Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you trying to decide whether the BLOSSS Portable MIG Welder, 3 in 1 Combo MMA/MIG/LIFT TIG Welding Machine (Flux Core Welder, MIG-520 Welder Machine, mig welding equipment) is the right addition to your toolbox?

Product Overview

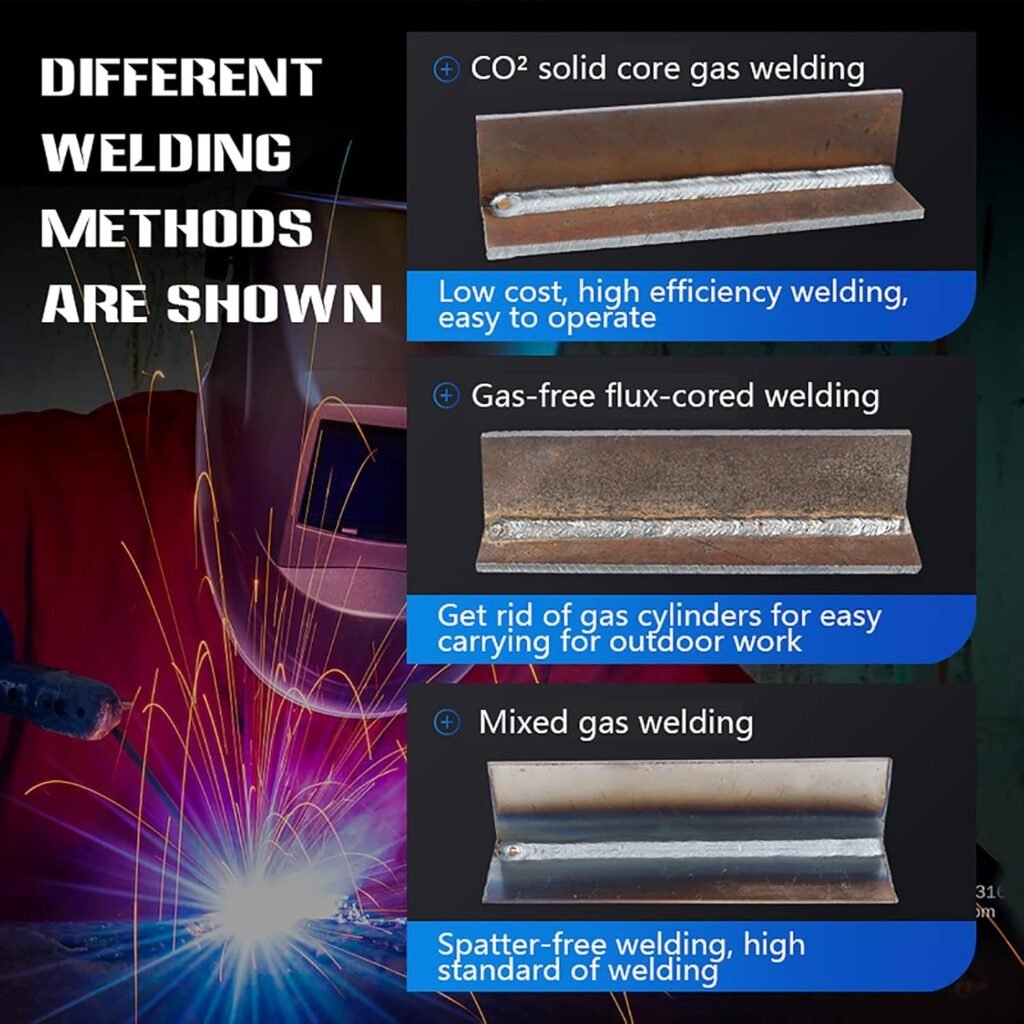

You’re looking at a multi-process welding machine that combines MIG, TIG (lift start), and MMA/ARC functionality into a single portable unit. This machine is marketed as suitable for both stainless steel and iron, with the flexibility to weld with shielding gas for stainless or go gasless when working with mild steel using flux-cored wire.

What the manufacturer highlights

The manufacturer emphasizes professional MIG capability with the option to connect gas for stainless welding and to run gasless for iron. They also highlight the selectable solid wire or flux-cored wire for MIG, the 3-in-1 functionality for MIG/TIG/ARC, and ease of use for both beginners and more advanced users.

Quick Feature Breakdown

Here’s a concise table to break the most important product details down so you can scan what matters quickly.

| Feature | What it means for you |

|---|---|

| 3-in-1: MIG / TIG (lift) / MMA (ARC) | One machine covers three common welding processes, reducing the need for separate machines. |

| Gas/gasless MIG capability | You can weld stainless with shielding gas and weld mild steel without gas using flux-cored wire. |

| Solid wire / flux-cored selectable | Flexibility to run different wire types depending on material and job conditions. |

| Beginner-friendly controls | Preset parameters and simple adjustments help you get started quickly, while still offering enough control for pros. |

| Portable design | Easier to move between job sites or around your shop than bulky industrial machines. |

| Intended materials | Designed for stainless steel and iron/mild steel applications. |

MIG Mode (Practical Use)

When you use MIG mode, you’re benefiting from a process that’s fast and well-suited for general fabrication and repair. For stainless steel, connect shielding gas (commonly argon/CO2 mixes) and use solid stainless wire; for mild steel you can choose flux-cored wire and run without gas if you prefer to work outdoors or on sites where gas handling is inconvenient.

How you’ll use it day-to-day

You’ll typically set voltage and wire feed speed for MIG jobs, clip a ground lead to your workpiece, and maintain a steady travel angle and speed. Flux-cored MIG makes fieldwork simpler because you don’t need gas cylinders, while gas-shielded MIG gives you cleaner welds on stainless and thinner materials.

TIG Mode (Lift-Start) — What to expect

Lift-start TIG means you initiate the arc by touching the tungsten to the workpiece and lifting slightly to start, rather than using a high-frequency start system. You’ll have better control for thin materials and can produce neat aesthetic welds when you practice enough.

Practical considerations for your TIG work

TIG will be your choice for precise, cleaner welds on thinner stainless and for tasks requiring more finesse. Expect a bit of a learning curve if you haven’t TIG welded before; managing the torch, filler rod, and foot/hand amperage control (if available) takes practice.

MMA / ARC Mode — When to pick it

MMA (stick welding) is the go-to in circumstances where portability and simplicity are paramount, especially outdoors or on rusty surfaces. You can use electrodes for structural repairs and heavier fabrication where slag removal is acceptable.

Why this adds value

Having MMA in the same machine means you can switch to stick quickly if wire feed or gas logistics aren’t practical on a job, or if you’re working on thick, dirty metal where stick excels.

Performance and Welding Capabilities

You want to know what this machine can actually weld. While exact performance depends on model specifications and your power supply, this 3-in-1 design is intended for light to medium-duty workshop and mobile repair work.

Typical materials and thickness ranges

You’ll be comfortable welding thin to moderate thicknesses—think sheet metal, automotive panels, farm equipment repairs, metal art, and light fabrication. For thicker plate or production welding you’ll want to confirm the machine’s maximum amperage and duty cycle against your needs. When using MIG with gas you’ll get cleaner welds and better penetration on stainless; with flux-cored wire you’ll trade some cleanliness for convenience and penetration on mild steel.

Suggested Settings Guide

This guide gives practical starting points you can adapt. Always test on scrap material first and consult the machine manual for exact control ranges.

| Material | Thickness (approx.) | Recommended Mode | Filler/Wire | Shielding Gas |

|---|---|---|---|---|

| Mild steel | 0.8–2 mm (thin sheet) | MIG (gas-shielded or flux-cored) | 0.8–0.9 mm solid or flux-cored | 75/25 CO2/argon for MIG; none for flux-cored |

| Mild steel | 2–6 mm | MIG (flux-cored or gas) / MMA | 0.9–1.2 mm | CO2 or mix if MIG |

| Stainless steel | 0.5–3 mm | MIG (gas) / TIG | Solid stainless wire for MIG; TIG rod for TIG | Argon or argon-based mix |

| Rusty/dirty steel | Any | MMA (stick) | E6010/E7018 electrodes | N/A |

Setup and First-Time Operation

You’ll want a logical setup plan to get welding quickly. The steps below are a practical checklist for getting up and running.

Step-by-step to start welding

- Choose your process (MIG/TIG/MMA) and install the appropriate consumables (wire spool and contact tip for MIG; tungsten for TIG; electrode holder for MMA).

- Connect the ground clamp to a clean part of the workpiece.

- If running MIG with gas, hook up the regulator and cylinder, set flow (typically 10–20 L/min, check manual).

- Select polarity and wire feed direction for MIG according to wire type (solid vs flux-cored) and connect power.

- Set initial parameters (voltage/amperage and wire feed speed) based on material thickness, then test and fine-tune on scrap.

Quick setup checklist

| Item | Why it matters |

|---|---|

| Ground clamp solid contact | Prevents poor arc and ground-related defects |

| Clean workpiece | Removes rust/paint for better weld penetration |

| Correct wire type installed | Flux-cored vs solid changes polarity and gas needs |

| Gas connected and leak-free (if using gas) | Prevents porosity in MIG/TIG welds |

| Proper PPE | Helmet, gloves, jacket, and ventilation protect you |

Controls and Usability

You’re likely to find the controls straightforward if they’re designed for ease of use. Many combo units give you basic knobs for voltage/amperage and wire speed with switches to select process and polarity.

What to expect from the control layout

Expect a small number of knobs and toggles rather than complex menus. This keeps operation simple for beginners, while allowing you to tweak settings as you gain experience.

Portability and Build

Since the product name includes “Portable,” you’ll appreciate a compact footprint and manageable weight for moving around the shop or taking to jobs. That portability does often mean trade-offs in continuous duty cycle compared to heavy industrial machines.

How you’ll use portability

Carrying the machine between jobs, from garage to driveway, or to a small farm is much simpler than hauling several dedicated units. Make sure you have safe lifting techniques and consider a small cart or trolley if you’re moving it frequently.

Pros and Cons

You want a balanced view before committing. Below are the main advantages and possible drawbacks to consider.

Pros

- You’re getting three processes in one unit, which saves space and upfront cost.

- Flexibility to use gasless MIG for convenience or gas for cleaner stainless work.

- Suitable for both beginners and experienced welders with adjustable controls.

- Good for light fabrication, automotive repair, hobby projects, and small professional jobs.

Cons

- This class of machine can have limited duty cycle for continuous heavy welding; it’s best for light-to-moderate workloads.

- Lift TIG requires practice and can be slower than high-frequency TIG starts for some tasks.

- You may need to buy additional accessories (gas regulator, spools, TIG torch consumables) to fully use all functions.

- Performance for very thick plate or heavy industrial use may be limited compared to dedicated, higher-amperage machines.

Safety Considerations

Safety should always be your top priority. You’ll need to combine standard welding safety practices with machine-specific checks before every use.

Key safety rules you should follow

Always wear an appropriate welding helmet with correct shade, flame-resistant clothing, gloves, and closed footwear. Ensure proper ventilation or fume extraction—especially when using flux-cored wire—and inspect cables, torch connections, and hoses for damage before each session.

Maintenance and Care

Treating the machine well will prolong its life and keep weld quality consistent. A little routine care will prevent many common problems.

Routine maintenance tasks

You should keep vents clear of dust and debris, check and change contact tips and nozzles as they wear, inspect the drive roller and wire feed path, and ensure gas fittings remain leak-free. If the machine sits idle for long periods, store in a dry place and recheck wire spools for rust or contamination.

Accessories and Consumables You’ll Need

To make full use of all three processes, you’ll likely want to add a few consumables and accessories to your purchase.

Recommended accessories

- Regulator/flow meter and gas hoses for MIG/TIG gas use.

- Spool(s) of solid stainless wire and flux-cored wire for mild steel.

- Tungsten electrodes for TIG, plus suitable filler rods.

- Extra contact tips, nozzles, and drive rollers for MIG.

- A quality welding helmet with auto-darkening and good coverage.

- Welding gloves, jacket, chipping hammer, wire brush, and angle grinder for prep and cleanup.

Troubleshooting Common Issues

You’ll run into issues occasionally; quick diagnosis keeps your job on schedule. Here are practical fixes for common problems you may face.

Wire feed problems

If the wire slips or the feeder clogs, check the tension on the drive roll, confirm the liner is clean and correctly sized, and ensure the spool is seated properly. Worn drive rollers or incorrect liner will cause inconsistent feed and burnback.

Porosity or poor weld bead

Porosity often comes from inadequate shielding gas, contaminated wire, or dirty base metal. If you’re using flux-cored wire outdoors, some spatter and slag are normal, but for gas MIG or TIG tanks ensure flow is correct and hoses are leak-free.

Excessive spatter

Spatter can be caused by incorrect polarity, wrong voltage/wire speed settings, or poor gas coverage. Fine-tune parameters and verify the gas type and flow are suitable for the wire you’re using.

TIG arc difficulty (lift-start)

If lift-start TIG doesn’t reliably initiate, make sure the tungsten is clean and sharpened appropriately, the torch and work connections are solid, and the machine’s amperage control is set in a responsive range for the thickness you’re welding.

Who Should Buy This Machine?

This machine fits a specific set of users well. You’ll find it compelling if you value multi-process capability in a compact package.

Ideal user profiles

- Hobbyists and metal artists who want to try MIG, TIG, and stick without buying three machines.

- Small shop owners and mobile repair technicians who need flexibility on job sites.

- Automotive restorers and DIYers who work on stainless and mild steel and need both gas and gasless options.

- Beginners who want a machine with manageable controls and the option to grow into TIG or stick welding.

Comparison to Single-Process Machines

You’ll appreciate the convenience of a combo machine, but it’s helpful to compare it to dedicated units.

Combo vs dedicated MIG

A dedicated MIG machine may offer higher duty cycle and more robust wire-feed systems for heavy production work, while the combo gives you flexibility and cost savings if you don’t weld constantly. If you’re welding full-time on thick materials, a dedicated MIG may be a better long-term investment.

Combo vs dedicated TIG

A dedicated TIG machine with high-frequency start and finer control often performs better for critical stainless and aluminum TIG work. If precision TIG is a core part of your work, pairing this combo with a dedicated TIG unit could be worthwhile; otherwise, the lift TIG in the combo is a versatile compromise.

Practical Use Case Scenarios

You’ll find specific jobs where this machine shines and scenarios where you might want a different setup.

Best jobs for this welder

- Auto body and small frame repairs where you switch between flux-cored MIG for thicker spots and gas MIG or TIG for stainless trim.

- Farm equipment maintenance where portability and MMA stick welding are helpful for on-site repairs.

- Home fabrication and metal art where you need a range of welding styles without multiple machines.

Jobs to avoid with this welder

- Heavy production welding of thick structural plate where long duty cycles and high amperage are required.

- Critical aerospace or medical fabrication where specialized TIG performance and certifications are needed.

Tips to Get the Best Results

A few practical tips will speed your learning and improve weld quality.

Best-practice tips

- Practice on scrap of the same thickness to dial in your settings before committing to the final piece.

- Keep your consumables clean and replace contact tips regularly to avoid inconsistent arcs.

- If welding outdoors with MIG, prefer flux-cored for reliable results unless you can shield the joint from wind.

- Invest in a quality regulator and hoses for the best gas performance when doing stainless or TIG work.

Frequently Asked Questions (FAQ)

You’ll likely have questions; here are answers to the most common ones.

Q: Can you weld stainless steel without gas on this machine?

A: You can weld stainless with flux-cored wire in a gasless mode, but for cleaner, corrosion-resistant stainless welds you’ll generally want shielding gas and solid stainless wire.

Q: Is the TIG suitable for thin sheet metal?

A: Lift TIG works well on thin stainless and provides better control than MIG for delicate joints, though it requires practice to master the technique.

Q: Will one machine replace my need for a dedicated TIG or MIG welder?

A: It depends on your workload and precision needs. For hobbyists and light shop work, yes. For continuous production or critical TIG applications, a dedicated machine may still be preferable.

Final Verdict and Recommendation

If you want a flexible, portable machine that lets you experiment with MIG, TIG, and stick without buying three separate units, this BLOSSS 3-in-1 combo is a strong candidate. It gives you the choice of gas and gasless MIG, offers lift TIG for precise stainless work, and provides stick welding for rugged field tasks—making it a versatile option for hobbyists, small shops, and mobile technicians.

Final suggestions before you buy

Before purchasing, confirm the machine’s detailed electrical requirements, maximum amperage, duty cycle, and included accessories so they match your planned projects. Plan to budget for essential extras—gas, regulator, filler wires, and safety gear—so you can start welding safely and effectively as soon as your machine arrives.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.