Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you trying to decide whether the CNC Plasma Cutter 3 In 1 Welding Machine Air Plasma Cutting LGK/CUT/TIG/MMA Welder Multifunction Welding Machine Plasma Welders is the right tool for your shop or projects?

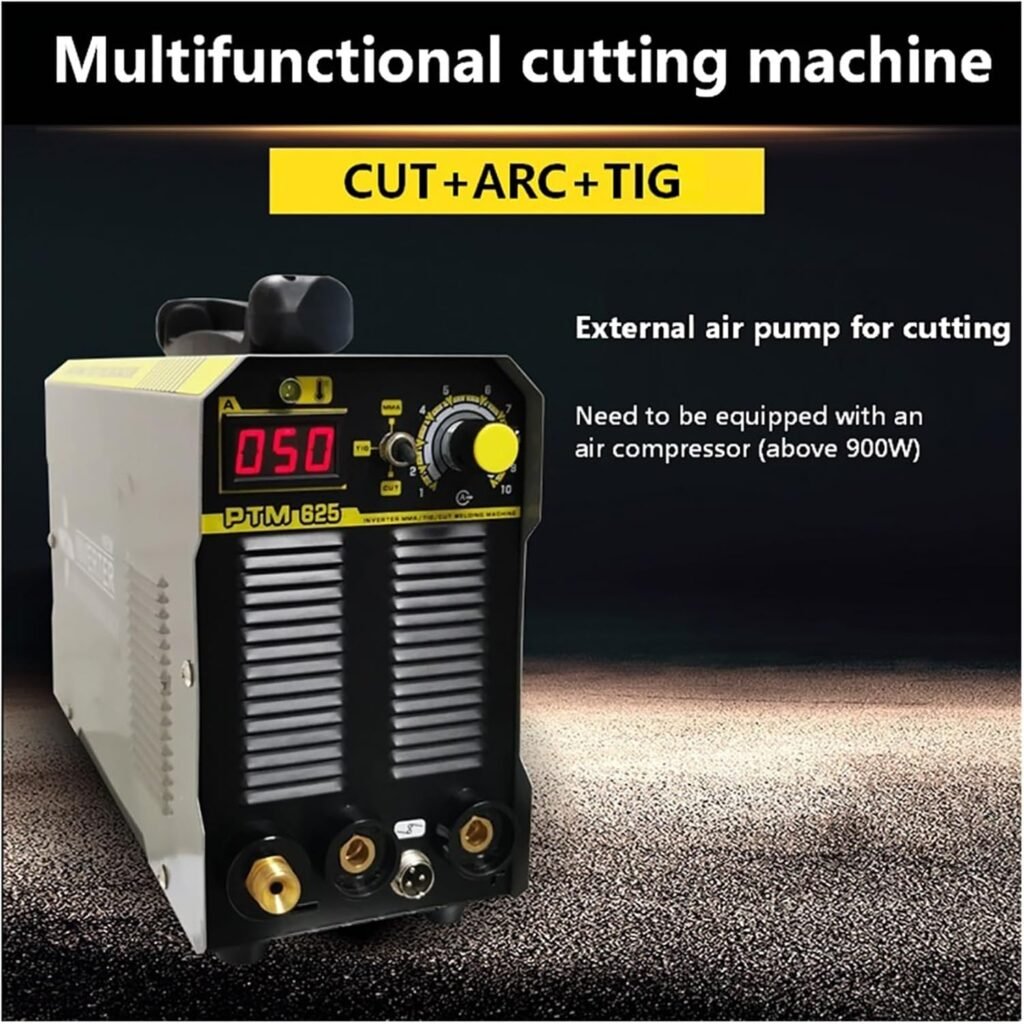

Overview of the CNC Plasma Cutter 3 In 1 Welding Machine Air Plasma Cutting LGK/CUT/TIG/MMA Welder Multifunction Welding Machine Plasma Welders

You’ll find this machine aims to combine cutting and welding capabilities into a single unit so you can handle a wider range of metalwork without swapping machines. It’s designed to use compressed air for plasma cutting, while also offering ARC and TIG (MMA) welding functions, making it a versatile addition to your workspace.

What this product promises

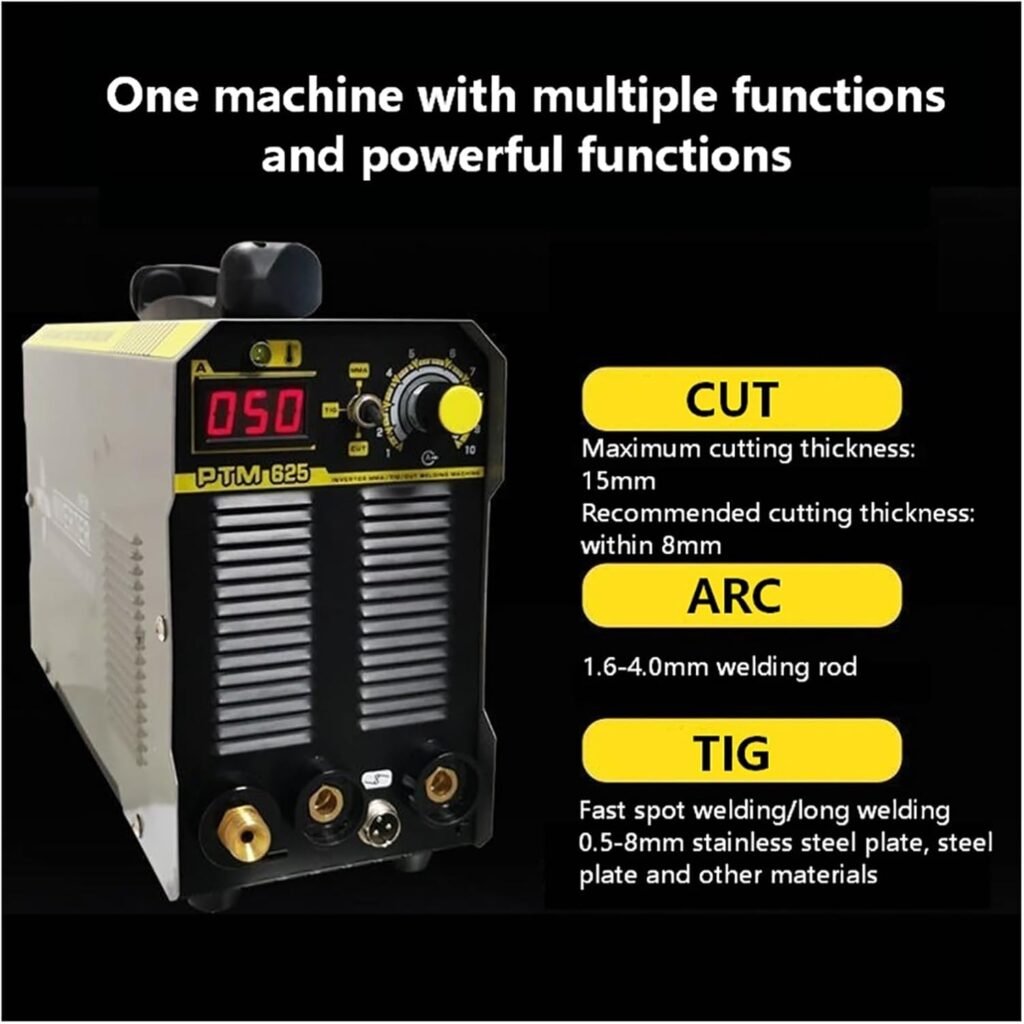

The product promises three main functions: CUT, ARC, and TIG. You’ll get plasma cutting powered by compressed air, plus conventional welding modes to tackle fabrication, repair, and finishing tasks.

Who this unit is for

This unit is targeted at hobbyists, small fabrication shops, metal artists, and maintenance technicians who want a compact, multifunction machine. If you need a space-saving device that handles cutting and multiple welding types, this product could be useful for your needs.

Key features and benefits

You’ll want to know what sets this machine apart from single-purpose units and whether those features translate into real advantages for your work.

Multiple functions in one machine

You’ll be able to switch between plasma cutting, ARC welding, and TIG/MMA welding, saving physical space and potentially cost compared with buying three separate machines. Having these functions in one chassis also streamlines storage and maintenance.

Compressed-air plasma cutting

The machine uses compressed air as the cutting gas source, which is cost-effective compared with bottled specialty gases. You do need an air compressor of at least 900W, and this keeps operating costs lower long term if you already have an air supply.

Front-panel air regulator and digital meter

You’ll appreciate the front-panel air regulator and digital meter because they make adjusting air pressure and viewing cutting current straightforward. That convenience cuts down on trial-and-error settings and makes consistent results easier to achieve.

Narrow cutting seams and smooth performance

This model claims narrow cutting seams with smooth edges and minimal thermal deformation, which is desirable when you need accurate, clean cuts and minimal post-cut finishing. That translates into less grinding or reworking for many projects.

Built-in protections

You’ll benefit from automatic protection features such as over-voltage, over-current, and over-heat protection, which add a layer of safety and reliability during extended or heavy-duty use. These protections help prevent damage to the machine and reduce downtime.

What’s included and what you’ll need

It’s important to know what comes in the box and what extras you must supply to get the machine running.

Typical package contents

The machine usually ships with a plasma torch, welding leads, ground clamp, user manual, and possibly basic consumable kit. You should verify the exact contents from the seller because bundles can vary.

Additional items you must provide

You’ll need a compatible air compressor rated above 900W to supply the plasma cutting torch. You’ll also want proper regulators, hoses, a reliable power supply, and personal protective equipment such as helmets, gloves, and protective clothing.

Technical specifications (at-a-glance)

The following table breaks down the critical technical aspects of the machine so you can compare specs quickly. You’ll find the main operational parameters mapped out for easier understanding.

| Specification | Details |

|---|---|

| Product Name | CNC Plasma Cutter 3 In 1 Welding Machine Air Plasma Cutting LGK/CUT/TIG/MMA Welder Multifunction Welding Machine Plasma Welders |

| Operating Modes | CUT (Plasma), ARC (MMA), TIG |

| Cutting Gas | Compressed air (requires air compressor above 900W) |

| Front Controls | Air regulator and digital meter for pressure and current |

| Cutting Performance | Narrow seams, smooth cuts, reduced deformation |

| Protections | Over-voltage, over-current, over-heat protection |

| Typical Consumables | Plasma electrodes, nozzles, contact tips, welding rods |

| Power Requirement | Varies by model; check label or manual for exact voltage & amperage |

| Use Cases | Metal fabrication, repair, automotive, HVAC, metal art |

| Dimensions & Weight | Varies; confirm with product listing |

| Warranty & Support | Depends on seller; confirm before purchase |

You’ll find this table useful for quick decision-making and to check compatibility with your workshop infrastructure.

Cutting performance: what to expect

When you use the CUT mode, you’ll want predictable, clean performance for the metals and thicknesses you work with.

Cut quality and seam width

You’ll likely notice narrow cutting seams with relatively smooth edges, which minimizes the need for secondary finishing. The good edge quality helps if you’re assembling parts where fit matters and reduces material loss.

Material thickness capability

The actual maximum and clean cutting thickness will depend on the specific model variant and its current output. You should refer to the product’s detailed specs or test samples, but generally, you can expect effective cutting on thin to medium-thick steel panels commonly used in fabrication shops.

Air supply impact

You’ll need a stable, adequately powered air compressor to achieve optimal cutting quality. If your air supply is inconsistent or underpowered, you’ll see degraded cut quality and increased slag or rough edges.

Welding performance: ARC and TIG/MMA

The ARC and TIG (MMA) welding modes expand your capabilities beyond cutting, so you can perform repairs and join metals with the same unit.

ARC (MMA) welding usability

You’ll find that ARC welding is robust and good for general repair and construction welding on thicker materials. MMA is forgiving for outdoor work and dirty surfaces, which is handy for maintenance tasks.

TIG capability and finish

TIG welding is usually valued for producing cleaner, more precise welds on thin metals or when aesthetic welds matter. You’ll want to check whether this multifunction unit’s TIG mode offers the fine control you need for delicate or stainless-steel work; some combo machines may be less refined than dedicated TIG machines.

Switching between modes

You’ll benefit from the convenience of switching modes without changing major hardware, but expect some learning to get settings right for each process. The front-panel controls and digital meter make this process easier, helping you adjust air pressure and welding current quickly.

Setup and installation

You’ll want clear guidance to set up safely and correctly so the machine performs well from the start.

Physical placement and ventilation

You should place the machine on a stable surface in a well-ventilated area to avoid heat buildup and to keep fumes away from breathing zones. Good airflow improves component longevity and operator comfort.

Electrical requirements

You’ll need to confirm the machine’s voltage and current requirements and ensure your shop supply matches them. Using a proper circuit and avoiding extension cords for heavy loads helps prevent voltage drop and machine stress.

Air compressor integration

You must connect a compressor rated above 900W and use hoses and fittings rated for the required pressure. The front-panel air regulator allows you to fine-tune pressure without going back to the compressor each time.

Operation and controls

The machine is designed to be user-friendly, but you’ll want to learn where each control is and how to use it efficiently.

Front-panel layout

You’ll find the air regulator and digital meter on the front panel, which simplifies on-the-fly adjustments. The readable display helps you keep track of cutting current and air pressure during operation.

Setting cutting parameters

You’ll select cutting current based on material thickness and monitor air pressure for stable arc and clean cuts. Keep some reference settings or a notes sheet for materials you work with frequently—this saves time and reduces scrap.

Welding parameter adjustments

You’ll adjust welding amperage for the ARC and TIG modes based on electrode type and material thickness. Small changes in current can significantly affect bead profile and penetration, so use the digital meter to repeat successful settings.

Consumables, maintenance, and lifespan

To keep the machine performing well, you’ll need to understand consumables and maintenance routines.

Common consumables

You’ll replace plasma electrodes, nozzles, contact tips, and welding rods or fillers as part of routine use. Having a stock of these items helps you avoid downtime.

Maintenance tasks

You’ll perform basic maintenance like keeping vents clear, checking cables and connections, cleaning the torch and nozzles, and verifying the air filter and regulator condition. Regular maintenance extends the life of the machine and keeps performance consistent.

Expected lifespan

With proper care and moderate use, you can expect many years of service from a machine like this; heavy industrial duty will shorten component life. Protecting it from moisture, dust, and overheating will boost longevity.

Safety considerations

You’ll want to prioritize safety every time you operate cutting or welding equipment.

Personal protective equipment

You’ll use a welding helmet with the correct shade, gloves, long sleeves, and protective footwear. For plasma cutting, high levels of UV and flying particles require eye and skin protection as well.

Machine safeguards

You’ll benefit from built-in protections like over-voltage, over-current, and over-heat protection. Still, you should follow recommended duty cycles and let the machine cool if protections engage repeatedly.

Workplace safety

You’ll keep flammable materials away, ensure good ventilation to remove fumes, and use fire-resistant barriers when cutting or welding. Have a fire extinguisher nearby and use proper grounding and cable management to reduce tripping and electrical hazards.

Pros and cons

You’ll want a balanced view to decide whether this multifunction unit is right for you.

Pros

- You’ll save space by combining cutting and multiple welding modes in one machine.

- You’ll reduce operating costs using compressed air instead of specialty gases for plasma cutting.

- You’ll enjoy front-panel controls that simplify adjustments and make operation more accessible.

- You’ll get features like narrow seam cutting and smooth edges that reduce finishing work.

- You’ll benefit from automatic safety protections that help prevent damage.

Cons

- You’ll need to invest in a sufficiently powerful air compressor (900W+), adding to initial setup costs.

- You may find mode-specific performance is not as refined as dedicated single-process machines.

- You’ll depend on proper maintenance and consumable replacement for consistent results.

- You should confirm warranty and local support before purchase because service quality can vary by seller.

Use cases and real-world applications

You’ll find this machine useful across a variety of tasks where both cutting and welding are needed in a compact setup.

Fabrication shops and small manufacturers

You’ll use the unit for prototyping, small-batch production, and repairs where flexibility matters. The combination of cutting and welding reduces time spent moving parts between machines.

Automotive repair and bodywork

You’ll appreciate the ability to cut rusted panels and weld new patches with the same machine. The plasma cutter helps remove metal quickly while the welding modes let you join replacement panels.

Metal art and custom projects

You’ll find the narrow seam cuts and welding options helpful when creating decorative metalwork or furniture. Smooth edges reduce the time you spend grinding or finishing surfaces.

Home hobbyists and DIY

You’ll benefit from having one tool that covers multiple needs for home projects, restorations, and custom fabrications. Be mindful of electrical and air requirements and maintain safety practices.

Tips to get the best results

You’ll get more consistent, high-quality outcomes if you follow some practical advice gleaned from experienced users.

Match air pressure to material and current

You’ll experiment to find the optimal air pressure that pairs with your cutting current for clean cuts and minimum slag. Keep a record of settings for each material thickness you frequently use.

Keep consumables clean and correctly installed

You’ll maintain nozzle and electrode condition for stable arcs and longer consumable life. Replace consumables at the first sign of irregular cutting or arc instability.

Preheat or clamp thin parts

You’ll reduce warping on thin materials by using tack welds, clamps, or preheating techniques where appropriate. That helps you preserve dimensional accuracy.

Practice mode transitions

You’ll practice switching between CUT, ARC, and TIG modes to become skilled at adjusting settings quickly. Familiarity reduces mistakes and scrap.

Troubleshooting common issues

You’ll likely face occasional issues with any multifunction unit; here are common problems and how you can address them.

Poor cut quality or rough edges

You’ll check air pressure, consumable condition, and torch-to-work distance. Inconsistent air or worn nozzles and electrodes commonly cause poor cuts.

Torch or electrode overheating

You’ll verify you’re within the recommended duty cycle and that ventilation is adequate. If protections trigger frequently, check for proper cooling and avoid operating continuously at max output.

Welding instability or porosity

You’ll check grounding, cable connections, and cleanliness of joint surfaces; contaminants and poor electrical connections can cause porosity. Adjust amperage and travel speed to match material and electrode.

Machine fails to power on or trips protection

You’ll inspect input voltage, circuit breakers, and fuses while ensuring the machine isn’t overheated. Over-voltage or over-current protections may indicate supply issues or internal faults—contact support if needed.

How it compares with dedicated machines

You’ll weigh the trade-offs when choosing a multifunction machine versus dedicated single-function units.

Versatility vs specialized performance

You’ll gain flexibility and space savings by choosing a 3-in-1 device, but you might sacrifice the absolute top-tier performance in each modality compared to dedicated machines. If you need best-in-class TIG welding for exotic alloys, a dedicated TIG might outperform the multifunction unit.

Cost considerations

You’ll often pay less than the combined price of three separate machines, but add-on costs (like a powerful compressor) and consumables still apply. If you already own a compressor, the overall savings improve.

Maintenance and downtime

You’ll deal with a single machine to maintain rather than three, simplifying service and parts management. On the other hand, if the machine goes down, you lose multiple capabilities at once—plan for backup or repair options.

Buying considerations

You’ll want to make a confident purchase by checking specific details beyond the headline features.

Verify exact model specs

You’ll confirm voltage, duty cycle, maximum cutting thickness, and included accessories before buying. Sellers may list multiple variants under the same model name, so compare carefully.

Check seller support and warranty

You’ll look for warranty terms and local service availability to avoid long downtimes if the machine needs repair. Reliable customer support can make a big difference in the ownership experience.

Factor in the compressor and additional equipment

You’ll budget for a suitable air compressor (900W+), hoses, regulators, PPE, and extra consumables. These items are essential and can affect total cost significantly.

Read user reviews and test when possible

You’ll read multiple user reviews and, where possible, try a demonstration to assess ergonomics, control layout, and cut/weld quality. Real-world use is the best way to judge fit for your needs.

Final recommendation

You’ll find the CNC Plasma Cutter 3 In 1 Welding Machine Air Plasma Cutting LGK/CUT/TIG/MMA Welder Multifunction Welding Machine Plasma Welders offers a compelling package if you need flexibility and space-saving convenience. It’s particularly attractive if you already have or plan to get a robust air compressor and you value the ability to perform cutting and welding without multiple machines. If your work demands niche, high-precision TIG or industrial heavy-duty continuous cutting at maximum throughput, you might still prefer dedicated units, but for many hobbyists and light-to-medium commercial users, this multifunction machine represents a very practical choice.

Frequently asked questions (short)

You’ll find the quick answers below helpful when you’re deciding or setting the machine up.

Do I need an air compressor?

Yes. You’ll need an air compressor rated above 900W to supply the plasma cutter properly. Inadequate air supply leads to poor cut quality.

Can it weld stainless steel?

Yes, you can weld stainless steel depending on the mode and settings, but results may vary compared to specialized TIG units. Use appropriate filler and settings for the best outcome.

How often do I change consumables?

You’ll replace consumables based on usage intensity and observed wear—keep spares on hand. Cutting and welding conditions affect consumable life.

Is it suitable for professional use?

You’ll find it suitable for many professional applications, especially in small shops and maintenance roles. For heavy production environments, review duty cycle and durability against your workload.

If you want, you can tell me the exact model variant or typical materials and thicknesses you work with, and I’ll help estimate cutting and welding settings and accessories you should pick.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.