Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Have you ever been frustrated with the inefficiency of traditional welding methods? The FAcoLL Ultrasonic Plastic Welding Machine could be the solution you’re looking for. It’s not just a tool; it’s an innovation designed to redefine your welding experience. Let’s explore what makes this machine a must-have for your projects.

Exceptional Efficiency

Imagine completing each welding task in just a few seconds. With this machine, you can. The FAcoLL Ultrasonic Plastic Welding Machine is engineered to handle your projects with incredible speed, finalizing each weld in a mere 0.4 to 8 seconds. This efficiency means you can get more done in less time, freeing up precious hours for other critical tasks.

Speed Redefined

The value of time cannot be overstated in any industry. This machine enhances your workflow by significantly reducing the time taken to complete each operation. You’ll find that tasks that once took hours can now be completed in a fraction of the time. This machine is a game-changer for productivity.

Superior Fusion with Ultrasonic Technology

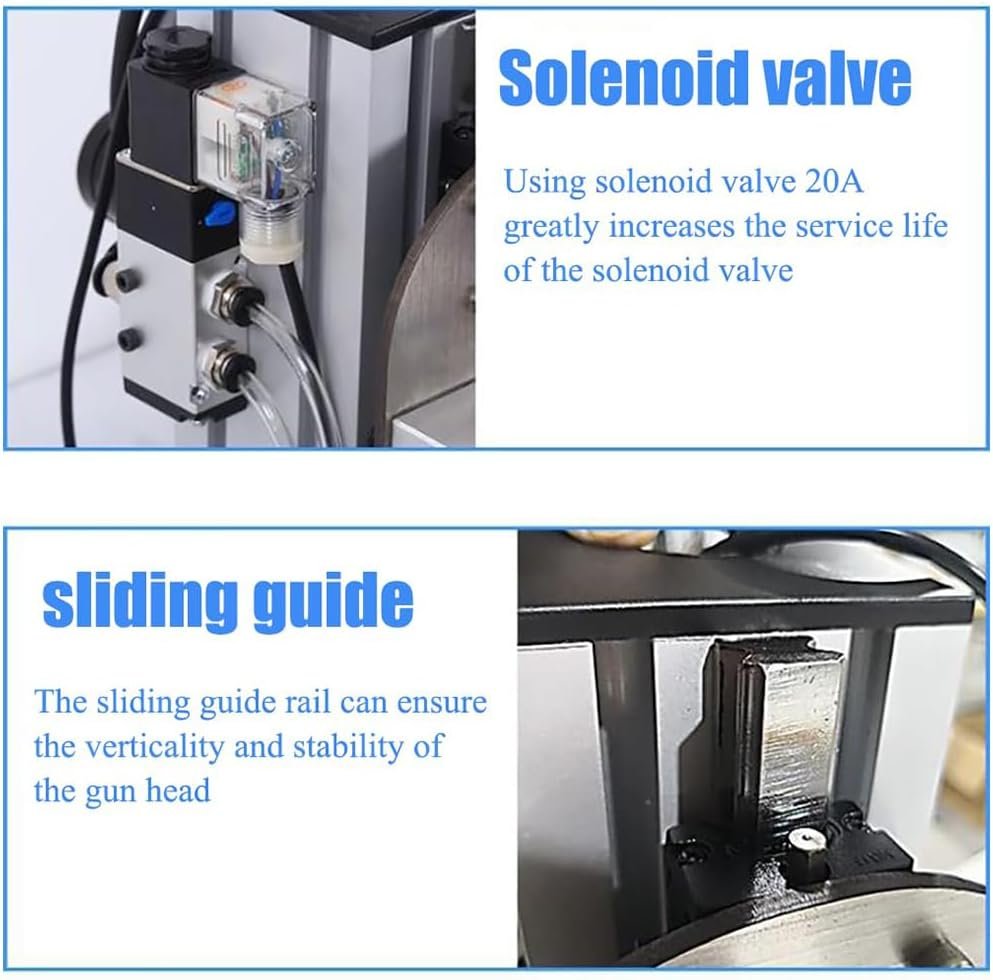

How does this device achieve such precise and efficient results? It employs high-frequency vibration waves to bond two surfaces together. This process, characterized by intense pressure, results in a molecular fusion that ensures durable and reliable welds.

The Science Behind the Seam

The heart of this technology lies in its ability to create strong bonds without additional materials like screws or glue. This not only results in a clean finish but also ensures that the materials welded are held together at the molecular level, drastically enhancing standard welding integrity. This is especially useful for materials that are prone to distortion or marks when traditional welding methods are applied.

Robust Construction

There’s nothing worse than investing in a tool that doesn’t withstand the test of time. The FAcoLL Ultrasonic Plastic Welding Machine is meticulously crafted from stainless steel, offering corrosion resistance, wear resistance, and deformation resistance. This means it’s built to last, no matter how demanding your projects may be.

A Material You Can Trust

The materials used in construction are a crucial factor to consider. Stainless steel not only ensures durability but also provides the needed strength to handle high-speed and intense welding tasks. This material choice reflects a commitment to quality that allows users to work confidently without fear of equipment failure.

Cost Efficiency

Are you tired of the costs associated with screws and glue? This welding machine allows you to bid farewell to those additional expenses. By utilizing ultrasonic vibration, you achieve seamless connections, cutting down on both labor and material costs. This approach not only saves money but increases your profitability by allowing you to complete more projects at a lower cost.

Boosting Income

Maximizing efficiency while minimizing expenses is a principle every business strives for. The FAcoLL Ultrasonic Plastic Welding Machine supports this principle, allowing you to invest saved resources back into your business or into other projects. It’s a small change that can have a big impact on your bottom line.

Versatile Applications

This machine isn’t just for one type of task. It’s designed to handle a variety of materials and tasks, ranging from welding and riveting to spot welding of non-woven fabrics, thermoplastics, nylon fabrics, and more. This versatility makes it an indispensable tool across different industries.

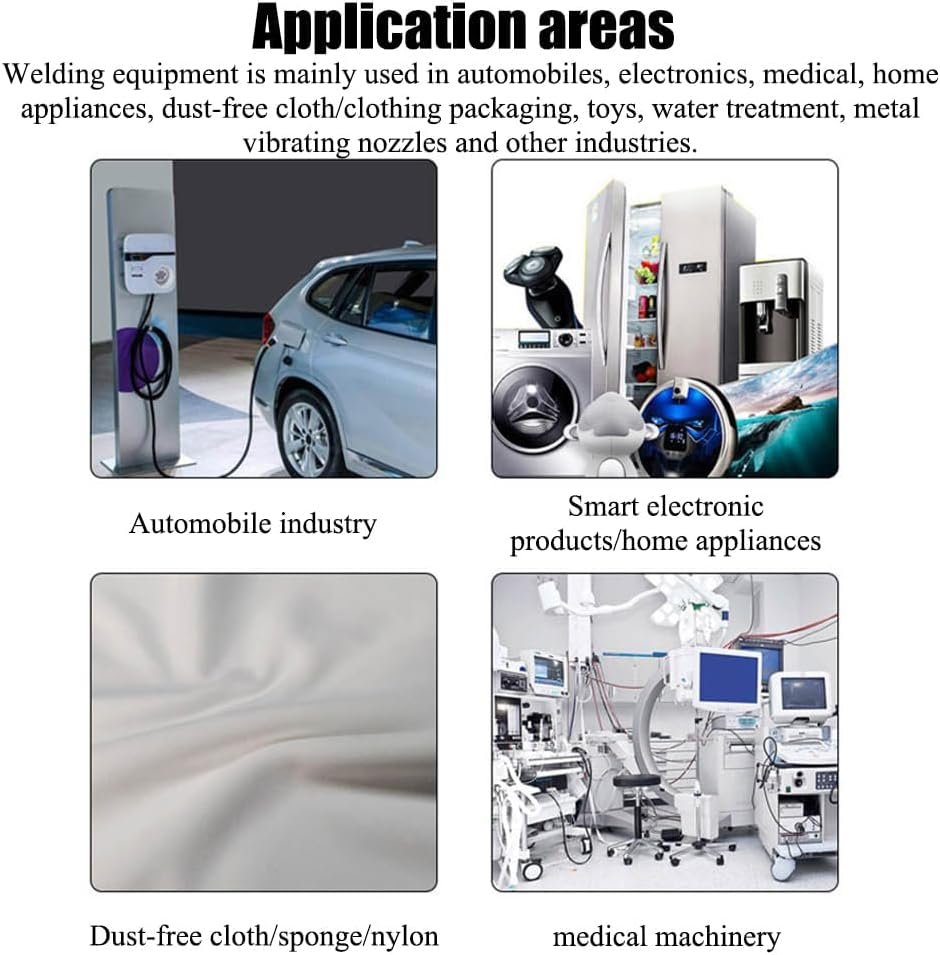

Adaptability Across Industries

Whether you’re in textile manufacturing, automotive industries, or any sector that requires robust fabric welding, this machine fits in perfectly. Its ability to adapt to various materials and tasks means you’re not limited by the equipment you have, making your work environment much more flexible and adaptable to new challenges.

Detailed Breakdown of Key Features

Here’s a quick breakdown of what you can expect from this machine:

| Feature | Description |

|---|---|

| Efficiency | Completes welding tasks in 0.4-8 seconds |

| Welding Technology | High-frequency vibration waves for molecular fusion |

| Construction Material | Stainless steel providing corrosion and wear resistance |

| Cost Savings | Reduces the need for screws and glue, cutting overall costs |

| Versatility | Suitable for fabrics, thermoplastics, nylons, and other materials |

User-Friendly Design

Despite its advanced capabilities, the FAcoLL Ultrasonic Plastic Welding Machine remains user-friendly. It comes with an electronic pedal that allows for hands-free operation, making it easier to manage large or intricate projects. This thoughtful design aspect enhances usability and reduces user fatigue, allowing you to maintain high efficiency throughout your workday.

Ergonomic Operation

User comfort may sometimes be overlooked in industrial applications, but not here. The thoughtful inclusion of the electronic pedal means your hands are free to guide and support the materials you are working with. This feature can significantly reduce the risk of errors during operation, making the entire welding experience smooth and comfortable.

In Summary

The FAcoLL Ultrasonic Plastic Welding Machine combines efficiency, durability, and versatility all in one package. Whether you’re saving time on tasks, reducing operational costs, or tackling a variety of materials, this machine is designed to enhance your productivity and project quality. With its innovative ultrasonic technology and robust construction, it’s not just a tool—it’s a trusted ally in your work processes. Choosing this machine means investing in a future of seamless welding experiences.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.