Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

?Are you looking for a compact, gasless MIG welder that you can carry to the jobsite or keep in your garage for quick repairs?

Product Overview: H HZXVOGEN Gasless MIG Welder 220V Flux Core 145A Welder

This section gives you a clear snapshot of what the H HZXVOGEN Gasless MIG Welder 220V Flux Core 145A Welder offers and what it’s designed for. You’ll learn the main capabilities and the kinds of jobs it’s intended to handle so you can quickly decide if it matches your needs.

The H HZXVOGEN Gasless 145A Dual-Voltage Welder is a portable MIG machine that supports flux core welding without shielding gas. It’s designed for light fabrication, home DIY, and quick repairs, and claims compatibility with multiple metal types and dual 220V operation.

Quick Features at a Glance

Below are the main selling points presented simply so you can scan and understand the core advantages quickly. Each bullet highlights what matters most when considering a small flux core MIG welder.

- Gasless flux core operation — plug-and-play torch with no gas setup.

- Maximum output of 145A — suitable for sheet metal and light thicknesses.

- Dual-voltage 220V operation — flexible for many workshop and jobsite power supplies.

- Compact and lightweight — 9 lbs (4.5 kg) and small footprint for portability.

- Smooth wire feed system — automatic matching of current and voltage for consistent arc.

- Smart cooling and industrial-grade chip — built-in fan protection and stable performance.

Technical Specifications (Table)

This table breaks down the main technical specs so you can compare them quickly and check the compatibility with your projects. It’s an easy way to see the machine’s limits and strengths.

| Specification | Details |

|---|---|

| Product Name | H HZXVOGEN Gasless MIG Welder 220V Flux Core 145A Welder |

| Output Current | Up to 145A |

| Voltage | Dual 220V (AC input) |

| Wire Type | Flux core wire (no gas) |

| Wire Size Compatibility | .030” and .035” (2 lbs spool recommended) |

| Material Thickness | 1–4 mm recommended for iron, stainless, galvanized, carbon steel, copper |

| Weight | 9 lbs (4.5 kg) |

| Dimensions | 13 x 5.6 x 6.1 inches |

| Cooling | Built-in fan protection |

| Control Type | Knob for current adjustment with auto-voltage matching |

| Electronics | IGBT inverter with industrial-grade chip |

| Use Case | Light fabrication, DIY, quick repairs, portable welding tasks |

Design and Portability

This part focuses on how the unit is built and how easy it is to move around. You’ll get a sense of whether the form factor suits your workshop or mobile needs.

The welder’s compact dimensions and 9 lb weight make it genuinely portable. You can toss it into a truck bed, store it on a shelf, or carry it to a jobsite without much hassle, which is perfect if you need something mobile for on-the-spot repairs.

Chassis and Ergonomics

You’ll want a machine that’s both rugged and easy to operate. This section describes the casing, handling points, and how comfortable it is to use day-to-day.

The chassis is compact and engineered for light mobility, with a handle designed for single-handed carrying. Because it’s small, you’ll also find it easier to place in tight workspaces or move around a busy garage.

Port Placement and Accessibility

You’ll appreciate ports and controls that are intuitive and reachable. Here you’ll see how wire feed, power inlet, and control knobs are positioned for ease of use.

The torch is all-in-one and designed for plug-and-play use, while the front knob lets you adjust current easily. The wire feed access seems straightforward for the supported spool sizes, and the overall layout minimizes fumbling when making adjustments.

Welding Performance and Capability

This section clarifies what the machine can actually weld and how well it handles different materials and joint types. You’ll get a realistic sense of performance based on specs and expected use.

At up to 145A, this welder is optimized for thin to medium sheet metals and small repairs. It handles iron, stainless steel, galvanized sheets, carbon steel, and copper in the 1–4 mm thickness range, which covers many hobby and light professional tasks.

Arc Stability and Heat Control

Arc stability affects bead quality and ease of welding, and heat control impacts how well you can avoid burn-through. This part explains what to expect in real-world use.

The IGBT inverter and industrial-grade control chip aim to maintain stable output, which generally produces a consistent arc. The knob-based current adjustment paired with automatic voltage matching should help you avoid sudden changes in heat that cause inconsistent beads or excessive spatter.

Practical Material Limits

Knowing exact material limits prevents you from pushing the welder beyond safe or effective thresholds. You’ll find realistic expectations here.

The recommended 1–4 mm thickness is practical for sheet metal repair, brackets, frames, and small structural fixes. For anything thicker, like structural steel sections or heavy plate, you’ll likely need a higher-amperage machine or gas-shielded MIG system to get deeper penetration and better weld quality.

Wire Feed System and Consumables

The wire feed mechanism is often the difference between a pleasant welding session and constant jams. You’ll get an overview of the feeder and what wire you’ll need to keep on hand.

HZXVOGEN advertises an automatic matching system that adjusts wire feed and voltage to maintain a steady arc. It’s designed for .030” and .035” flux core wire on 2 lb spools, which keeps consumables simple and affordable.

Wire Sizes and Spools

You’ll want to use the recommended wire sizes to avoid feeding problems. This section explains what wire options are supported and why that matters.

The machine supports .030” and .035” flux core wire, which are common for the thickness range the welder targets. Because it’s intended for 2 lb spools, you’re limited to smaller capacity—meaning you’ll swap spools more often during extended work sessions.

Feed Mechanism and Troubleshooting

Feeding issues are common on small machines. Here you’ll learn what to watch for and how the built-in system should help.

The automatic match of current and voltage should reduce the need to fine-tune feed speed, yet you’ll still need to keep wire clean and loaded correctly. Typical troubleshooting steps include checking tension, ensuring the liner is clear, and using the correct drive roll for the wire diameter.

Controls, Usability, and Beginner Friendliness

This section focuses on how easy the machine is to operate and whether it’s suitable for someone new to welding. You’ll learn if the controls and setup enhance or hinder your learning curve.

This welder is marketed as beginner-friendly with plug-and-play operation and a single knob for current, which simplifies getting started. The digital LED display adds clarity so you can quickly confirm settings without guesswork.

Control Layout and LED Readout

A clear control layout saves time and frustration. You’ll see how the display and knob work together to give you an easy experience.

The smart digital LED gives you feedback on settings, and the knob adjusts current with automatic voltage matching. This approach reduces cognitive load for beginners and speeds up setup time when switching between tasks.

Torch Design and Handling

The actual torch design affects grip comfort and welding posture. Here you’ll get a quick idea of how the gun feels in hand and how intuitive the trigger is.

The all-in-one torch simplifies things because you don’t need to assemble separate components or connect gas lines. Grip comfort and ergonomics are adequate for short jobs, though heavier or extended welding sessions may highlight the torch’s lightweight, basic construction.

Cooling, Safety, and Electronics

Safety and thermal management are crucial for both machine longevity and user safety. You’ll get details on how the unit deals with heat and what protections are built in.

HZXVOGEN includes a built-in fan and thermal protection to mitigate overheating during extended runs. The IGBT inverter and industrial-grade chip aim to deliver consistent performance while protecting electronics under load.

Thermal Management and Fan Operation

Overheating can kill a machine quickly. You’ll learn how the fan system operates and what to expect during prolonged use.

The integrated fan circulates air to keep the inverter and internal components cooler. For longer continuous welds, you’ll still need to manage duty cycles and allow cooling periods to prevent thermal shutdowns.

Safety Features and Protections

Safety features reduce risk to both operator and machine. This subsection outlines protections like overcurrent, thermal cutoff, and circuit stability.

Beyond thermal protection, stable IGBT electronics help prevent voltage spikes and offer more precise control. You should still use basic welding safety gear—helmet, gloves, and proper ventilation—since gasless flux core produces smoke and spatter.

Build Quality and Electronics (IGBT & Industrial-Grade Chip)

Here you’ll read about the internal technology that supports stable welding. You’ll get insight into the advantage of modern inverter designs and what industrial-grade components mean for you.

An IGBT inverter provides efficient power conversion and smoother current control compared to older transformer-based units. The claim of an industrial-grade chip suggests reliable regulation and consistent performance, which helps with arc stability and overall reliability.

Longevity and Component Expectations

You’ll want a machine that doesn’t fail after a few uses. Understandably, small welders have trade-offs, and this section covers realistic expectations.

The compact size means components are optimized for portability, but not necessarily for heavy production use. With proper care—routine cleaning, correct duty cycle use, and sensible loads—you can expect decent longevity for DIY and light professional work.

Repairability and Parts

Replacement parts and user-serviceability matter for long-term ownership. You’ll find suggestions here on what parts to expect as wear items and how easy they are to replace.

Consumables like contact tips, drive rollers, and nozzles will be the most frequently replaced parts. Because the unit uses standard flux core wire and common torch components, sourcing replacements should be manageable for most users.

Applications and Real-World Use Cases

Knowing where the machine shines and where it struggles helps you match it to your projects. You’ll read about ideal jobs and scenarios where this welder fits best.

This welder works very well for metal repair, automotive sheet metal patching, home fabrication, small farm fixes, and light structural tasks. It’s not designed for heavy industrial plate welding, thick structural beams, or continuous high-amperage production.

Best Use Cases

You’ll quickly see which projects will benefit most from this tool. Use these as guidelines to avoid disappointment.

- Sheet metal bodywork and auto patch repairs.

- Light fabrication—brackets, shelves, and frames.

- Gate and fence repairs where thin sections are common.

- Hobbyist metal art and DIY welding projects.

What to Avoid

You’ll also want to avoid tasks that push the machine beyond reasonable limits. This prevents poor-quality welds and premature wear.

- Thick plate welds over the 4 mm recommended limit.

- Heavy structural welding where deep penetration is required.

- Long, continuous welds without allowing for cooling periods.

Setup, First Use, and Tips

This section guides your first steps from unboxing to making your initial welds. You’ll get practical tips to reduce setup time and common rookie mistakes to avoid.

Setup is straightforward: install the 2 lb spool of .030” or .035” flux core wire, plug into a 220V outlet, adjust the current knob based on material thickness, and you’re ready to weld. The plug-and-play torch reduces setup complexity.

Step-by-Step First Weld

You’ll benefit from a short checklist that helps you get positive results on your first try. Follow these steps to avoid common pitfalls.

- Inspect the machine and accessories for shipping damage.

- Load the recommended wire spool and set drive tension correctly.

- Connect the work clamp to clean metal and ensure good contact.

- Set the current knob to a mid-range value for the material thickness.

- Use short test beads on scrap metal to fine-tune settings before critical work.

Practical Tips for Better Results

Little adjustments improve your welding quality significantly. These tips aim to make your welding cleaner and more consistent.

- Keep the metal surfaces clean of paint and heavy rust for better arc stability.

- Maintain a steady travel speed and consistent gun angle to reduce spatter.

- Use short stitch welds on thin material to prevent burn-through.

- Replace contact tips and clean the wire feed path regularly to avoid jams.

Pros and Cons

This section presents a concise list of advantages and disadvantages so you can weigh whether the trade-offs align with your priorities. You’ll get a direct comparison to help you decide.

Pros

- Truly portable and lightweight for easy transport.

- Plug-and-play torch makes it beginner friendly.

- Smart LED readout simplifies setting selection.

- Good arc stability thanks to IGBT inverter and industrial-grade chip.

- Suitable for common DIY metals and thin gauge work.

Cons

- Limited to small spool sizes (2 lb), requiring more frequent changes for bigger projects.

- 145A maximum limits deeper penetration and thicker material welding.

- Designed for 220V only—no 110V compatibility for typical household outlets.

- Not ideal for heavy production or continuous high-amperage tasks.

Comparison to Similar Machines

Comparing this unit with similar budget flux core MIG welders helps you understand relative value. You’ll see how it stacks up on portability, features, and performance.

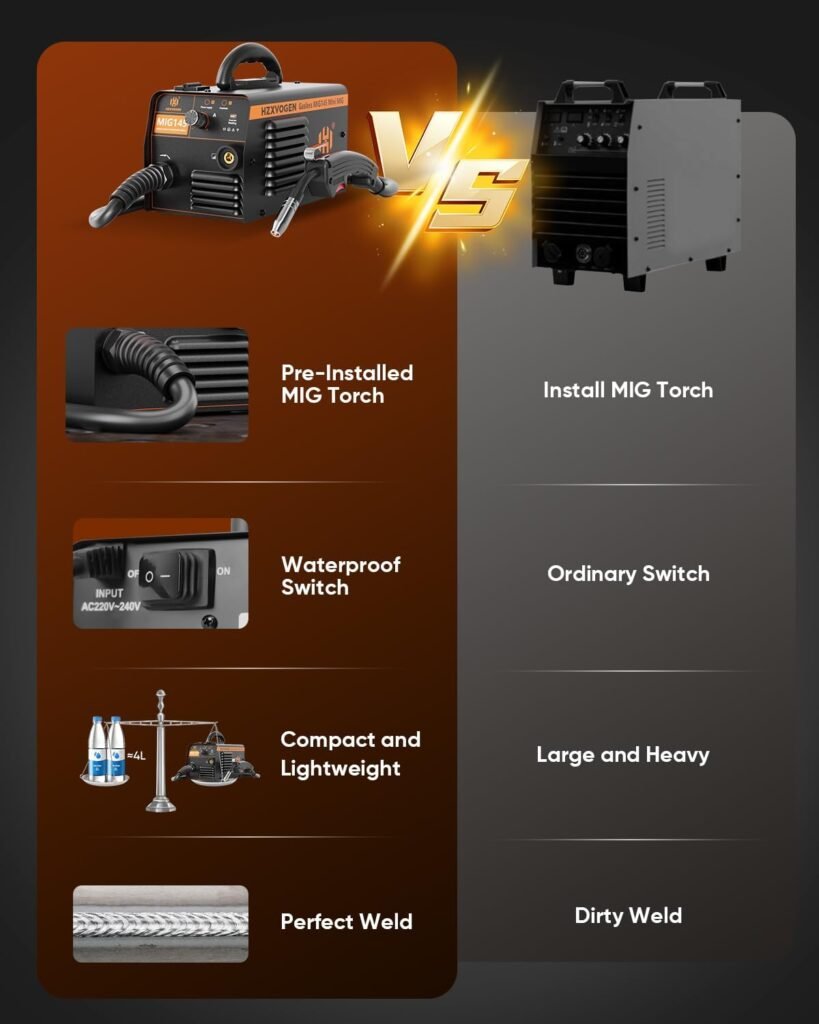

Compared to heavier, higher-amperage machines, HZXVOGEN emphasizes portability and ease of use. You sacrifice maximum power and spool capacity but gain a compact, beginner-oriented tool that performs well for small tasks. If you need larger spool capacity or 110V operation, you’ll want to consider alternate models.

Where It Excels Versus Peers

You’ll see the specific areas where this welder stands out among competitors in the same category.

It excels in size-to-power ratio, offers user-friendly controls, and provides modern inverter technology for consistent performance. These points make it a compelling option for hobbyists and mobile repair technicians.

Where It Trails

You’ll also learn which areas might push you toward a different machine.

If you need continuous duty at high amperage, larger spool sizes, or dual-voltage including 110V compatibility, other machines may serve you better. This unit is tuned for portability and light tasks rather than heavy industrial work.

Who Should Buy This Welder?

This section helps you decide if this particular model matches your skill level and project needs. You’ll see clear buyer profiles who will likely be satisfied with this purchase.

You should consider this welder if you do DIY repairs, light fabrication, auto body patching, or need a portable unit for occasional jobsite work. It’s ideal for beginners due to its simple controls and for experienced users who need a compact backup tool.

Ideal User Profiles

You’ll get a quick match for common user types to guide your decision.

- Hobbyists and home mechanics who work on thin metals.

- Small farm or property owners needing occasional fence or gate repairs.

- Mobile repair technicians who require a lightweight, transportable tool.

- Beginners learning flux core MIG welding without gas complexity.

Not Recommended For

You’ll be warned about scenarios where this unit won’t meet expectations.

- Heavy fabrication shops that need continuous, high-power welding.

- Contractors requiring thick-plate welding and deep penetration.

- Users who need 110V operation at standard household outlets.

Maintenance and Longevity

Taking care of your welder extends its usable life and keeps it performing reliably. You’ll learn what maintenance tasks to prioritize and how to store the unit safely.

Routine maintenance includes cleaning dust and spatter from the machine, replacing consumables like tips and drive rollers, and ensuring consistent power and grounding. Proper storage in a dry area and avoiding overloading the duty cycle will help preserve electronics.

Regular Maintenance Checklist

A simple checklist keeps maintenance manageable and prevents avoidable failures. Follow these steps routinely.

- Clean the exterior and vents to ensure proper airflow.

- Inspect and replace contact tips and nozzles when they wear.

- Keep the wire feed path clear and lubricated if recommended.

- Check cables and plugs for damage before each use.

- Allow cooling time to avoid repeated thermal cutoffs.

Troubleshooting Common Issues

Knowing quick fixes saves you time when things go wrong. You’ll find common problems and solutions here.

- If the wire doesn’t feed: check drive roll tension, liner, and spool alignment.

- If the arc is unstable: verify ground clamp contact, clean the joint, and check wire quality.

- If the unit overheats: reduce duty cycle, let the fan cool the unit, and reduce load.

Final Thoughts and Recommendation

This closing section sums up who will benefit most and gives a clear recommendation based on use case and priorities. You’ll have a concise verdict to help you decide whether to buy.

If you want a lightweight, user-friendly, gasless MIG welder that performs well on thin materials and is easy to transport, the H HZXVOGEN Gasless MIG Welder 220V Flux Core 145A Welder is a strong contender. It’s especially well-suited for hobbyists, home mechanics, and anyone needing a portable plug-and-play solution.

Final Recommendation

You’ll find this machine useful if portability, ease of use, and flux-core convenience are your priorities. For heavier-duty welding or longer continuous runs, consider stepping up to a higher-amperage or gas-shielded MIG system, but for general DIY and light fabrication tasks, this HZXVOGEN model offers good value and practical performance.

If you want, I can also provide a quick buying checklist, accessory suggestions (like recommended helmets, gloves, or wire brands), or a short comparison with specific alternate models in the same price range. Which would you like next?

Disclosure: As an Amazon Associate, I earn from qualifying purchases.