Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you trying to find a reliable, all-in-one solution for welding and finishing band saw blades for both wood and metal?

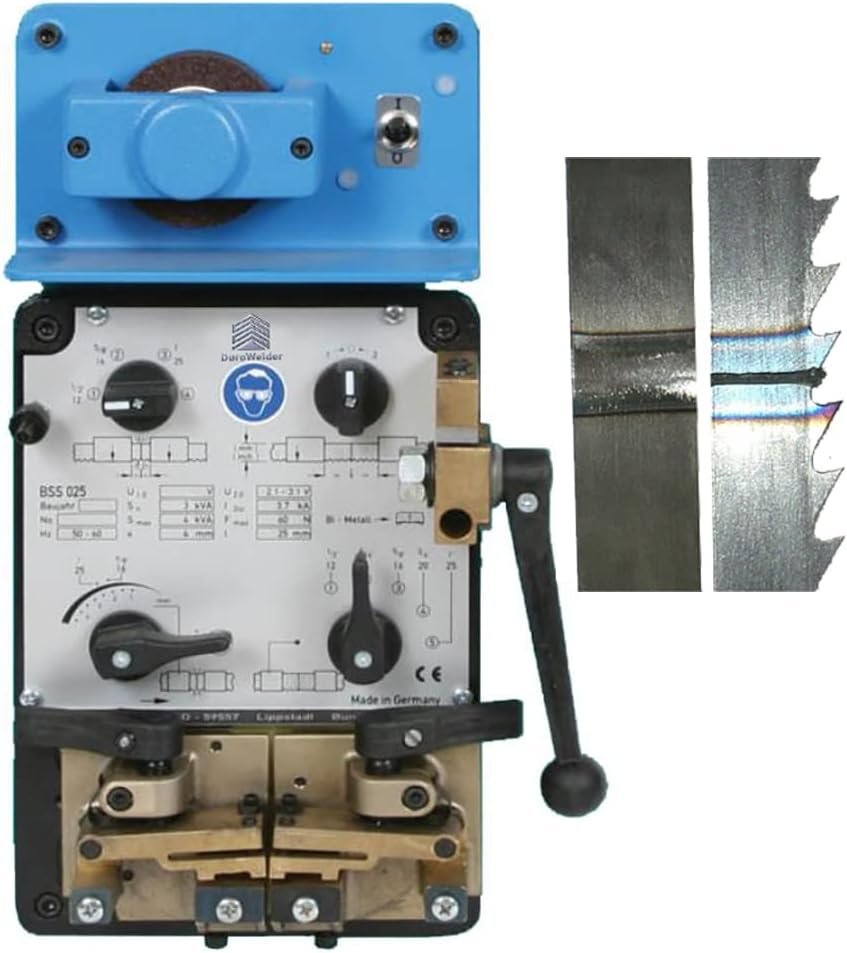

First Impressions of BandSaw Blade Welder Machine – 3 in 1 Wood Metal Grinder Cutter for 0.4-0.7mm Thickness and 6-20mm Width BandSaw Blades

When you first see the BandSaw Blade Welder Machine – 3 in 1 Wood Metal Grinder Cutter for 0.4-0.7mm Thickness and 6-20mm Width BandSaw Blades, you’ll notice its compact footprint and the sense that it’s ready for shop work. The integrated design that combines a butt welder, grinder, and cutter immediately suggests convenience, and you’ll appreciate that it targets both wood and metal band saw blades.

The form factor feels practical for a small industrial shop or a busy woodworking or metalworking setup. You’ll want something that doesn’t take up too much bench space but still gives you professional results, and this model aims to deliver that.

Key Specifications

Below is a clear breakdown of the main specifications so you can quickly see whether this machine fits your blade dimensions and production needs. You’ll find the critical numbers for welding range, pressure, speed, and included functions.

| Feature | Specification |

|---|---|

| Product Name | BandSaw Blade Welder Machine – 3 in 1 Wood Metal Grinder Cutter for 0.4-0.7mm Thickness and 6-20mm Width BandSaw Blades |

| Welding Range (Metal) | 6 x 0.6 mm to 20 x 0.8 mm |

| Welding Range (Wood) | 6 x 0.4 mm to 25 x 0.7 mm |

| Upset Pressure | 50 N |

| Welding Time | Approximately 2 seconds per weld |

| Functions Included | Butt welding (no auxiliary materials), annealing, grinder (compact wheel), cutter (white hacksaw with blade) |

| Accessories | Built-in compact grinding wheel, annealing control, white hacksaw with blade |

| Application | Industrial use for wood and metal band saw blades |

| Additional Notes | Designed to produce high tensile strength after tempering |

Welding Range and Material Compatibility

You’ll be able to weld a wide variety of band saw blades with this machine thanks to the specified ranges. For metal blades you’re covered from 6×0.6 mm up to 20×0.8 mm, and for wood blades the range opens up to 6×0.4 mm to 25×0.7 mm.

This flexibility means you won’t need multiple welders if your shop runs different band saw blades. You can standardize on a single unit for both woodworking and metalworking blades, making for a more efficient workflow.

Upset Pressure and Welding Speed

The welder applies an upset pressure of 50 N, which is calibrated to create a consistent upset bead without over-compressing the joint. You’ll notice the welds are completed quickly — roughly 2 seconds for a strong weld — which helps you keep downtime low.

Fast welding doesn’t mean rushed quality here; the machine is designed to combine speed with the required force to form a durable joint. You’ll still need to follow best practices for alignment and preparation to achieve optimal results.

Annealing and Heat Control

A precise annealing function is included so you can temper the weld area after the butt weld is formed. You’ll appreciate the ability to control tempering to reduce brittleness and increase the toughness of the joint.

Proper annealing improves tensile strength and fatigue life of the blade at the weld, which is especially important when you’re cutting demanding materials. The built-in function removes the need for external tempering equipment in many cases, saving you time and bench space.

Integrated Grinder and Cutter

The machine’s built-in compact grinding wheel is intended for burr removal and smoothing the joint after welding. You’ll be able to clean up flash and ensure a consistent blade profile before tempering and final finishing.

A white hacksaw with blade is included for cutting, so you won’t need to buy a separate cutter immediately. The combination of welding, annealing, grinding, and cutting in one unit lets you control the entire splicing process on one workbench.

Compactness, Build Quality, Accessories

The unit’s compact design makes it approachable for smaller shops and mobile operations. You’ll find it easier to place on a bench and integrate into your blade preparation workflow.

Accessories are practical — the compact grinding wheel and the included hacksaw save you from making immediate additional purchases. If you value a complete kit out of the box, this product is designed to get you up and running quickly.

Setup and Installation

Setting this machine up is a straightforward process, and you’ll appreciate the clear workflow during the initial assembly and first use. A little care during setup ensures you get reliable results from your first welds.

You should plan to allocate time for a careful initial setup, including verifying power requirements and confirming that all accessories are present. With some basic tools and a little calibration, you’ll be ready to weld.

Unboxing and Components

When you unbox the BandSaw Blade Welder Machine, you’ll find the main welding unit, the built-in grinder wheel, the white hacksaw and blade, and potentially some small setup fixtures or clamps. Check the package for shipping damage and confirm all items are present.

You’ll want to inventory the accessories and ensure the grinding wheel is securely attached before plugging anything in. If any parts are missing or damaged, contact the supplier immediately.

Power and Environmental Requirements

Before you power the unit, verify the machine’s voltage and current requirements to match your shop’s electrical setup. You’ll also want to place the machine on a stable bench with adequate clearance to operate the grinder and cutter safely.

Operate the machine in a well-ventilated area and on a fire-resistant surface since metalworking and annealing can generate heat and small sparks. Protect combustible materials and ensure good lighting for precise alignment.

First-time Setup Steps

Start by securely mounting the machine or placing it on a level surface. You’ll then attach the grinding wheel if it’s shipped separate and confirm the cutter/hacksaw is mounted and aligned for accurate blade cutting.

Follow the manufacturer’s calibration recommendations: clamp a test blade, align edges, and run a few practice welds on scrap stock to fine-tune pressure and timing. You’ll want to verify the annealing function settings produce the expected temper without discoloration beyond the joint.

Operation and Workflow

The typical workflow with this machine is preparation, butt welding, annealing, grinding, and cutting to length. You’ll find the cycle straightforward once you’ve practiced the sequence a few times.

A disciplined approach to preparation and alignment will produce consistent joints. When you follow procedure, the fast welding time becomes an advantage rather than a source of variability.

Preparing the Blade for Welding

Your preparation should include cleaning the blade ends, matching tooth sets if required, and forming a precise butt fit. You’ll get the best results when there are no gaps and the blade faces are square to each other.

If you’re splicing blades with different tooth geometries or thicknesses, you’ll need to consider grinding or profiling them before the butt weld. Take your time to clamp the blade securely so there’s no misalignment during the weld.

Butt Welding Process Step-by-step

Clamp the blade in the welder fixture aligning the ends precisely. Activate the weld cycle; the machine applies upset pressure and completes a butt weld typically in about 2 seconds.

After the weld, inspect the upset bead and remove any large burrs before annealing. The immediate result will be a formed joint that requires finishing to remove flash and ensure a smooth run through the saw guides.

Using the Annealing Function

Once the weld is complete and flash is removed, use the annealing function to temper the weld zone. You’ll set the annealing time and temperature according to blade material and thickness, aiming to reduce brittleness without over-softening the steel.

The annealing step is critical for restoring ductility and achieving a joint that resists fracture under cyclic cutting loads. You’ll notice improved tensile strength and better fatigue life after proper annealing.

Grinding and Cutting after Welding

After tempering, run the compact grinding wheel across the joined area to remove burrs and contour the weld so the blade tracks smoothly. You’ll want to ensure the grind doesn’t reduce the blade thickness in a way that weakens the weld.

Use the included white hacksaw for cutting blade ends or trimming, making it easy to get blades to the exact length you need. The cutter complements the welder by letting you prepare and finish the blade without moving to a different station.

Performance and Results

You’ll be testing the machine against factors that matter to you: weld strength, repeatability, finish quality, and cycle time. The BandSaw Blade Welder Machine is designed to perform well across these measures for small industrial use.

Expect strong welds when you follow recommended practices and perform proper annealing. The combination of precision pressure, rapid welding, and integrated tempering helps produce joints that meet operational demands.

Strength and Joint Quality

The upset weld forms a solid mechanical bond that, when annealed correctly, attains good tensile strength. You’ll find that weld quality is often comparable to more expensive resistance welders when thickness and blade type fall within specifications.

Consistent pressure and timing are keys to repeatable joint quality. If you align blades accurately and perform the annealing step properly, the joints will resist breaking under normal cutting loads.

Repeatability and Speed

The rapid welding cycle — approximately 2 seconds — turns what used to be a multi-step process into a quick operation. You’ll be able to put many splices in a single day without the fatigue and time loss that come with slower methods.

Repeatability depends on consistent clamping and set-up. Once you create a standard procedure for temperature and timing, results become much more predictable and production throughput increases.

Precision and Blade Alignment

The machine’s fixtures help you achieve square, flush ends, but you still need to take care in alignment. You’ll notice that slight misalignment will create a bulge or an imbalance that affects tracking on the saw.

Invest a little time in creating alignment jigs or using a small square and clamps to ensure blades are positioned perfectly. Precise alignment reduces the need for excessive grinding and yields a better finished blade.

Use Cases and Applications

This welder is suitable for a broad set of scenarios, and you’ll find it most valuable if you manage blade inventories, repair shop blades, or run mixed material shops. It serves both woodworking and metalworking needs well.

If you’re a saw shop, blade refurbisher, or production shop with frequent blade changes, having an integrated welder/grinder/cutter on your bench will save time and money. You can tailor how you use it based on blade types and production volumes.

For Metal Bandsaws

For metal bandsaws you’ll use the machine primarily for blades in the 6×0.6 to 20×0.8 mm range. You’ll do well to verify the heat treatment and annealing settings for high-speed or bimetal blades to maintain tooth hardness and joint integrity.

You’ll appreciate the speed and robustness for welds on metal cutting blades, especially in a fabrication shop or metal service center where downtime is costly. Proper annealing helps prevent brittle fractures at the butt joint.

For Wood Bandsaws

The broader thickness range for wood blades — down to 0.4 mm and widths up to 25 mm — makes the machine suitable for resaw and woodcutting applications. You’ll be able to splice narrow and wider wood blades without changing equipment.

When you weld wood blades, you’ll still anneal and grind to keep blade tracking and reduce noise or vibration in the saw. The integrated grinder is particularly handy for removing burrs created by softer steel during the upset weld.

Industrial vs Small Workshop Use

In an industrial setting, you’ll value the machine’s speed and repeatability to maintain production uptime. In a smaller workshop, you’ll appreciate the all-in-one nature and compact footprint that saves bench space.

If you’re deciding whether this unit fits your environment, consider your blade change frequency and the types of blades you most often use. High-volume shops may still want larger automated welders, but many shops will find this machine a highly efficient solution.

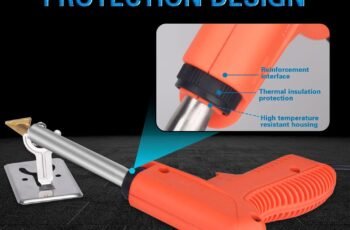

Safety Considerations

Working with a welder, grinder, and cutter in one unit requires disciplined safety practices. You’ll need to combine standard welding safety with grinding and cutting precautions to protect yourself and the workspace.

This machine produces heat, sparks, and metal fragments, so you’ll want to be mindful of personal protective equipment and workplace safeguards at all times.

Safe Welding Practices

Keep your hands clear of moving parts and the welding interface during operation. You’ll want to ensure any clamping fixtures are secure and that the blade is held rigidly in place before actuating the weld.

Be aware of the heat produced at the joint and allow cooling as necessary before touching or re-clamping the blade. Avoid direct skin contact with the heated area and use pliers or protective gloves when adjusting the part immediately after welding.

Handling Annealing and Grinding

The annealing function raises the weld area temperature, so you’ll manage heat dissipation and use tongs or heat-resistant gloves for handling. You’ll also want to control ventilation to avoid breathing heated metal fumes.

When grinding, keep your face and eyes away from the wheel, and always wear eye protection and a face shield if possible. Sparks and metal particles can be hazardous, so maintain a safe distance and use guards.

Personal Protective Equipment

Wear appropriate PPE: safety glasses, face shield, heat-resistant gloves, and hearing protection while the grinder and cutter are in use. You’ll also benefit from a respirator or dust mask if you’re in a confined space without adequate ventilation.

A fire extinguisher and non-flammable work surface are useful additions to your setup. Keep flammable materials away from the immediate area when annealing and grinding.

Maintenance and Troubleshooting

Maintaining this 3-in-1 machine is straightforward, and you’ll extend its life with regular checks. A maintenance routine will keep performance stable and help you identify issues before they affect weld quality.

Most tasks are basic: inspect clamps and fixtures, check the grinding wheel, and ensure the annealing controls and pressure system perform consistently.

Routine Maintenance Tasks

You’ll want to inspect the grinder wheel for wear and replace it when it shows significant damage. Clean any metal debris from the welding area and lubricate moving parts as recommended in the manual.

Check the clamping surfaces and fixtures for deformation or wear, and verify the upset pressure is consistent. Replace consumables such as the hacksaw blade and grinding wheel when performance drops.

Common Issues and Fixes

If welds are inconsistent, first check blade alignment and clamping. You’ll often find that small misalignments or uneven pressure cause weak spots, and correcting fixturing usually restores quality.

If annealing doesn’t produce the expected temper, verify temperature and timing settings and make sure the heating element or control circuit is functioning properly. For persistent electrical or mechanical faults, consult a qualified technician.

When to Seek Professional Service

If you encounter electrical failures or hydraulic/pneumatic pressure problems, seek professional service. You’ll avoid worsening the issue and potentially creating unsafe conditions by attempting complex repairs solo.

Also seek professional help if you notice persistent alignment or mechanical wear that affects weld quality after you’ve exhausted simple fixes. A service check will help you avoid downtime and more expensive repairs later.

Pros and Cons

You’ll want a clear view of what this machine does well and where it might fall short so you can make a buying decision. The pros and cons below reflect typical experiences for shops that use this type of integrated welder.

Pros:

- You’ll appreciate the all-in-one functionality that reduces the need for separate tools.

- Rapid approximate 2-second weld cycle increases throughput.

- Annealing function is integrated, improving the joint toughness.

- Wide welding range covers both wood and metal band saw blades.

- Compact and suitable for bench-top use in small to medium shops.

- Comes with a compact grinding wheel and a hacksaw for cutting.

Cons:

- You’ll need to be precise with alignment; small errors can affect joint quality.

- For very high-volume industrial operations, you might prefer a larger automated welder.

- Consumable parts like the grinding wheel and saw blade will need replacement over time.

- Not all specialized blade types (e.g., advanced bimetal variants) will necessarily behave the same; you’ll need to test specific blade grades.

Comparison with Alternatives

When you compare this machine to single-function welders or larger industrial units, consider the trade-offs in flexibility, footprint, and automation. You’ll get more immediate versatility than a dedicated bench welder and a smaller footprint than heavy industrial systems.

If you prioritize automation and ultra-high throughput, a fully automated industrial welding line may serve you better. However, if your workflow requires a compact, multi-purpose device for both wood and metal blades, this model offers strong value and convenience.

Tips for Best Results

A few practiced habits will dramatically improve the quality of your welds, and you’ll see the difference in joint strength and blade performance. Implement these tips to maximize the machine’s capabilities.

- Always clamp blades square and check alignment before welding. You’ll prevent common misalignments that create tracking problems.

- Run test welds on scrap to dial in annealing and pressure settings when you switch blade types. You’ll learn the sweet spot for your materials without risking production blades.

- Keep the grinding wheel in good condition and use it to clean up the joint carefully. You’ll want a smooth profile to prevent interference with guides.

- Record settings for different blade thicknesses and materials so you can reproduce results quickly. You’ll save time on setup and maintain consistent quality.

- Protect the work area from flammable materials and ensure good ventilation. You’ll maintain a safer environment for annealing and grinding operations.

Frequently Asked Questions

You likely have specific questions about what this machine can and cannot do. Below are common questions and clear answers to help you decide whether this unit meets your needs.

Q: What blade thicknesses and widths can it handle? A: It supports metal band saws from 6×0.6 mm to 20×0.8 mm and wood band saws from 6×0.4 mm to 25×0.7 mm. You’ll want to ensure your blade dimensions fall within these ranges for reliable welds.

Q: How long does a weld take? A: The approximate butt weld cycle is 2 seconds, though you’ll add time for preparation, annealing, grinding, and cutting. You’ll see excellent throughput when you’re set up correctly.

Q: Is annealing automatic? A: The machine includes an annealing function with control over the process. You’ll set the parameters and apply the function post-weld according to the blade material and thickness to ensure proper tempering.

Q: Do I need additional tools to use this machine? A: The unit comes with a compact grinding wheel and a white hacksaw with blade, so you’ll have core functions covered. You might still want measuring tools, clamps, PPE, and a file or bench grinder for additional finishing steps.

Q: Can it weld bimetal blades? A: Performance with bimetal blades depends on their specific construction. You’ll need to test any specialized blade types carefully and adjust annealing and welding parameters accordingly.

Q: How often will I need to replace consumables? A: Consumables such as the grinding wheel and hacksaw blade will wear out based on use. You’ll schedule replacements as part of routine maintenance, depending on welding volume.

Final Verdict

If you’re looking for a compact, practical, and versatile machine that combines butt welding, annealing, grinding, and cutting specifically for band saw blades, the BandSaw Blade Welder Machine – 3 in 1 Wood Metal Grinder Cutter for 0.4-0.7mm Thickness and 6-20mm Width BandSaw Blades is a strong candidate. You’ll gain fast cycle times, an integrated annealing function, and built-in finishing tools that simplify blade repairs and assembly.

This unit is particularly attractive if you manage both wood and metal blades in your shop and want a single bench-top tool to handle splicing and finishing. With careful setup, attention to alignment, and adherence to safety protocols, you’ll produce reliable welds that stand up to typical cutting workloads. If you need extremely high-volume automation, you might consider larger industrial welders, but for many shops this machine balances functionality, footprint, and value very well.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.