Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you thinking about whether the AZZUNO MIG Welding Machine 200A 110V/220V 8 in 1 Welding Machine Aluminum MIG/Coil Gun Compatible/Gas MIG/MAG/Flux Core MIG/Spot MIG/Lift TIG/Stick Welding Multi Process Welding Machine will meet your needs for multi-process welding?

Overview of the AZZUNO MIG Welding Machine 200A 110V/220V 8 in 1

You’re looking at a compact multi-process welder that promises a lot: dual-voltage operation, eight welding modes, and a mix of features aimed at hobbyists, small shops, and mobile work. This section summarizes the unit’s core purpose and what it tries to deliver so you can quickly see if it aligns with your projects.

You’ll appreciate that the machine is positioned as a true all-in-one solution, combining MIG (gas and flux-core), MAG, aluminum MIG, coil gun compatibility, spot MIG, lift TIG, and stick welding. That breadth is helpful if you switch between materials and processes often.

What “8-in-1” actually means for you

The “8-in-1” label refers to eight welding functions integrated into a single machine. This gives you flexibility: you can weld mild steel and stainless with gas MIG/MAG, handle flux-core when shielding gas isn’t available, do spot welds, tack aluminum with the included setup, and use lift TIG and stick for other metals or positional work.

You should note that the TIG burner and coil gun (required for certain aluminum coil-gun-style setups) are not included. The unit supports two methods for aluminum: using the included Teflon liner in the standard MIG torch or using an optional coil gun (LBT150) if you prefer that feeding method.

Key specifications and how they affect your work

You want clear numbers to judge capability. Below is a breakdown of what the seller lists and some practical notes so you can translate specifications into real-world expectations.

| Feature | Spec (as listed) | What this means for you |

|---|---|---|

| Input voltage | 110V / 220V | You can use household power (110V) or workshop power (220V) — good for portability and higher output when needed. |

| Max output current | 200A | Strong enough for medium-thickness steel and many aluminum tasks; gives decent penetration for up to around 6–8 mm steel in single pass with the right technique. |

| Welding modes | Gas MIG, MAG, Flux Core MIG, Aluminum MIG, Coil Gun MIG (gun not included), Spot MIG, Lift TIG, Stick | Very versatile — reduces need for multiple machines but requires you to learn each mode’s setup and consumables. |

| Wire compatibility (listed) | 0.58 cm / 0.30 inch / 0.35 inch / 101.6 cm solid and flux core; 0.35 inch / 0.40 inch aluminum | The listing contains inconsistent units. Expect common MIG wire diameters (.023–.035 in) compatibility and typical aluminum .030–.035 in. Verify with seller for exact supported diameters. |

| Liners | Includes Teflon liner | Useful for feeding softer aluminum wire to reduce birdnesting and feeding issues. |

| Control modes | SYN automatic adjustment, 2T, 4T, Spot | SYN simplifies setup by auto-adjusting parameters; 2T/4T give you trigger options for long welds; Spot for tack/spot welds. |

| Protection | Overheat, over-current, VRD (voltage reduction device) | Built-in safety and protection for both machine and operator — VRD reduces open-circuit voltage risk. |

| Warranty | 1-year quality guarantee | You have a year of support if defects arise — handy for peace of mind. |

| Included accessories | MIG torch (15AK), earth clamp, electrode holder, adapter cable 110/220, brush/hammer, gas hose, tape, drive rollers, contact tips, Teflon liner, user manual | Basic consumables and a torch are included so you can get started, though TIG burner and coil gun are not supplied. |

Clarifying the wire compatibility issue

The product description as posted has inconsistent units (centimeters, inches, and suspiciously large numbers). For your planning, assume the usual MIG wire sizes are supported: common solid/flux-core diameters in the MIG world are 0.6 mm (.023″), 0.8 mm (.030″), and 0.9 mm (.035″). Aluminum welding often uses softer aluminum wire like .030″ or .035″ and benefits from a Teflon liner or coil gun. If precise wire-diameter compatibility matters, confirm with the seller before purchase.

Setup and first-time use

You’ll want a readable, step-by-step approach so you can get welding quickly without mistakes. This section explains what to check and the sequence you should follow.

Start by unpacking and inventorying everything in the box. The common items included are the 15AK MIG torch, earth clamp, electrode holder, adapter cable (110/220), brush/hammer, gas hose, drive rollers, contact tips, and a Teflon liner. Check the user manual and note that the manual might not be guaranteed in English — so be prepared to rely on this review or online resources.

Next, choose your input voltage based on your power supply. Use 110V for easy portability and 220V to access full power for heavier work. Install the correct drive roller and contact tip for the wire diameter you plan to use, and swap in the Teflon liner if you’ll be feeding aluminum wire through the torch.

Check shielding gas and regulator if you intend to use gas MIG/MAG. Connect gas for mild steel (usually CO2 or C25 mix) and pure argon for aluminum. If you plan to weld flux-core, you can skip gas and set the machine to flux-core MIG mode.

Finally, select SYN or manual mode. SYN (synchronization) will auto-adjust parameters to simplified presets—handy when you don’t want to fine-tune settings.

Quick wiring and safety checklist

You shouldn’t rush electrical connections. Confirm the input voltage switch (if required) matches your outlet, use properly rated cables and plugs, and ensure the earth clamp is securely attached to clean metal. Keep the area ventilated, use an appropriate welding helmet, gloves, and protective clothing, and make sure the VRD and protections are active. If you’re in doubt, have a qualified electrician inspect the outlet for 220V use.

Performance across welding modes

You’ll want practical expectations for each mode. This section gives a realistic view of where the machine will perform well and where it might show limits.

MIG / MAG (gas)

Gas MIG/MAG is where this machine shines for everyday steel work. With the right gas and proper setup, you can get clean beads and good penetration on sheet metal and medium-thickness plates.

Because the machine is rated to 200A, you can weld thicker material at 220V. Use SYN mode to get good starting parameters, but expect to fine-tune voltage and wire feed speed for your joint, thickness, and travel speed.

Flux-core MIG

Flux-core lets you weld outdoors or without gas. The machine’s flux-core mode is convenient for quick repairs and farm work. Expect more spatter and slag compared to gas MIG, but also better tolerance to wind and dirt.

For high-quality flux-core results, select the correct polarity and wire type, and use a drive roller matched to the wire diameter.

Aluminum MIG (using Teflon liner)

Aluminum can be fussy, but the included Teflon liner helps a lot. When you use a Teflon liner with the standard torch, feeding softer aluminum wire gets much smoother and reduces birdnesting.

You should start with clean aluminum, appropriate pure-argon shielding, and a lower travel speed than steel. If you intend to frequently run long aluminum feeders, consider purchasing the optional coil gun (LBT150) for even more reliable feeding.

Coil gun MIG (gun not included)

The machine lists coil gun compatibility, but the coil gun is sold separately. If you want to weld large volumes of aluminum with long continuous feed, the coil gun is a recommended upgrade. Without it, the Teflon liner will help but may be less reliable for extended aluminum runs.

Lift TIG

Lift TIG capability is handy for welding thin stainless steel and aluminum when you need a TIG finish. The machine’s lift TIG is great for tack and precise welds, but remember the TIG torch is not included — you’ll need to purchase a TIG burner separately.

Lift TIG is typically lower power and better for thinner materials — it’s not a full TIG powerhouse but will handle many light TIG jobs.

Stick welding

Stick welding adds flexibility for repairs and outdoor work. The included electrode holder lets you use basic stick rods for thicker fabrications or rusty materials where flux-core isn’t the best choice.

This mode is useful when you need deep penetration and don’t want to rely on shielding gas.

Spot MIG

Spot MIG function is ideal for sheet metal and automotive work when you need to make quick tacks or plug welds. It saves time and helps prevent burn-through on thin materials.

Use spot mode for assembly and bodywork where you want consistent, repeatable short welds.

Controls and user experience

You should be able to operate this machine without a steep learning curve. The control panel is designed with usability in mind, but there are a few subtleties.

The SYN function automatically sets voltage and wire feed speed based on your material thickness and wire size — great if you want a fast start. However, once you’re comfortable, you’ll want to manually tweak settings for the best appearance and penetration.

2T (two-touch) and 4T (four-touch) modes give you trigger control for longer beads. 2T is like a normal trigger (hold to weld), while 4T lets you latch the trigger on and off for long runs — handy when working on large panels.

The display and knobs are straightforward; you’ll find wire speed and voltage adjustments, plus mode selection. The VRD and protective features add confidence, especially in less-than-ideal environments.

What’s included and what you’ll likely buy separately

Having the right accessories saves time and money, but you’ll probably want to add a few extras.

Included in the box:

- Multi-process welder main unit

- 15AK MIG torch

- Earth clamp

- Electrode holder

- 110V~220V adapter cable

- Brush and hammer (for slag removal)

- Gas hose

- 2 hose tapes

- 2 drive rollers

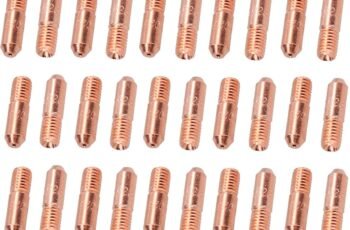

- 4 contact tips

- 1 Teflon liner

- User manual (English not guaranteed)

Items you’ll likely need to purchase:

- Coil gun (LBT150) if you’ll do heavy aluminum coil feed welding

- TIG torch/burner for more serious TIG work (not included)

- Additional drive rollers and contact tips for different wire diameters

- Quality regulator and gas bottle for MIG/MAG and aluminum work

- Replacement consumables over time (nozzle, nozzle gel, extra liners)

Safety features and considerations

You must take safety seriously. The machine includes several protections and good practices to adopt.

Built-in protections:

- Overheat protection: helps avoid damage and reduces risk of thermal shutdowns.

- Over-current protection: helps prevent short circuits and electronics damage.

- VRD (Voltage Reduction Device): lowers open-circuit voltage for safer idle conditions.

You should still wear full PPE: an auto-darkening helmet, welding-rated gloves, jacket, and proper footwear. Ensure good ventilation or use extraction when welding materials that produce harmful fumes. For aluminum, avoid high humidity and keep your workspace dry.

Maintenance and troubleshooting

You want the machine to last and perform reliably. Regular maintenance and a few troubleshooting steps will keep you welding.

Routine maintenance:

- Keep the power and control vents clear of dust and metal debris.

- Inspect drive rollers and replace when worn.

- Change contact tips and nozzles to prevent spatter build-up.

- Clean the torch liner and replace the Teflon liner periodically if feeding aluminum.

- Check gas hoses and fittings for leaks.

Troubleshooting tips:

- If wire feeding is inconsistent, check the liner, tension on the drive roll, and ensure the contact tip is the correct size.

- Birdnesting (wire tangles) often means liner friction or incorrect drive roller pressure; Teflon liner helps with aluminum.

- Excessive spatter: tweak voltage/wire feed speed, clean the tip and nozzle, or check gas flow/type.

- Machine overheating: reduce duty cycle, ensure vents are clear, or switch to 220V for heavy work.

Pros and cons — what you’ll like and what to watch out for

You want a clear summary so you can weigh this machine against alternatives.

Pros

- Very versatile 8-in-1 functionality saves space and cost compared to multiple machines.

- Dual-voltage (110V/220V) offers portability and power when you need it.

- Includes a Teflon liner for aluminum and several consumables to start right away.

- SYN function simplifies setup for beginners or quick jobs.

- Safety features (overheat, over-current, VRD) provide extra protection.

Cons

- TIG burner and coil gun are not included, limiting out-of-the-box TIG and advanced aluminum coil-feeding work.

- Wire size listing in the product description is inconsistent — you’ll want to verify compatible diameters.

- User manual may not be available in English in all cases, which could make advanced setup harder.

- Multi-process machines often require more learning to switch modes correctly and may not match the performance of dedicated machines for extreme professional use.

Who should buy this machine?

If you want a single machine to handle a wide variety of shop and field tasks, this unit is appealing. You’ll be a good candidate if:

- You’re a hobbyist or small-shop operator tackling mixed materials and processes.

- You need portability between job sites and home with 110V and 220V options.

- You want the flexibility to try MIG, flux-core, stick, and light TIG without buying separate machines.

- You plan moderate aluminum welding and can either use the Teflon liner or invest in a coil gun later.

If you’re a high-end production shop focused exclusively on TIG aluminum or very heavy-duty continuous welding, you might prefer dedicated machines specialized for those tasks.

Buying tips and accessories to consider

You should prepare to get the right accessories to unlock the machine’s full potential.

- Buy the coil gun (LBT150) if you plan heavy aluminum work — it makes feeding smoother and reduces downtime.

- Invest in a good regulator and high-quality shielding gas. For aluminum, pure argon is standard; for steel, C25 (75% Ar/25% CO2) or pure CO2 are options depending on bead profile.

- Purchase extra contact tips, nozzles, and drive rollers matched to your chosen wire sizes.

- If you plan TIG welding beyond light tasks, get a proper TIG torch and a gas valve compatible with the unit.

- Consider a welding cart and storage for consumables to keep your workspace efficient.

Real-world use cases and tips

You want practical examples so you can picture this machine on your bench.

Automotive bodywork:

- Use spot MIG and short bursts to avoid warping thin panels. Spot mode is a big time-saver for panel attachment.

Home and farm repairs:

- Flux-core is great for outdoor repairs where gas isn’t feasible. Stick mode helps when you’re welding rusty or dirty steel.

Metal art and fabrication:

- Use gas MIG or lift TIG for cleaner finishes. The SYN mode helps you quickly dial in settings before you refine them for aesthetics.

Aluminum projects:

- Start with the Teflon liner and pure argon. Use short, controlled passes and keep the workpiece clean. Consider the coil gun for longer runs.

Troubleshooting common questions (FAQ)

You’ll want quick answers to likely questions before and after purchase.

Q: Can you run this machine on 110V and 220V without modifications? A: Yes, it’s designed for dual-voltage operation, but ensure your input is set correctly and that the adapter cable and connectors match your outlet.

Q: Is the coil gun included for aluminum? A: No. The coil gun (LBT150) is compatible but sold separately. The included Teflon liner supports aluminum feeding through the standard MIG torch.

Q: Do I get a TIG torch with this package? A: No. Lift TIG is supported by the unit, but a compatible TIG torch/burner is not included.

Q: How accurate are the listed wire sizes? A: The product listing contains inconsistent sizing units. Expect standard MIG wire support (common diameters around .023–.035″); confirm exact supported sizes with the seller for certainty.

Q: How long is the warranty? A: The machine includes a 1-year quality guarantee. Contact the seller within that period for warranty support or issues.

Final verdict and recommendation

If you want a single, affordable machine that gives you meaningful capability across MIG, flux-core, stick, and light TIG, the AZZUNO MIG Welding Machine 200A 110V/220V 8 in 1 is a smart choice. You’ll get flexibility and useful safety features like VRD and overload protection, and the SYN mode helps you get welding quickly.

Be aware of the limitations: coil gun and TIG burner are not included, the wire-size listing is inconsistent, and the user manual may not reliably be in English. If you plan extensive professional TIG or continuous heavy aluminum production, consider a dedicated machine. For hobbyists, DIYers, and small shops who value versatility and portability, this machine is worth serious consideration.

If you want, I can help you:

- Create a checklist for the first day setup tailored to your expected projects.

- Recommend specific consumables and gas setups based on the materials you’ll weld.

- Walk through a step-by-step aluminum weld setup using the Teflon liner.

Which option would you like next?

Disclosure: As an Amazon Associate, I earn from qualifying purchases.