Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

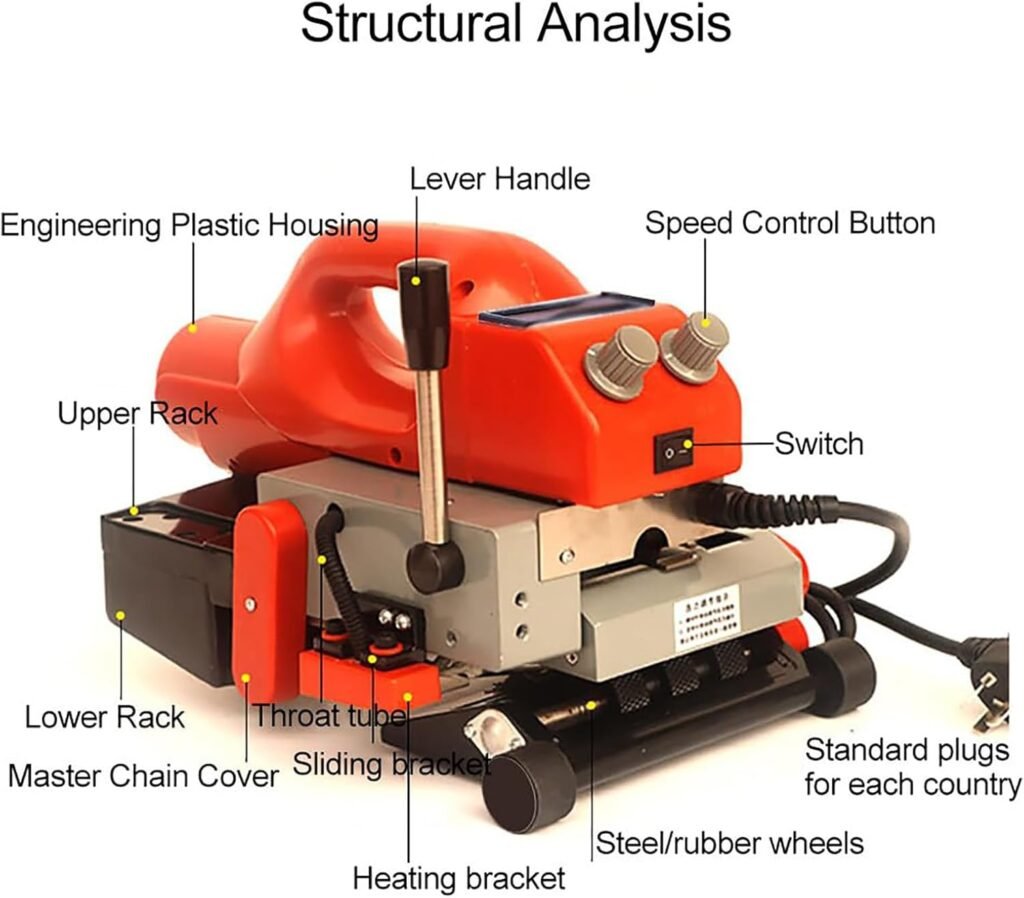

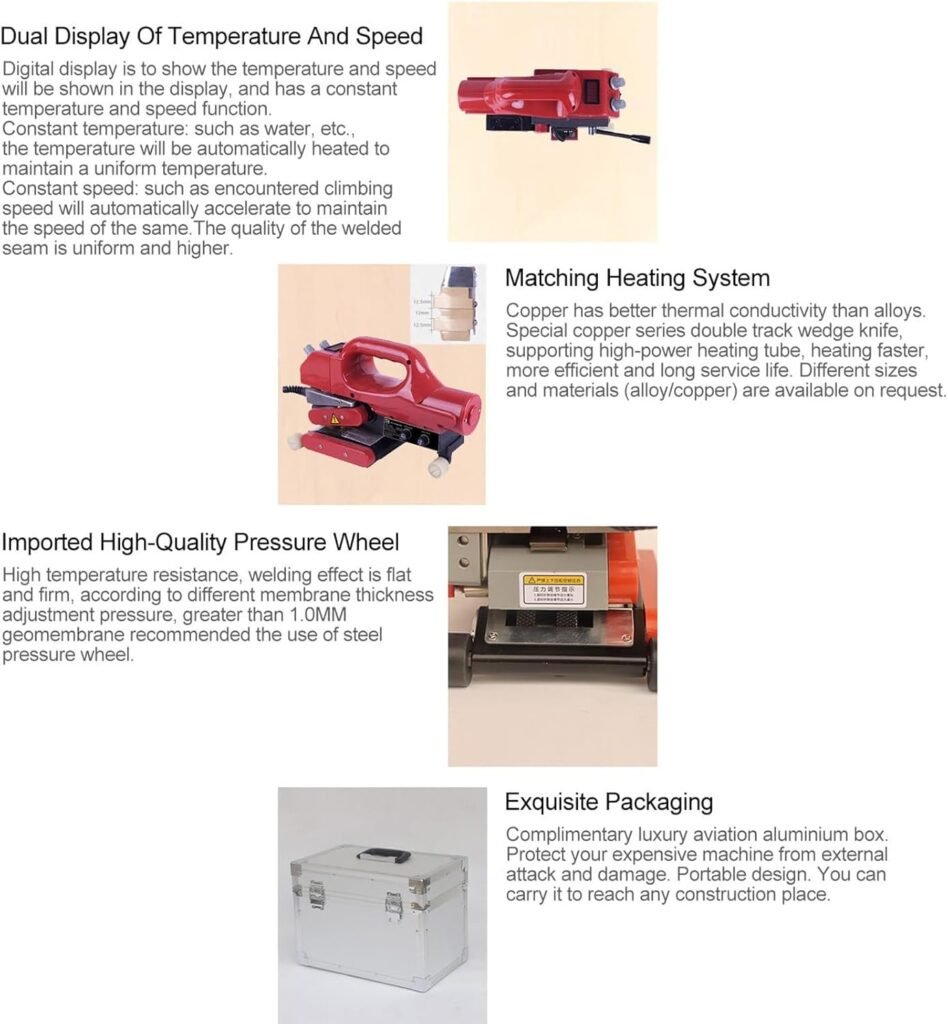

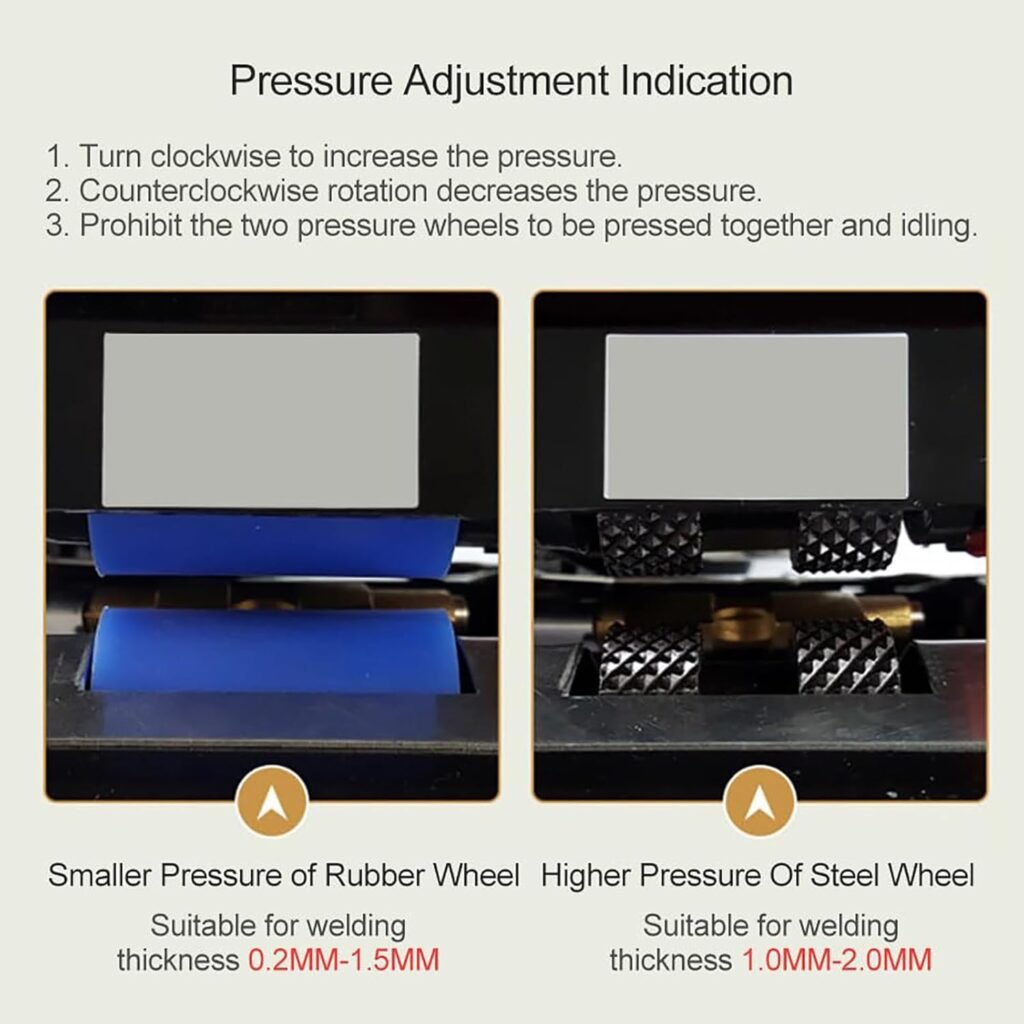

Have you been looking for a reliable Geomembrane Welding Machine that can handle a variety of welding tasks with ease? Look no further than the Geomembrane Welding Machine, PVC Film Sealing Machine(0.2-1.5mm), equipped with Steel Wheels + Rubber Wheels, Welding Width of 12.5mm, and Temperature range of 0~450℃. This versatile machine offers exceptional welding quality and high efficiency, making it a valuable addition to your toolkit.

Unpacking and Setup

When you receive your Geomembrane Welding Machine, the first step is to carefully unpack it and set it up according to the provided instructions. The package should include the welding machine itself, power cord, and any additional accessories. Make sure to inspect the machine for any damage during shipping before proceeding with setup. Once everything is in good condition, you can start assembling the machine and connecting it to a power source.

Setting up the Geomembrane Welding Machine is straightforward, thanks to the included user manual that provides detailed instructions on how to assemble the machine and operate it safely. The machine is designed for easy setup and use, even for beginners in welding.

Key Features

Here are some key features of the Geomembrane Welding Machine that set it apart from other welding machines on the market:

| Feature | Description |

|---|---|

| Welding Speed | 0.5-5 m/ min |

| Heating Temperature | 0-450 degree |

| Thickness of Material | 0.2mm-1.5mm |

| Overlap Width | 100mm |

| Welding Width | 12.5mm×2, interior cavity 12mm |

| Seam Strength | >85% base material (tensile resistant in shear direction) |

| Weight | 5Kg |

| Insulation Class | Class II |

| Power | 800w |

| Voltage | 110v/220v |

| Frequency | 50Hz |

Operating Instructions

To ensure optimal performance and longevity of your Geomembrane Welding Machine, it is essential to follow the operating instructions provided by the manufacturer. Operating regulations state that welding quality is directly related to speed and temperature setting during operation, so it’s crucial to have specified personnel operate the machine for excellent quality and high efficiency.

Proper operation of the machine requires careful attention to detail and adherence to safety protocols outlined in the user manual. Make sure to read the instructions thoroughly before using the welding machine to prevent any accidents or damage to the machine.

Safety Precautions

Here are some safety precautions to keep in mind when operating the Geomembrane Welding Machine:

- Read the instruction manual carefully before operation.

- Use a grounded 3-cords mains cable and socket with a 10A capacity.

- Do not modify the plug without prior permission.

- Assign specified personnel for operation to ensure good welding quality.

Following these safety precautions will help you operate the Geomembrane Welding Machine safely and efficiently.

Welding Process

The welding process of the Geomembrane Welding Machine is straightforward and efficient, thanks to its innovative design and user-friendly operation. By understanding the operation principle of the machine, you can achieve excellent welding quality and reliable results.

The Geomembrane Welding Machine operates by driving upper and lower pressure rollers to rotate through a reduction gearbox and chain. The slide carriage drives the hot wedge and inserts it between the two base materials, while the lever presses the pressure rollers to engage the fused base materials.

Tips for Optimal Welding

To achieve optimal welding results with the Geomembrane Welding Machine, consider the following tips:

- Adjust welding speed and temperature settings according to the material thickness.

- Ensure proper alignment of base materials before welding.

- Maintain consistent pressure on the pressure rollers for uniform welds.

By following these tips, you can maximize the performance of the Geomembrane Welding Machine and complete your welding tasks efficiently.

Customer Service

As a responsible international seller, the manufacturer of the Geomembrane Welding Machine is committed to providing quality service to its customers. With a loyal customer base and a reputation for excellence, the manufacturer offers sincere and responsive customer service to address any inquiries or issues customers may have.

If you have any questions or encounter any problems with your Geomembrane Welding Machine, do not hesitate to contact the manufacturer. They will actively work to solve your problems and provide quality services to ensure your satisfaction with the product.

Warranty Information

The Geomembrane Welding Machine comes with a warranty that covers manufacturing defects and malfunctions. If you experience any issues with the machine during the warranty period, you can contact the manufacturer for assistance with repairs or replacements.

In conclusion, the Geomembrane Welding Machine is a reliable and efficient tool for welding a variety of materials with precision and quality. With its durable construction, innovative design, and user-friendly operation, this welding machine is a valuable addition to any workshop or job site. Invest in the Geomembrane Welding Machine today and experience the benefits of professional-grade welding equipment in your projects.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.