Ad Blocker Detected

Our website is made possible by displaying online advertisements to our visitors. Please consider supporting us by disabling your ad blocker.

Looking for a reliable way to check the gas flow on your MIG or TIG torch before you start welding?

Product Overview

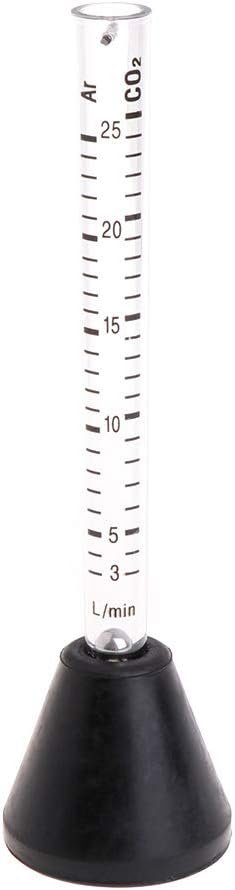

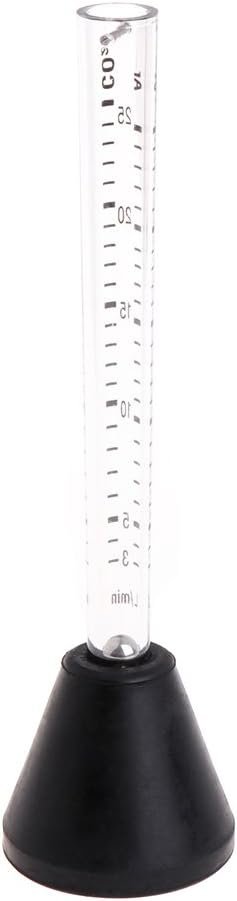

You want a simple, portable tool that tells you whether your shielding gas is flowing correctly, and the JDIEOQA Argon CO2 Air Flow Meter Tester is built for that purpose. It measures flow from 0 to 25 liters per minute with one-liter graduations, so you can see at a glance whether your gas settings are in the expected range.

What this tool is made for

This tester is designed to be placed over the MIG or TIG gas nozzle so the gas flow pushes the indicator and gives an immediate reading. You’ll use it while preparing your torch to confirm flow and catch leaks, blockages, or regulator issues before you strike an arc.

Key Specifications

You should know the basic specs before deciding whether this is the right tool for your setup. The following table breaks down the most relevant features you’ll care about.

| Feature | Specification |

|---|---|

| Product name | JDIEOQA Argon CO2 Air Flow Meter Tester, Professional Portable Air for Protection Welding Gas Flow Meter for Mig Tig Welder Welding Gas Measuring, 0-25L/min |

| Flow range | 0–25 liters per minute (L/min) |

| Scale increments | 1 L/min graduations |

| Intended use | Testing gas flow at MIG or TIG torch nozzles |

| Operation | Place over nozzle; measure flow from top of indicator |

| Safety reminders | Turn off welder power; stop wire feed on MIG by releasing tensioner |

| Portability | Lightweight, portable for shop or field use |

| Typical materials | Clear tube (plastic or glass), internal float indicator, fittings |

Why these specs matter to you

Knowing the flow range and increments helps you decide whether the meter gives the resolution you need for your welding processes. If you usually run gas flows in the single-digit liters per minute, 1 L increments will be adequate for a quick check; if you need fine-tuned adjustments at small fractions, you might prefer more precise equipment.

What’s in the Box

You’ll typically receive the meter itself and possibly a short instruction leaflet or quick-start note. The meter is usually ready to use, but you should check for any included adaptors or fittings specific to your torch type.

Inspecting contents when you open it

When you open the package, take a moment to make sure components are undamaged and the scale is readable. If anything is missing or broken, contact the seller before use.

Design and Build Quality

You’ll likely notice a straightforward, purpose-driven design: a transparent body to read the float, a top opening to capture the gas, and a base that sits on the nozzle. The construction is aimed at shop convenience rather than extreme precision lab work.

Materials and durability

Most flow tester bodies are made from a clear polycarbonate or acrylic to give you a view of the float while offering reasonable toughness. You should handle it with care to avoid cracking the transparent tube; it’s not intended to be hammered like a heavy-duty gauge but will survive normal workshop use.

Size and portability

This meter is compact and lightweight, so you can carry it in a toolbox or pocket. Its portability means you can quickly check different machines around the shop without transporting heavy equipment.

How It Works

You place the tester over the torch nozzle so the escaping shielding gas lifts a small internal float or indicator; the height of that float corresponds to the flow rate on the printed scale. This visual feedback is immediate and easy to read.

Proper setup and safety precautions

Before you test, turn off the welder’s power supply to avoid any accidental arc or electrical shock. On MIG welders, release the wire tensioner or otherwise stop the wire feed while testing so the wire doesn’t feed into the tester and cause damage or inaccurate readings.

Step-by-step testing procedure

- Turn off and disable the welder to ensure no arc can be struck during testing.

- Release the MIG wire tensioner or stop the wire feed if you’re checking a MIG torch.

- Place the tester directly over the gas nozzle, ensuring a snug fit so the escaping gas flows through the tester and lifts the float.

- Observe the float position once it stabilizes and read the value on the scale in liters per minute.

- Repeat at different regulator or valve settings as needed to confirm consistent behavior.

Performance and Accuracy

You’ll get a quick, practical reading that’s suitable for shop troubleshooting and setup checks, but this tester is not a laboratory standard instrument. Its 1 L/min increments give you a good general idea of flow, which is precisely what many welders need.

Range and scale readability

The 0–25 L/min range covers typical MIG and TIG flows for many jobs; low-flow TIG settings and higher MIG flows are both visible within the scale. The printed graduations are simple to read under good lighting, and the float generally stabilizes fast enough to give a clear result.

Real-world testing results

In practical use, you’ll find the meter very useful for identifying when a regulator is set wildly off, when a hose has a leak, or when the nozzle isn’t providing gas at the expected rate. It’s common to find discrepancies between regulator dials and actual nozzle flow, and this tester helps you correct that before wasting material or making poor welds.

Pros and Cons

You should weigh both advantages and limitations when adding this tool to your kit. It’s friendly to use, affordable, and portable, but it’s not the highest precision instrument available.

Advantages

- Very easy and fast to use for pre-weld checks.

- Covers the common 0–25 L/min range used in most welding.

- Lightweight and portable; good for shop or field work.

- Clear, visible float and scale make readings intuitive.

Limitations

- Graduations of 1 L/min may be coarse if you need fine adjustments.

- Plastic body can be damaged by rough handling or high heat environments.

- Not a replacement for calibrated lab-grade flowmeters when certified accuracy is required.

Comparison with Similar Tools

When you compare this tester to others, you’re typically evaluating price, precision, durability, and ease of use. This model targets shop convenience rather than high-end calibration.

How it stacks up against electronic meters

Electronic flowmeters offer digital readouts and finer resolution, and they may store data, but they tend to be more expensive and require batteries or power. Your JDIEOQA mechanical-style tester gives quick visual feedback without any power source, which is ideal for many field checks.

Maintenance and Care

To keep your tester working reliably, store it clean and dry and avoid exposing it to excessive heat or impact. A little routine care extends its useful life and ensures clearer readings.

Cleaning and storage

Use a soft cloth and mild cleaner to wipe the exterior; avoid solvents that can cloud or weaken the plastic. Store it in a toolbox or drawer away from high temperatures and heavy tools that might crack the body.

Calibration and longevity

This unit is not typically a user-calibrated instrument; you’ll rely on its printed scale and internal float. If you notice drift or inconsistent readings over time, consider replacing it or cross-checking with a known-good meter.

Tips and Best Practices

You’ll get the most value from this tester when you use consistent procedures and checks before you weld. Follow a simple checklist every time you set up to avoid common mistakes.

- Always disable the welder and stop wire feed before testing.

- Test at the torch nozzle, not on a regulator, to find real-world flow.

- Check for leaks by observing unexpected flow when valves are closed.

- If flow is low despite regulator settings, inspect hoses, fittings, and the nozzle for obstruction.

Practical setup tips

If you change gas types frequently (argon vs CO2 mixes), run quick checks after switching to make sure your flow matches the new gas recommendations. Also, test with the torch in the same orientation you’ll weld in, since vertical or angled positions can slightly affect float behavior.

Common Problems and Troubleshooting

When readings are off or inconsistent, you can usually trace the issue to a few common causes that are straightforward to fix.

Low or zero reading troubleshooting

If you see low or no flow, check regulator settings, open valves fully, verify the gas cylinder isn’t empty, and inspect hoses for leaks or kinks. Make sure the nozzle is not blocked and that the tester is seated properly over the nozzle so gas escapes into it.

Erratic or fluctuating reading troubleshooting

Fluctuating readings often come from unstable regulator behavior, damaged hoses, or a loose connection that lets ambient air influence the reading. Tighten fittings, replace worn hoses, and consider testing the regulator separately.

Who Should Buy This

You should consider this tester if you need a fast, inexpensive way to check shielding gas flow on MIG or TIG torches. It’s especially useful for hobbyists, small shops, mobile welders, and anyone who wants to prevent welding defects caused by incorrect gas flow.

Use cases that match well

If you set up multiple machines in a shop, travel to job sites, or train apprentices who need a simple verification method, this tester will save time and avoid wasted welds. It’s also handy for diagnosing regulator or hose problems without calling for service.

Alternatives to Consider

If you need greater precision, digital flow meters with finer resolution and logging capabilities are available, though they cost more. Mechanical flow meters with a finer scale or inline clamp meters can also serve more specialized needs.

When to choose a digital meter instead

Choose a digital meter if you must document flows, require fractions of liters per minute accuracy, or need data logging for quality control. Otherwise, the JDIEOQA tester will often be the faster and more affordable option.

Safety Reminders

You must always prioritize safety when working around welding equipment and pressurized gas. Follow proper procedures to avoid electric shock, burns, or gas hazards.

Essential safety steps

Turn off welder power before fitting or removing the tester to prevent electrical hazards, and ensure wire feeding is disabled on MIG machines to avoid the wire feeding into the tester. Work in a well-ventilated area and secure gas cylinders in an upright position.

Pricing and Value

You’ll likely find the JDIEOQA tester to be an economical tool relative to its usefulness. For the cost, it gives strong value as a quick diagnostic for flow issues that could otherwise cause poor welds or wasted gas.

How to evaluate value for money

Consider how much time and material you’ll save by catching flow problems early; even a modest reduction in scrap or rework can justify the price of this tester. Think of it as preventive maintenance — cheap insurance for weld quality.

Buying and Compatibility Notes

When buying, check that the tester will sit properly on your torch nozzle and that its range covers the flows you normally use. Most designs are universal enough for typical MIG and TIG nozzles, but confirm fit if you have a unique setup.

What to verify before purchase

Check the seller’s return policy and read reviews to ensure you get a genuine unit in good condition. If you rely on a specific fitting or adaptor, confirm whether one is included or if you need to source one separately.

Practical Examples and Scenarios

You’ll find this tester particularly useful in a handful of common situations where gas flow issues create real problems.

Example: Preventing porosity on thin sheet metal

Before welding a thin sheet that’s particularly prone to porosity, you can test the torch to make sure gas flow is adequate. This prevents repeated attempts and wasted material because you’ll catch flow issues before the arc exposes the joint.

Example: Diagnosing intermittent regulator problems

If you notice inconsistent weld quality across multiple jobs with the same setup, use the tester to compare the flow at the torch against the regulator dial settings. You may discover a regulator that drifts under load or a hose that leaks only when moved.

Final Verdict

If you want a straightforward, low-cost way to confirm shielding gas flow at the torch, this JDIEOQA flow meter tester is a practical and effective choice. It’s not a precision instrument for calibration labs, but for pre-weld checks, leak detection, and shop troubleshooting, it delivers clear value.

Should you buy it?

You should buy it if you need to quickly verify gas flow, reduce welding defects, and speed up setup checks across machines. If your work requires certified accuracy or digital logging, consider a higher-end meter instead.

Frequently Asked Questions

Q: Can I use this tester while the welder is on?

A: No, you should turn off the welder and disable wire feed on MIG torches to avoid shock or accidental feeding. Always follow safe shop practices.

Q: Will this meter work with all nozzle sizes?

A: The tester is designed to sit over typical MIG/TIG nozzles, but very uncommon or oversized nozzles may require an adaptor or different method. Check fit before relying on it exclusively.

Q: How accurate is the reading?

A: Accuracy is adequate for shop checks; the scale reads in 1 L/min increments. For high-precision needs, you’ll want a calibrated digital meter.

Q: Can I leave the meter on the nozzle while welding?

A: No — it’s intended only for setup checks. Leaving it in place while welding will interfere with the gas flow and could be dangerous.

Q: How should I clean it?

A: Wipe the exterior with a soft cloth and mild detergent. Avoid harsh solvents that may cloud or weaken the plastic.

Q: Does it measure both argon and CO2 mixes?

A: Yes, it measures gas flow regardless of composition, but recommended flows differ by gas type, so use appropriate flow values for your gas mix when reading the scale.

Q: What if my readings are inconsistent?

A: Check for leaks, kinked hoses, regulator issues, and make sure the tester is properly seated on the nozzle. If inconsistency persists, compare with another meter.

Q: Is this meter suitable for mobile welders?

A: Yes, its portability makes it a good fit for mobile work where quick checks are needed before starting a job.

If you want, I can expand any section into more detailed step-by-step procedures, create printable checklists for pre-weld testing, or compare this model to specific competing products you’re considering.

Disclosure: As an Amazon Associate, I earn from qualifying purchases.