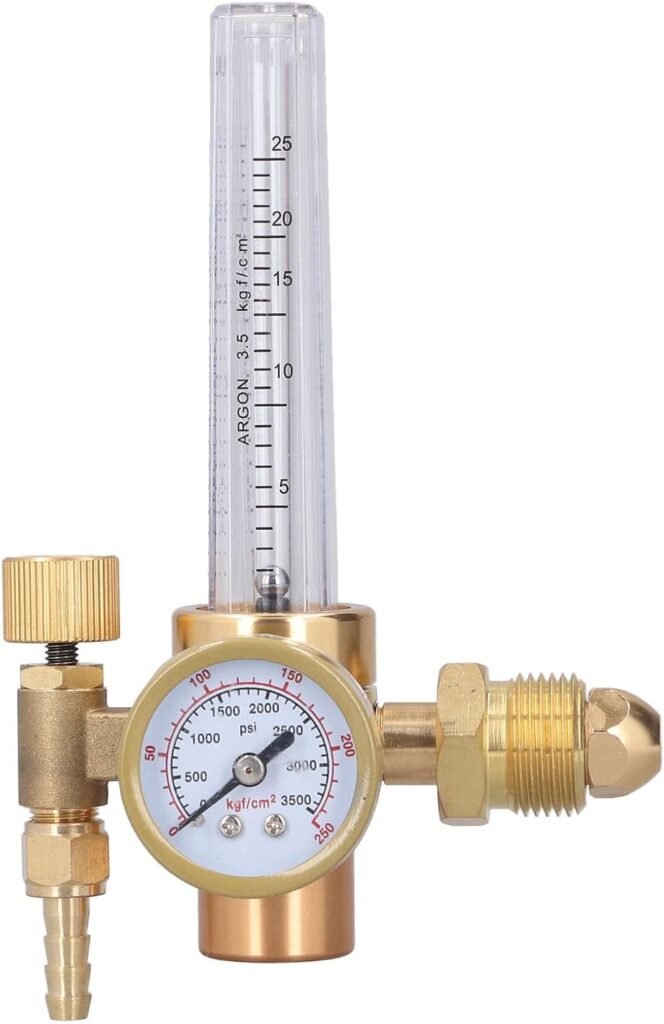

Overview of the Artillery Argon Flowmeter Regulator, OBC-191 Y Welder Gas Regulator Gauge, 0-3500psi All Brass MIG Flowmeter Welding Accessory for TIG and MIG Welding

This regulator is built to give you accurate readings and stable flow for argon and CO2 applications in MIG and TIG welding. You’ll notice a brass construction, a flowmeter tube with a ball indicator, and a pressure range that supports high-pressure cylinders up to 3500 psi.

What this product is meant to do

You’ll use this regulator to control shielding gas flow precisely while welding, which helps prevent oxidization and ensures weld quality. It reduces cylinder pressure to a steady working pressure and displays the flow from 0 to 25 liters per minute (lpm), making it suitable for many hobbyist and professional welding tasks.

Key Features

Below are the main features that stand out and why they matter to you when welding.

Precise Control

You can set the gas flow with good resolution using the ball-in-tube indicator that rises and falls to show flow rate. That visual feedback helps you confirm the setting quickly without guessing, which is helpful when switching between MIG and TIG jobs.

Leak-Proof Design

The 1/4 inch connector with a female thread nut is intended to create a secure, leak-resistant seal. When you tighten it correctly, you should have minimal leakage, which protects your gas supply and prevents wasted shielding gas that can impact weld quality.

Easy Adjustment

The flow range from 0 to 25 lpm is simple to adjust via the regulator knob and is shown directly in the flows tube by a moving ball. If you change welding processes or materials, you can change the flow quickly and clearly.

Durable Construction

Made primarily of brass, the regulator is built to withstand cylinder pressures up to 3500 psi. The brass body is corrosion resistant and offers lasting durability, which matters if you work in busy shops or variable environments.

Versatile Application

You can use this regulator with HTP and most other welders that accept standard fittings, making it versatile for both CO2 and argon applications in MIG and TIG welding. That flexibility helps if you run multiple machines or switch gases frequently.

Technical specifications (quick reference)

This table helps you quickly see the core technical specs so you can match the regulator to your gear and needs.

| Specification | Value |

|---|---|

| Product name | Artillery Argon Flowmeter Regulator, OBC-191 Y Welder Gas Regulator Gauge, 0-3500psi All Brass MIG Flowmeter Welding Accessory for TIG and MIG Welding |

| Flow range | 0–25 liters per minute (lpm) |

| Max inlet pressure | 3500 psi |

| Material | Brass body with flow tube (likely polycarbonate or similar) |

| Connector | 1/4 in female thread nut |

| Display | Ball-in-tube flow indicator |

| Compatible gases | Argon, CO2 (and mixes) |

| Typical uses | TIG welding, MIG welding, CO2 shielding |

| Package includes | Regulator with flowmeter (verify exact contents with seller) |

Unpacking and first impressions

When you first get this regulator, you’ll likely notice the weight and solid feel from the brass body. The flow tube and ball should be visible and intact, and the fittings should thread smoothly.

Visual inspection tips

Check the flow tube for cracks and make sure the ball moves freely when you blow gently through the inlet (with the unit disconnected from a pressurized cylinder). Inspect threaded fittings for any burrs and confirm the regulator knob turns without grinding.

What to expect in the box

You typically receive the regulator itself and possibly protective caps or an instruction sheet. If fittings or hose connections aren’t included, you should have the appropriate hoses and connectors on hand.

Installation and setup

Setting up the regulator is straightforward, but you should follow basic safety and leak-check steps.

Connecting to your gas cylinder

You connect the 1/4 inch female nut to your cylinder valve or to the gas hose/fitting appropriate to your system. Tighten with a wrench to a snug fit, but avoid over-torquing which can damage threads or deform fittings.

Initial pressure and flow adjustments

Open the cylinder valve slowly while watching the inlet pressure gauge (if present) and then adjust the flow knob to your target lpm. It’s safer to start on low flow and increase to the recommended amount for your welding process and material thickness.

Flow accuracy and performance

Flow accuracy is critical for welding quality; too little gas can cause porosity and too much wastes gas and can cause turbulence.

How the ball-in-tube design performs

The ball-in-tube indicator gives you an intuitive visual cue of flow rate. You’ll be able to set flows like 10–15 lpm for some MIG applications or lower flows for TIG. It’s accurate enough for most shop and field use, though very high-precision labs may want electronic mass flowmeters.

Stability and response

You’ll find the regulator holds flow fairly steady under normal cylinder pressure drops, but as the cylinder empties you should monitor and adjust as needed. For consistent long-term flow, ensure the regulator is seated correctly and that the cylinder pressure is sufficient.

Pressure handling and safety

Handling high-pressure gas needs attention to safety.

Pressure capacity and safety margin

With a 3500 psi maximum inlet pressure rating, this regulator handles typical welding cylinders. You should always confirm the regulator’s working pressure against your cylinder and ensure all components in your system (hoses, fittings) are rated appropriately.

Leak checking and routine safety checks

After installation, do a leak check using a soap solution or approved leak detection fluid. Look for bubbles at each connection. Also, periodically check the regulator and hoses for wear or damage and replace any suspect parts.

Compatibility and applications

This regulator is intended for broad use but there are specific points to consider when matching it to your setup.

Which welders and systems it fits

You can use this with HTP-brand welders and most MIG/TIG machines that use a standard 1/4 inch connector and common gas mixtures. If your machine has a proprietary connection, you’ll need an adapter.

Suitable welding tasks

Use the regulator for MIG welding with CO2 or argon blends, for TIG welding with pure argon, and for smaller fabrication or repair tasks where precise gas flow matters. It’s suitable for light industrial, automotive, and hobbyist work.

Durability and materials

Brass is chosen for its strength and resistance to corrosion, which is important near welding operations.

Brass advantages

The brass body resists rust and stands up to the mechanical stresses of shop life. You’ll notice the regulator will likely outlast similar regulators built with less robust metals or plastics.

Considerations for the flow tube

The flow tube itself is probably made of a clear plastic such as polycarbonate. Avoid exposing it to direct flame, harsh chemicals, or heavy impact that could crack or discolor the tube.

Real-world use: How it performs on the job

Here are practical notes you’ll appreciate if you use the regulator regularly.

Everyday welding scenarios

For routine MIG welding on steel panels, you’ll set flows anywhere from 15–25 lpm depending on nozzle size and gas mix; this unit covers that range comfortably. For TIG welding, lower flows (6–15 lpm) are common and easy to dial in.

Switching between processes

Because the regulator adjusts easily and shows flow instantly, switching between TIG and MIG or between different welders is quicker. You’ll avoid guesswork because you can visually confirm the ball’s position.

Maintenance and care

You’ll extend the regulator’s life with basic maintenance and careful handling.

Routine maintenance steps

Keep the regulator clean and free of spatter, store it in a dry place, and cap the inlet when not in use to prevent dust from entering. Periodically check o-rings and threads and replace worn parts.

When to service or replace

If you notice drifting flow, leaks that don’t stop with tightening, or damaged gauges/tube, it’s time to service the regulator or replace it. Don’t attempt major repairs unless you have proper replacement parts and knowledge.

Troubleshooting common issues

Here are typical problems you might encounter and how to fix them.

Flow reading seems inaccurate

If the ball is sticky or doesn’t move smoothly, there may be debris in the tube or a pressure imbalance. Disconnect and inspect for dirt; flush carefully if appropriate, and recheck for leaks.

Leaks at fittings

If you detect leaks, tighten connections but avoid over-tightening. Replace damaged seals or ferrules. Use leak detection fluid rather than open flame to find leaks.

Pressure gauge reads zero but gas is present

Make sure the cylinder valve is fully open and that the regulator inlet is connected properly. If the gauge remains at zero, the internal gauge could be faulty and may require replacement.

Pros and cons

This balanced list helps you weigh strengths and limitations.

Pros

- You get precise visual feedback with the ball-in-tube flowmeter, making adjustments fast.

- Brass construction gives durability and corrosion resistance that handles shop use.

- Wide flow range (0–25 lpm) covers many MIG and TIG applications.

- 3500 psi inlet capacity suits standard welding cylinders and gives a good safety margin.

- Simple, common connections increase compatibility across equipment.

Cons

- The flowmeter’s accuracy is mechanical and may not match lab-grade electronic mass flowmeters.

- You’ll need to ensure proper adapters if you use non-standard connectors or international cylinder valves.

- The flow tube plastic can be vulnerable to impact, heat, or chemical damage if not protected.

Comparison to alternative regulators

When choosing a regulator, you might compare this to digital or two-stage regulators.

Single-stage mechanical vs digital regulators

Mechanical single-stage regulators like this one are simpler, rugged, and usually less expensive. Digital regulators offer higher accuracy and recorded flow data, but they cost more and can be less tolerant of rough shop handling.

Two-stage regulators

Two-stage regulators provide better stability as cylinder pressure drops. If you work with long weld times and need extremely consistent flow without re-adjustment, a two-stage option could be better. For most intermittent and shop use, a single-stage brass unit performs well.

Tips for getting the best results

Small habits will make the regulator more effective and extend its life.

Set flow for the job

Match flow rates to the welding process, material, and nozzle size. Typical starting points: TIG on thin steel 6–10 lpm, MIG on thicker mild steel 15–25 lpm—adjust based on puddle behavior and visibility.

Keep connections snug and clean

Clean threads and use the correct fittings to avoid leaks. Replace seals or washers if you see wear.

Protect the flows tube

Avoid striking or placing the regulator where spatter or tools can hit the flow tube; a cracked tube will affect reading and can leak.

Who should buy this regulator?

This regulator is suited for a variety of users who need reliable gas control without spending on high-end gear.

Ideal buyers

- Hobbyist welders and metalworkers who need reliable shielding gas control.

- Small shops and maintenance operations that require durable hardware on a budget.

- Mechanics doing auto body and farm repairs where argon and CO2 shielding is routine.

Situations where you might look elsewhere

If you need laboratory-grade flow accuracy, automated flow logging, or two-stage pressure stabilization for critical production environments, consider a higher-end digital or two-stage regulator.

Price and value considerations

You should evaluate cost versus the features you actually need.

Is it worth the money?

If you want a solid, brass-built flowmeter regulator with a clear flow range and common fittings, this model gives strong value for most welding work. You pay less than premium digital regulators while gaining dependable mechanical performance.

Long-term value

Because of the brass construction and simple mechanics, you’ll likely get years of service with proper care. Factor in the cost of possible adapters or replacement flow tubes if you work in harsh conditions.

Real user scenarios and examples

Here are some realistic examples of how this regulator performs in common tasks.

Auto body panel welding

You’ll set flows to reduce splash and contamination; the visible ball helps you hit the exact value you use for each panel type. The brass body resists shop abuse and lasts through many repair sessions.

Fabrication and metal art

When switching between MIG and TIG for different parts of a project, you’ll appreciate the quick visual confirmation of flow rate and the ability to make fast adjustments on the fly.

Light production welding

For short-run production that doesn’t demand electronic logging, this regulator gives repeatable flows and a robust build that will stay in service.

Frequently asked questions

These short answers address common concerns you may have.

Can it be used with mixed gases like C25?

Yes — as long as the fittings match and the pressure requirements are within range, you can use argon mixes such as C25 (argon-CO2 mixes) for MIG welding.

How accurate is the flow reading?

It’s mechanically accurate for shop use and gives repeatable readings, though not as precise as high-end electronic mass flowmeters used in labs.

Is the flow tube replaceable?

Some models allow replacement of the flow tube; check with the seller or manufacturer for spare parts. If not, protect the tube to reduce the chance of damage.

Final recommendation

If you need a reliable, durable, and straightforward regulator for TIG and MIG welding that gives visible flow readings and handles standard cylinder pressures, the Artillery Argon Flowmeter Regulator, OBC-191 Y Welder Gas Regulator Gauge, 0-3500psi All Brass MIG Flowmeter Welding Accessory for TIG and MIG Welding is a strong contender. You’ll get the durability of brass, a useful 0–25 lpm flow range, and a secure 1/4 in connector. It’s especially well suited for hobbyists, small shops, and practical field use where ruggedness and clear visual control matter more than laboratory precision.

If you want, I can give a short checklist for setup and a checklist for spare parts to keep on hand. Which would you prefer?

Disclosure: As an Amazon Associate, I earn from qualifying purchases.