Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a multiprocess welder that can handle aluminum without a spool gun and still give you flexibility for MIG, Stick, and TIG work?

Quick verdict

You’re getting a compact, versatile machine in the AZZUNO Aluminum MIG Welder 155Amp, Dual Vlotage 110V/220V 5-in-1 Welder Machine Gasless MIG/Gas MAG/Aluminum MIG/Stick/Lift TIG Welding, Multiprocess Welding Machine. It’s aimed at hobbyists, DIYers, and small shops who want a single unit that covers common welding tasks while giving some specialized support for aluminum MIG welding.

Product overview

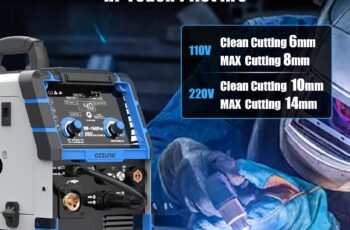

This multiprocess welder gives you Gasless MIG, Gas MAG, Aluminum MIG, Stick, and Lift TIG modes, plus dual voltage capability so you can plug into standard 110V circuits or 220V outlets. You’ll find adjustable current settings, multiple wire spool options, and modes like SYNERGIC, 2T and 4T to help simplify setup and control when you’re welding different materials.

Key features at a glance

You’ll appreciate the machine’s support for a range of wire diameters and spool sizes, plus the claim that you can MIG weld aluminum without swapping to a Teflon liner or using a spool gun. The unit also promises compact portability, a set of useful accessories, and the convenience of automatic fine-tuning in SYNERGIC mode.

| Feature | Specification | Why it matters to you |

|---|---|---|

| Welding processes | Gasless MIG / Gas MAG / Aluminum MIG / Stick / Lift TIG | One machine for many tasks, saving space and cost |

| Voltage | Dual 110V / 220V | Use at home or in a shop with different power supplies |

| Current range | Up to 155A | Handles light-to-medium gauge work and some thicker joints |

| Wire sizes supported | .030″, .035″ flux core; .030″ solid; .035″/.040″ aluminum | Flexibility to use common welding wires, including aluminum |

| Spool capacity | 1 lb to 2 lbs spools | Smaller spools mean easier handling and compatibility |

| Modes | SYNERGIC, 2T, 4T | Automatic settings and user control modes for varied work |

| Accessories included | Torch, electrode holder, ground clamp, wire, contact tips, rollers | Good starter kit so you can begin welding sooner |

| Special claim | Aluminum MIG without Teflon liner or spool gun | Reduces accessory cost and setup changes for aluminum work |

Performance overview

When you pick up this AZZUNO unit, you’ll notice it’s designed to be a generalist with a few specialist capabilities, especially for aluminum. The 155A max output means it’s not a heavy industrial machine, but it handles typical welding tasks for automotive repair, fabrication of small parts, and home projects.

MIG welding performance

For steel MIG and flux-core welding, you’ll find the machine provides stable arcs and predictable bead appearance once you dial in the wire feed speed and voltage. In SYNERGIC mode the unit helps by adjusting voltage relative to wire feed automatically, which is useful if you’re not fully confident in manual tuning.

Aluminum MIG performance

The unit’s selling point is simplified aluminum welding without needing a spool gun or a Teflon liner swap. If you use the recommended aluminum wire sizes and set your parameters correctly, you can get smooth aluminum welds. That said, aluminum welding is sensitive to technique and cleanliness, so expect a learning curve if you’re new to it.

Stick and Lift TIG performance

Stick welding with E6013 electrodes is straightforward for thin-to-medium steel repairs and maintenance. Lift TIG mode gives you the ability to TIG weld without high-frequency start, which is adequate for many simple TIG tasks and when you want cleaner starts on thin material. These modes broaden the machine’s usefulness but won’t replace dedicated TIG or MMA machines for advanced fabrication or very thick sections.

Usability and controls

You’ll find the control layout is designed to be approachable. The SYNERGIC mode reduces guesswork, and the 2T/4T options let you choose between simple trigger operation and continuous weld hold for longer runs.

SYNERGIC, 2T and 4T modes explained

SYNERGIC mode limits manual tweaking by correlating wire feed and voltage automatically, which is great when you want consistent results without lots of trial runs. 2T is your basic trigger-on/trigger-off arrangement, while 4T locks the torch for continuous welding so you can focus on the weld path without holding the trigger down.

Interface and adjustments

The front panel typically includes knobs for current, wire feed speed, and sometimes finetuning for parameters depending on mode. You’ll want to spend a little time experimenting with the knobs on scrap steel and aluminum until you become comfortable reading arc behavior and adjusting settings to match material thickness and wire type.

Wire feeding and spool options

You can use 1 lb to 2 lb wire spools and several common wire diameters, which keeps consumable costs low and gives you flexibility for many jobs. The machine includes both V-groove and U-groove rollers to handle steel and aluminum wire without changing the drive system entirely.

Supported wire types and sizes

The machine accepts .030″/.035″ flux core, .030″ solid copper-clad wire, and .035″/.040″ aluminum wire. Having these options means you can choose flux-core for outdoor or windy conditions and solid wire for cleaner shop work with shielding gas, while the wider aluminum sizes are there for softer metal feed.

Feed roller setup and maintenance

Changing between rollers is simple and you’ll want to check tensions, liner condition, and contact tip wear regularly to avoid feed problems. If you do experience skips or burnbacks, inspect the feed system and replace tips or rollers as needed; aluminum feed demands extra attention because the softer wire is easier to deform.

Build quality and portability

The chassis is compact and lightweight relative to larger industrial units, so you can move it around your garage or jobsite fairly easily. The tradeoff for portability is that thermal management and enclosure robustness might not match heavy-duty welders, so you’ll want to treat it as a semi-portable, shop-level unit rather than an industrial workhorse.

Materials and cooling

You’ll notice a metal exterior with ventilation slots and an internal fan. That cooling approach works for intermittent use and typical small shop duty cycles, but heavy continuous welding may push the cooling system toward thermal limiters.

Size and weight considerations

Because it’s dual-voltage and supports multiple processes, the unit packs a lot into a relatively small footprint, which is convenient if you lack space or plan to transport the machine occasionally. Just remember that the weight will increase when you add spools, wires, and accessories.

Installation and initial setup

When you unbox your AZZUNO unit, you’ll be able to set it up for either 110V or 220V with the correct cable and plug. You should check your power supply, set the voltage selector correctly, and follow safety wiring guidelines to avoid damage.

Power connection and safety checks

Make sure your outlet and cable can handle the welder’s current at the chosen voltage. You’ll also want to ground the machine correctly, inspect the torch and clamp connections, and confirm that the gas flow (if you’re using shielding gas) is set appropriately before you strike your first arc.

First welds and recommended settings

Start with scrap pieces at various thicknesses; use SYNERGIC mode to get the unit close to the right parameters and then fine-tune wire feed and current to match bead shape. For aluminum, clean the surface thoroughly and consider running a few practice passes to establish travel speed and torch angle that give you a full-penetration, clean bead.

Included accessories and package contents

The package includes a MIG torch, electrode holder, ground clamp, flux-cored wire spool, contact tips, nozzles, drive rollers, a gas hose, and a brush & hammer. These accessories give you a functional starter kit so you can begin many common welding tasks right after setup.

How the accessories help you get started

You’ll appreciate that the contact tips and rollers for different wire sizes are included, which saves you a trip for consumables. The electrode holder and ground clamp mean you can start stick welding immediately, and the included wire allows you to perform initial tests without ordering consumables.

What you might add later

You may choose to buy larger spools of wire, shielding gas and regulator if you prefer gas MAG welding, or additional contact tips and nozzles if you plan to weld frequently. If you’re focused on aluminum, consider buying extra aluminum wire spools and practicing with different travel speeds and torch angles to perfect your technique.

Safety and maintenance

You should always follow standard welding safety practices: proper eye and skin protection, ventilation, and safe handling of cables and gas cylinders. Routine maintenance like cleaning the contact tip, checking cables, and replacing liners as they wear will keep your unit performing reliably.

Routine checks to maintain performance

Inspect the torch, ground clamp, electrode holder, and all cables for wear before each use. Clean the nozzle regularly to prevent spatter build-up, check the drive rollers and contact tips for wear, and verify fan operation and vents aren’t clogged to avoid overheating.

Safety equipment and setup tips

Besides a welding helmet and gloves, use a respirator or adequate ventilation when welding aluminum or flux-core wire, as fumes can be more hazardous. Keep flammables away from your work area, and make sure you’re using appropriate personal protective equipment for the processes you run.

Practical applications and ideal use cases

This welder suits a range of common tasks like automotive repair, small fabrication, home projects, and renovation tasks where you need process flexibility. It’s particularly useful when you want to switch between MIG, flux-core, stick, and TIG without maintaining multiple machines.

Automotive and bodywork

For body panels and light frame repairs, the unit’s MIG and flux-core capability handles thinner steel if you dial in lower current and wire feed speeds. Aluminum repair work on trailers, small boats, or motorcycles benefits from the unit’s aluminum MIG support, especially when you don’t want to invest in a separate spool gun.

Home hobbyists and fabricators

If you enjoy building furniture, metal art, or DIY metal projects, this machine gives you the tools to learn several welding methods and practice with a single machine. The SYNERGIC mode reduces the set-up frustration that often slows beginners down, so you’ll spend more time welding and less time configuring.

Light industrial and small shop use

For small shops and light production environments that don’t require long duty cycles or multi-shift welding, the AZZUNO can act as a flexible backup machine or a primary unit for simpler jobs. Keep expectations reasonable: for intensive production you’d typically want a higher-duty-cycle industrial welder.

Pros and cons

You’ll find several advantages in feature breadth and price-to-performance, but there are tradeoffs in heavy-duty performance and some refinement compared to dedicated machines. Below are concise lists to help you weigh whether this model fits your needs.

Pros:

- Multiprocess flexibility for MIG, Aluminum MIG, Stick, and Lift TIG.

- Dual voltage for home and shop adaptability.

- SYNERGIC mode simplifies setup and makes welding more approachable.

- Includes useful accessories to get started.

- Compatible with common wire sizes and small spool options.

Cons:

- 155A limit restricts you from heavy plate welding.

- Not a replacement for a dedicated spool gun for very high-volume aluminum work.

- Cooling and duty cycle may limit continuous industrial use.

- Build and finish might be less robust than premium brands.

Troubleshooting common issues

If you face wire feeding problems, spatter, or unstable arcs, there are straightforward checks you can perform. Most issues come down to feed tension, worn consumables, incorrect settings, or contamination of the base metal or wire.

Common problems and fixes

If the wire birdnests in the spool area, check spool mounting and drive tension; replace or clean the liner and ensure the spool is mounted correctly. For porosity in aluminum welds, ensure the workpiece is clean and free from oxides and that shielding gas is used or the flux wire is appropriate for the application. If you experience overheating cutouts, reduce duty cycle, ensure proper ventilation, or allow the unit to cool as recommended.

When to contact support

If the unit fails to power on, trips breakers unexpectedly, or you have persistent electrical faults, stop using it and contact AZZUNO support or your seller. Avoid attempting complex internal repairs unless you’re qualified, because dual-voltage welding machines involve potential shock and component risks.

Comparison with alternatives

If you compare this AZZUNO unit to entry-level single-process welders, the clear advantage is the range of processes it supports. When compared to mid-range dedicated TIG or heavy industrial MIG machines, the AZZUNO sacrifices top-end duty cycle, precision controls, and long-term durability for cost and versatility.

How it stacks up for aluminum work

For casual aluminum welding or occasional repair jobs, this welder is very competitive because it eliminates the need for a spool gun in many scenarios. If you’re doing high-volume aluminum fabrication or welding very thick sections, a dedicated spool gun system or a higher-end MIG with spool gun capability will give better performance.

Price-versus-function tradeoff

You’re paying for a multipurpose tool rather than best-in-class performance for any single process. If you want one machine to learn on and to handle most home and light-shop tasks, this has strong value. If you need professional, continuous-duty operation, consider spending more on a dedicated unit.

Tips to get the best results

Practice on scrap material before tackling your project, and keep a log of settings that work for specific materials and thicknesses. Proper cleaning, wire handling, and heat control will dramatically improve your weld quality and make the machine feel more capable than you might expect from the spec sheet alone.

Aluminum-specific tips

Remove oxide with a stainless brush and use consistent travel speed; aluminum melts and flows differently from steel so you’ll need to adjust travel speed and torch angle. Keep the wire feed tension low and use the correct U-groove roller and contact tip for aluminum to reduce feeding deformation.

General setup and technique tips

Use SYNERGIC mode as a baseline, but fine-tune manually if you see spatter or poor penetration. Start with conservative current and wire feed settings, and gradually increase until you see a smooth, well-penetrated bead. Always check ground clamp contact and ensure your workpiece is securely clamped to prevent poor arc stability.

Who should buy it?

You should consider this AZZUNO machine if you’re a hobbyist, weekend fabricator, or small-shop operator who needs one flexible machine to cover many tasks. If your work involves occasional aluminum repairs, small structural welding tasks, or learning multiple welding processes without investing in separate machines, this model is a solid candidate.

When to choose another option

If you need constant, heavy-duty production welding or frequent deep-penetration aluminum welding for large structures, you should look at higher-amperage industrial units or a MIG with spool gun capability. Also consider dedicated TIG machines if you do a lot of precision TIG work on thin materials or exotic metals.

Final recommendation

If you want versatility, portability, and reasonable aluminum capability in a single machine, you’ll likely be satisfied with the AZZUNO Aluminum MIG Welder 155Amp, Dual Vlotage 110V/220V 5-in-1 Welder Machine Gasless MIG/Gas MAG/Aluminum MIG/Stick/Lift TIG Welding, Multiprocess Welding Machine. It gives you a great way to learn multiple welding processes and handle a wide variety of home, hobby, and light-shop tasks without the need to maintain several separate machines.

Buying tips and next steps

Before purchasing, confirm your power availability (110V vs 220V), plan what wire types and gas you’ll use, and consider buying extra contact tips, aluminum wire spools, and a quality welding helmet if you don’t already have them. Once you have everything set up, practice on scrap and document effective settings for your typical materials so you can reproduce good results quickly.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.