Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a single welder that can handle MIG (gas and gasless), TIG, stick and spot welding without forcing you to be an expert technician?

Overview

You’ll find the DECAPOWER 110V 220V Dual Voltage 200 amps gas gasless MIG Welder 3 in 1 MIG FLUX TIG Stick multi function MIG Aluminum welding machine with spot function aimed at people who want a versatile, workshop-ready machine without excessive complexity. The design pushes convenience with a large visualization interface and synergic MIG mode, so you can spend less time guessing settings and more time welding.

What this product is

You’re looking at a multi-process combo welder that promises to bridge home, garage and light industrial needs. The unit supports Gas MIG, Flux Core MIG, SPOT MIG, Lift TIG and Stick welding, so you can tackle a broad range of projects with one machine.

Who this suits

If you’re a hobbyist, small-fabrication shop owner, DIYer, or mechanic who wants to work on cars, furniture, frames, or general repairs, this machine is aimed at you. The automatic/synergic MIG mode is especially friendly if you’re still getting comfortable with welding parameter selection.

Key Features

You’ll appreciate that the machine packs multiple welding processes into one chassis, plus some usability-focused touches. The visualization interface and dual-voltage capability are two of the features that make it attractive for changing work environments.

Multi-function welding modes

You can switch between Gas MIG, Flux Core MIG, SPOT MIG, Lift TIG and Stick welding modes to match the task at hand. That range lets you weld iron, carbon steel, stainless steel and aluminum depending on which process and consumables you use.

Dual voltage (110V / 220V) and 200 amps

You can plug the unit into standard household 110V circuits or heavier 220V supplies, so you’re not limited to a single power environment. The 200-amp maximum gives you enough output to handle medium-thickness work and many repair jobs.

Visualization Interface and controls

All settings are presented on one large screen, which means you don’t need to flip through multiple menus while making adjustments. You’ll find the interface helpful for quick setup and keeping an eye on parameters while you weld.

Synergic MIG and manual control

If you want simplicity, the synergic MIG mode automatically pairs current and voltage to match the wire feed speed you select. If you prefer fine control, you can switch to manual wire feed speed and voltage adjustments to fine-tune your arc.

Spot function

The SPOT MIG function gives you a repeating or timed welding output ideal for joining sheet metal without warping. You’ll appreciate this for automotive panel work and assembly where controlled spot welds are needed.

Lift TIG and Stick

The Lift TIG functionality allows you to use TIG without a high-frequency start, which keeps complexity down. Stick mode is useful when you’re working outdoors or on rusty surfaces where gas shielding isn’t practical.

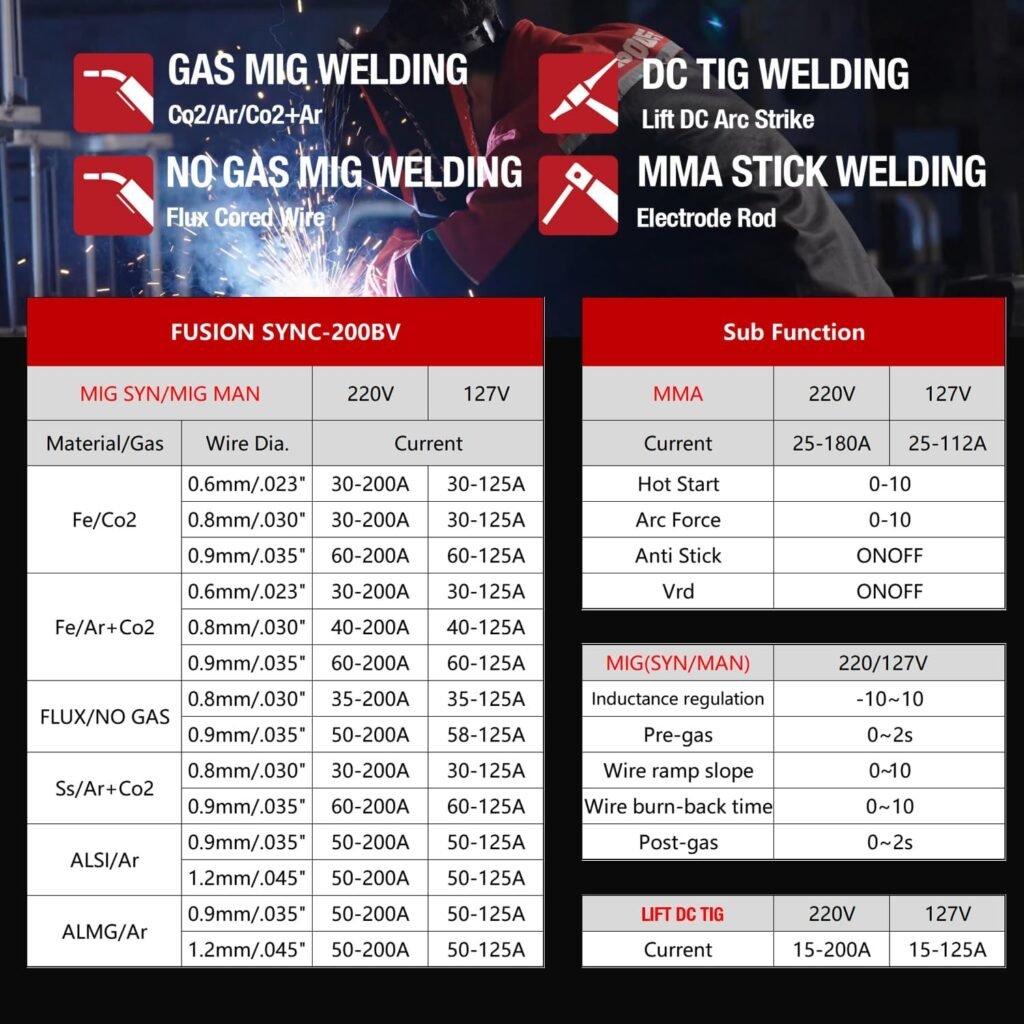

Quick Specs Table

You’ll find the essential specs summarized below so you can quickly see whether the machine fits your power and process needs.

| Specification | Details |

|---|---|

| Model | DECAPOWER SYNCMIG-200 (marketed as DECAPOWER 110V 220V Dual Voltage 200 amps gas gasless MIG Welder 3 in 1 MIG FLUX TIG Stick multi function MIG Aluminum welding machine with spot function) |

| Welding Processes | Gas MIG, Flux Core MIG, SPOT MIG, Lift TIG, Stick |

| Input Voltage | 110V / 220V (dual voltage) |

| Max Output Current | 200 A |

| Materials Supported | Iron, carbon steel, aluminum, stainless steel (with appropriate setup/consumables) |

| Interface | Large visualization screen with synergic and manual controls |

| Wire Feed Control | Adjustable; synergic mode available |

| Warranty | 2 years (manufacturer) |

| Typical Applications | Home, garage, light industrial, automotive, fabrication |

| Accessories Included | Varies by package; check seller for exact list |

| Manufacturer Support | Parts availability emphasized by manufacturer |

Setup and First Use

You’ll want to be methodical when you first unbox and set up the machine to avoid issues later. A clean setup reduces troubleshooting and improves weld quality from the start.

Unboxing checklist

When you open the box, check that you have the welder, power cable(s), MIG torch or gun, ground clamp and cable, electrode holder (for stick), TIG torch or adapter (if included), wire spool or feeder components, any extra nozzles/tips, user manual and warranty card. If anything is missing, contact the seller before you start.

Initial setup steps

You should place the unit on a stable surface, attach the ground clamp to a clean metal surface, mount the appropriate wire spool, load the correct wire size, and set the inlet gas hookups if you plan to use Gas MIG or TIG. Turn the machine to the correct input voltage setting if it requires manual switching between 110V and 220V.

Safety checks before first weld

Always ensure you’ve wearing your PPE: welding helmet with the right shade, gloves, jacket and boots. Make sure the area is well ventilated and that there are no flammable materials nearby. Inspect cables and connections for damage and verify that gas flows correctly if using shielding gas.

Switching between 110V and 220V

You’ll need to confirm whether the machine auto-senses input voltage or has a manual selector. Some dual-voltage models require a plug or switch change; check your manual. Always power the machine down and unplug it before changing the input voltage configuration.

Performance: Real-World Use

You’ll care most about how the machine behaves when you’re actually welding. The following sections describe practical performance expectations across different modes.

MIG Performance (Gas and Flux-Core)

The MIG performance will depend on your wire choice, gas type (for solid wire), and setup. You should see a stable arc in synergic mode for common mild steel thicknesses; flux-core will give you easier outdoor performance with more spatters. If you wire the machine correctly and tune the wire feed speed, the arc should be smooth and forgiving for beginners.

Aluminum MIG considerations

You can weld aluminum with this machine, but success depends on using the correct spool, wire (ER4043 or ER5356), and possibly a spool gun or push-pull arrangement for longer torch leads. You’ll need to remove oxide from the aluminum and use a short, controlled arc to reduce burn-through and porosity.

TIG (Lift TIG) Performance

Lift TIG gives you the ability to TIG weld without an HF start. When you strike the arc by touching and lifting, you’ll be able to lay cleaner beads on thinner materials if you have proper shielding gas and a TIG torch. You shouldn’t expect the performance of a high-end TIG inverter but you will get acceptable results for repair and light fabrication tasks.

Stick Welding Performance

Stick welding works well when you need portability or are working outdoors on dirty metal. The machine should handle common electrodes like E6011 and E7018; your technique will largely determine bead appearance. Expect slightly different arc characteristics compared to dedicated stick-only machines, but adequate performance for most fix-it jobs.

Spot MIG Function Performance

Spot MIG is great for tack welding and joining thin panels without warping. You’ll be able to set spot duration and interval and produce consistent, repeatable spots when you dial in the right settings. It’s especially useful in sheet metal fabrication and auto body panel assembly.

Arc stability, heat control and duty cycle

You’ll notice the synergic control helps stabilize the arc when you’re working in MIG mode, making it easier to maintain penetration. Duty cycle specifics are often model-dependent; check the manual for exact figures. For prolonged heavy use, use 220V where possible to reduce strain and heat buildup.

Materials and Thickness Capacity

You’ll want to match process and power to material thickness to get the best results. Below is a guideline table to help you decide which process to use with typical thickness ranges.

| Material | Recommended Process | Typical Thickness Range (approx.) | Notes |

|---|---|---|---|

| Mild steel | Gas MIG / Flux-core / Stick | 0.5 mm (thin sheet) to ~6–8 mm | Use flux-core for outdoor work; gas MIG for cleaner finish |

| Stainless steel | Gas MIG / TIG / Stick | ~0.5 mm to ~6 mm | Use proper filler and gas to prevent contamination |

| Aluminum | MIG (with spool gun recommended) / TIG | ~0.8 mm to ~6 mm | Clean oxide before welding; consider TIG for thinner/wider control |

| Cast iron | Stick (special electrodes) / TIG with care | Varies | Preheat and use suitable consumables for cast iron repairs |

| Thin automotive sheet | SPOT MIG / MIG | 0.5 mm to ~1.2 mm | Use spot welding to avoid warping; careful heat control needed |

Note that these thickness ranges are approximate and will depend on your skill, setup and the specific filler materials and shielding gas you use.

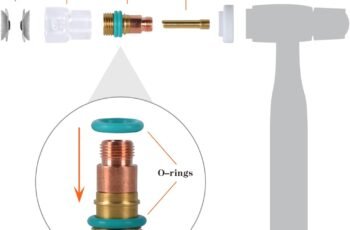

Consumables and Accessories

You’ll get better results if you use correct consumables and a few helpful accessories. The machine may include a basic set, but investing in extras is smart.

Typical consumables you’ll need

You’ll use MIG wire (ER70S-6 for mild steel), flux-core wire if you plan gasless MIG, TIG rods (ER4043/ER5356 for aluminum), TIG gas (argon), MIG contact tips and nozzles, replacement gas diffusers, and stick electrodes if you plan to use the stick mode. Keep a small inventory of common tip sizes and wire types.

Recommended accessories to buy

You should consider a spool gun or push-pull setup for aluminum, a quality MIG torch replacement (if the included one is low-end), a gas regulator and hose with flowmeter, a decent chipping hammer and wire brush, anti-spatter spray, and a welding cart if you plan to move the unit around.

What might be included

Package contents vary by seller and region; typically you’ll see a MIG torch, ground clamp, gas hose and regulator (sometimes), electrode holder and earth clamp, and possibly spare contact tips or a small spool of wire. Confirm exact contents before purchase.

Practical Tips for Better Results

You’ll find that small adjustments and consistent prep habits will dramatically improve weld quality. These tips come from common practices that work across many machines.

MIG setup tips

Set wire feed speed and voltage in synergy until the arc sounds steady and the bead looks smooth. Clean the base metal of rust and oil, use the right gas mix (C25 or 100% CO2 for flux-core vs. 75/25 argon/CO2 for better appearance), and run small practice beads on scrap before committing to your part.

TIG/Lift TIG tips

Use a sharp tungsten and appropriate shielding gas flow (usually 15–20 cfh/7–10 lpm of argon). Make sure to ground well and keep the torch steady during the lift start. Practice the touch-and-lift motion until the arc is consistent.

Stick welding tips

Match electrode diameter to amperage and material thickness. Clean the area where possible and maintain correct arc length (about the diameter of the electrode). For vertical or overhead, use electrodes designed for those positions.

Aluminum-specific tips

Use a specialized aluminum wire and consider a short torch lead or spool gun to prevent bird-nesting. Use alternating current (AC) is typical for TIG aluminum — if your machine only has DC TIG, MIG with appropriate wire and spool gun will be more practical.

Reducing spatter and porosity

Control wire feed speed and voltage; too fast or too hot will create spatter. For porosity, ensure your shielding gas flow is correct, the gas nozzle is clean, and the joint is free of contaminants.

Troubleshooting Common Issues

You’ll encounter some common issues during setup or use; knowing quick fixes will keep you welding instead of troubleshooting.

Wire feeding problems / bird-nesting

If the wire tangles or does not feed smoothly, check spool tension, drive roll pressure, and the correct drive roll groove for wire diameter. Clean or replace the liner if it’s kinked. For aluminum, use a spool gun or push-pull system for long torch leads.

Excessive spatter

You should check your gas type and flow, reduce voltage slightly, or adjust wire feed speed. Use anti-spatter on the nozzle and replace worn contact tips.

Porosity in welds

You’ll want to verify shielding gas flow, change to a fresh gas cylinder if needed, and thoroughly clean the base metal of oils, paint and rust. For aluminum, remove oxide using a stainless steel brush dedicated to aluminum.

Inconsistent arc or arc dropouts

Check ground clamp cleanliness and cable connections. Confirm the machine isn’t overheating—if it is, pause to let it cool. Verify the earth clamp is on clean metal and the cable is not damaged.

TIG arc start issues

With lift TIG, you may need to refine your touch-and-lift motion and ensure the tungsten tip is clean and sharp. Check gas flow and the TIG torch connections if the arc is inconsistent.

Maintenance and Care

You’ll keep the machine running longer and more reliably with a few routine maintenance tasks.

Daily or before-use checks

Inspect cables for wear, check gas hoses for leaks, ensure drive rolls are free of debris, and confirm contact tips and nozzles are clean. Wipe down the machine and store in dry conditions.

Monthly or periodic care

Open the side cover to clean accumulated dust and spatter from inside the machine—use compressed air or a vacuum. Check brushes (if the unit has motors requiring brush replacement) and inspect the wire feeder mechanism and liner.

Long-term care

Replace consumables when worn, keep firmware updated if the unit supports software updates, and keep a log of any parts replaced under warranty. If you use the machine heavily, plan for periodic professional servicing.

Safety and Personal Protective Equipment (PPE)

You’ll protect yourself and others by following basic welding safety. Good habits prevent injuries and improve your welding environment.

Essential PPE

Wear a welding helmet with the correct lens shade, flame-resistant jacket or gloves, safety glasses with side shields, ear protection if you’re grinding, and closed-toe leather footwear. Use respirators when welding materials that produce harmful fumes.

Work area safety

Ensure proper ventilation, remove flammable materials, secure cylinders in an upright position, and use a fire extinguisher nearby. Keep bystanders at a safe distance and use welding screens to protect others from UV exposure.

Comparison with Similar Machines

You’ll want to see where this unit stands relative to other multi-process combo welders in the same class. The DECAPOWER SYNCMIG-200 focuses on usability, multi-process ability and dual-voltage flexibility.

How it stacks up

Compared to entry-level single-process machines, this unit wins on versatility; compared to higher-end professional machines it may be less refined in TIG-only performance and long duty cycles. For most hobbyists and small shops, the 200 A output and synergic MIG make it a good middle ground.

| Category | Typical Strengths of SYNCMIG-200 | Considerations vs. Higher-end Units |

|---|---|---|

| Versatility | Supports MIG (gas & gasless), TIG, Stick, Spot | May not match specialized TIG machines for fine pipe work |

| Usability | Large visualization screen and synergic mode | Interface is simpler than some industrial HMIs but very usable |

| Portability | Dual-voltage makes it flexible | Weight and cooling design can differ by package |

| Value | Good feature-to-price ratio for hobby/garage | Industrial shops may prefer higher duty cycles and advanced TIG features |

Pros and Cons

You’ll want an honest list to weigh benefits against limitations before buying. Here’s a concise breakdown.

Pros

- Multi-process capability (MIG, Flux-core, Spot, Lift TIG, Stick) gives you flexibility.

- Large visualization interface simplifies operation, especially if you’re new to welding.

- Dual-voltage input lets you work in a garage or on a shop floor without changing machines.

- Synergic MIG mode helps you find workable settings faster.

- 2-year warranty and manufacturer support make parts/access more reliable.

Cons

- High-end TIG-only features (AC control for aluminum TIG) may be limited compared with dedicated TIG inverters.

- For best aluminum MIG results you may still want a spool gun or specialized setup.

- Exact duty cycle numbers and some specs may not be clearly documented in basic listings — verify before heavy industrial use.

- Package contents vary; you may need to purchase accessories like a regulator, spool gun, or better torch separately.

Warranty and Support

You’ll be covered by the manufacturer’s two-year warranty according to the product details, which is reassuring for a machine intended for regular use. The manufacturer also emphasizes parts availability, so you should be able to get replacement parts without excessive delays.

How to use the warranty

Keep your purchase receipt, register the product if required, and follow any service instructions in the manual. If you need parts or service, contact the seller or DECAPOWER’s support channels as specified in the warranty documentation.

Buying Advice and Final Recommendation

If you want a multi-process machine that gets you up and welding quickly, the DECAPOWER 110V 220V Dual Voltage 200 amps gas gasless MIG Welder 3 in 1 MIG FLUX TIG Stick multi function MIG Aluminum welding machine with spot function is a sensible choice. You’ll get enough capability for home, garage and light industrial projects, and the synergy between automatic and manual modes helps both new and intermediate users.

You should choose this machine if:

- You want a single unit to cover MIG, TIG and stick tasks.

- You need dual-voltage flexibility for varied job sites.

- You value an intuitive interface and a synergic MIG mode to simplify settings.

Consider other options if:

- You need professional-grade AC TIG performance for aluminum at thin gauges (specialized TIG inverters may be better).

- You require documented heavy-duty continuous duty cycle data for industrial 24/7 work.

Frequently Asked Questions (FAQ)

You’ll likely have some practical questions before buying or using the machine. These FAQs address common concerns.

Q: Can you weld aluminum directly with this machine? A: Yes, the machine supports aluminum welding, but for best MIG aluminum results you’ll likely want a spool gun or push-pull setup and to use the correct aluminum wire type. For TIG aluminum you’ll want to ensure compatibility with AC TIG if the job specifically requires it; the unit provides Lift TIG which works for many aluminum tasks but may not replace a high-end AC TIG machine.

Q: Do you have to switch a physical selector to change between 110V and 220V? A: That depends on the specific unit and firmware revision; check your user manual. Some models auto-sense voltage while others require a manual change. Always unplug the machine and follow instructions when switching.

Q: Is a regulator included for shielding gas? A: In many packages you’ll see a gas regulator and hose included, but this varies by seller and region. Confirm with the seller to avoid surprises.

Q: What is the duty cycle? A: The listing emphasizes 200 amps but often does not provide a precise duty cycle across all amperages in a concise listing. Check the manual or product spec sheet for exact duty cycle ratings at specific amperages (e.g., 60% at 200A is common on some machines but verify for this model).

Q: Is this a good machine for auto bodywork? A: Yes, the SPOT MIG function and MIG process are very useful for auto body panel work. You’ll be able to make small spot welds and use MIG for seams when properly dialed in.

Q: How beginner-friendly is it? A: Very beginner-friendly for MIG welding due to the synergic mode and large visual interface. You’ll still need to practice technique and learn safety protocols, but the machine helps remove some guesswork around settings.

Final Thoughts

You’ll find the DECAPOWER SYNCMIG-200 (marketed under the long product name DECAPOWER 110V 220V Dual Voltage 200 amps gas gasless MIG Welder 3 in 1 MIG FLUX TIG Stick multi function MIG Aluminum welding machine with spot function) offers strong value for people who need flexibility across multiple welding processes. The user-friendly interface, dual-voltage capability and diverse process support make it an appealing choice for hobbyists, repair technicians and small-shop fabricators. With sensible accessories and a little setup time, you’ll be welding a wide range of materials and projects with confidence.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.