Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

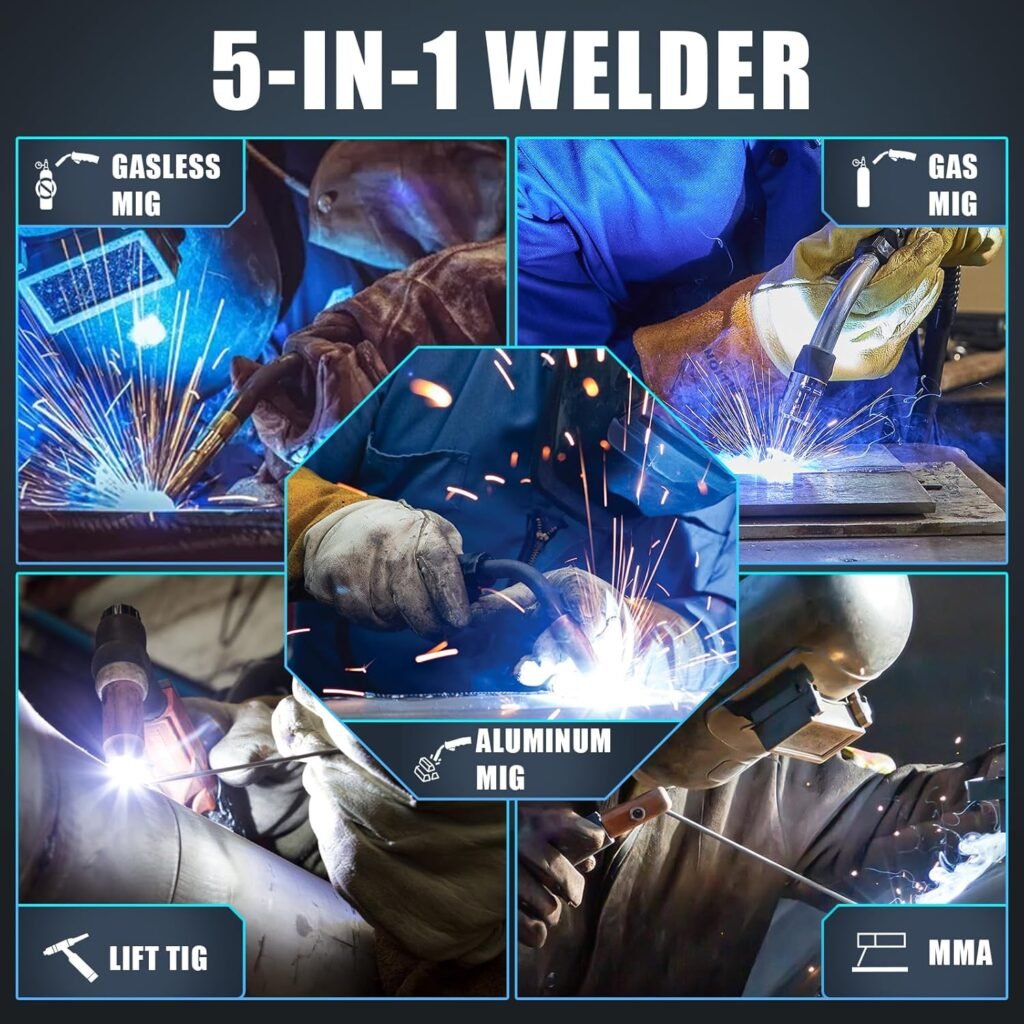

?Are you looking for a versatile welder that handles aluminum without the hassle of a spool gun and still gives you options for MIG, MAG, Stick, and Lift TIG?

Product Overview

You’ll find that the AZZUNO Aluminum MIG Welder 155Amp, Dual Vlotage 110V/220V 5-in-1 Welder Machine Gasless MIG/Gas MAG/Aluminum MIG/Stick/Lift TIG Welding, Multiprocess Welding Machine is built to be a multi-use tool for a variety of welding tasks. It aims to give you the flexibility to switch between processes and handle different materials and thicknesses without swapping machines.

Key Features

You can use this machine in Gasless MIG, Gas MAG, Aluminum MIG, Stick, and Lift TIG modes, so it covers most basic and intermediate welding needs. You’ll also appreciate the dual voltage capability (110V/220V), multiple wire diameter support, and included accessories that help you get started right away.

Specifications at a Glance

You’ll want a clear snapshot of specs before committing to a purchase, so here’s a breakdown you can scan quickly. This table summarizes the most important technical details and included items to help you decide whether it matches your projects.

| Specification | Details |

|---|---|

| Product Name | AZZUNO Aluminum MIG Welder 155Amp, Dual Vlotage 110V/220V 5-in-1 Welder Machine Gasless MIG/Gas MAG/Aluminum MIG/Stick/Lift TIG Welding, Multiprocess Welding Machine |

| Welding Modes | Gasless MIG, Gas MAG, Aluminum MIG, Stick (E6013), Lift TIG |

| Output Current | Up to 155 Amp |

| Input Voltage | 110V / 220V (dual voltage) |

| Wire Spool Support | 1 lb and 2 lbs spools |

| Wire Diameters Supported | .030″/.035″ flux core, .030″ solid, .035″/.040″ aluminum |

| Included Wire | .030″/2 lbs Flux-cored Wire (one spool) |

| Torch & Accessories | MIG torch, electrode holder, ground clamp, gas hose, contact tips (.030″, .035″), nozzles, drive rollers (V & U groove), brush & hammer |

| Modes for MIG Control | SYN (synergic), 2T, 4T |

| Special Features | Aluminum-ready without Teflon liner or spool gun, SYNERGIC mode for auto-settings |

| Recommended Electrodes | E6013 for Stick |

Performance Overview

You’ll find the AZZUNO machine performs well across different processes for light to medium duty work. It’s not a heavy industrial unit, but for home workshops, hobbyists, and small fabrication tasks, it delivers reliable arcs and decent weld quality when set up and tuned properly.

MIG Welding Performance

You’ll be pleased with gas MAG and gasless MIG performance for mild steel and many routine repairs because the machine provides stable wire feed and easy-to-tune current. The SYNERGIC mode helps you get close to ideal parameters quickly, which is useful when you want to avoid extensive trial-and-error.

Aluminum MIG Specifics

You’ll appreciate that aluminum MIG is possible without a spool gun or Teflon liner, which simplifies setup and saves you from buying extra accessories. With the right aluminum wire (.035″/.040″) and correct parameters, you can produce smooth aluminum welds; however, your results will improve significantly if you practice bead rhythm and match travel speed.

Stick Welding and Lift TIG

You’ll find the unit handles Stick welding (with E6013) acceptably for general-purpose welding and repair work, providing you with another process when filler metals are needed or gas supply isn’t available. Lift TIG is handy for thin aluminum or steel parts where TIG-style control is beneficial; expect a learning curve if you’re new to TIG or Lift TIG techniques.

Usability and Controls

You’ll find the front panel is designed to be approachable for both beginners and intermediate users, offering a mix of automatic and manual control modes. The inclusion of SYNERGIC mode means the machine can auto-tune many settings, but you still have manual adjustments for fine-tuning when you want to take control.

Modes: SYNERGIC, 2T, and 4T

You’ll use SYNERGIC mode for simplified setup: it adjusts voltage and wire feed in tandem so you get closer to ideal settings faster. 2T and 4T modes give you more control over trigger operation — 2T for standard press-and-weld operation and 4T for continuous welding without holding the trigger the entire time.

Wire Feeding and Spool Support

You’ll have flexibility with spool options from 1 lb to 2 lbs and several wire diameters which makes it easy to switch between steel, flux-core, and aluminum wires. The package includes V and U groove drive rollers for different wire types, so you won’t be fighting your feeder when you change materials.

Setup and Installation

You’ll be able to set this welder up in a standard home garage or small shop with accessible power sources and a safe area for welding. The dual voltage feature means you can plug into 110V circuits for lighter tasks or switch to 220V for higher output and thicker materials.

Dual Voltage Setup: 110V vs 220V

You’ll choose 110V when you want portability and access to common household outlets, but you’ll switch to 220V when you need higher amperage for thicker metals. Changing voltage often requires a power cord/adaptor or rewiring plug ends depending on how your workshop power is configured — follow the manual to avoid electrical mishaps.

Accessories Included

You’ll get a fairly complete starter kit: MIG torch, electrode holder, ground clamp, flux-cored wire spool (.030″/2 lbs), gas hose, contact tips, nozzles, drive rollers (V and U), and a brush & hammer. These inclusions mean you can get welding quickly, and you won’t need to shop immediately for basic consumables.

| Included Item | Purpose |

|---|---|

| MIG Torch | Primary torch for MIG/MAG and aluminum MIG |

| Electrode Holder | For Stick welding with electrodes like E6013 |

| Ground Clamp | Work return connection to complete the circuit |

| .030″ Flux-cored Wire (2 lbs) | Immediate flux-core welding out of the box |

| Gas Hose & Hose Bands | For gas MAG and gas aluminum MIG setups |

| Contact Tips (.030″, .035″) | Consumables for proper arc contact and consistent feed |

| V Groove Drive Roller (.030″) | For steel/flux core wire |

| U Groove Drive Roller (.035″/.040″) | For softer aluminum wire |

| Brush & Hammer | Finishing and slag removal for stick/flux-core welds |

Build Quality and Portability

You’ll notice a compact chassis that balances ruggedness with mobility; it’s not a heavy-duty industrial frame, but it’s sturdy enough for shop and garage use. The unit is portable enough to carry between projects, though for extended on-site use you’ll want to secure it on a cart or small trolley.

Controls and Display

You’ll find the control layout intuitive with clear labels and the SYNERGIC mode reduces guesswork by auto-adjusting parameters. A simple digital or analog readout (depending on model variant) makes it straightforward to confirm settings before you weld.

Cooling and Duty Cycle

You’ll want to be aware that this is a mid-range welder, so duty cycle limitations apply; for prolonged heavy welding you’ll need to let the machine cool to prevent overheating. The onboard cooling fan helps maintain performance, but you should plan for intermittent breaks for long, continuous work.

Safety and Best Practices

You’ll want to maintain standard welding safety precautions: proper PPE (helmet with appropriate shade, gloves, jacket), ventilation for fumes, and a clear workspace. The machine itself doesn’t replace safe practices, so treat sparks, molten metal, and electrical connections with caution.

Grounding and Electrical Safety

You’ll ensure the ground clamp is securely attached to clean metal and that power connections match the machine’s voltage requirements. Double-check wiring and use appropriate extension cables and circuit protection if you frequently switch between 110V and 220V setups.

Fume Control and Ventilation

You’ll need good ventilation or fume extraction when welding aluminum or flux-core materials because both produce fumes that can be harmful if inhaled repeatedly. A local exhaust system, fan, or open-air environment will help keep your workspace safe.

Pros and Cons

You’ll weigh the strengths and weaknesses before buying, so here’s a clear breakdown to help you decide if this welder fits your priorities. The following table lays out the major pros and cons so you can quickly compare what matters to you.

| Pros | Cons |

|---|---|

| Multiprocess capability covers MIG, MAG, Aluminum MIG, Stick, Lift TIG | Not intended as a heavy industrial welder; limited duty cycle for long runs |

| Aluminum-ready without need for spool gun or Teflon liner | For best aluminum results, technique and practice still required |

| Dual voltage (110V/220V) adds flexibility | Switching voltages may require additional setup or adapters |

| SYNERGIC mode simplifies settings for beginners | Auto settings may still need manual tweaking for optimal welds |

| Includes many accessories and consumables to start | Consumables will wear; replacement costs add up over time |

| Supports multiple wire diameters and spool sizes | Wire feed consistency depends on proper setup and maintenance |

Common Use Cases

You’ll find multiple scenarios where this machine proves especially useful, from hobby work to light professional tasks. It’s targeted at users who need one machine to perform a variety of tasks rather than a dedicated, purpose-built industrial unit.

Hobbyist and Home Garage Projects

You’ll appreciate the flexibility for general repairs, garden gate fabrication, small trailer repairs, or motorcycle and bicycle frame touch-ups. The ease of switching between modes means you can take on different tasks without buying multiple machines.

Small Fabrication and Workshop Use

You’ll be able to use it for fixtures, brackets, and small fabrication jobs where materials typically fall within the light-to-medium thickness range. If you run a small repair shop or do custom small-batch work, this welder gives you the multiprocess capability to adapt to job needs.

Automotive and RV Work

You’ll find it handy for bodywork, exhaust repair, patch panels, and some aluminum RV repairs when you need control and a clean aluminum weld. For very thick structural elements or production environments, you might want a more powerful 220V-only or industrial machine.

Tips for Getting the Best Results

You’ll get better performance and longer consumable life if you follow a few practical tips tailored to multiprocess welders like this one. Small setup and technique adjustments significantly affect the output quality.

Aluminum MIG Tips

You’ll set the U groove drive roller and use the proper aluminum wire diameter (.035″/.040″) to prevent crushing and feeding problems. You’ll also use the right travel speed, avoid excessive wire stick-out, and maintain a clean oxide-free surface with proper preparation (brushing, chemical cleaning as needed).

Gasless Flux Core Tips

You’ll want to maintain a steady travel speed and appropriate wire stick-out for gasless flux-core welding to minimize porosity and ensure good penetration. You’ll also check the polarity and drive roller settings, since flux-core and solid wire require different feed tensions and grooves.

TIG and Stick Tips

You’ll practice Lift TIG technique to get smooth starts on aluminum and fine-tune the arc length for cleaner beads. For Stick welding, you’ll pick the right electrode (E6013 provided compatibility) and match amperage to electrode size and base material thickness.

Troubleshooting Common Issues

You’ll run into some common issues when you use a multiprocess machine; most are straightforward to fix with a methodical approach. This section helps you quickly identify and resolve problems so you can get back to welding.

Wire Feeding Issues

You’ll check drive roller alignment, groove type (V for steel, U for aluminum), tension settings, and spool placement if you see inconsistent feeding or bird-nesting. You’ll also inspect contact tips for wear and replace them when the orifice enlarges or the tip becomes deformed.

Arc Stability and Porosity

You’ll confirm shielding gas flow (for gas MAG and aluminum MIG), wire match, and surface cleanliness when you notice arc instability or porosity. You’ll remember that aluminum oxide and inadequate shielding are common causes of porosity and weak welds.

Overheating and Duty Cycle

You’ll monitor the unit’s duty cycle by consulting the manual and noting that extended continuous welds at high amperage will cause thermal cutouts. You’ll let the machine cool and reduce the duty cycle by using staggered welds or stepping down heat input when possible.

Maintenance and Care

You’ll extend the life and reliability of the machine with regular maintenance routines like cleaning, checking consumables, and ensuring proper ventilation. A little preventive care prevents most common failures and keeps your welds consistent.

Regular Cleaning and Consumable Checks

You’ll clean spatter off the torch nozzle, replace contact tips as needed, and keep the drive rolls and wire path free of debris. You’ll also make it a habit to check the condition of cables and clamps to prevent electrical resistance and poor connections.

Fan and Ventilation Care

You’ll make sure the cooling fan and vents are free from dust and obstructions to avoid overheating. You’ll give the machine periodic compressed air cleaning (while powered off and disconnected) to remove built-up grime.

Comparison With Similar Machines

You’ll want to know how this unit stacks up against other options, especially if you’re deciding between a single-purpose high-end machine and a multiprocess model like this. Here’s a brief comparison to help you weigh options.

Against Single-Process Budget MIGs

You’ll get more versatility with the AZZUNO 5-in-1 versus a basic single-process MIG that only handles flux-core or solid wire. The trade-off is that single-process machines can be more specialized and sometimes slightly more robust in their dedicated process.

Against Dedicated Aluminum Machines

You’ll find dedicated spool-gun-compatible aluminum welders can be easier to use in production aluminum environments, but they often cost more and are single-purpose. You’ll appreciate that this AZZUNO model removes the need for a spool gun for many aluminum jobs, which is a convenience and cost saver for occasional aluminum work.

Accessories and Consumables to Consider

You’ll need to budget for extra consumables and useful accessories that make life easier and keep productivity up. Having backups and accessories on hand prevents downtime and helps you improve weld quality.

Essential Consumables

You’ll want to stock contact tips, nozzles, drive rollers (V and U), and a selection of wire diameters and spool sizes. You’ll also keep extra electrodes for Stick welding and spare gas if you plan to run gas MAG or gas aluminum MIG frequently.

Helpful Accessories

You’ll think about a high-quality helmet with auto-darkening, welding gloves, a cart or trolley for portability, spool guns (if you later decide to go heavier on aluminum), and a small fume extractor or shop fan for ventilation. These accessories make welding safer and results more consistent.

Who Should Buy It?

You’ll consider this machine if you’re a home hobbyist, a DIY enthusiast, or run a small shop needing multiprocess flexibility without buying multiple purpose-built machines. It fits users who want to weld steel and aluminum occasionally, perform light repairs, or want a single tool for several processes.

Ideal User Profile

You’ll be ideal for this product if you need a versatile welder for general repairs, custom small-fabrication work, and occasional aluminum tasks, and you want a unit that won’t require a spool gun for basic aluminum welding. You’ll not choose it if you regularly run heavy continuous production or need industrial duty cycles day after day.

Final Verdict

You’ll find the AZZUNO Aluminum MIG Welder 155Amp 5-in-1 to be a compelling choice for mixed-process needs, balancing convenience, performance, and price. You’ll get multiprocess flexibility, aluminum-friendly features without extra hardware, and an accessory kit to get started — ideal for hobbyists and light professional use.

Recommendation Summary

You’ll get the most value if you need an all-in-one machine for a variety of jobs and don’t require industrial duty cycles. You’ll benefit from practicing aluminum technique, keeping spare consumables on hand, and following proper safety and maintenance steps to maximize the unit’s effectiveness.

If you plan to weld occasionally, want to avoid extra spool-gun purchases, and want a machine that adapts as your skills grow, this AZZUNO model is a practical, friendly option that gives you powerful versatility in a compact package.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.