Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Are you trying to decide whether the Draper 70047 Gas/Gasless MIG Inverter Multi-Welder DTi combined with GYS 086128 0.8mm 5Kg Steel MIG Wire is the right kit for your workshop or home projects?

Overview of the Draper 70047 Gas/Gasless MIG Inverter Multi-Welder DTi and GYS 086128 Wire

You’ll find this bundle aims to give you a flexible MIG welding solution for both gas-shielded and gasless (flux-cored) work. The Draper unit is an IGBT inverter welder with digital technology (DTi) and synergic-style operation to simplify welding, while the GYS wire provides a 0.8mm steel option suited to many general fabrication tasks.

This combination positions you to tackle sheet metal repairs, light fabrication, automotive work and general maintenance with a single setup. The included accessories make it a more complete package for users who want to start welding quickly without buying extra consumables.

What the kit includes

You’ll get a comprehensive kit that reduces the number of extra purchases you need to start welding. The package includes the Draper 70047 Gas/Gasless MIG Inverter Multi-Welder DTi (160A), a 200A electrode holder with 1.6m cable, a 200A earth clamp with 1.6m cable, a 3m MIG torch, a 2m gas hose, two 0.8mm contact tips, a chipping hammer/wire brush, and a face mask.

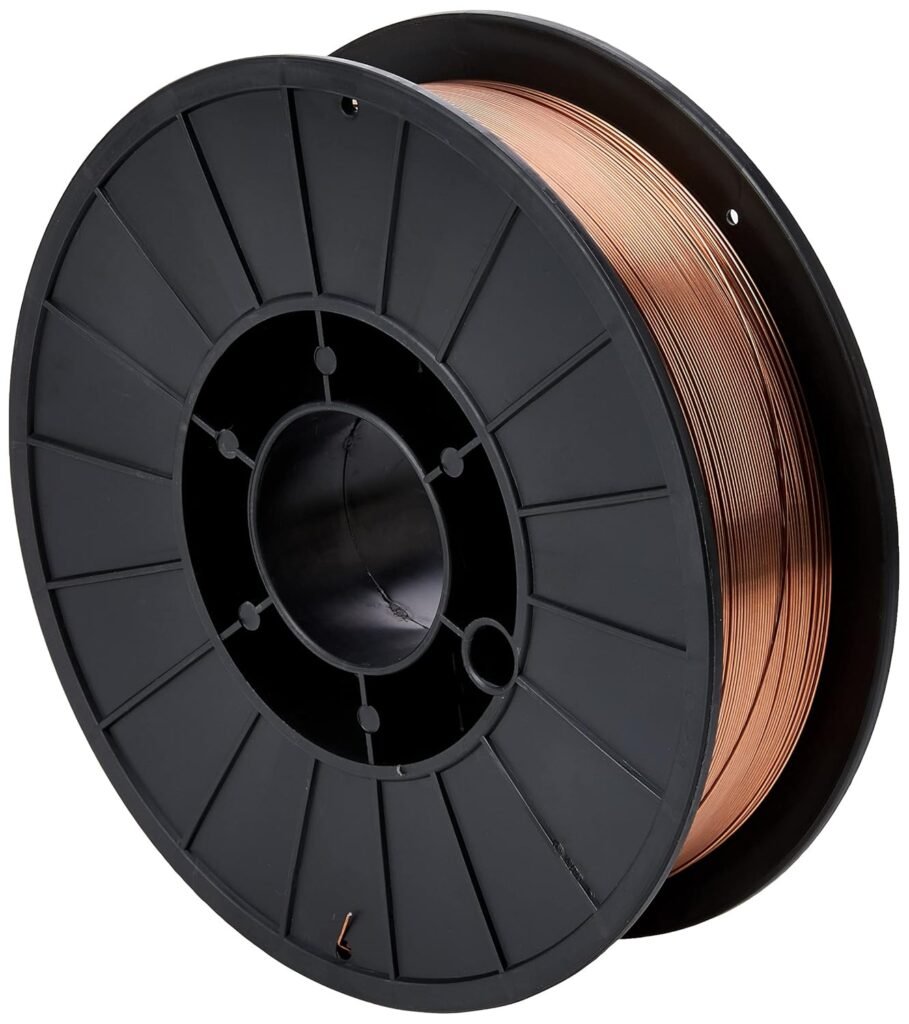

Pairing this with the GYS 086128 0.8mm 5Kg steel MIG wire gives you a ready-to-use wire spool that’s corrosion-resistant and designed for good arc stability at higher currents. That means you get both the machine and an appropriate consumable to match the machine’s intended use.

Key technologies: IGBT Inverter and DTi digital control

You’ll appreciate that the Draper 70047 uses IGBT inverter technology, which improves power efficiency, reduces weight and allows more precise current control than older transformer-based welders. In practical terms that means more stable arcs, better energy usage and a lighter package you can move around more easily.

DTi (digital technology) provides a digital display and one-touch/one-knob operation that simplifies setup. The DTi system aims to give you consistent parameters, easier repeatability and quicker transitions between different metals and thicknesses.

Synergic operation and ease of use

The machine’s synergic mode automates feed rate and voltage relationships, so you don’t have to manually balance those settings as much when you change wire diameter or material thickness. If you’re newer to MIG welding, synergic operation helps you get usable welds faster and with fewer adjustments.

Even experienced welders benefit from the simplified interface because it reduces time spent on dialing settings and increases time spent welding. The visible digital display and single-touch adjustments are designed to make everyday production or hobby tasks less fiddly.

Physical features and build quality

You’ll notice the Draper unit is compact for a 160A MIG inverter, with a blue finish that’s easy to spot in a busy shop. The supplied torch with a 3m cable and the 1.6m electrode/earth leads give you useful reach around a typical workbench or vehicle.

The included accessories—face mask, chipping hammer, brush—show the kit is targeted at users who want to start immediately and handle finish and preparation tasks without extra shopping. The overall construction feels appropriate for light-to-medium duty garage and workshop environments, though like any welder you’ll want to treat it with care.

Technical specifications

You’ll want to know the core numbers so you can match the tool to the jobs you plan to do. The machine is rated to 160A output and is designed to work in both gas and gasless modes with DTi digital control and IGBT inverter technology.

For more precise planning, the wire included is 0.8mm steel wire on a 5kg spool, offering good resistance to corrosion and stable performance at higher currents. Those specs suit a broad range of automotive repair, sheet metal fabrication and light structural work.

Specification table

Here is a clear breakdown of the most relevant specifications for both the Draper welder and the GYS MIG wire so you can compare at a glance:

| Item | Draper 70047 Multi-Welder DTi | GYS 086128 0.8mm Steel MIG Wire |

|---|---|---|

| Type | Gas/Gasless MIG Inverter (IGBT) | Solid/Flux-cored compatible steel wire |

| Model | 70047 DTi | 086128 |

| Max output | 160 A | N/A (consumable) |

| Wire diameter | Supports 0.8 mm (supplied tips) | 0.8 mm |

| Spool weight | Compatible with up to 5 kg spools | 5 kg |

| Torch cable length | 3.0 m | N/A |

| Electrode/earth cable | 1.6 m | N/A |

| Gas hose length | 2.0 m | N/A |

| Display/controls | Digital DTi display, one-touch settings | N/A |

| Included consumables | 2 x 0.8mm contact tips, face mask, chipping hammer/wire brush | Good wire resistance to corrosion, high arc stability on high currents |

| Welding positions | MIG in gas/gasless modes — multiple positions achievable | Suitable for welding in various positions depending on flux type and technique |

This table gives you the quick facts to weigh capacity, convenience and the actual consumable included. You’ll see the machine and wire are matched for general-purpose MIG work where 0.8mm wire is a practical choice.

Performance and welding quality

You’ll notice practical welding performance is shaped by a mix of machine electronics, torch quality, wire characteristics and how closely you match settings to material thickness. In many real-world tasks the Draper unit produces smooth, controllable arcs that are forgiving enough for hobbyists while offering features an experienced welder can appreciate.

Arc stability benefits from the GYS wire’s described high arc stability at higher currents and the machine’s inverter control. That combination produces consistent bead appearance and fusion on mild steel when you tune voltage and wire feed rate appropriately.

MIG with gas (CO2/Ar mixtures) performance

You’ll get the best-looking beads and lower spatter when you use a suitable shielding gas mix, typically CO2 or an argon/CO2 blend for mild steel. With gas shielding the weld puddle is easier to control and you can achieve cleaner welds that reduce cleanup time.

Using the Draper unit in gas mode with the digital synergic settings tends to give you consistent feed and voltage automatically adjusted for the wire diameter, which is particularly helpful when switching between thin and thicker panels. You’ll still need to watch travel speed and torch angle to minimize undercut and ensure fusion.

Gasless (flux-cored) performance

If you choose gasless welding with a flux-cored or self-shielded wire, you’ll appreciate the convenience for outdoor or windy conditions where a gas shield would be blown away. Gasless welding typically makes for more spatter and a rougher bead profile, but it’s excellent for quick repairs and positional welding when aesthetics are not the top priority.

The GYS 0.8mm steel wire is described as providing good corrosion resistance and arc stability, which helps when you’re running higher current for thicker sections. You’ll need to fine-tune wire feed speed and voltage to get the right penetration and bead formation in gasless mode.

Welding positions and joint types

You’ll be able to weld in flat, horizontal and some vertical positions with this kit, depending on your technique and process settings. For overhead or specialized positional welding, you’ll want to practice and perhaps use appropriate flux-cored wire formulations if gasless is chosen.

The GYS wire’s characteristics assist in maintaining arc stability across differing positions, but remember that travel speed, torch angle and joint preparation still determine whether you get a sound weld free of porosity and poor fusion. Joint fit-up and cleanliness remain critical for consistent results.

Arc stability and penetration

You’ll see reliable arc stability thanks to the IGBT inverter electronics and the GYS wire’s composition, which is claimed to offer high arc stability at elevated currents. That translates to predictable penetration and consistent bead width when you select the right parameters.

If you need deeper penetration for thicker plates, run higher current and slower travel, but monitor for burn-through on thinner sections. The digital settings and the synergic control help you hit target parameters faster so you can focus on welding technique.

Usability and controls

You’ll find the user interface emphasizes simplicity: a digital display and straightforward controls that make common adjustments quick to set. This is useful if you’re frequently changing between tasks or teaching someone basic MIG technique.

Beyond the digital control, physical ergonomics matter: the torch length, cable flexibility and weight influence how comfortable you are during longer welding sessions. The supplied 3m torch gives reasonable reach without dragging, and the included accessories reduce time spent sourcing tools.

Digital display and one-touch settings

You’ll appreciate the DTi digital display because it shows key parameters at a glance and simplifies repeatability when you switch tasks. The one-touch setting approach aims to reduce the guesswork, especially for less experienced users who benefit from recommended presets.

If you’re used to non-digital analog machines, the DTi system will feel more modern and efficient, but take a little time to get familiar with how the synergic curves behave across thickness ranges. Practice on scrap plates and note favorite presets so you can recall exact numbers for future jobs.

Torch and consumables

You’ll receive a 3m MIG torch and two 0.8mm contact tips, which cover a range of light to moderate welding tasks without immediately needing spares. Keeping a stock of extra tips and nozzles is good practice, since consumables wear and influence arc performance more than many users expect.

Pay attention to the torch’s trigger feel and cable management because a comfortable, responsive torch reduces wrist fatigue and promotes steady travel speed. If you plan prolonged work or heavy repair tasks, consider upgrading torches and cabling to heavier-duty options for comfort and durability.

Safety features and included PPE

You’ll get a face mask included in the kit, which is helpful for starting out right away. That said, don’t rely solely on the supplied mask—invest in a properly rated auto-darkening helmet, gloves, apron and eye protection for comprehensive safety.

The machine itself lacks heavy-duty industrial safety interlocks common on larger units, so you should follow standard welding safety practice: ensure proper ventilation, use a fire-resistant workspace and inspect cables and connections frequently. The included earth clamp and electrode holder are fine for routine use but inspect and maintain them to prevent poor contact or overheating.

Setup and installation

You’ll want to set aside time for careful setup so the machine operates reliably and safely. The kit is designed to be user-friendly, but wire loading, gas hookup and verifying polarity are steps you should perform methodically.

A quick checklist approach helps: read the manual, check cable connections, confirm mains supply and earth, load the spool properly and test on scrap before starting a critical job. Taking these steps reduces downtime and avoids common errors like reversed polarity or poor gas flow.

Unboxing and initial checks

You’ll want to inspect all components as they are unpacked: check torch and cable integrity, confirm the presence of contact tips, and ensure the spool is in good condition. Verify that the face mask, chipping hammer, brush and gas hose are present and undamaged.

Turn on the machine briefly to confirm the digital display initializes correctly without error codes, and confirm the mains plug and cable are appropriate for your workshop supply. If anything feels loose or damaged, contact the retailer before proceeding.

Gas hookup and wire loading

You’ll attach the supplied 2m gas hose to a suitable regulator and gas cylinder (if you plan to work in gas mode); ensure all fittings are tight and leak-free. Loading the wire requires correct feed direction, tension setting and selecting the right contact tip; doing these steps properly prevents feeding issues and bird-nesting.

If you intend to weld gasless, set the machine to the proper mode for flux-cored wire and route the wire the same way but without the gas connection. Always run a bead on scrap to confirm feed rate and voltage are balanced before working on your actual part.

Recommended settings for common tasks

You’ll get predictable results if you match thickness, wire diameter and power settings correctly. Start with the manufacturer’s synergic presets and then fine-tune wire feed speed and travel rate to the look of the bead and penetration.

Here’s a practical starting-point table for common steel thicknesses with 0.8mm wire on the Draper 160A unit to help you begin:

| Material thickness (mm) | Approx. Amperage | Wire Feed Speed (m/min) | Voltage setting (approx.) | Mode |

|---|---|---|---|---|

| 0.8 – 1.2 mm (thin sheet) | 40 – 60 A | 3 – 4 m/min | Low | Gas (Argon/CO2) |

| 1.2 – 2.0 mm | 60 – 80 A | 4 – 6 m/min | Low-Mid | Gas |

| 2.0 – 3.0 mm | 80 – 110 A | 6 – 8 m/min | Mid | Gas or Gasless |

| 3.0 – 5.0 mm | 110 – 140 A | 8 – 11 m/min | Mid-High | Gasless (for quick welds) |

| 5.0 – 8.0 mm | 140 – 160 A | 11 – 14 m/min | High | Gas or Gasless (multiple passes) |

Use this table as a baseline and adapt by watching bead shape and penetration. Keep travel speed steady and modify wire feed if the arc is noisy or if bead buildup is poor.

Maintenance and consumables

You’ll keep performance consistent by maintaining the torch, contact tips, drive rolls, and cleaning spatter from the nozzle and tip. Regular maintenance extends component life and prevents poor arc quality and feeding problems.

Check the gas hose and electrical cables for wear, and replace any parts that show heat damage or frayed insulation. Store spare contact tips, nozzles and a replacement spool so you’re not stalled mid-job.

Wire spool care and storage

You’ll prolong wire shelf life by storing spools in a dry, low-humidity environment—steel wire can develop surface oxidation if left exposed to moisture. If you buy wire in bulk, keep spools in sealed bags with desiccant or in a dry cabinet.

Before loading, visually check wire for rust or kinks, and clean the spool hub to ensure smooth rotation. Proper spool installation reduces feeding problems and helps the drive rolls maintain consistent grip.

Contact tip replacement and nozzle cleaning

You’ll want to replace contact tips when you see signs of wear or a widened hole, since tip wear increases spatter and reduces arc focus. Clean the nozzle and tip regularly with a wire brush or nozzle cleaning tool to remove slag and spatter buildup.

Consistent cleaning and timely replacement of tips prevents erratic feeding and helps the machine maintain arc stability and weld quality. Keeping spare tips on hand (different sizes if you change wire diameter) saves downtime.

Electrode holder and earth clamp maintenance

You’ll check the electrode holder and earth clamp for tight connections and corrosion at contact points. Poor grounding or loose electrode connections can cause inconsistent arc starts, overheating and poor welds.

Clean contact surfaces and tighten clamps often, and store them off the floor to protect them from oil and coolant contamination. Ensure insulation around cable terminations is intact and replace any damaged cable immediately.

Advantages and limitations

You’ll find a number of practical advantages with this kit, including portability, digital control and a well-matched consumable that supports your first spool of welding. The package focuses on convenience and usability for hobbyists and light professional use alike.

At the same time, understand the limitations: a 160A inverter is not aimed at heavy industrial plate welding where larger machines and water-cooled torches are needed. Also, long continuous heavy use may push duty cycles and require monitoring or occasional rest.

Pros

You’ll appreciate the compact IGBT design that saves space and energy while offering good arc control. The DTi digital display and synergic settings make the machine friendly to less experienced welders and speed up setup for repeated tasks.

The included accessories and the 5kg steel wire make this a good starter kit for DIYers, home mechanics and light fabrication shops. The GYS wire’s advertised arc stability and corrosion resistance add confidence in consistent performance.

Cons

You’ll need to be aware that the 160A rating has limits for thick, structural welding or heavy industrial use where higher amperage machines excel. Professional welders doing long runs on thick sections will likely need a larger duty-cycle machine and heavier duty torches.

Also, the kit’s standard torch and tips are appropriate for many tasks but serious users may want to upgrade consumables and helmets for comfort, longer duty, and improved ergonomics. If you plan to weld specialty metals like stainless or aluminum, you’ll need different wire, shielding gas or a spool gun for aluminum.

Who should buy this?

You’ll want this kit if you’re a DIYer, hobby fabricator, auto restorer or a small workshop operator who needs a flexible MIG welder that performs well in both gas and gasless modes. The Draper 70047 plus the GYS 0.8mm wire offers a quick-start package that reduces the number of additional initial purchases.

If you’re a heavy production shop or you weld thick sections daily, you might outgrow the unit’s 160A rating and prefer a machine with a higher duty cycle and industrial-grade torches. For weekend mechanics and small projects, though, this kit is a practical, cost-effective choice.

Practical tips to get the most from the kit

You’ll get the best results when you pair sound technique with correct consumables and maintenance. Always practice on scrap material to dial in parameters, and keep a simple log of settings that worked for specific thicknesses and joint types.

Use clean materials, check gas flow and nozzle cleanliness frequently, and keep backup consumables on hand. If you plan long welds or repetitive tasks, add a more comfortable auto-darkening helmet, quality gloves and a torch sleeve to reduce fatigue and improve control.

Troubleshooting quick guide

You’ll encounter occasional common issues like poor feed, porosity, or spatter, and knowing basic fixes saves time. Typical fixes include checking drive roll tension, swapping worn contact tips, ensuring good earth connection, and confirming gas flow and nozzle cleanliness.

If you get undercut, reduce voltage or slow travel; if you get lack of fusion, increase voltage or reduce travel speed. If feed issues occur, re-check spool seating, drive roll type (grooved for solid wire), and liner routing for kinks.

Final verdict

You’ll find the Draper 70047 Gas/Gasless MIG Inverter Multi-Welder DTi bundled with GYS 086128 0.8mm 5Kg Steel MIG Wire to be a capable, user-friendly kit aimed at hobbyists and light workshop users. Its IGBT inverter, DTi digital control and synergic operation make it convenient and efficient for a wide range of mild steel tasks.

If your projects are mostly automotive repairs, light fabrication, and general maintenance, this kit gives you both the machine and an appropriate consumable to start welding right away. For heavier industrial work you’ll want a higher-capacity machine, but for many users this combination is an excellent balance of affordability, flexibility and performance.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.