Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

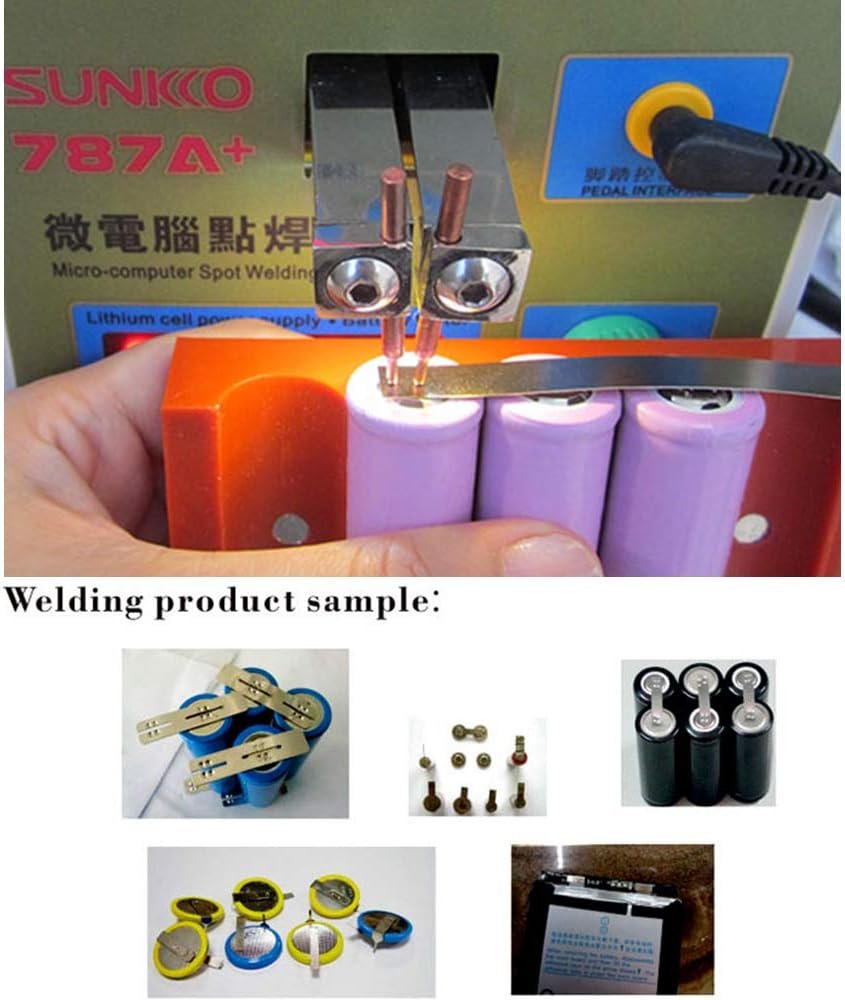

The Hanchen Pulse Spot Welder 1.5KW Battery Welding Machine 2 in 1 for Welding Charging Test 18650 Lithium Battery Pack CE 220V is a versatile tool that combines both welding and charging capabilities. With the ability to weld battery-connected nickel sheets as thin as 0.05-0.15mm, this machine is ideal for various applications, including single-row 18650 battery packs, button battery lead pieces, and mobile phone battery lead pieces. It also allows for charge testing of lithium batteries or polymer charging cells. With precise welding parameter settings and the option for single or double pulse welding, this machine ensures accurate and efficient welds. Additionally, the professional welding needle pressure adjustment and double LED high-brightness lighting function enable seamless operation in various lighting conditions.

Why Consider This Product?

When it comes to battery welding and charging, the Hanchen Pulse Spot Welder 1.5KW Battery Welding Machine is a top-notch choice. This product offers a 2-in-1 functionality, allowing you to both weld battery-connected nickel sheets and perform charge tests on lithium batteries or polymer charging cells. With its advanced features and benefits, the Hanchen Pulse Spot Welder stands out as a reliable and efficient tool for any battery-related applications.

One significant reason to consider this product is its precision welding capabilities. With microcomputer control and up to 199 levels of precision welding parameter settings, you have the flexibility to adjust and optimize your welds according to your specific needs. Additionally, the fast welding options, such as single pulse and double pulse, ensure quick and efficient spot welding, saving you time and effort.

Furthermore, the Hanchen Pulse Spot Welder offers adjustable welding needle pressure, ranging from 300g to 750g. This feature allows you to adapt to different thicknesses of workpieces, making it convenient for a variety of battery welding applications. Whether you are working on single-row 18650 battery packs, button battery lead pieces, or mobile phone battery lead pieces, this welder can handle it all.

Lastly, the double LED high-brightness lighting device on this spot welder enhances visibility during spot welding operations. Whether you’re working in low-light environments or even at night, this feature ensures precision and accuracy in your welds. It also proves beneficial for employees with poor eyesight, as it provides efficient spot welding without straining their vision.

Features and Benefits

Advanced Welding Control System

The microcomputer control system of the Hanchen Pulse Spot Welder enables precise and accurate welding parameter settings. With up to 199 levels of precision, you can achieve the desired weld for your specific application.

Fast Welding Options

The versatility of this welder is demonstrated by its ability to deliver fast welding options using either single pulse or double pulse modes. This feature enables quick and efficient spot welding, making your work more productive.

Adjustable Welding Needle Pressure

With a welding needle pressure adjustment range of 300g to 750g, you can easily adapt to different workpiece thicknesses. This flexibility ensures optimal welding performance and convenience for a wide range of battery welding applications.

Double LED High-Brightness Lighting

The Hanchen Pulse Spot Welder comes equipped with a double LED high-brightness lighting device, enhancing visibility during spot welding operations. This feature allows for precision and accuracy in low-light environments or even during night-time welding, ensuring quality results.

Product Quality

The Hanchen Pulse Spot Welder is designed with high-quality materials and advanced technology to ensure reliability and durability. The microcomputer control system guarantees precise weld settings, while the adjustable welding needle pressure allows for convenient use on various workpiece thicknesses. The inclusion of double LED high-brightness lighting further enhances the product quality, ensuring clear visibility during spot welding operations.

Moreover, this welder is CE certified, indicating compliance with European safety standards. This certification adds credibility and reassurance to the product’s quality and safety.

What It’s Used For

Welding Battery-Connected Nickel Sheets

The Hanchen Pulse Spot Welder is ideal for welding battery-connected nickel sheets ranging from 0.05mm to 0.15mm in thickness. This feature makes it suitable for various battery packs, including single-row 18650 battery packs, button battery lead pieces, and mobile phone battery lead pieces.

Charging Test for Lithium Batteries or Polymer Charging Cells

In addition to welding capabilities, this product also allows you to perform charging tests on lithium batteries or polymer charging cells. By testing the charging efficiency and performance of these batteries and cells, you can ensure their optimal functionality.

Product Specifications

| Specification | Details |

|---|---|

| Power | 1.5KW |

| Voltage | 220V |

| Welding Thickness Range | 0.05mm – 0.15mm |

| Welding Needle Pressure | Adjustable from 300g to 750g |

| Lighting | Double LED high-brightness lighting |

| Welding Modes | Single pulse and double pulse |

| Certification | CE |

Who Needs This

The Hanchen Pulse Spot Welder is a valuable tool for various professionals and hobbyists working with battery-related applications. It is particularly useful for:

-

Battery Pack Manufacturers: This spot welder simplifies the welding process for battery-connected nickel sheets, making it an essential tool for battery pack production.

-

Electronics Repair Technicians: If you’re involved in repairing electronic devices that use lithium batteries or polymer charging cells, this welder ensures efficient charging tests and spot welding.

-

DIY Enthusiasts: With its user-friendly features and adjustable settings, this spot welder is perfect for DIY enthusiasts who enjoy working on various battery-related projects.

Pros and Cons

Pros:

- Precision welding control

- Fast welding options

- Adjustable welding needle pressure

- High-brightness LED lighting

- CE certification for safety compliance

Cons:

- Requires basic knowledge of spot welding techniques

FAQ’s

- Can this spot welder be used with other types of batteries apart from 18650 lithium batteries?

Yes, the Hanchen Pulse Spot Welder is compatible with a range of battery applications, including button batteries and mobile phone batteries.

- Does the double LED lighting function have an on/off switch?

Yes, the LED lighting can be turned on and off as needed during spot welding operations.

- Is the welding needle pressure adjustable for different workpiece thicknesses?

Yes, the welding needle pressure can be conveniently adjusted from 300g to 750g, allowing for versatile use with various battery-connected nickel sheet thicknesses.

What Customers Are Saying

Customers who have purchased the Hanchen Pulse Spot Welder are highly satisfied with its performance. They appreciate the precision welding control, adjustable welding needle pressure, and the double LED high-brightness lighting. Many users have noted that this spot welder is easy to use and provides reliable results.

Overall Value

The Hanchen Pulse Spot Welder offers excellent value for professionals and hobbyists working with battery-related applications. Its advanced features, including precise welding control, adjustable welding needle pressure, and double LED lighting, provide convenience and efficiency in welding and charging tests. With its reliable performance and CE certification, this spot welder is a worthwhile investment.

Tips and Tricks For Best Results

- Familiarize yourself with the user manual and safety guidelines before using the welder.

- Start with lower welding parameter settings and gradually increase them to achieve the desired weld strength.

- Make sure the nickel sheets are clean and free from oil or grease before welding.

- Perform regular maintenance and cleaning of the welding needle to ensure consistent performance.

Final Thoughts

Product Summary

The Hanchen Pulse Spot Welder 1.5KW Battery Welding Machine is a versatile tool for battery welding and charging tests. With its microcomputer control system, precise welding parameter settings, adjustable welding needle pressure, and high-brightness LED lighting, this spot welder offers convenience and efficiency in various battery-related applications. It is a quality product backed by positive customer feedback and CE certification.

Final Recommendation

If you are in need of a reliable and efficient spot welder for battery welding and charging tests, the Hanchen Pulse Spot Welder is an excellent choice. Its advanced features, durability, and versatility make it a valuable asset for professionals and hobbyists alike. Invest in this welder and experience the convenience and efficiency it brings to your battery-related projects.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.