Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a compact, affordable welder that can handle MIG, TIG, and stick work without needing a gas bottle?

Overview of the bestarc 145A MIG Welder, 110V/220V Gasless Flux Core MIG Welder/Lift TIG/Stick 3 in 1 Synergic MIG145 5GEN Welding Machine, Portable Flux Welder with Digital Screen Display

You’ll find this unit aims to combine three common welding processes into a single portable package, which makes it appealing if you want flexibility without buying separate machines. It’s especially targeted at hobbyists, small-shop users, and DIYers who need a machine that can work on a variety of mild steel, stainless steel, and other metals.

What’s in the box

You’ll appreciate knowing exactly what comes with the machine before you begin. The package includes all basic consumables and accessories you need to start practicing welds right away.

- 1×MIG145 MIG welder machine

- 1×8.2ft MIG torch (detachable)

- 1×Earth clamp

- 1×Stick holder

- 1×0.030″ Flux cored wire

- 2×Contact tips

- 1×220V to 110V Wire adapter

- 1×Wire brush

- 3×welding rods

- 1× User manual

Quick specification table

This table breaks down the most important specs so you can compare at a glance. You can use this as a quick reference when deciding if it matches your needs.

| Feature | Specification |

|---|---|

| Model | bestarc 145A MIG Welder (MIG145 5GEN) |

| Welding Modes | Gasless Flux Core MIG, Lift TIG (torch not included), Stick |

| Max Output Current | 145 A |

| Input Voltage | 110V / 220V (auto-detect) |

| Wire Size Supported | 0.030″ / 0.035″ flux-cored wire |

| Torch Length | 8.2 ft (detachable MIG torch) |

| Control Type | Synergic control with adjustable knob ±3V |

| Display | LED digital screen (voltage, current, parameters) |

| Included Consumables | 0.030″ flux cored wire, 2 contact tips, welding rods |

| Portability | Compact with detachable torch |

| Extras | 220V to 110V adapter, earth clamp, stick holder |

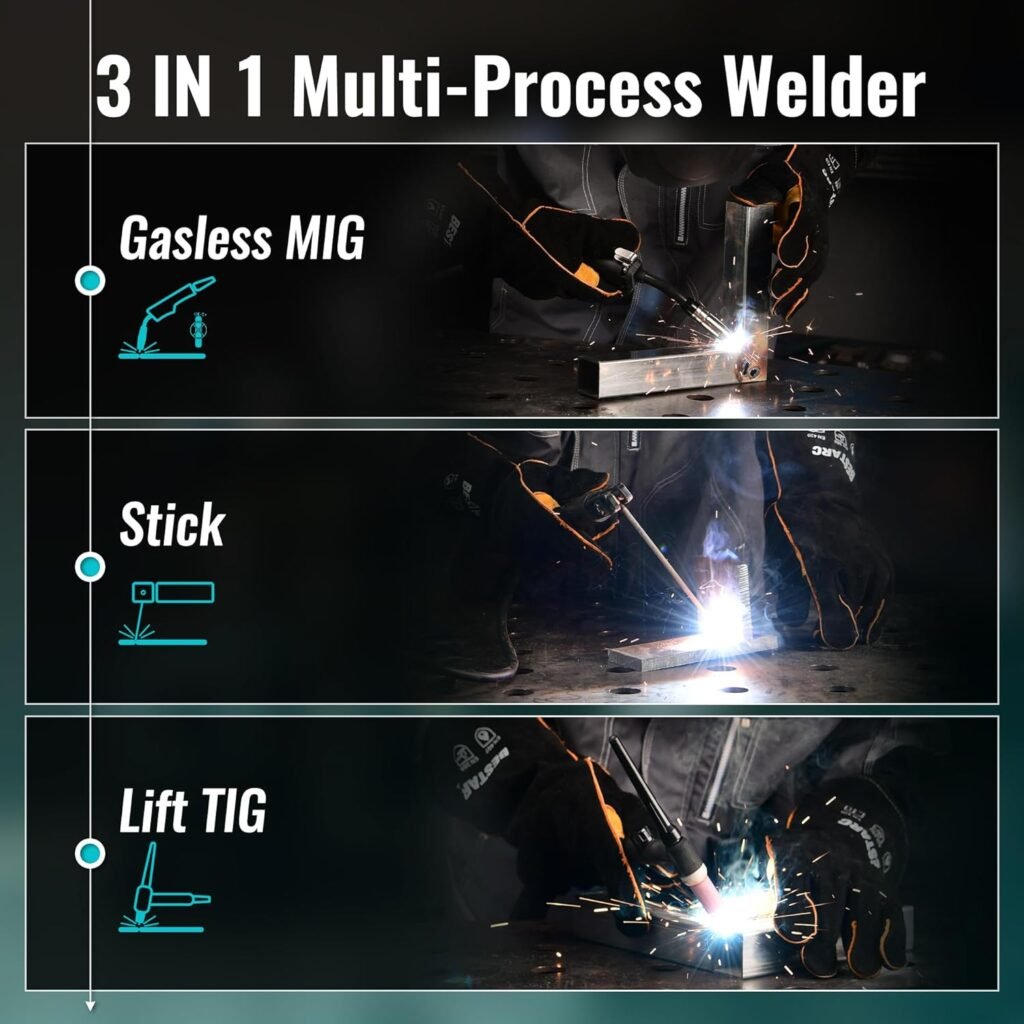

3-IN-1 Functionality

You can switch between gasless MIG, lift TIG, and stick welding, giving you three common processes in one machine. That means you don’t need three separate units if you want to do light fabrication, repair work, and general maintenance.

- Gasless MIG (flux core): Best for quick outdoor or garage work where shielding gas is inconvenient.

- Lift TIG: Allows cleaner TIG-style welds for thinner metals, though you’ll need to buy a dedicated Lift TIG torch to use this mode.

- Stick: Useful for thicker, rusty, or dirty materials and works well outdoors.

Digital Screen Display

You’ll like the LED digital display because it shows voltage, current, and other parameters clearly. That reduces guesswork and means you can make changes while staying aware of the exact settings you’re using.

The visual feedback is particularly helpful when you’re fine-tuning settings for different materials or when you return to a job after a break and want to resume exact parameters.

Synergic Control

The synergic control system automatically matches recommended voltage and wire feed speed, which simplifies the process, especially if you’re newer to welding. You can still manually tweak the voltage by ±3V with the adjustment knob when you want finer control.

This hybrid approach is friendly for learning and still gives you the precision required for more experienced users.

110/220V Dual-Voltage Support

You’ll appreciate the automatic input-voltage detection that allows this welder to operate from both 110V and 220V sources. That flexibility is great if you sometimes work at home on standard household circuits and sometimes at a job site or shop with 220V.

The front-panel indicator clearly displays the detected voltage, so you don’t have to guess or worry about switching settings manually.

Portability and Accessories

The unit’s compact size and detachable 8.2 ft torch make it easy to move around your workspace, and the included adapter and consumables let you start welding immediately. If you plan to travel with it, the detachable torch and relatively light footprint will be helpful.

Keep in mind you’ll need to buy a Lift TIG torch separately to use the TIG function, which is a one-time additional cost if you want that capability.

Build Quality and Safety Features

You’ll notice a practical, utilitarian build typical of budget multi-process machines — solid enough for hobby and light professional use. The IGBT technology helps with stable power output and contributes to the unit’s safety profile.

Standard protections like over-current, over-voltage, and thermal overload protection are common in this class and should be present to protect both the operator and the machine.

Performance on Different Metals

You can weld stainless steel, carbon steel, and thicker mild steel using the flux-cored MIG mode, which is the unit’s strength. The stick mode gives you options for thicker and less clean metals where flux-cored MIG might struggle.

For best results on stainless and thin materials, you’ll want to experiment and possibly use a TIG torch (purchased separately) for the cleanest welds. The MIG flux-cored mode produces good penetration on thick steel and is forgiving of surface contamination.

Wire Compatibility and Consumables

This machine supports 0.030″ and 0.035″ flux-cored wire, two of the most common sizes for small shop welding and automotive repair. That makes it simple to source consumables.

Contact tip wear is normal, so the included spare tips are useful. You’ll eventually want to keep a stock of tips, nozzles, and wire spools based on your regular projects.

Duty Cycle and Heat Management

You should expect a modest duty cycle typical for a 145A class machine — likely suitable for intermittent light to medium welding tasks. That means for long continuous welds you’ll need pauses to avoid thermal cutoff.

If you plan heavy industrial use, consider a higher-duty-cycle machine. For home, garage, and hobby tasks, this welder’s duty cycle is usually adequate as long as you manage run times and allow cooling.

Real-World Weld Quality

When you use the correct wire size, polarity, and feed speed, you’ll get solid welds with decent penetration and appearance for flux-cored MIG. The synergic control helps you find a starting point quickly, and manual micro-adjustments allow you to refine bead profile.

Stick welding performance is comparable to entry-level inverter stick units and works well for maintenance and farm use.

Ease of Setup

You’ll find set-up straightforward: mount the spool, thread the wire, set the synergic profile or manual feed, and you’re ready to go. The included user manual explains the basic steps and wiring.

If you’re new to welding, allow extra time to read the manual, gather safety gear, and practice on scrap metal to dial in settings.

User Interface and Controls

The digital screen reduces the need to constantly remove your helmet to check settings, and the knob-based adjustment is intuitive. You’ll appreciate the simplicity, which is designed to help you focus on the weld rather than complex menus.

While it’s not a fully featured touchscreen with presets, it hits a sweet spot of usability and affordability.

Maintenance and Troubleshooting

You should perform basic maintenance like cleaning the wire feed mechanism, inspecting the torch cable for damage, and replacing worn contact tips. These simple steps will extend the life of the machine and improve consistency.

Common issues like wire feed jams, contact tip wear, and inconsistent arcs are often fixed with routine cleaning, tension adjustment, and tip replacement.

Table: Recommended Settings by Material (Starting Points)

This table gives starting points for common materials and thicknesses. Use this as a baseline and refine based on welding test beads and your wire spool.

| Material | Thickness | Wire Size | Current (A) | Wire Feed Speed | Polarity |

|---|---|---|---|---|---|

| Mild Steel (flux-cored) | 18 ga (1.2 mm) | 0.030″ | 50-70 A | Low | DCEP |

| Mild Steel (flux-cored) | 1/8″ (3 mm) | 0.030″/0.035″ | 80-110 A | Medium | DCEP |

| Mild Steel (flux-cored) | 1/4″ (6 mm) | 0.035″ | 110-145 A | High | DCEP |

| Stainless Steel (flux-cored) | 20 ga | 0.030″ | 45-65 A | Low | DCEP |

| Stick (6013/7018) | 1/8″ | N/A | 80-120 A | N/A | As per rod |

Note: DCEP (Direct Current Electrode Positive) is commonly recommended for self-shielded flux-cored wire. Always run test beads and adjust for your individual technique and material condition.

Setup Walkthrough with Practical Steps

You’ll get the quickest success if you follow these simple steps in order. Taking a few extra minutes to set things up properly pays off in weld quality and reduces frustration.

- Inspect packaging and all components for damage.

- Mount your wire spool and align it with the drive rolls. Use correct drive rolls for 0.030″/0.035″.

- Feed the wire through the torch liner and into the drive mechanism, then through the contact tip.

- Attach the ground clamp to clean metal, not painted or rusty surface, for best arc stability.

- Select synergic MIG mode, choose wire size/profile if indicated, and let the machine suggest voltage/feed settings.

- Set appropriate welding polarity (typically DCEP for flux-cored feed).

- Wear PPE (helmet, gloves, jacket) and do a short test bead on scrap metal.

- Fine-tune voltage ±3V and feed speed until you get a smooth, consistent bead.

Practical Tips for Better Welds

Use these friendly tips to improve your welding quickly. They focus on simple adjustments and habits that make a visible difference.

- Clean contact surfaces where possible — even flux-cored welding benefits from a scrap-free joint.

- Use correct travel speed: too fast causes thin beads and poor fusion, too slow causes excessive buildup and burn-through.

- Keep the nozzle and contact tip clean to avoid spatter buildup and erratic wire feeding.

- Use small stick or MIG runs and pause for cooling if you notice overheating or wire feed problems.

Portability and Use Cases

You’ll find this machine handy for mobile repair work, backyard projects, auto body touch-ups, and light fabrication. Its size and dual-voltage capability make it flexible across different job sites.

If you frequently work far from power sources, consider generator compatibility and make sure your generator provides clean sine wave power for inverter electronics.

Safety Considerations

You should always prioritize safety when welding. Use a properly rated welding helmet, gloves, and protective clothing, and ensure adequate ventilation when using flux-cored wire because it produces smoke and fumes.

Make sure to set the machine on a stable surface and keep flammable materials away from your welding area. The machine likely has thermal protection, but user precautions help avoid hazards.

Pros and Cons

Laying out pros and cons helps you decide if this machine fits your needs. You’ll see where it excels and where compromises are expected for the price point.

Pros:

- Multi-process (MIG flux-cored, Lift TIG, Stick) in one compact machine.

- Dual-voltage auto-detection (110/220V) for flexibility.

- Synergic control makes setup faster and easier.

- Digital display gives clear readout of voltage and current.

- Portable with detachable 8.2 ft torch and included consumables.

Cons:

- Lift TIG torch not included; needs separate purchase for TIG work.

- Duty cycle is limited compared to industrial welders — not ideal for long continuous runs.

- Flux-cored MIG produces more spatter and smoke than gas-shielded MIG.

- Build and finish are typical for budget machines; not a heavy-duty industrial unit.

Comparison with Alternatives

When you compare this unit to other entry-level multi-process welders, you’ll see it competes on features and price, with a strong emphasis on synergy and digital readouts. Many comparable machines offer similar 3-in-1 capability, but some include a TIG torch or better duty cycle at higher prices.

If you want pure MIG gas-shielded performance, you may prefer a dedicated MIG machine with gas setup. If you want high-duty-cycle TIG welding, a dedicated TIG inverter will outperform a multi-process hobby welder.

Who Should Buy the bestarc 145A MIG Welder…

This machine is a suitable pick if you fit any of these roles:

- You’re a hobbyist or DIYer who needs flexibility for different welding tasks.

- You work on light automotive repair, sheet metal, or farm maintenance.

- You want a portable unit that runs on household power and shop power.

- You want an easy learning curve thanks to synergic settings and a digital readout.

If you’re a production welder doing heavy continuous work, you might want to choose a higher-capacity, higher-duty-cycle machine instead.

Who should not buy this machine

You may want to avoid this model if you:

- Need continuous long welds without cooling breaks.

- Expect top-tier TIG functionality out of the box (since the Lift TIG torch is extra).

- Require a gas-shielded MIG setup for cosmetically critical, low-spatter stainless or aluminum MIG welding.

Accessories you’ll likely want to buy

You’ll probably want or need a few extras to expand usability and reduce downtime. These add-ons are inexpensive compared to the machine and improve your overall welding experience.

- Dedicated Lift TIG torch (for full TIG functionality)

- Extra spools of 0.030″ and 0.035″ flux-cored wire

- Extra contact tips and nozzles

- Quality chipping hammer and wire brush for slag cleanup (for stick welding)

- Welding cart or case for easier portability

- Spare liners and drive rolls suited to your wire diameters

Troubleshooting Common Problems

You can fix most beginner issues quickly with a few checks. These steps will save you time and keep your workflow smoother.

- Wire feeding inconsistently: check drive roll tension, wire spool alignment, and liner cleanliness.

- Excessive spatter: try reducing voltage slightly, increase travel speed, or use anti-spatter spray.

- Poor arc stability: check ground clamp contact, replace worn contact tip, and verify correct polarity.

- Machine shuts down during use: allow cooling time and check duty cycle or ventilation for the unit.

Practical Project Ideas to Practice With

You’ll gain confidence fast if you practice real, short projects that let you try different settings. Each project teaches control, joint prep, and finishing techniques.

- Simple steel bench or shelf — practice butt and lap joints.

- Small trailer repair sections — learn penetration and bead blending.

- Metal art sculptures — practice bead appearance and patterning.

- Automotive patch panels — sharpen tack welding and small bead control.

Maintenance Checklist (Simple, Regular)

Keeping the machine in good condition will prolong its life and improve results. These tasks are quick and keep performance consistent.

- Weekly: Inspect torch cable, contact tip, and nozzle; clean spatter.

- Monthly: Clean wire feed mechanism and check tension; inspect liners.

- Every few months: Check internal fans and vents for dust buildup; check all connectors.

- As needed: Replace consumables (tips, nozzles, liners) when wear affects performance.

Final Verdict

You’ll find the bestarc 145A MIG Welder, 110V/220V Gasless Flux Core MIG Welder/Lift TIG/Stick 3 in 1 Synergic MIG145 5GEN Welding Machine, Portable Flux Welder with Digital Screen Display is a compelling option if you want a compact, multi-purpose machine for home, hobby, and light shop tasks. It combines useful features like synergic control, a digital display, and dual-voltage operation into a package that’s easy to transport and set up.

If you want the convenience of three welding modes in one unit and you’re comfortable buying a Lift TIG torch later if needed, this welder gives you a lot of capability for the price. If your work involves heavy continuous welding or you require a gas-shielded MIG setup for precision stainless or aluminum MIG welds, consider a dedicated machine for those specific needs.

If you have any specific projects in mind or want recommended starting settings for a particular metal thickness, tell me the details and I’ll give you tailored settings and tips.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.