Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

? Are you trying to decide whether the DC 24V 40W Mig Welder Feeder, Welder Roll Wire Feed Motor with copper Interface Assembly Support 0.6-1.0mm wire up to 5kg welding wire, for Flux Core MIG Welder/Lift TIG/Stick 3 in 1 Welding Machine is the right wire feeder for your welder?

Product overview

You get a compact, single-drive DC wire feeder designed for gasless MIG setups and 3-in-1 welding machines. The DC 24V 40W Mig Welder Feeder supports up to 5 kg spools and accepts 0.6–1.0 mm wire, which makes it a strong match for hobbyists and small shop users who run flux-core MIG welding or combined MIG/TIG/Stick machines. The copper interface assembly and selectable V- or K-groove drive wheels are notable hardware features that improve contact and versatility.

What this unit is built for

This feeder is meant to attach to gasless MIG (flux-core) systems and multi-process machines that offer lift TIG and stick welding as well. It’s not a full professional industrial feeder, but it’s robust enough for continuous and spot welding in light fabrication, automotive repair, farm work, and maintenance tasks. You’ll appreciate the balance between portability and capability.

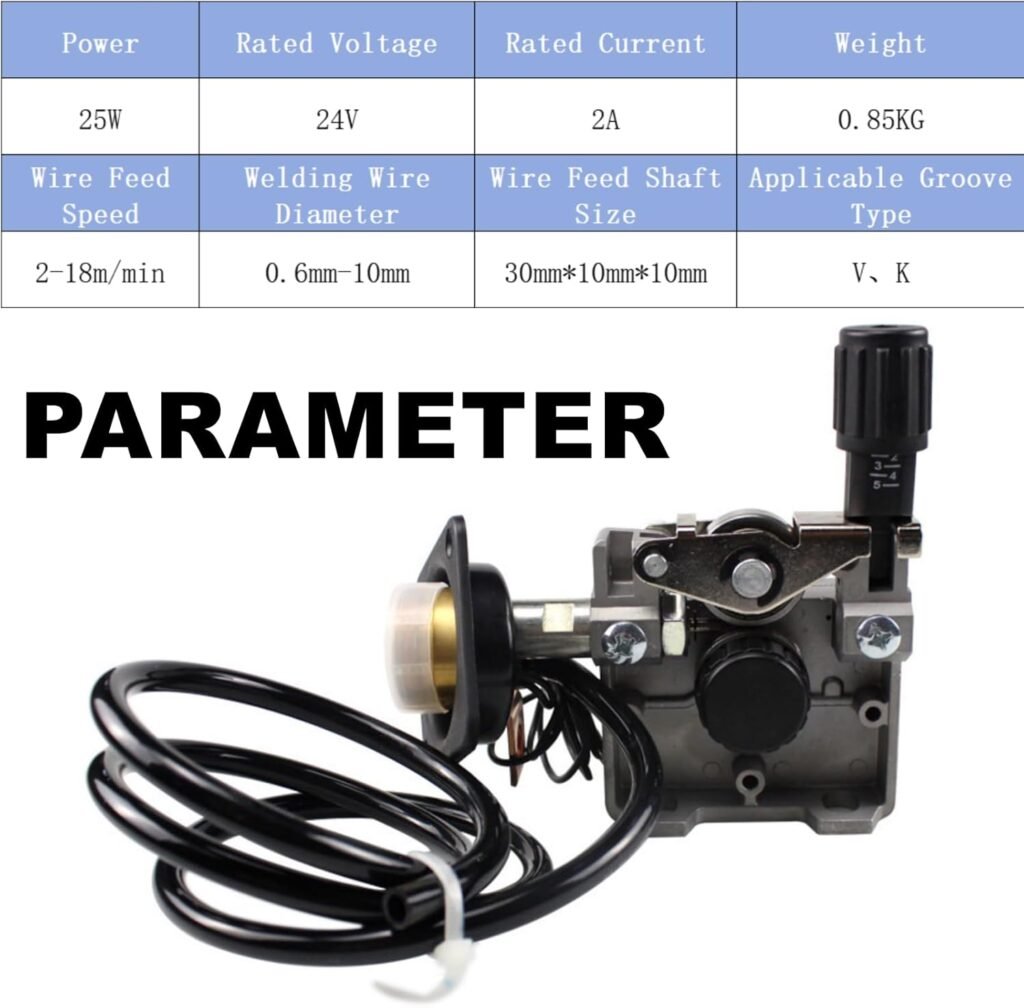

Key specifications

Below is a compact breakdown of the most important specs so you can quickly match the feeder to your needs. Use this when comparing to your welder’s requirements.

| Feature | Specification |

|---|---|

| Input voltage | DC 24V |

| Current draw | 2.5A |

| Power | 40W |

| Wire diameter supported | 0.6 mm – 1.0 mm |

| Spool capacity | Up to 5 kg |

| Drive type | Single drive motor |

| Wire feed speed | 2 m/min – 18 m/min |

| Max continuous torque | 15 kg·cm |

| Instantaneous max torque | 36 kg·cm |

| Drive wheels | V-groove and K-groove supported |

| Wire conduit length compatibility | 3 m – 10 m |

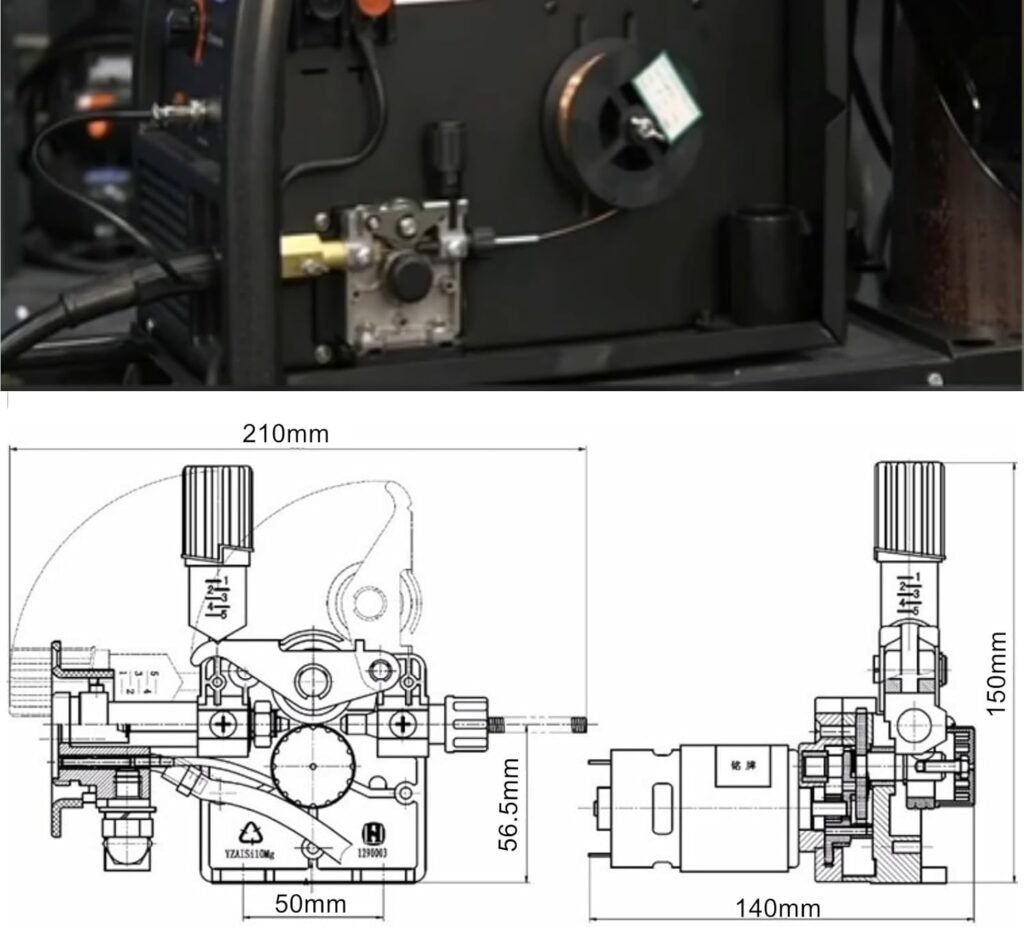

| Width | 140 mm |

| Height (with handle locked) | 150 mm |

| Noise level | Low noise (manufacturer claim) |

You can use this table to check compatibility with your machine and to set expectations for performance. The numbers tell you the basic electrical and mechanical limits so you won’t push the feeder beyond what it can handle.

Performance and build quality

You should notice a stable, reliable feed out of the box if you set the tension and liner correctly. The single-drive motor is focused on delivering constant torque and smooth feeding rather than high-speed industrial throughput. The copper interface assembly increases conductivity and reduces heat at the connection points, which helps with longevity.

The housing and handle dimensions make this feeder portable but still substantial enough to handle longer welding sessions. Given the power rating (40W) and 2.5A draw at 24V, it’s an energy-efficient component for smaller welding machines.

Motor feel and real-world torque

When you run flux-core wire, you’ll want consistent pressure from the drive wheel to avoid slippage or birdnesting. The feeder’s continuous torque rating of 15 kg·cm gives good push for smaller to medium wires; the instantaneous peak torque of 36 kg·cm helps when you start or when a bit more torque is needed during heavy puddles or rough wire. In practice, this means you won’t see frequent feed interruptions on clean, straight wire spools up to the 5 kg limit.

You should avoid overworking the feeder beyond sustained high feed speeds with thick wire—doing so stresses the motor and the drive mechanism and shortens life.

Noise and vibration

The unit is described as low-noise and will typically be quieter than older, high-torque feeders because it’s optimized for lower power draw and steady delivery. You’ll still hear the motor, but it shouldn’t be intrusive in a small workshop. Vibration is minimal if the drive wheel and tensioner are set correctly; misalignment or dirty drive wheels are the main causes of noise and vibration.

Installation and compatibility

Setting this feeder up is straightforward if you follow basic mounting and wiring practices. You’ll attach the feeder to your 3-in-1 welding machine or mount it near your work area, feed the welding wire through a liner (3–10 m length supported), and connect the 24V DC input. Check that your machine provides the appropriate power or use the feeder’s own supply as specified.

You should confirm that your machine’s spool mounting and the feeder’s 5 kg capacity match, and that your weld cable routing doesn’t create sharp bends in the liner. If your machine produces a secondary voltage for feeder control, make sure the signal is compatible with a 24V DC feeder.

Mounting steps (high-level)

- Secure the feeder in a stable position next to your welding machine or on a mount designed for external feeders.

- Install the spool onto the feeder’s spindle, ensuring the spool rotates freely and is within the 5 kg limit.

- Select and install the correct drive wheel (V or K groove) for the wire you’ll use.

- Thread the wire through the liner and into the welding torch or contact tip.

- Hook up the DC 24V input, observing polarity and solid connections.

- Adjust the drive pressure and set an initial feed speed for testing.

You’ll want to run a few test beads on scrap material to confirm feed consistency and to dial in feed speed vs. machine current settings.

Wire wheel selection: V-groove vs K-groove

You get both V-groove and K-groove drive wheels for different wire types. Choosing the correct groove is one of the simplest ways to avoid feeding problems and to preserve the wire surface.

- V-groove: Best for softer solid wires and for when you want less surface marking on the wire. You’ll use this for typical mild-steel solid MIG wires in thinner diameters.

- K-groove: More aggressive; designed for flux core or softer wires where more grip is required to prevent slipping. This is typically your go-to for flux-cored gasless welding.

You should match the groove to the wire and keep drive pressure moderate—excess pressure will deform the wire and cause inconsistent feeding.

Wire diameter and feed speed guidance

This feeder supports 0.6–1.0 mm wire. That range covers common flux-core wires (0.6 mm/0.023″, 0.8 mm/0.030″, 1.0 mm/0.039″) that are used in many gasless MIG applications.

- 0.6 mm: Good for thin sheet metal, sheet repairs, and delicate welds. You’ll likely run lower feed speeds (around 2–6 m/min) and lighter machine amperages.

- 0.8 mm: A versatile middle choice for general repair work and medium thickness sheet and plate. Feed speeds roughly mid-range (6–12 m/min) depending on machine settings.

- 1.0 mm: Use for thicker sections or where you need deeper penetration. Expect higher feed speeds (10–18 m/min) and more heat input.

This guidance is approximate because actual current and voltage are controlled by your welding machine; wire feed speed and machine power must be balanced to achieve the correct arc.

Practical uses and applications

You’ll find this feeder useful for a number of practical tasks. It’s built for gasless MIG welding (flux-core), and because it’s compatible with 3-in-1 machines, you can use it in combined setups for small lift-TIG and stick welding tasks too.

Common applications include:

- Automotive panel repair and body work (thin-gauge sheet).

- Farm equipment maintenance and light structural repairs.

- Small fabrication shops doing moderate-length beads.

- Hobbyist and DIY projects where portability and spool size are important.

If your needs include continuous high-hour production welding on thick plate, you may want to consider a heavier-duty industrial feeder.

Spot welding vs continuous welds

The feeder is suited to both spot welding and continuous bead welding. For spot welding, the instant torque capability will help start the wire and feed quickly for short bursts. For continuous welding, you’ll appreciate the stable feed and low noise, as long as you operate within the feeder’s torque and speed limits.

Pros and cons

You should weigh the benefits against limitations before buying. Here’s a concise view to help with that decision.

Pros

- Compact and lightweight for portability.

- Supports up to 5 kg spools, which reduces spool changes.

- Accepts common wire diameters 0.6–1.0 mm.

- V- and K-groove wheels allow flexible wire selection.

- Copper interface assembly for improved electrical contact and durability.

- Low energy draw (24V, 2.5A) and low noise operation.

Cons

- Single drive motor may not match the feed consistency of dual-drive industrial systems for heavy-duty welding.

- Maximum continuous torque limits higher-duty cycles with thick wires at high speeds.

- Not a full industrial-grade feeder for high-production environments.

- Requires correct setup and occasional maintenance to sustain smooth operation.

Use these points to decide if the feeder matches the workload and expectations for your welding tasks.

Comparison with other feeder types

When you compare this feeder to other common alternatives, several differences become clear.

Single-drive vs dual-drive

- Single-drive units (like this one) are compact and simpler but rely on a single contact point to push wire, which can be less stable with longer torch runs or heavy spools.

- Dual-drive systems provide two contact points and more consistent pressure, making them better for long liner runs and heavier production.

Motor power and torque

- The 40W motor with 15 kg·cm continuous torque suits small to medium wire sizes well.

- Higher-power feeders with larger motors are preferable if you regularly weld with 1.0 mm wire at high speed or do long continuous welds.

Portability vs production

- This feeder favors portability and economy over heavy production throughput. If you’re mobile or occasionally produce longer runs, this unit remains a great choice. If you run a high-volume shop, invest in a higher-capability feeder.

Setup tips to get the best feed

You can improve feed reliability quickly with the right setup and routine checks.

- Match spool orientation and rotation to the wire feed path; avoid binding and spool torque.

- Use a liner with the correct inner diameter for your wire size and keep it as short as possible within the supported 3–10 m range.

- Set drive tension so the wire slips under heavy drag but doesn’t deform under normal pressure.

- Choose the correct drive wheel (V or K) and make sure it’s centered on the wire.

- Trim the contact tip cleanly after a jam and keep the liner and tip clean from spatter and dirt.

- Run a few test passes on scrap metal to balance feed speed with welding current and voltage.

Following these steps will significantly reduce feeding problems and improve weld quality.

Maintenance and troubleshooting

You should expect some basic maintenance and occasional troubleshooting. Below are common issues and how to address them.

Common issues and fixes

- Birdnesting (wire tangles): Check spool rotation, reduce drive tension, clean drive wheel grooves, and ensure the liner is straight without kinks.

- Slipping wire: Increase drive tension slightly, switch to a more aggressive groove if needed, and clean the drive wheel surface.

- Inconsistent feed: Inspect liner for obstructions, replace worn drive wheel, verify spool runs free, and check connections to the motor.

- Motor hum or weak feed: Check voltage supply and wiring, verify the motor brushes if applicable, and test with a known-good spool to rule out wire issues.

- Excessive wire marking/deformation: Reduce drive pressure and verify wheel alignment.

Routine maintenance checklist

- Weekly: Clean the drive wheel, inspect drive pressure, check spool mount and rotation.

- Monthly: Inspect liner interior and replace if frayed; check motor mounting screws and connectors.

- Every few months or under heavy use: Inspect motor brushes and bearings if the design allows, lubricate moving parts recommended by the manufacturer, and test torque under load.

Performing this routine will extend the feeder’s service life and keep feed consistency high.

Safety considerations

You should always operate welding equipment with proper safety measures. Even though this is a feeder, it’s part of an arc welding system and shares common hazards.

- Wear appropriate PPE: welding helmet, gloves, long sleeves, and hearing protection if needed.

- Make sure the feeder and welder are properly grounded.

- Keep the feeder and power connections dry and clean to avoid shorts or corrosion.

- Don’t exceed the spool weight or recommended wire size limits.

- Disconnect power before servicing the feeder, changing drive wheels, or replacing liners.

Following these precautions protects you and helps avoid damage to the unit.

Frequently asked questions

You’ll likely have practical questions before you buy. Here are answers to common concerns.

Q: Can this feeder be used with solid MIG wire (gas-shielded)? A: It’s optimized for gasless flux-core MIG and supports the wire diameters used for flux core. You can physically feed solid wire as long as groove selection and liner match, but performance and groove choice will matter for clean solid wire.

Q: Will it work with long torch liners, say 10 meters? A: The feeder supports 3–10 m liners. Keep in mind the longer the liner, the more consistent your spool, liner inner diameter, and torch alignment must be to avoid drag and feeding problems.

Q: Is the copper interface assembly a big advantage? A: Yes. Copper improves electrical contact, reduces heat at connection points, and is generally more durable than lower-quality alloys. This helps reliability over many cycles of use.

Q: What spool sizes will fit? A: The feeder supports up to 5 kg spools. Check spool hub diameter and mount for fitment when using different spool types.

Q: Do I need a separate power supply for the feeder? A: The feeder requires DC 24V and 2.5A. If your welding machine provides a compatible feeder supply, use it. Otherwise, you’ll need a 24V DC supply rated for the feeder.

Q: How often will I need to replace drive wheels or liners? A: It depends on usage and wire types. Clean drive wheels regularly and replace when grooves wear or the surface becomes damaged. Liners typically last longer but replace them when you see fraying, clogging, or degraded feed.

Q: Is this suitable for production welding? A: It’s suitable for small-scale production and light to medium duty jobs. For high-volume industrial production, a heavier-duty dual-drive feeder would be a better fit.

Q: How do I prevent birdnesting? A: Ensure correct spool orientation, set proper drive tension, keep the liner clean and straight, and use the correct drive wheel. If birdnesting occurs, stop immediately and clear the spool and liner before continuing.

Final recommendation

If you want a reasonably priced, portable, and capable wire feeder for flux-core MIG welding and for use with a 3-in-1 welding machine, the DC 24V 40W Mig Welder Feeder, Welder Roll Wire Feed Motor with copper Interface Assembly Support 0.6-1.0mm wire up to 5kg welding wire, for Flux Core MIG Welder/Lift TIG/Stick 3 in 1 Welding Machine is a practical choice. It gives you flexibility with groove wheels, supports common wire sizes, and offers enough torque and feed speed for most hobby and light shop tasks.

You should buy this feeder if you value portability, lower noise, and the ability to use 5 kg spools with a compact assembly. If you routinely perform heavy industrial work with long torch runs or require continuous high-speed feeding of thick wire, consider a heavier-duty or dual-drive alternative instead.

If you want, tell me what welding machine and wire sizes you currently use and I can help confirm compatibility and recommend setup settings tailored to your gear.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.