Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

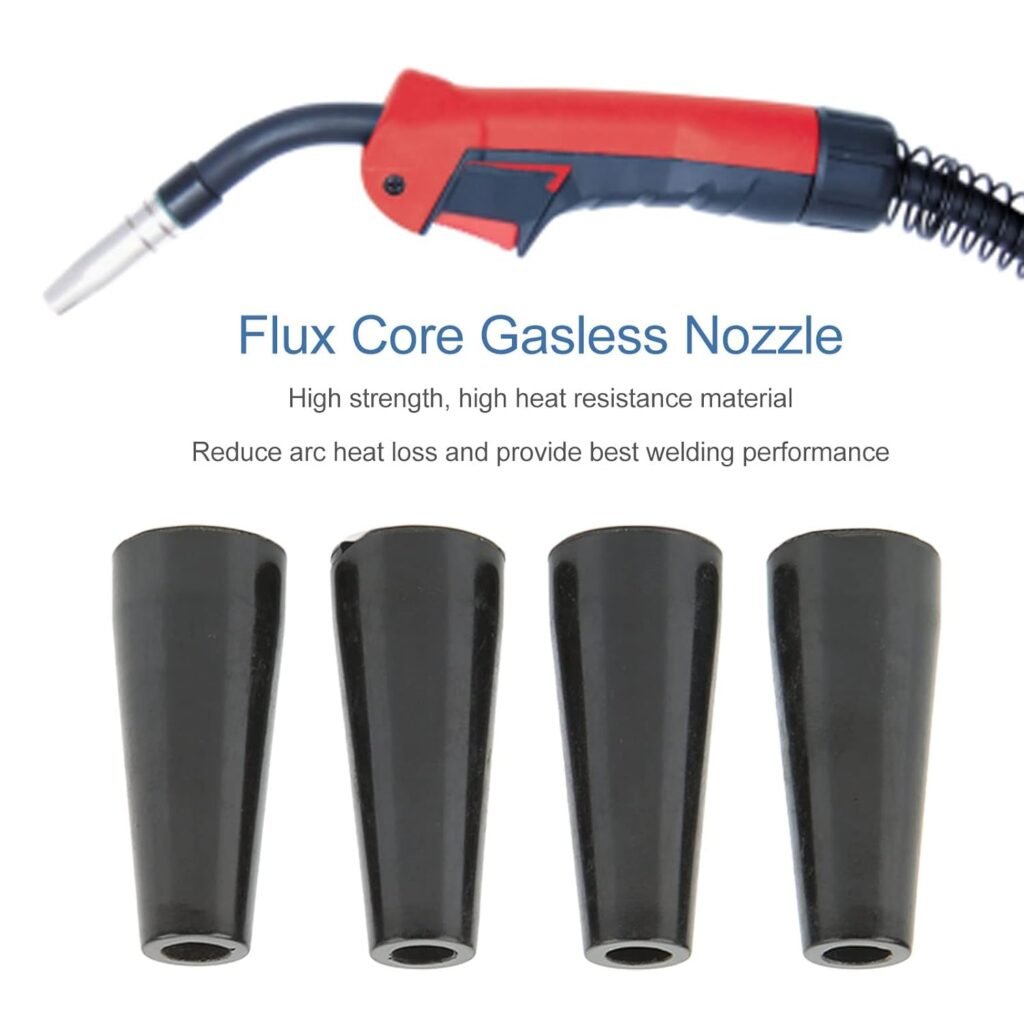

Looking for a safe, practical replacement nozzle that makes your MIG welding quicker and more comfortable?

Product Overview

You want gear that simply works without giving you extra hassle, and the Flux Gasless Nozzle, 4 Pack MIG Nozzle Welder Part, Compatible with MIG Welding Torch 100L aims to do exactly that. This product is a set of four nozzles designed specifically for gasless flux-cored welding, and it focuses on safety, protection, comfort, and heat resistance so you can keep working with fewer interruptions.

What the Flux Gasless Nozzle Is

This nozzle is a replacement part designed for use with flux-cored, gasless MIG welding setups and specifically calls out compatibility with the MIG Welding Torch 100L. It electrically insulates you from the circuit, protects the thread and opening of your nozzle holder, and reduces arc heat loss during welds.

What’s Included in the Package

You receive four identical flux gasless nozzles in one package, giving you spares to switch out when one wears down or gets clogged. Having four on hand means you can keep a backup ready while another nozzle cools or gets cleaned, reducing downtime.

Key Features

Your time and safety matter, and the Flux Gasless Nozzle package lists features meant to address both concerns. The highlights include insulation for operator safety, protection of expensive torch components, lightweight construction for handling comfort, and strong heat resistance to support consistent welding performance.

Safe Welding: Insulation Benefits

Because the nozzle insulates the operator from the circuit, you’re less exposed to stray electrical contact or shorts at the front end of the torch. That insulation is particularly important in gasless welding where the nozzle sits close to the arc and spatter can create conductive paths.

Effective Protection for Thread and Opening

The nozzle shields the thread and opening of the nozzle holder from spatter, slag, and mechanical wear, which helps preserve the integrity of the holder and the contact tip behind it. By protecting these parts, you can avoid frequent replacements of more expensive components downstream.

Lightweight and Comfortable

A lighter nozzle improves the balance and handling of your MIG torch, so you’ll notice less fatigue in longer welding sessions. That small change in weight and mobility can improve accuracy and consistency when you’re welding along tight seams or doing repeated passes.

Strong Heat Resistance

It’s made from a high-strength, heat-resistant material that’s intended to reduce arc heat loss and maintain shape under prolonged arc exposure. The stronger the material’s heat tolerance, the less likely the nozzle will deform, which keeps your gasless welds more stable and predictable.

Pack Size and Convenience

Four nozzles in a single pack means you get immediate spares to rotate, use, or keep as backups for different jobs. You don’t have to stop to order replacements as often, and you can assign certain nozzles to specific wire types or processes if you prefer.

Specifications

This section lays out the main specs in a straightforward way so you can confirm compatibility and performance expectations. The values below are based on the product description and typical flux-cored nozzle roles; if you need exact alloy or manufacturing standards check the vendor or packaging.

| Specification | Details |

|---|---|

| Product Name | Flux Gasless Nozzle, 4 Pack MIG Nozzle Welder Part, Compatible with MIG Welding Torch 100L |

| Quantity | 4 pieces per pack |

| Compatibility | Designed to fit MIG Welding Torch 100L (confirm fit before purchase) |

| Primary Function | Insulation from circuit, protection of nozzle holder threads and opening |

| Material | High-strength, high heat-resistant material (manufacturer description) |

| Weight | Lightweight design to improve torch flexibility and comfort |

| Heat Resistance | Strong heat resistance to reduce arc heat loss |

| Use Case | Flux-cored (gasless) MIG welding |

| Benefits | Safety, protection, flexibility, heat tolerance, convenience |

Performance and Real-World Use

You want nozzles that help produce repeatable welds, reduce downtime, and protect your torch. In everyday use, these nozzles are aimed at spatter-heavy flux-cored welding where protection and insulation at the nozzle end make a measurable difference.

Safety Performance

When you’re welding without shielding gas, stray spatter and close arcs increase the chance of accidental shorts or contact with conductive residue near the nozzle. The insulation properties of these nozzles reduce that risk, helping protect both you and your torch’s electrical path.

Heat Management and Arc Efficiency

Reducing arc heat loss means your arc remains stable and transfers energy where you need it most. Because the material claims strong heat resistance, you’ll likely see less nozzle deformation and a more consistent arc profile over longer runs, which matters for bead quality and penetration.

Comfort and Handling

Lightweight nozzles let you move the torch more freely and with less arm strain. If you do long seams or work in awkward positions, a lighter nozzle reduces fatigue and helps you hold steady for cleaner, more even beads.

Durability and Lifespan

Durability depends on the specific alloy and how abrasive your spatter conditions are, but the description of “high strength” and “strong heat resistance” indicates these nozzles are built to last longer than cheap, thin alternatives. With proper rotation and cleaning, you should be able to get good life from each nozzle before replacement.

Compatibility and Fit

Confirming fit and proper compatibility before purchasing saves you time and frustration. These nozzles are listed as compatible with the MIG Welding Torch 100L, but fit checks and minor adjustments are sometimes necessary across torch generations or aftermarket parts.

How it Works with MIG Welding Torch 100L

Designed to thread or seat onto the nozzle holder associated with the 100L torch, the nozzle covers the contact tip and directs spatter away from the holder. That seal and spacing ensure you maintain a stable arc and keep the contact tip protected from direct spatter accumulation.

Checking Fit Before Use

Before you weld, verify dimensions and the seating method—threaded, slip-fit, or clip-on—by comparing the old nozzle or the torch’s manual to this nozzle’s shape. If the product listing doesn’t include thread pitch or exact outer diameter, ask the seller for measurements or try fitting a single nozzle before committing all four to a specific torch model.

Installation and Use

You’ll spend little time swapping these nozzles in and out, but a careful approach prevents damage and extends both nozzle and torch life. The process is straightforward and similar to most other MIG nozzle installs, with a few precautions.

Removing the Old Nozzle

Turn off and cool down your torch before handling the nozzle. Use proper pliers or a nozzle removal tool to avoid damaging the nozzle holder or contact tip; if the old nozzle is stuck because of spatter, apply a suitable cleaning method (soaking in a nozzle-cleaning solution or using a pick) rather than forcing it off.

Installing the Flux Gasless Nozzle

Slide or thread the new nozzle into place and ensure it seats correctly without cross-threading. Confirm that the contact tip remains centered and that the nozzle opening lines up with your wire path to avoid arc deflection or inconsistent spatter patterns.

Tips for Best Results

Rotate nozzles as you work: keep one nozzle on the torch, one cooling, one in the cleaning stage, and a spare in the box. Clean nozzles regularly and inspect the contact tip and holder thread; a clean system performs better and lasts longer. Also, match nozzle selection to the wire size and welding current you use most often.

Maintenance and Care

If you want these nozzles to last and perform consistently, incorporate simple cleaning and storage habits into your workflow. Routine care will significantly reduce welding interruptions and protect your torch components.

Cleaning After Use

After a session, allow the nozzle to cool then remove caked-on spatter with a soft steel brush or a nozzle cleaner; avoid aggressive grinding that can change the nozzle shape. Soaking heavily spattered nozzles in a mild remover designed for welding residue can make cleanup easier and reduce wear from scraping.

Storing Spare Nozzles

Store unused nozzles in a dry, labeled container so you can quickly pick the right nozzle when needed. Keep them away from corrosive chemicals and rough handling; organized storage helps you track wear and rotate spares appropriately.

Pros and Cons

You should weigh benefits against limits to decide if this 4-pack is right for your needs. The package gives you spares, safety, and reasonable heat resistance, but the product listing lacks extremely specific material and dimension details that some pros rely on.

- Pros: Safer insulation, protects thread and opening, lightweight, heat resistant, 4 nozzles for rotation and backup.

- Cons: Manufacturer material details are general rather than specific alloy specs; confirm fit with your torch model; may not be optimized for every wire size or specialty welding technique.

Comparison with Alternatives

Picking between nozzles can depend on the welding style, frequency of use, and budget. Compared to basic cheap nozzles, these emphasize insulation and heat resistance; compared to premium branded nozzles, they may be less documented in material specs but still offer good practical value.

Gasless Nozzles vs Standard Nozzles

Gasless (flux-cored) nozzles typically need more frequent cleaning due to spatter; these nozzles focus on shielding the holder and insulating you from the circuit, which is especially important in gasless setups. Standard gas-shielded nozzles may be optimized for different flow patterns and require different geometries.

Price and Value Consideration

You pay for convenience when buying a 4-pack with safety-focused design—having spares reduces downtime and cost per weld session. If you weld infrequently, buying in bulk may not be necessary, but for regular flux-cored welding this pack improves value through reduced replacement frequency and better torch protection.

Who Should Buy This

You should consider this product if you do flux-cored MIG welding regularly, especially with a MIG Welding Torch 100L or a similar torch that accepts this nozzle style. These nozzles are particularly useful if you need safer operation, reduced spatter impact on the torch, and quick access to spares for uninterrupted work.

Common Issues and Troubleshooting

Common nozzle issues typically involve fit, spatter build-up, and heat-related deformation; most problems are avoidable with proper maintenance and fit verification. If you encounter performance issues, systematic checks usually identify the cause quickly.

Buying the Wrong Size

If the nozzle doesn’t seat properly, it can wobble or misalign the wire path, causing erratic arcs and uneven beads. Measure the outer diameter and thread type of your existing nozzle or check with the seller before buying replacements to avoid fit problems.

Nozzle Clogging and Spatter

When spatter accumulates, it restricts airflow and distorts the arc; you’ll see inconsistent bead appearance and more frequent tip burnback. Clean nozzles regularly, keep the contact tip healthy, and consider anti-spatter sprays or coatings suited for flux-cored applications if you struggle with heavy spatter.

Electrical Insulation Problems

If you notice poor insulation—twitching arcs or unexpected grounding points—verify that the nozzle is fully seated and that the contact tip and holder are intact and clean. Replace worn threads, damaged holders, or corroded contact tips to restore reliable insulation and electrical continuity.

FAQs

You likely have small practical questions before buying or using this product; here are answers to common ones to help you decide.

Q: Will these nozzles fit torches other than the 100L? A: They’re marketed as compatible with the MIG Welding Torch 100L, but fit can vary across torch models and manufacturers. Compare dimensions or ask the seller for precise measurements to be sure.

Q: Are these nozzles reusable after cleaning? A: Yes, you can reuse them until the nozzle surface or shape degrades from heat and spatter. Regular cleaning and correct handling extend their useful life.

Q: Do these nozzles change weld appearance? A: They won’t change metallurgy or penetration directly but can improve consistency by maintaining arc stability and protecting the contact tip, which indirectly improves bead quality.

Q: How often should you replace a nozzle in regular use? A: Replacement frequency depends on how much you weld and how spattery your process is. Rotate and inspect nozzles regularly; replace if deformed, cracked, or if threads are stripped.

Q: Can I use these with gas-shielded MIG setups? A: They’re designed for flux-cored, gasless welding. If you try them on a gas-shielded torch, make sure the nozzle geometry suits gas flow and that the fit matches your equipment.

Q: Is any special tool required to install these? A: Typically no special tool is needed beyond standard nozzle pliers or a small wrench to remove and install the nozzle safely after the torch cools.

Q: Will the nozzle protect the contact tip? A: Yes—by shielding the tip and reducing direct spatter impact, the nozzle helps prolong contact tip life and reduce tip burnback.

Q: Are replacement nozzles covered by warranty? A: Warranty coverage varies by seller or manufacturer; check the vendor’s return policy and warranty details before you buy if that’s a concern.

Practical Tips and Best Practices

You can maximize nozzle life and welding performance with a few simple habits that pay off quickly during production or hobby runs. These tips are practical and easy to implement in any welding environment.

- Rotate nozzles to keep one in use, one cooling, one in cleaning, and one in reserve.

- Inspect nozzle seating and threads each time you change the contact tip.

- Use gentle cleaning tools to remove spatter; avoid reshaping the nozzle by grinding.

- Match nozzle usage to the current and wire size you use most commonly to reduce wear.

- Keep a small supply on hand so you can switch nozzles quickly when necessary.

Safety Reminders

You should always prioritize safety when working around an active arc, hot metal, and electrical connections. No nozzle replaces good technique and appropriate personal protective equipment.

- Always power down and allow cool-down before swapping nozzles.

- Wear welding gloves, jacket, and eye protection to guard against spatter.

- Keep the workspace ventilated, especially when welding flux-cored wire, as fumes can be significant.

Final Verdict

If you use flux-cored MIG welding frequently and want a straightforward, practical solution to protect your torch and improve operator safety, the Flux Gasless Nozzle, 4 Pack MIG Nozzle Welder Part, Compatible with MIG Welding Torch 100L is a solid choice. The pack gives you immediate spares, good insulation characteristics, and heat resistance that helps keep your welding consistent and your equipment protected.

You should buy this if you value reduced downtime, better torch protection, and increased handling comfort, especially when you work with a MIG Welding Torch 100L or an equivalent torch that accepts this nozzle type. Just confirm fit and consider your specific welding conditions to ensure it meets your expectations for material and geometry.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.